Patents

Literature

58results about How to "Short demulsification time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method of oil-containing sludge

InactiveCN108314290AHigh surface tension reduction abilityStrong flocculationDewatering/demulsification with chemical meansSludge treatment by de-watering/drying/thickeningAlkylphenolOil sludge

The invention discloses a treatment method of oil-containing sludge and belongs to the field of environmental engineering. The treatment method comprises the following steps of: introducing the oil-containing sludge into a separating groove, discharging into a deemulsifying groove for deemulsification after initially separating, and carrying out oil-water-sludge separation on deemulsified productsin an oil-sludge separating device; recovering dirt oil at the upper part, settling sludge-water mixture at the lower part, recovering clear liquor, and carrying out coagulation treatment, settling separation, mechanical dewatering, sludge drying and sludge incineration treatment in sequence on the sludge-water mixture at the bottom part and residual active sludge. Composite deemulsifying agentspreferred by the invention include a polyethylene polyamine blocked polyether deemulsifying agent, a silicon-containing deemulsifying agent, a phenolic-resin deemulsifying agent, an alkylphenol polyoxyethylene ether deemulsifying agent, a polyphosphoester deemulsifying agent or a polyaluminium-chloride deemulsifying agent. The deemulsifying method disclosed by the invention has the beneficial effects that the safe and environment-friendly effects are achieved, the water content of oil sludge can be reduced, most crude oil in the oil sludge can be recovered, and the difficulty of the followingtreatment of the sludge can be reduced.

Owner:YANGZHOU DAYANG WATER SUPPLY EQUIP

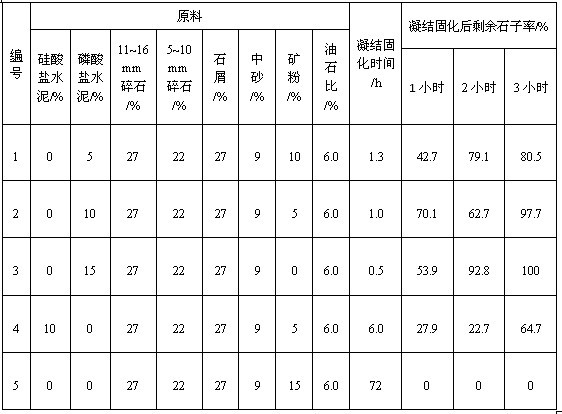

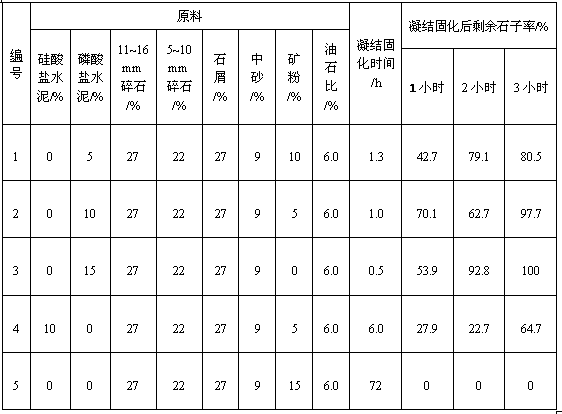

Fast repairing method for asphalt concrete pavement

InactiveCN102505601ASimple demulsification speedFast demulsificationIn situ pavingsRoads maintainenceChipsealMagnesium phosphate

The invention discloses a fast repairing method for an asphalt concrete pavement. The method adopts the following materials by weight part: 1 to 40 parts of magnesium phosphate cement; 10 to 30 parts of rubble with particle sizes ranging from 5 to 10 mm; 20 to 40 parts of rubble with particle sizes ranging from 11 to 16 mm; 20 to 50 parts of stone chips with particle sizes smaller than 5 mm; 5 to 15 parts of medium sand; 0 to 10 parts of mineral powder; and emulsified asphalt added according to 4 to 10 percent of bitumen-aggregate ratio. After being stirred uniformly, all the materials are poured to the damaged pavement which is cleaned; and when the materials are tamped and flattened, the damaged pavement is only maintained for about 3 hours. As the method adopts the pouring forming method in the practical application, and no stirring equipment and no construction equipment are required during the application process, the method has the advantages that the construction is convenient; the maintenance time is short; the impact on transportation is low; and application requirements on both mechanical property and lasting quality can be met. The method is particularly suitable for the fast repairing of the asphalt concrete pavement, and also can be used in small-area of asphalt concrete engineering requiring cold construction.

Owner:CHONGQING UNIV

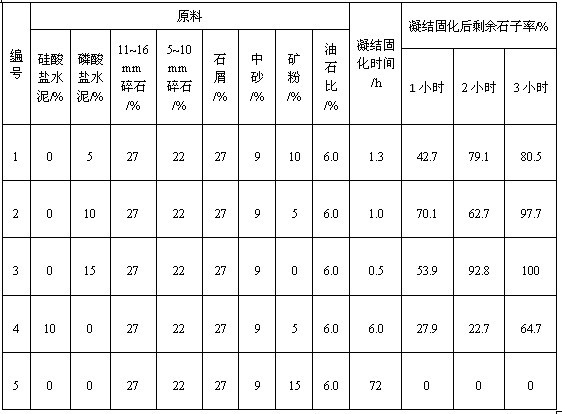

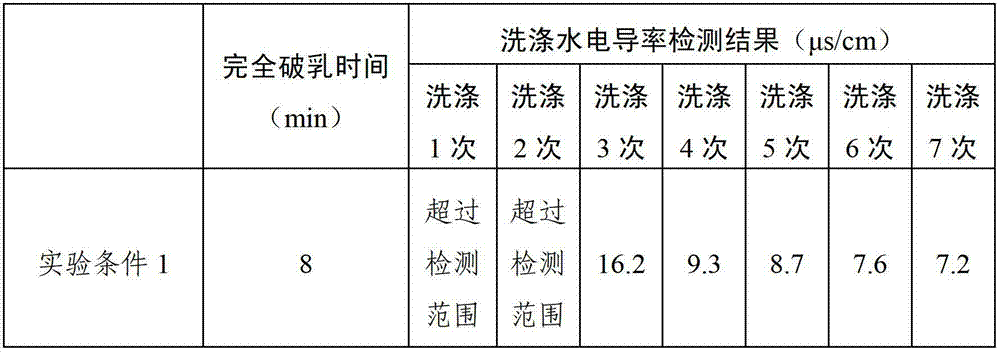

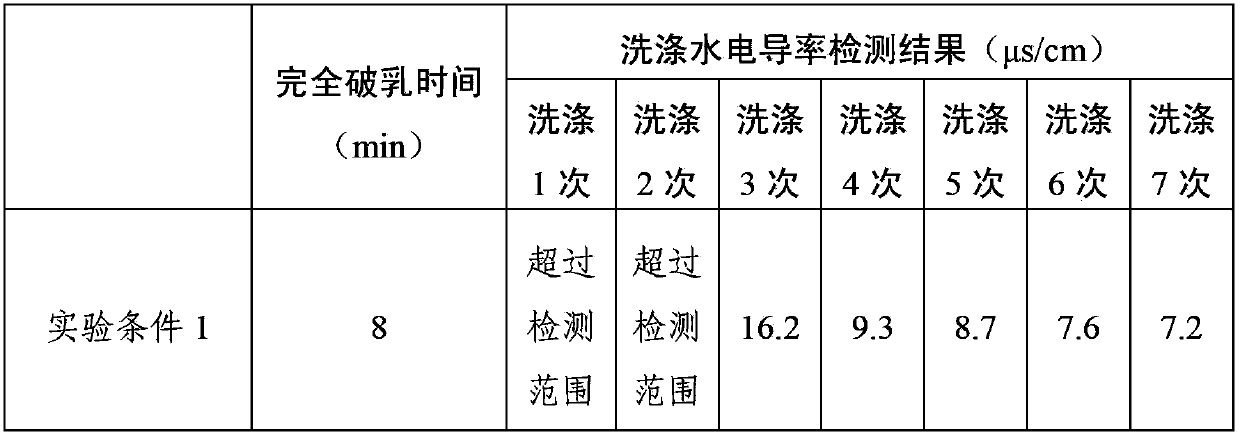

Condensing washing method of polyvinylidene fluoride emulsion

The invention relates to a condensing washing method of polyvinylidene fluoride emulsion. The condensing washing method comprises the steps as follows: (1) adding water at 1 to 15 DEG C to polyvinylidene fluoride emulsion; adjusting specific gravity of emulsion to value between 1.04 and 1.18; (2) condensing the polyvinylidene fluoride emulsion obtained in an agitating mode; controlling the agitating speed to 500 to 2000 rotation per minute; completely demulsifying for 1 to 15 minutes; and (3) washing the separated polyvinylidene fluoride emulsion resin after condensing with water. According to the condensing washing method provided by the invention, the production capacity of equipment is greatly improved, water consumption is reduced, the processing period is shortened, and the benefit is brought to the scale industrial production.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Emulsified bitumen crack pouring material

ActiveCN102167966AShort demulsification timeIncrease the softening point of asphaltOther chemical processesBuilding insulationsChemistryButadiene-styrene rubber

The invention relates to an emulsified bitumen crack pouring material, wherein A component comprises 40 to 60% of No.70 bitumen, 1 to 2% of emulsifier, 18 to 30% of water, 1 to 1.8% of modifier, 0.1 to 1% of stabilizer and 0.1 to 2% of pH conditioning agent, the emulsifier is one or more selected from quaternary ammonium salt, fatty amine, lignin amine, imidazoline or amide, the modifier is one or more selected from styrene butadiene latex, neoprene latex or styrene-butadiene-styrene latex, the stabilizer is one or more selected from calcium chloride, sodium phosphate, polyacrylic acid, polyvinyl alcohol or methyl cellulose, and the pH conditioning agent is one or more selected from hydrochloric acid, sulfuric acid, phosphoric acid or oxalic acid; and B component is 11 to 30% of coagulating agent, the coagulating agent is inorganic active powder, particle size of which is between 0.001 and 0.1mm, and the coagulating agent is one or more selected from CaO, SiO2 or P2O5. The crack pouring material has strong cohesiveness and good elasticity recovery performance.

