Breathing automatic dehydration oil return system and method for siphon oil tank

An oil return system, siphon type technology, applied in the field of breathing automatic dehydration oil return system, can solve the problems of low dehydration efficiency and low dehydration quality, and achieve the effect of good oil quality, high dehydration efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

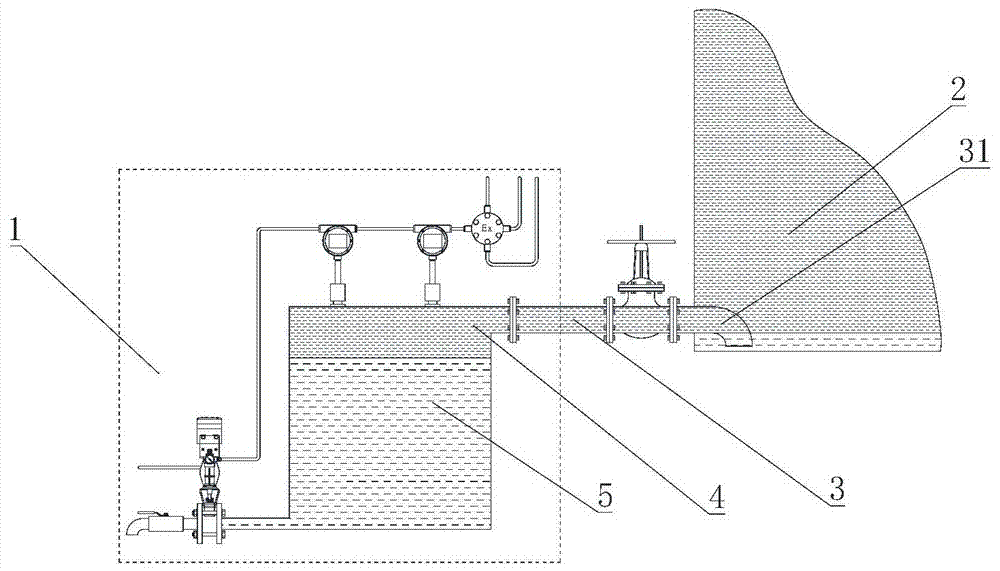

Embodiment 1

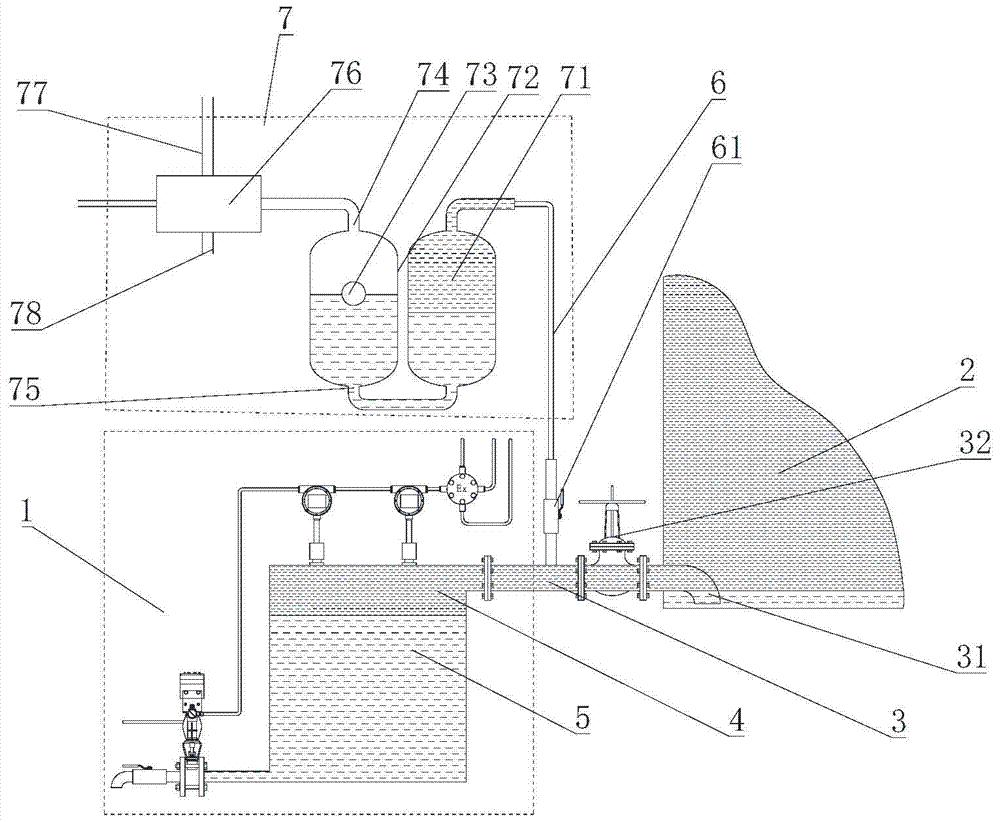

[0046] Such as figure 2 As shown, the breathing type automatic dehydration and oil return system for siphon oil tanks of the present invention includes a dehydrator 1, an oil tank 2, an oil return mechanism 7 and a main unit connecting the oil tank 2 and the dehydrator 1 Oil pipeline 3, at least a part of the dehydrator 1 is located below the oil tank 2, one end of the main oil pipeline 3 is arranged on the upper end of the dehydrator 1, the other end extends into the oil tank 2, and passes through the elbow 31 extends to the bottom of the oil tank 2, and the oil return mechanism 7 includes a first buffer tank 71 and a second buffer tank 72 whose bottoms communicate with each other, and a branch oil pipeline 6 connecting the first buffer tank 71 and the main oil pipeline 3 , the bottom of the second buffer tank 72 is provided with a first communication port 75 communicating with the bottom of the first buffer tank 71, and its top is provided with a first vent 74 communicating...

