Bleaching and dyeing sludge rotary compression dewatering device convenient for material discharging

A technology of rotary compression and dehydration device, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc., to avoid manual sludge removal again, improve the release rate, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

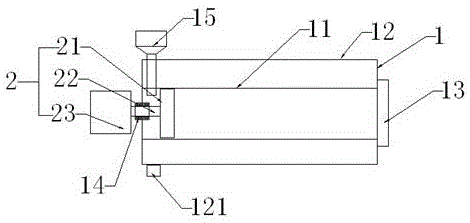

[0016] A rotary compression dehydration device for bleaching and dyeing sludge convenient for unloading, comprising: a horizontal dehydration cylinder 1 and a rotary compression mechanism 2 .

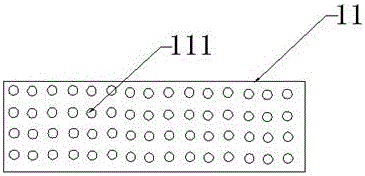

[0017] The dehydration cylinder 1 includes a dehydration inner cylinder 11 and a dehydration outer cylinder 12 welded together, and the two end surfaces of the dehydration inner cylinder 11 and the dehydration outer cylinder 12 are coplanar. Among them, the cylinder body of the dehydration inner cylinder 11 has evenly distributed permeable holes 111, which is convenient for the water in the sludge to flow out during the extrusion process; The sewage flowing out in the permeable hole 111 of 11 is discharged in a confluence. The center of one end face of the dehydration cylinder 1 is provided with a sealing door plate 13, and the center of the other end face is provided with a sealing bushing 14; The diameter of the cylinder 12 is used to facilitate the discharge of the sludge after comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com