Owner:PETROCHINA CO LTD +1

Agglomeration washing method of fluorinated ethylene propylene

This invention discloses a method for condensing and washing perfluoroethylene-perfluoropropylene copolymer prepared by emulsion polymerization. The method comprises: (1) adding 1-10 deg.C deionized water to perfluoroethylene-perfluoropropylene copolymer emulsion, stirring, demulsifying, and washing the precipitate with 40-80 deg.C deionized water for 2-6 times (1-5 min for each time). The method can largely increase the equipment productivity, lower the consumption of pure water, save the raw materials, and shorten the treatment period.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Rapid demulsifier for fracturing acidification and preparation method thereof

InactiveCN102250608AReduce manufacturing costShort demulsification timeDrilling compositionDemulsifierEther

The invention relates to a rapid demulsifier for fracturing acidification and a preparation method thereof. The rapid demulsifier consists of the following components in percentages by weight: 2-10% of polyoxypropylene polyoxyethylene octadecyl ether, 5-15% of alkylphenyl polyoxyethylene ether, 0.1-1% of stabilizer, 5-30% of cosolvent and the balance of water, wherein the stabilizer is isoascorbic acid or citric acid and the cosolvent is methanol, ethanol, ethylene glycol or isopropyl alcohol. By the synergy of the multiple compounded components, the demulsifier provided by the invention can shorten the demulsification time, improve the demulsification efficiency and save the production cost and has broad market prospects; and the preparation method of the demulsifier is reliable in principle and simple to operate.

Owner:SOUTHWEST PETROLEUM UNIV

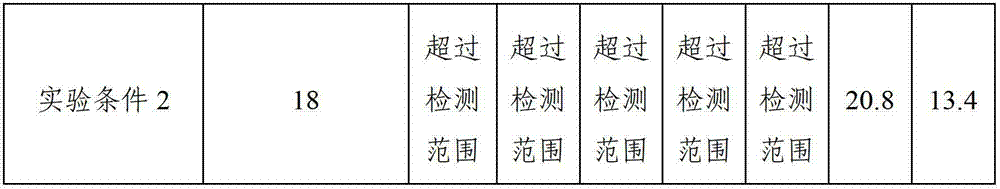

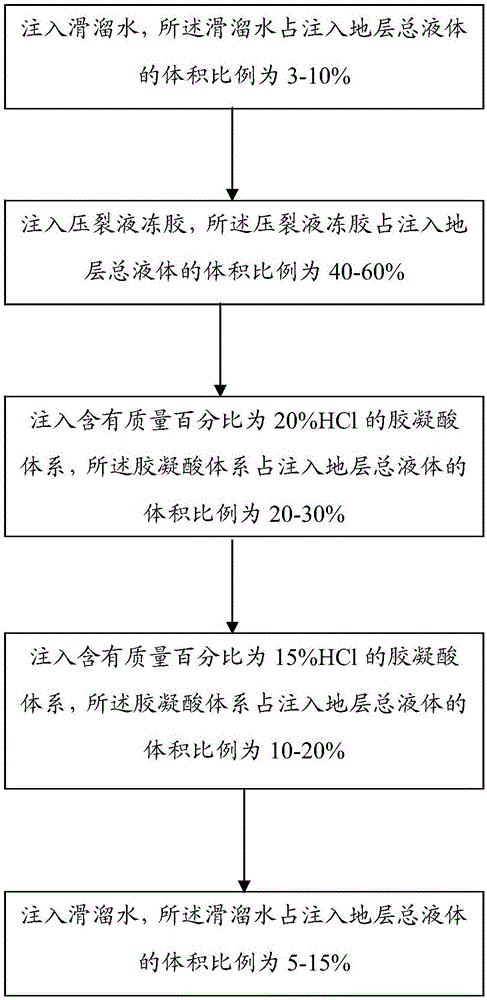

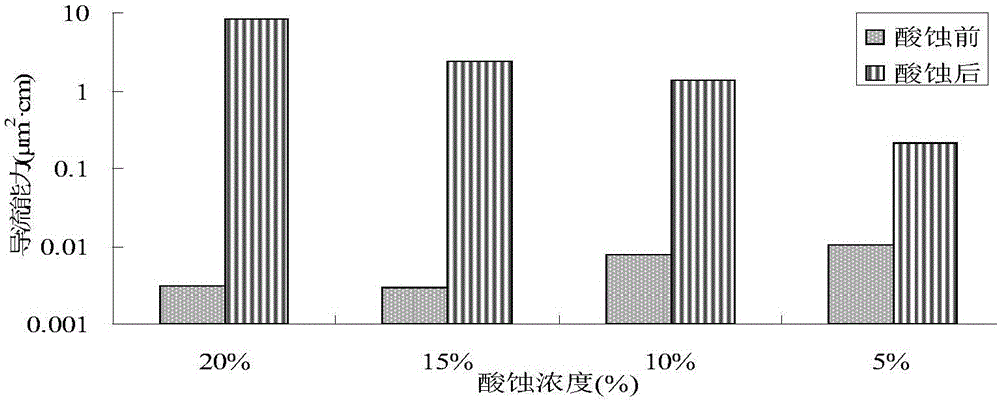

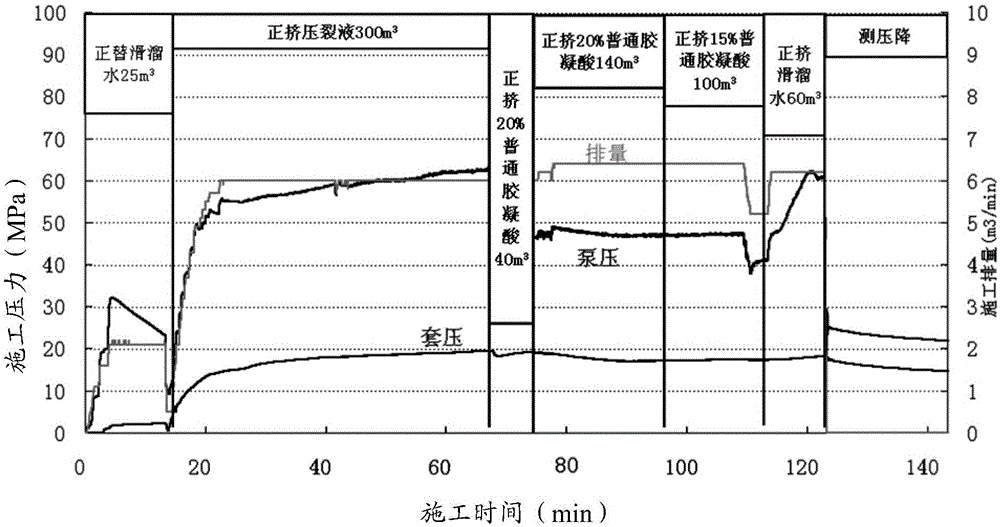

Variant-hydrochloric-acid-concentration acid fracturing method for carbonate reservoir

InactiveCN105089602AEmulsification is less difficultReduce the difficulty of demulsification and dehydrationFluid removalDrilling compositionHigh concentrationAcid fracturing

The invention relates to variant-hydrochloric-acid-concentration acid fracturing method for a carbonate reservoir. The variant-hydrochloric-acid-concentration acid fracturing method is characterized by sequentially injecting high-concentration hydrochloric acid and low-concentration hydrochloric acid into the stratum and particularly comprises the following procedures: (1) injecting slick water into the stratum; (2) injecting a fracturing fluid into the stratum, wherein the viscosity of the fracturing fluid is 100-400 mPa.s; (3) injecting a gelled acid system in which the mass percent of HCL is 20 percent into the stratum; (4) injecting a gelled acid system in which the mass percent of HCL is 15 percent into the stratum; and (5) injecting slick water into the stratum. The volume ratios of liquid injected in the procedures (1), (2), (3), (4) and (5) in the total amount of liquid in the stratum are respectively 3-10 percent, 40-60 percent, 20-30 percent, 10-20 percent and 5-15 percent in sequence, and the volume unit is m<3>.

Owner:CHINA PETROLEUM & CHEM CORP

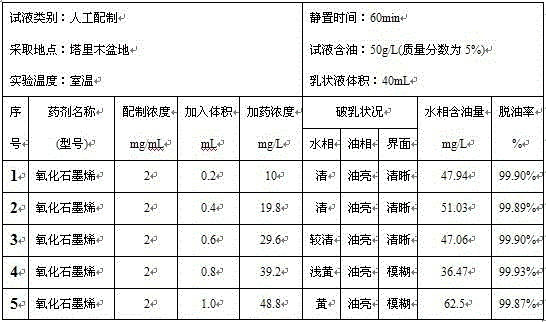

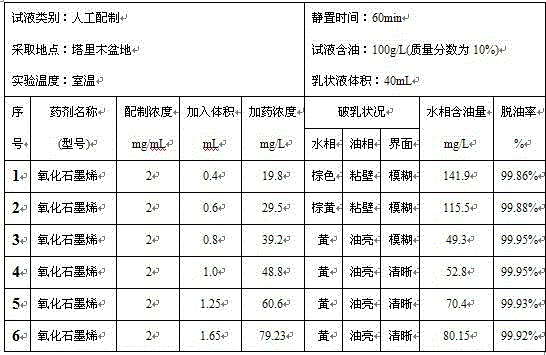

Demulsification method of oil-in-water type crude oil emulsion

InactiveCN104877706ALow water content in oil phaseReduce oil contentDewatering/demulsification with mechanical meansDemulsifierRoom temperature

The invention discloses a demulsification method of an oil-in-water type crude oil emulsion. The method employs oxidized graphene as de-emulsifier to carry out dehydration treatment to the oil-in-water type crude oil emulsion at the room temperature. The de-oiling rate of the oil-in-water emulsion is more than 96%. The demulsification method of the invention can be applied to the dehydration treatment of oil-water emulsion with high water content in the petroleum industry.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Biodemulsifier, its preparation method and application

A biologic demulsifier for the recovered oil-in-water liquid in oil field or the oil-in-water emulsion is prepared from bacillus and atoleine through fermenting and collecting the surficial thalluses of fermented liquid. Its advantages are high effect and high selectivity.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