Embodiment 2

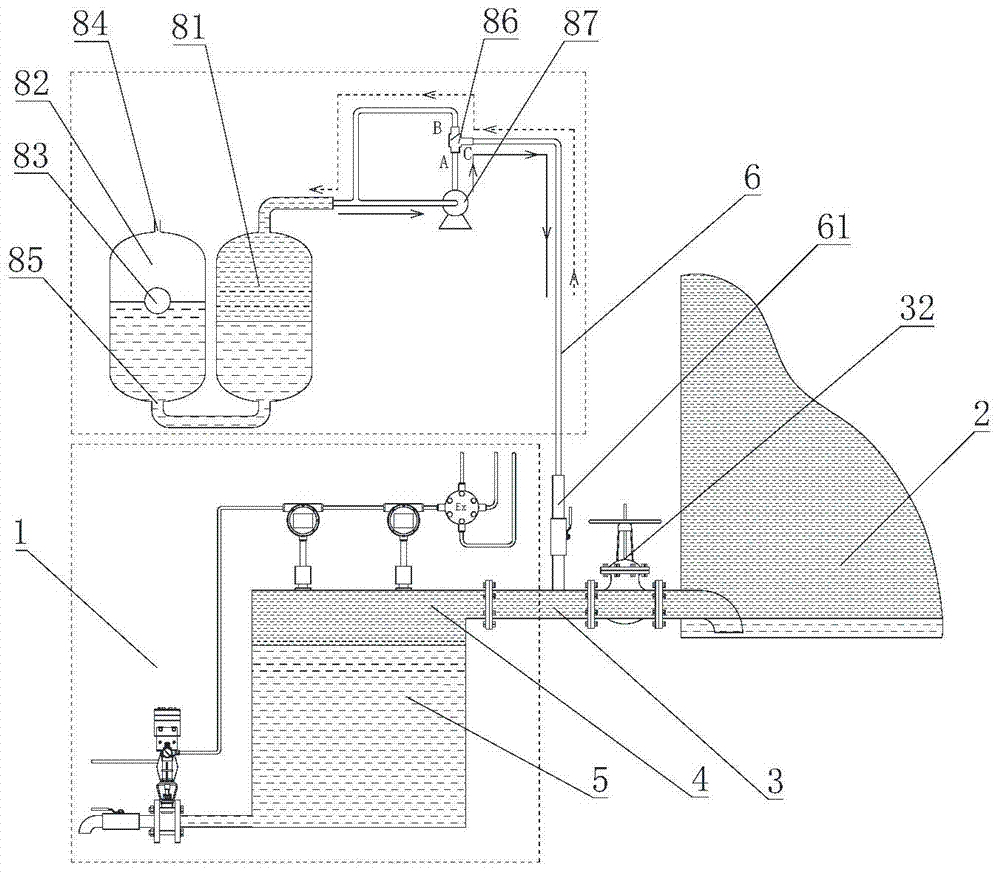

[0054] Such as image 3 As shown, in this embodiment, except that the oil return mechanism is different, other structures are the same as in Embodiment 1, and in this embodiment

[0055] The oil return mechanism includes a first buffer tank 81 and a second buffer tank 82 connected at the bottom, the top of the second buffer tank 81 is provided with a first vent hole 84, and its bottom is provided with a first communication port 85. A second liquid level controller 83 is arranged in the second buffer tank 82, and a liquid medium having a density higher than that of oil and not compatible with oil is housed in the second buffer tank 82. The liquid medium in this embodiment is water. The second liquid level controller 83 blocks the first communication port 85 or the first ventilation hole 84 along with the rise and fall of the water level in the second buffer tank 82 .

[0056] The branch oil pipeline 6 is provided with a control mechanism, and the control mechanism includes a T...

Embodiment 3

[0063] Such as Figure 4 As shown, except that the oil return mechanism of this embodiment is different from that of Embodiment 1, other structures and working principles are the same as those of Embodiment 1. The oil return mechanism includes a first buffer tank 91, a second buffer tank 92 and a first The buffer tank 91 and the first conduit 921 of the second buffer tank 92, the second buffer tank 92 is arranged above the first buffer tank 91, and one end of the first conduit 921 is arranged at the bottom of the second buffer tank 92, The other end extends to the bottom of the first buffer tank 91, and the first buffer tank 91 is provided with an input port near the top, and the first buffer tank 91 communicates with the main oil pipeline 3 by connecting the branch oil pipeline 6 through the input port , the second buffer tank 92 is equipped with a liquid medium with a density higher than that of oil, the liquid medium is water, and a third liquid level controller 93 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com