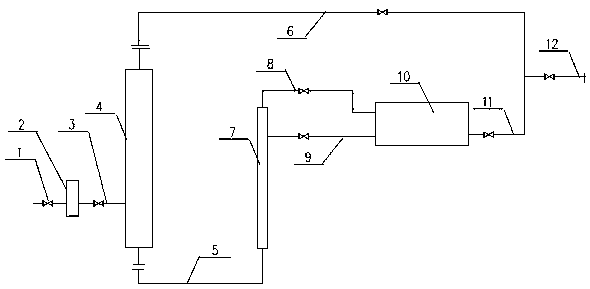

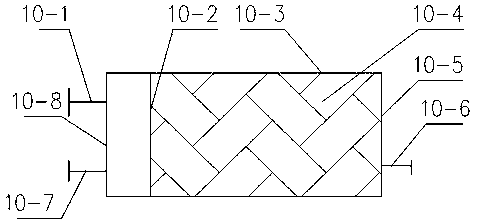

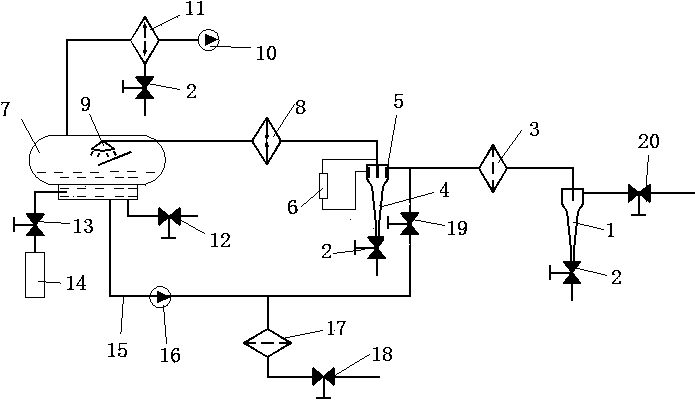

Water-in-oil demulsification method for oil field

PendingCN109337713AReduce water pressureImprove demulsification efficiencyDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansCyclonePetroleum

The invention relates to equipment applied to the oil and gas industry, wastewater treatment industry and the like, and in particular relates to a water-in-oil demulsification method for an oil field.The equipment is characterized by at least comprising a filter, a flow stabilizer, a cyclone emulsion breaker and a coalescing emulsion breaker. The method comprises the following steps: enabling water-in-oil emulsion to pass through a filter from a liquid inlet pipe, filtering impurities in the liquid, enabling the emulsion to enter the flow stabilizer via a connecting pipeline, stabilizing andbuffering the water-in-oil emulsion by the flow stabilizer, performing gas-liquid separation, and enabling the separated associated gas to enter a gas pipeline on the top of the flow stabilizer to output; enabling the separated oil water to enter the bottom inlet of the cyclone emulsion breaker via an emulsified oil water connecting pipeline; making a high-speed cyclone motion inside the cyclone emulsion breaker, enabling the emulsion to respectively enter the coalescing emulsion breaker via the oil outlet pipeline of the cyclone emulsion breaker and an oily wastewater outlet pipe, performingrectifier demulsification by the coalescing emulsion breaker, decomposing the water-in-oil emulsion into water and oil for the second time, gathering the decomposed water and oil to an oil-water mixing pipeline, merging with the gas pipeline, delivering to a separation device via a gas-liquid mixing pipeline so as to perform oil-water separation, thereby realizing oil and water demulsification.

Owner:XIAN TIANXIANG ENERGY TECH

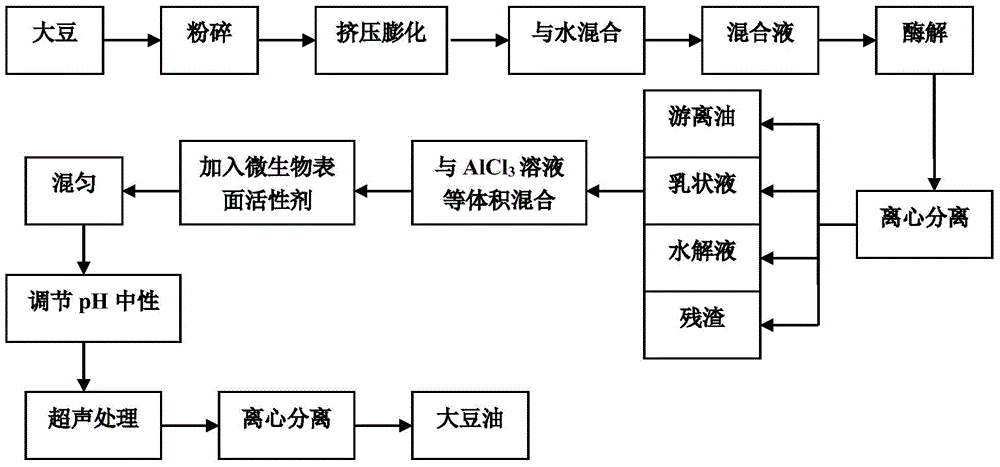

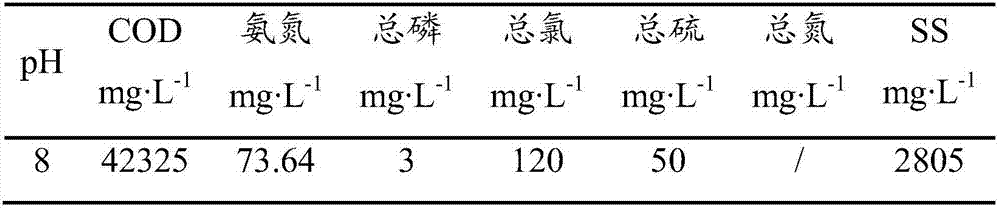

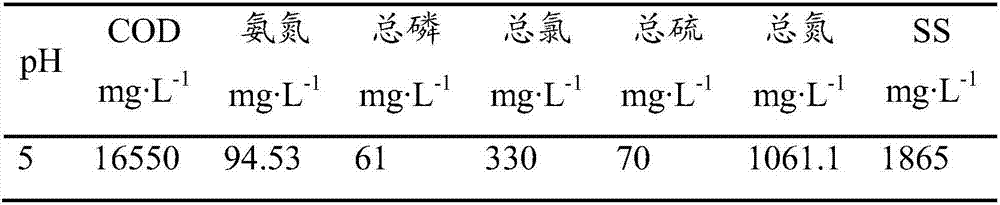

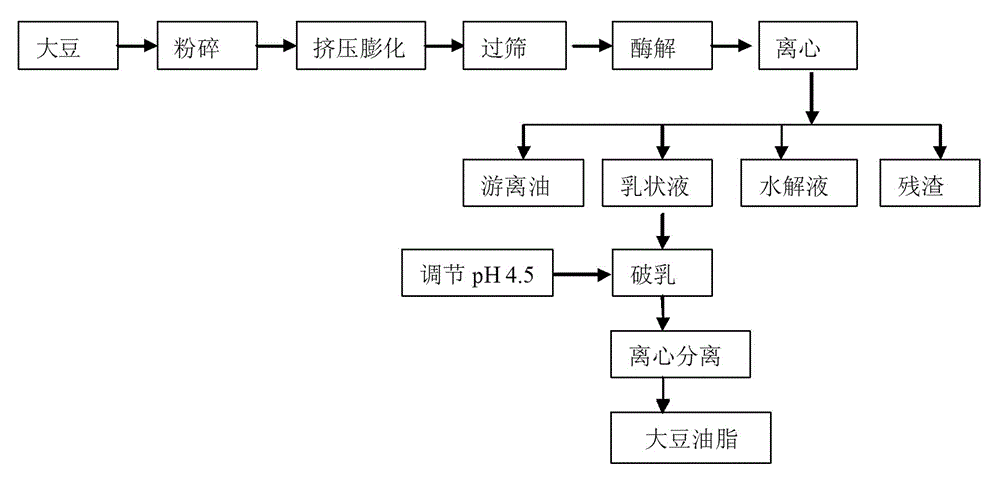

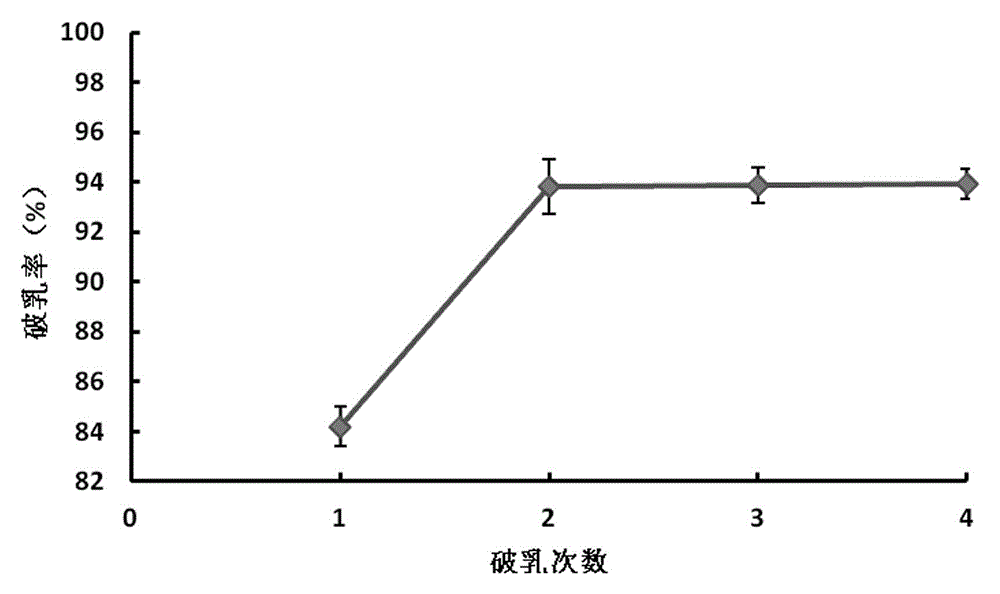

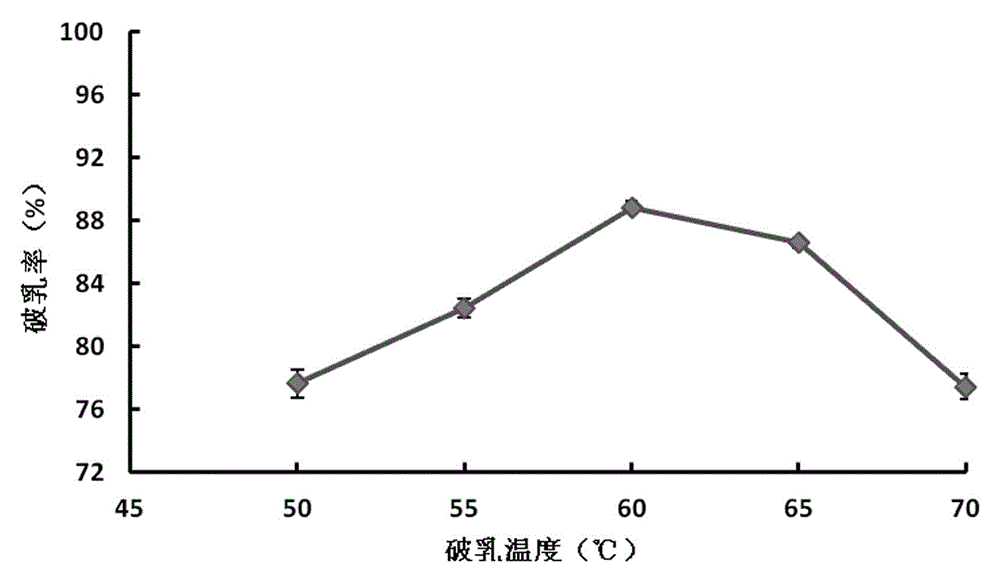

Method for extracting soybean oil compound breakdown emulsion by virtue of aqueous enzymatic method

ActiveCN104893817AHigh demulsification rateHigh purityFatty-oils/fats productionOil and greaseVegetable oil

The invention provides a method for extracting soybean oil compound breakdown emulsion by virtue of an aqueous enzymatic method, and belongs to extracting and processing technologies of vegetable oil and fat. The method comprises the following steps: (1) crushing soybeans, then performing extrusion puffing to obtain a puffed material, mixing the puffed material with water to obtain a mixed solution, adding alkali protease into the mixed solution to perform enzymolysis, and then performing centrifugal separation to obtain free oil, emulsion, hydrolysate and residues; (2) mixing the emulsion with a AlCl3 solution at equal volumes, then adding a microbial surfactant, mixing uniformly, and then adjusting the pH value to be neutral; and (3) performing ultrasonic treatment on the treated emulsion, and then performing centrifugal separation to obtain soybean oil. By adopting the method, the inorganic salt AlCl3, the microbial surfactant and an ultrasonic technology are organically combined together to form an integral compound demulsification system which is low in cost and pollution-free, and is short in demulsification time and high in demulsification rate, and the obtained soybean oil is high in purity and good in quality and has a wide application prospect in processing of the vegetable oil and fat.

Owner:山东国宏生物科技有限公司

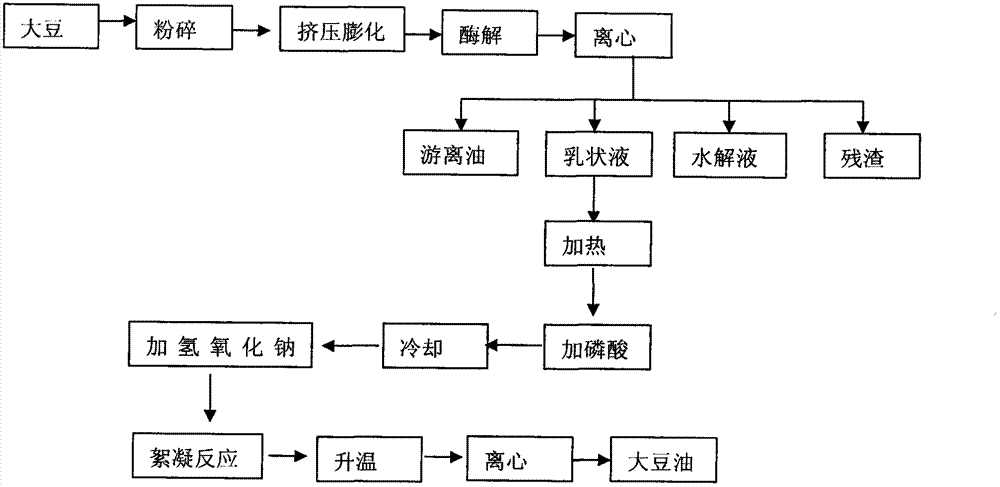

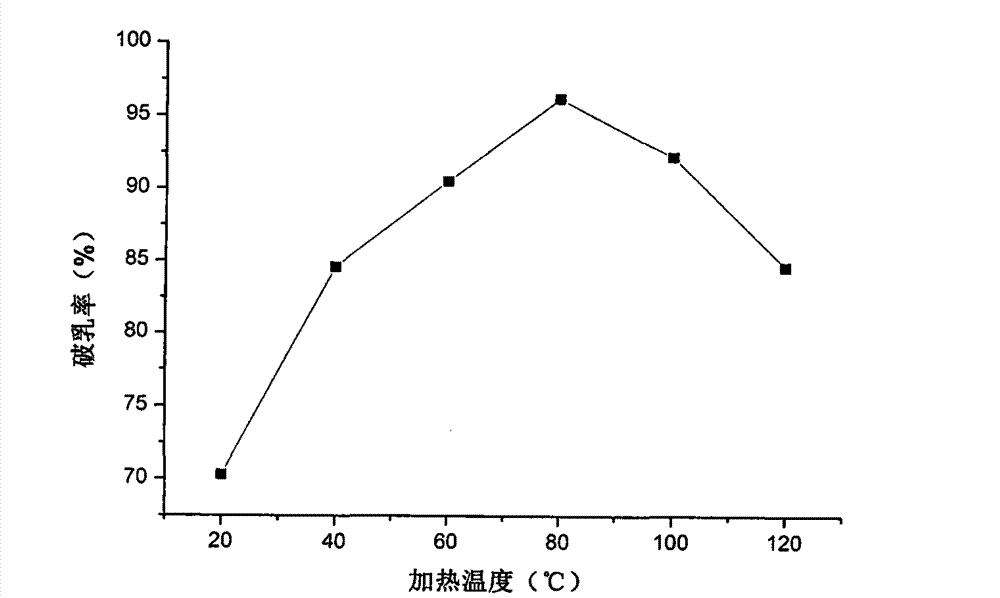

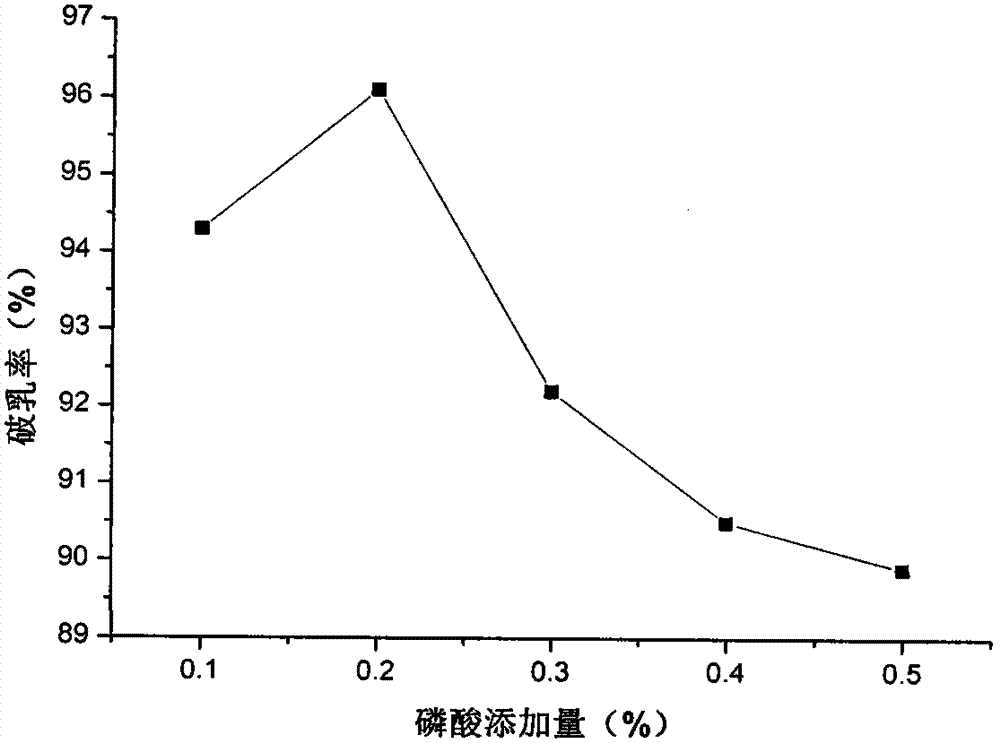

Demulsification method for extracting soybean oil by aqueous enzymatic method

ActiveCN102732371ASimple process equipmentShort demulsification timeFatty-oils/fats productionVegetable oilProcess equipment

The invention relates to a demulsification method for extracting soybean oil by an aqueous enzymatic method, belonging to a vegetable oil and fat extraction technology. The method comprises the following steps of: (1) pulverizing soybeans, extruding, puffing and pretreating to obtain a puffed material; mixing the puffed material with water to obtain a mixed solution; adding alkali protease to themixed solution for enzymolysis, and then centrifuging and separating to obtain free oil, an emulsion, hydrolysate and residues; (2) heating the emulsion obtained in the step (1), and adding phosphoric acid to the heated emulsion for conditioning; cooling the reaction system, and then adding a sodium hydroxide solution to carry out a flocculation reaction; and continuously heating the system afterthe reaction, and centrifuging and separating to obtain soybean oil. The method has the advantages of simple required process equipment, short demulsification time and high demulsification rate.

Owner:山东万得福生物科技有限公司

Modified emulsified asphalt and preparation method thereof

InactiveCN104356658AImprove stabilityImprove performanceBuilding insulationsPolymer scienceBitumen emulsion

The invention discloses modified emulsified asphalt and a preparation method thereof, belonging to the technical field of emulsified asphalt. The emulsifier used by the modified emulsified asphalt is formed by a basic emulsifier and a co-emulsifier via compounding, and a certain stabilizer is added to enhance the stability of the emulsified asphalt, so that the finally produced emulsified asphalt is favorable in product property and high in storage stability, and has the characteristics of short demulsification time and favorable blocking property with aggregates when being used for pavement construction projects; and the preparation method of the modified emulsified asphalt is simple to operate, wide in source of raw materials and low in cost.

Owner:广东道衡建设工程有限公司

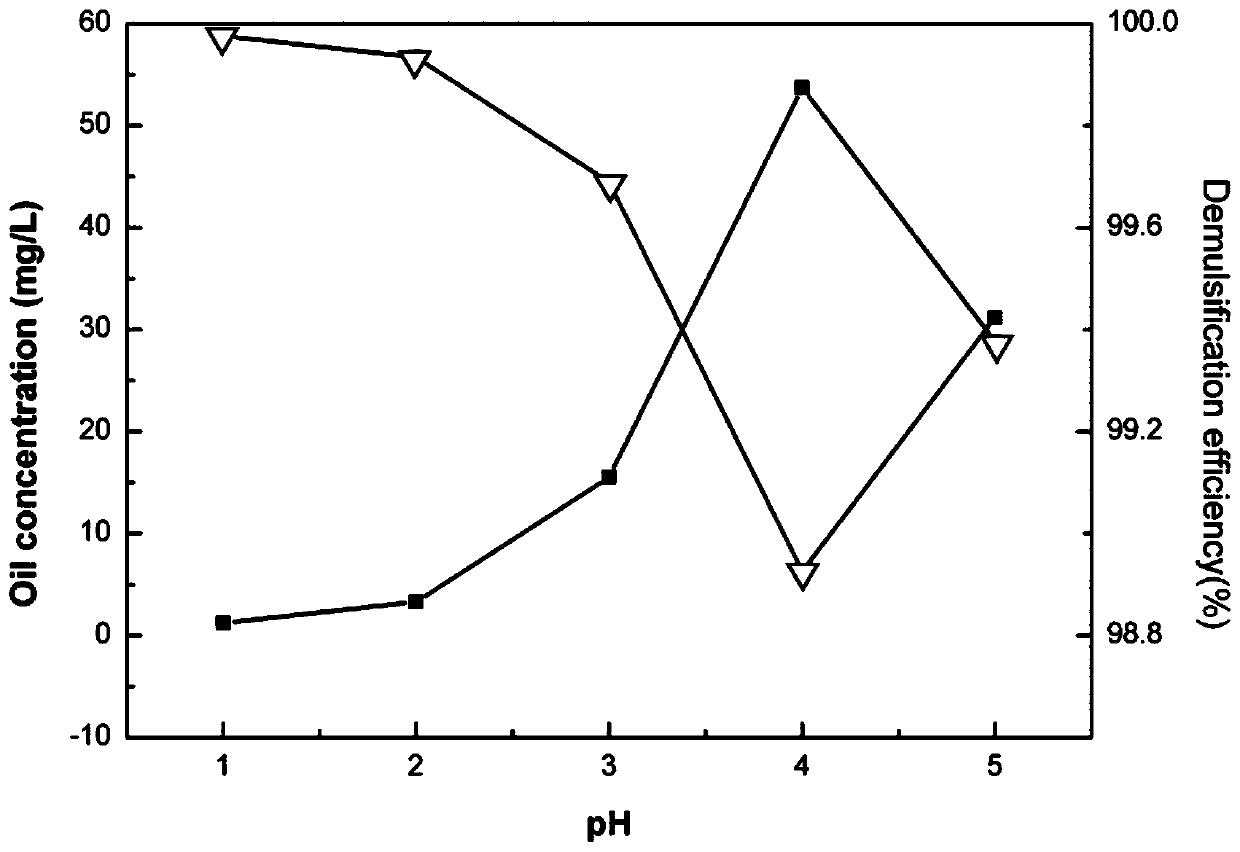

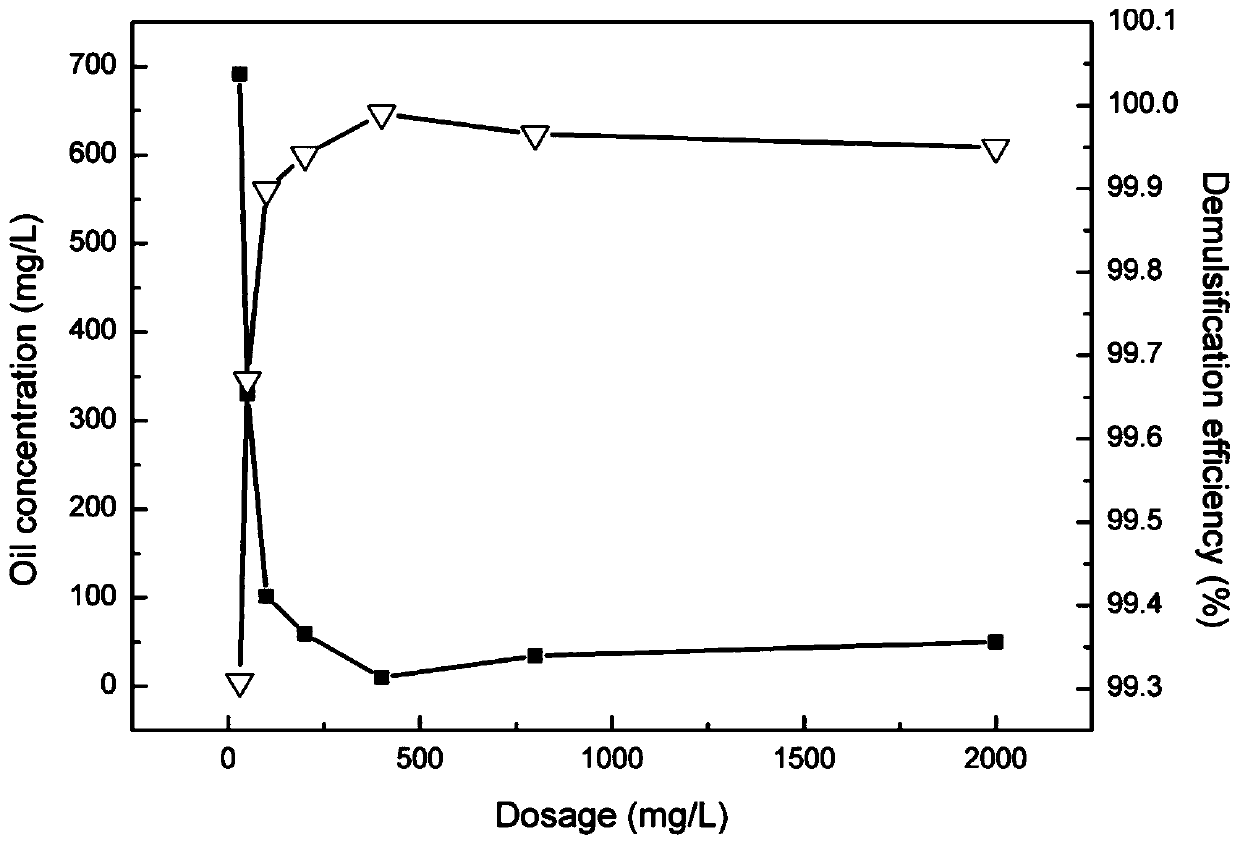

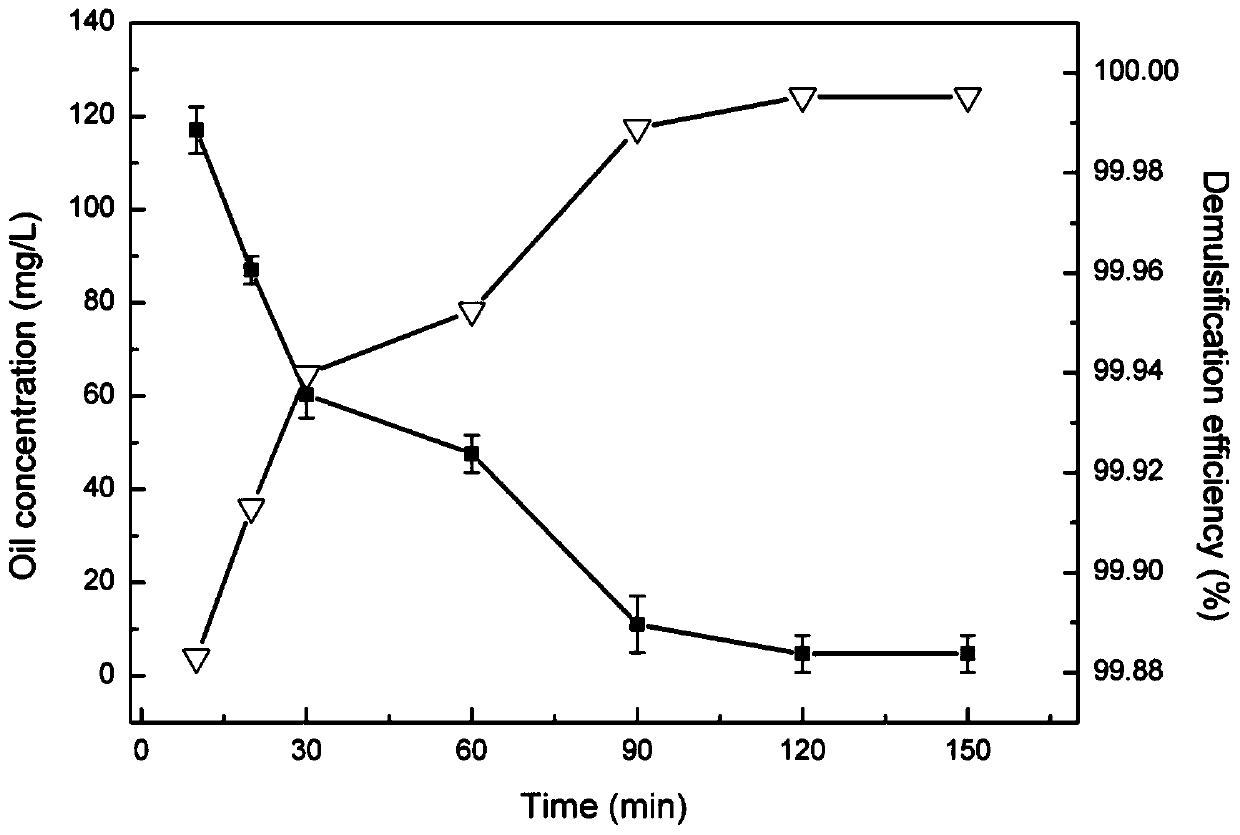

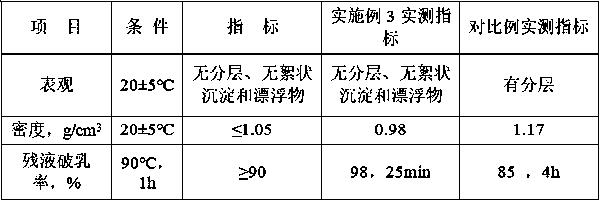

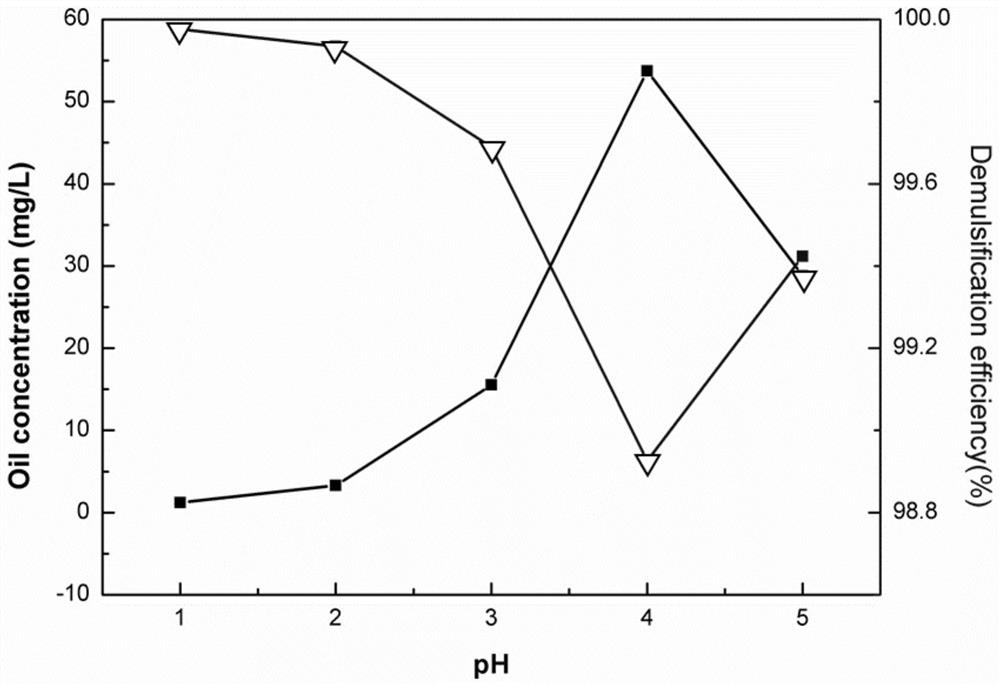

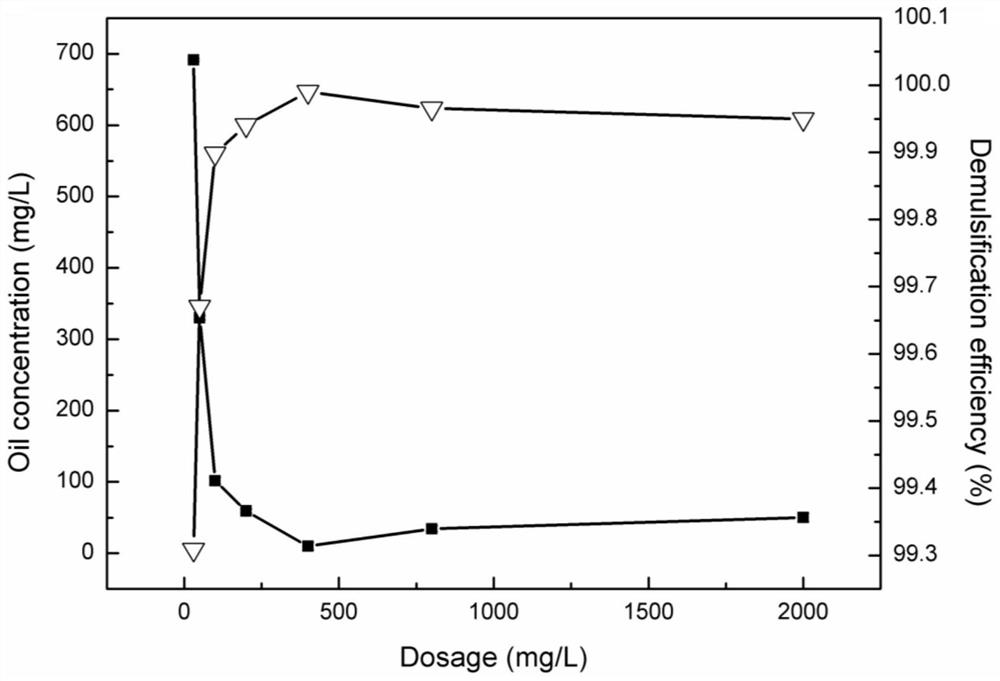

Novel clay mineral demulsifier, preparation method thereof, and method for demulsifying and recycling oil-in-water crude oil emulsion

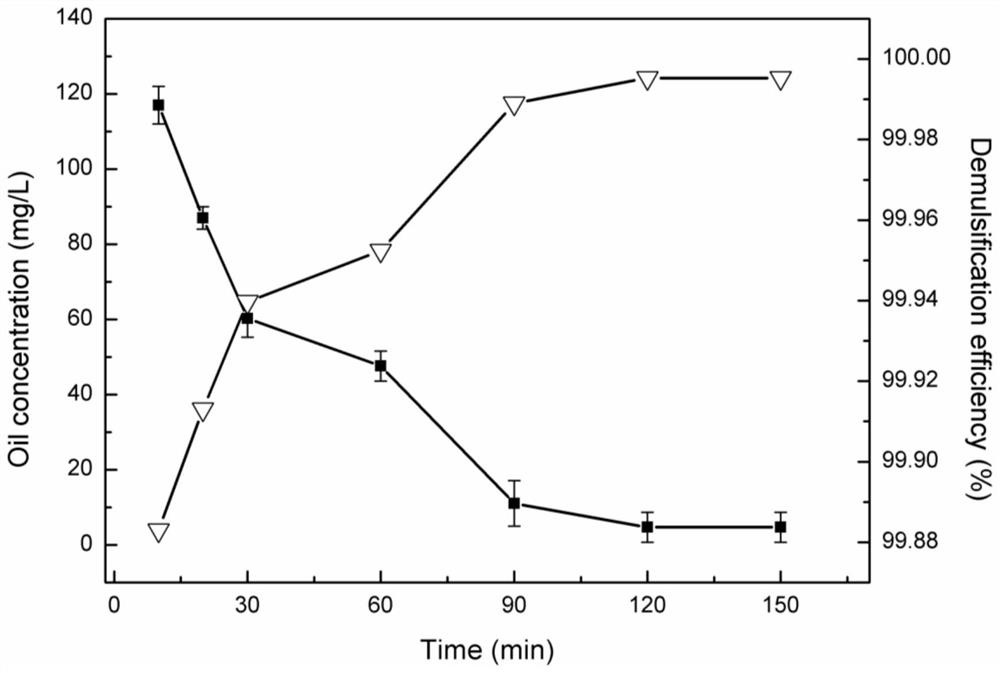

ActiveCN109929584AImprove demulsification efficiencyReduce oil contentDewatering/demulsification with chemical meansClay mineralsPolyethylene glycol

The invention relates to a novel clay mineral demulsifier, a preparation method thereof, and a method for demulsifying and recycling an oil-in-water crude oil emulsion. The preparation method comprises the following steps: mixing pretreated clay mineral with iron chloride, sodium citrate, ethylene glycol and polyethylene glycol, performing ultrasonic dispersing to uniformity, placing the obtainedmixture in a reactor with a PTFE lining, raising the reaction temperature in the reactor to 200-240 DEG C, carrying out a constant temperature reaction for 20-28 h, and cooling the obtained reaction product to obtain the demulsifier. The novel clay mineral demulsifier prepared in the invention is used for the demulsification and dehydration treatment of the oil-in-water crude oil emulsion, the demulsification efficiency on the water-in-oil crude oil emulsion reaches up to 99.0% or more, and the water content of removed water is less than 10 mg / L, and basically meets the discharge standards ofsecondary water. The demulsifier provides an inexpensive and efficient method for the demulsification and dehydration treatment of the oil-in-water crude oil emulsion, and has an excellent applicationprospect.

Owner:JIANGXI UNIV OF SCI & TECH

Anti-emulsion demulsifier for acid fracturing and preparation method thereof

InactiveCN111139055AEase of industrial productionMild reaction conditionsDrilling compositionPolyethylene glycolAlkylphenol

The invention is applied to the field of oil and gas resource exploitation, and particularly relates to an anti-emulsion demulsifier for acid fracturing and a preparation method thereof. The demulsifier is prepared from the following raw materials: sodium perfluorononenyloxy benzenesulfonate, polyoxyethylene, polyethylene glycol octadecanol ether, alkylphenol ethoxylates, a cosolvent and a stabilizer. In order to overcome the defect of long demulsification time of the existing demulsifier, the invention provides a novel demulsifier for acid fracturing, which can demulsify and stratify crude oil emulsion in a short time, meets the requirements of acid fracturing construction, and has good application and popularization values in oil field production, especially in acid fracturing construction.

Owner:克拉玛依中科恒信科技有限责任公司

Supercritical carbon dioxide extraction technology of suaeda salsa seed oil

InactiveCN108004015AImprove oil yieldFacilitated releaseFatty-oils/fats refiningFatty-oils/fats productionCulture fluidLinoleic acid

The invention relates to the technical field of plant oil extraction, in particular to a supercritical carbon dioxide extraction technology of suaeda salsa seed oil. The supercritical carbon dioxide extraction technology comprises the following steps: performing raw material pretreatment, performing primary enzymolysis treatment, performing supercritical extraction, performing secondary enzymolysis treatment, preparing a whole culture fluid of composite demulsifying bacteria and performing demulsification treatment. By the preparation method, through enzymolysis, supercritical extraction, enzymolysis treatment, and then demulsification treatment with the composite demulsifying bacteria, the oil extraction rate of suaeda salsa seeds is greatly increased and the linoleic acid content of thesuaeda salsa seed oil is also increased.

Owner:WEIFANG YOURONG IND

Fast repairing method for asphalt concrete pavement

InactiveCN102505601BSimple demulsification speedFast demulsificationIn situ pavingsRoads maintainenceChipsealMagnesium phosphate

The invention discloses a fast repairing method for an asphalt concrete pavement. The method adopts the following materials by weight part: 1 to 40 parts of magnesium phosphate cement; 10 to 30 parts of rubble with particle sizes ranging from 5 to 10 mm; 20 to 40 parts of rubble with particle sizes ranging from 11 to 16 mm; 20 to 50 parts of stone chips with particle sizes smaller than 5 mm; 5 to 15 parts of medium sand; 0 to 10 parts of mineral powder; and emulsified asphalt added according to 4 to 10 percent of bitumen-aggregate ratio. After being stirred uniformly, all the materials are poured to the damaged pavement which is cleaned; and when the materials are tamped and flattened, the damaged pavement is only maintained for about 3 hours. As the method adopts the pouring forming method in the practical application, and no stirring equipment and no construction equipment are required during the application process, the method has the advantages that the construction is convenient; the maintenance time is short; the impact on transportation is low; and application requirements on both mechanical property and lasting quality can be met. The method is particularly suitable for the fast repairing of the asphalt concrete pavement, and also can be used in small-area of asphalt concrete engineering requiring cold construction.

Owner:CHONGQING UNIV

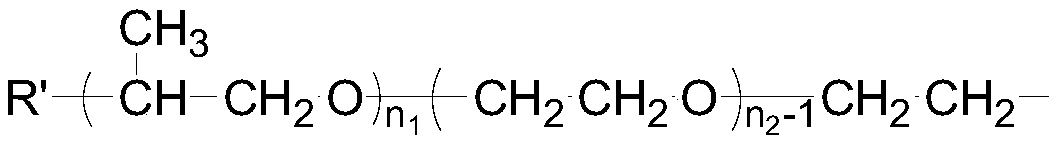

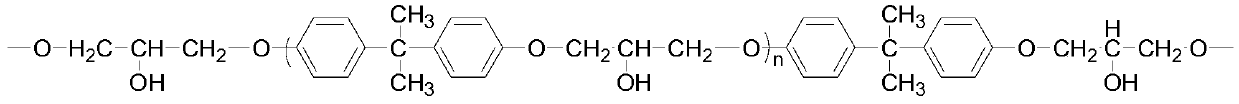

Solid type crude oil demulsifier and preparation method and application thereof

ActiveCN110343545AHigh molecular weightShorten Diffusion TimeDewatering/demulsification with chemical meansDemulsifierSolvent

The invention provides solid type crude oil demulsifier. The solid type crude oil demulsifier is prepared by adopting the following steps that (1) starting agent is prepared: polyethylene polyamine, phenol and methanol are mixed and then successively heated, refluxed and dehydrated from water and solvent, and cooled to obtain the starting agent; (2) an intermediate is prepared: alkali powder is added to the starting agent, epoxypropane and oxirane are successively added under vacuum, reaction is conducted under 120DEG C-140DEG C for 4-6h, and the intermediate is obtained by cooling; and (3) the demulsifier is prepared: bisphenol A type epoxy resin is added to the intermediate and reaction is conducted under 75DEG C-90DEG C for 4-6h, and the demulsifier is obtained by cooling. According tothe solid type crude oil demulsifier, a solid type structural final product can be obtained, the molecular weights of final demulsifier products are increased, at the same time, the penetration and diffusion of demulsifier molecule in heavy oil can be further enhanced, the diffusion time of the demulsifier is shortened, and the demulsification performance of demulsifier products is improved.

Owner:DESHI ENERGY TECH GRP CO LTD +1

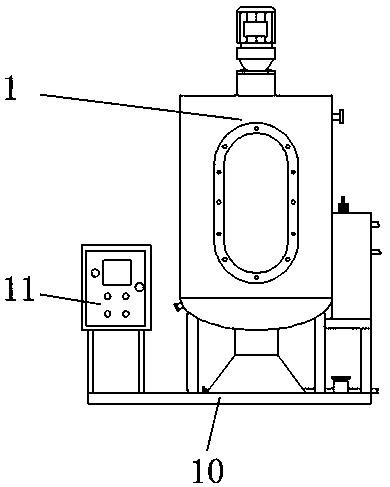

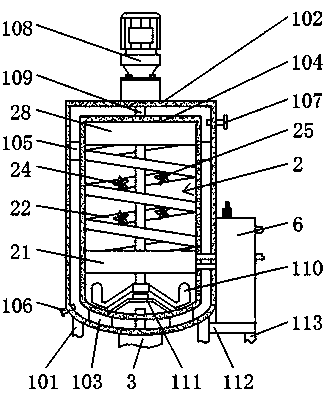

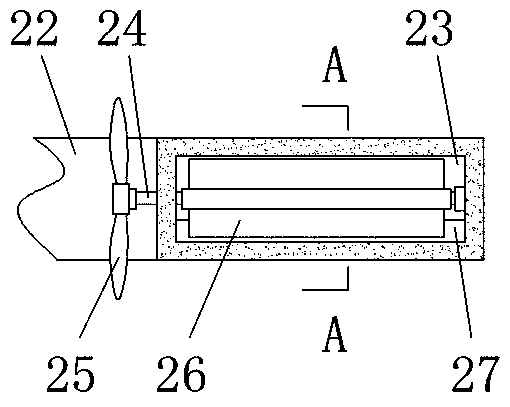

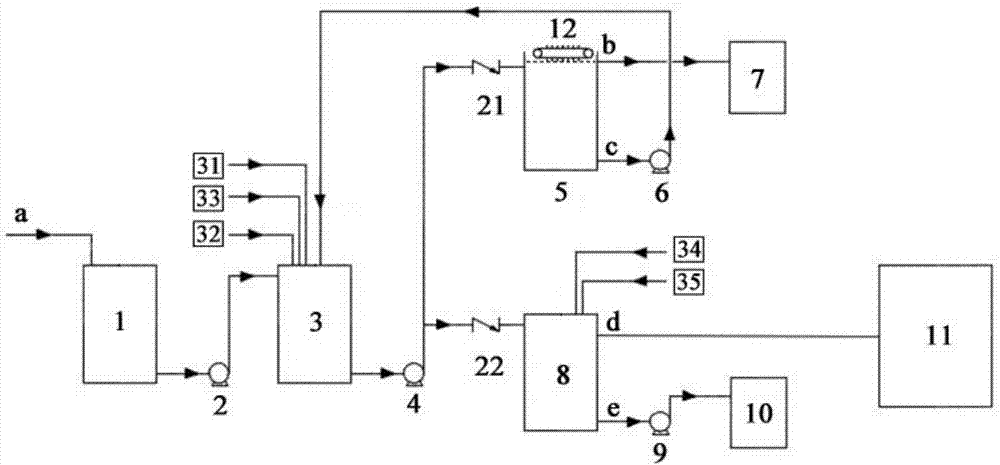

Treatment and recovery device for mixed waste emulsion

ActiveCN110844970AExtend exercise timeExtension of timeFatty/oily/floating substances removal devicesRotary stirring mixersDemulsifierDistribution control

The invention discloses a treatment and recovery device for mixed waste emulsion. The treatment and recovery device comprises a bottom plate, a power distribution control box is fixedly mounted at theleft end of the top surface of the bottom plate, and a demulsification device is arranged at the right end of the top surface of the bottom plate; the purposes of automatically injecting the waste emulsion and a demulsifier are achieved through the cooperation of a cutoff device and a regulation and control device, the injection amount of the waste emulsion and the addition amount of the demulsifier do not need to be manually controlled, the automation degree is high, and the demulsified mixed liquid can be automatically discharged through a liquid level control device. The demulsification process can be continuously carried out on line, time and labor are saved, the treatment efficiency is high, through cooperation of a strain device and the regulation and control device, the treatment and recovery device for the mixed waste emulsion can be adjusted in time according to the concentration of the waste emulsion, the situation that the adding amount of the demulsifier is too large or too small is avoided, the demulsifier is not wasted, and the production cost is reduced. The utilization rate of the demulsifier is high, the treatment effect is good, the demulsification time is short,and the practicability of the treatment and recovery device for the mixed waste emulsion is improved.

Owner:YANTAI VOCATIONAL COLLEGE

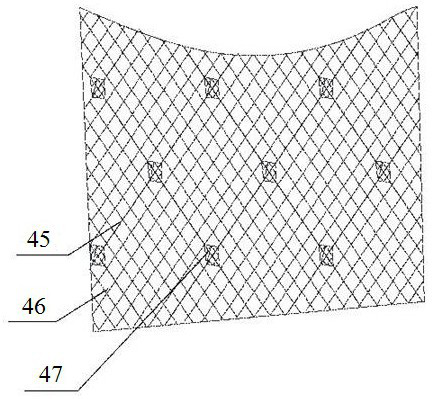

Multi-field joint lubricating oil dehydration and purification device

ActiveCN103289808BThoroughly dehydratedRealize deep purification and dehydrationFiltration circuitsLubricant compositionNitrogen generatorHigh water content

The invention discloses a multi-field joint lubricating oil dehydration and purification device. Lubricating oil is sequentially connected with a primary swirler, a strainer, a secondary swirler and a vacuum tank through pipelines, wherein a pulse electrode is arranged in the secondary swirler, a heater is arranged on a pipeline between the secondary swirler and the vacuum tank, the upper part of the vacuum tank is connected with a vacuum pump through a pipeline, a condenser is arranged on the pipeline for connecting the vacuum tank with the vacuum pump, the bottom of the vacuum tank is connected with an oil drain valve and a nitrogen generator and provided with a backflow pipe, and an oil pump is arranged on the backflow pipe and connected with the oil drain valve through an oil outlet pipe. The multi-field joint lubricating oil dehydration and purification device can be used for thoroughly dehydrating the lubricating oil, realizing deep purification and dehydration, and greatly shortening demulsification time so as to quickly finish the lubricating oil purification treatment and reduce the energy consumption of the oil purification. The multi-field joint lubricating oil dehydration and purification device can be used for removing trace moisture in the lubricating oil, and also can be applied to the dehydration and purification treatment of the lubricating oil with high water content, thus being wide in applicable range.

Owner:CHONGQING UNIV OF TECH

Demulsification device and method

PendingCN107572630AFlexible switchingReduce processing costsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWater treatment

The invention relates to the technical field of water treatment and in particular relates to a demulsification device and method. The demulsification device comprises a demulsification reaction container, an air flotation container and a flocculating and settling container, wherein the outlet of the demulsification reaction container is alternatively connected with the inlet of the air flotation container and the inlet of the flocculating and settling container; the lower outlet of the air flotation container is connected with the inlet of the demulsification reaction container.

Owner:ENN ENVIROTECH CO LTD

Emulsified asphalt for spraying and rapid hardening rubber asphalt waterproof coating material and preparation method of emulsified asphalt

The invention relates to the technical field of high polymer materials, in particular to emulsified asphalt for a spraying and rapid hardening rubber asphalt waterproof coating material and a preparation method of the emulsified asphalt. According to the emulsified asphalt disclosed by the invention, an anionic type asphalt emulsifying agent is prepared by adopting oleic acid, sodium hydroxide, sodium dodecyl benzene sulfonate, OP-10 and rosin and by combining reaction, and then maleic anhydride and tin tetrachloride are added for modifying asphalt, so that the temperature stability, the mechanical stability, the compatibility and the demulsification performance of the emulsified asphalt are improved, the requirements on spraying performance and waterproofness of the spraying and rapid hardening rubber asphalt waterproof coating material can be well met, and the defects that after traditional emulsified asphalt is applied to a spraying waterproof coating material, blocking and caking can be easily caused, the film forming property is poor, and the like are overcome.

Owner:BEIJING AOTAILI NEW TECH CO LTD

Aqueous enzymatic method for soybean fat extraction through isoelectric point demulsification

InactiveCN104987947AGuaranteed stabilitySimple process equipmentFatty-oils/fats productionOil and greaseEmulsion

The invention relates to an aqueous enzymatic method for soybean fat extraction through isoelectric point demulsification. The method comprises the following steps: crushing soybeans, extruding, crushing, screening, and adding water for mixing; adding basic protease (Protex 6L), and performing enzymolysis; centrifuging a mixed solution after enzymolysis, performing demulsification, and collecting demulsified oil and free oil together. As the emulsion contains lots of discretely distributed oil bodies serving as the main storage parts of fat, the oil bodies are positioned in the same protein net, and protein plays a role of maintaining the oil body stability, the protein structure can be destroyed to release the fat through isoelectric point demulsification. The method is simple in process and equipment, short in demulsification time and high in demulsification rate.

Owner:SHENYANG INST OF TECH

A kind of clay mineral demulsifier and its preparation method, application and recycling method

ActiveCN109929584BImprove demulsification efficiencyReduce oil contentDewatering/demulsification with chemical meansClay mineralsPolyethylene glycol

The invention relates to a novel clay mineral demulsifier, a preparation method thereof, and a method for demulsifying and recycling an oil-in-water crude oil emulsion. The preparation method comprises the following steps: mixing pretreated clay mineral with iron chloride, sodium citrate, ethylene glycol and polyethylene glycol, performing ultrasonic dispersing to uniformity, placing the obtainedmixture in a reactor with a PTFE lining, raising the reaction temperature in the reactor to 200-240 DEG C, carrying out a constant temperature reaction for 20-28 h, and cooling the obtained reaction product to obtain the demulsifier. The novel clay mineral demulsifier prepared in the invention is used for the demulsification and dehydration treatment of the oil-in-water crude oil emulsion, the demulsification efficiency on the water-in-oil crude oil emulsion reaches up to 99.0% or more, and the water content of removed water is less than 10 mg / L, and basically meets the discharge standards ofsecondary water. The demulsifier provides an inexpensive and efficient method for the demulsification and dehydration treatment of the oil-in-water crude oil emulsion, and has an excellent applicationprospect.

Owner:JIANGXI UNIV OF SCI & TECH

Condensing washing method of polyvinylidene fluoride emulsion

The invention relates to a condensing washing method of polyvinylidene fluoride emulsion. The condensing washing method comprises the steps as follows: (1) adding water at 1 to 15 DEG C to polyvinylidene fluoride emulsion; adjusting specific gravity of emulsion to value between 1.04 and 1.18; (2) condensing the polyvinylidene fluoride emulsion obtained in an agitating mode; controlling the agitating speed to 500 to 2000 rotation per minute; completely demulsifying for 1 to 15 minutes; and (3) washing the separated polyvinylidene fluoride emulsion resin after condensing with water. According to the condensing washing method provided by the invention, the production capacity of equipment is greatly improved, water consumption is reduced, the processing period is shortened, and the benefit is brought to the scale industrial production.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

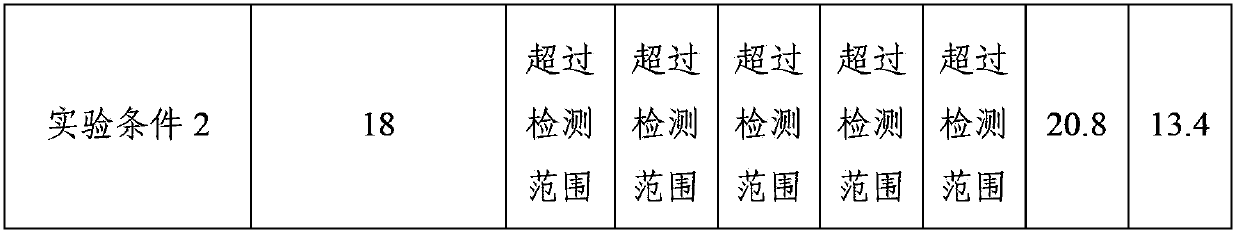

Device for demulsifying emulsified oil product and method thereof

ActiveCN113122308ASolve secondary pollutionSolve efficiency problemsHydrocarbon oil dewatering/demulsificationFiberDemulsifier

The invention discloses a device and a method for demulsifying an emulsified oil product. The device comprises a gas dissolving system, a primary demulsifying system and a secondary demulsifying system, gas is dissolved and dispersed into an emulsified oil product raw material in the gas dissolving system to form a gas-in-oil type fluid, and then the gas-in-oil type fluid is subjected to a diameter shrinkage-straight tube-diameter expansion structure of a first-stage demulsifier of the first-stage demulsification system, so that dissolved gas in the gas-in-oil type fluid destroys a stable emulsified structure of the emulsified oil product in the gas expansion and bubble coalescence growth process, the emulsion drops are dispersed into tiny liquid drops, and finally the tiny liquid drops sequentially pass through a membrane tube bundle in a first cavity, an oleophylic and hydrophobic fiber braid layer, a hydrophilic and oleophobic fiber braid layer and a membrane tube bundle in a second cavity in the second-stage demulsification system, so that water-in-oil type and oil-in-water type emulsion drops are thoroughly destroyed, and demulsification is realized. According to the device and the method disclosed by the invention, a physical method is adopted, so that the pollution of a chemical demulsifier is avoided, the problems of low demulsification efficiency, poor adaptability and high demulsification difficulty are solved, the demulsification efficiency is improved, and the demulsification time is shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

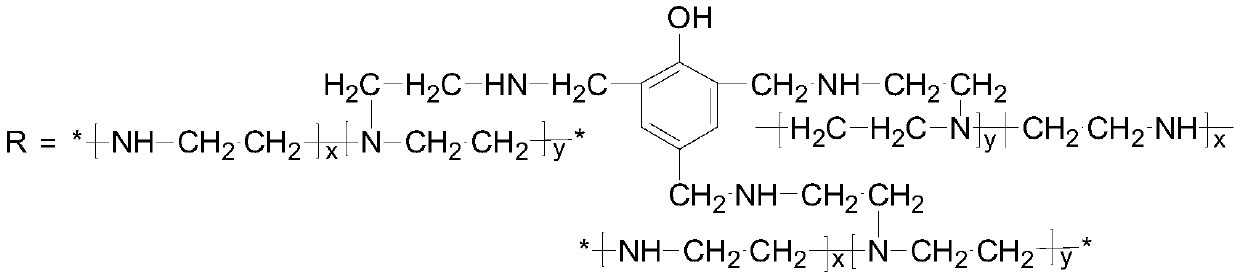

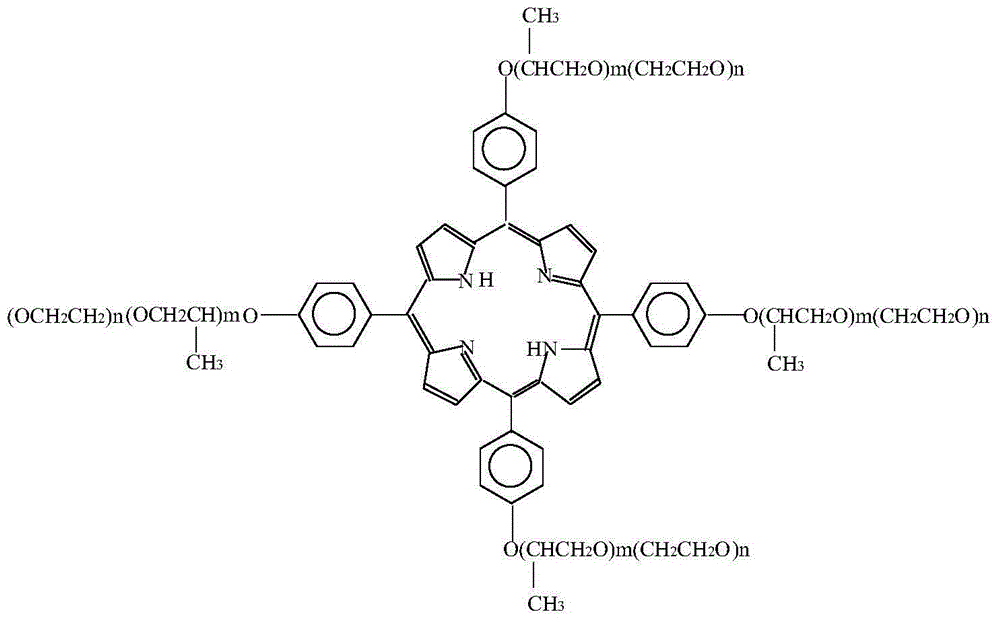

Polymer, and preparation method and use thereof

ActiveCN105622919AGood dispersionHigh interface activityDewatering/demulsification with chemical meansDemulsifierPorphyrin

The invention provides a polymer, and a preparation method and a use thereof. The structure of the polymer is shown in the description; and in the structure, m is an integer in a range of 5-50, and n is an integer in a range of 5-40. The polymer is a product of a polymerization reaction of tetra(4-hydroxyphenyl)porphyrin, epoxypropane and ethylene oxide. The polymer can be used as a lubricating oil demulsifier, can be stably dispersed in lubricating oil, has the advantages of high interface activity, great reduction of oil-water interface tension, short demulsification time and good demulsification effect, and is especially suitable for internal combustion engine lubricating oil, industrial gear oil, steam turbine oil and marine crankcase oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Comprehensive preparation method for seed oil, crude proteins and crude fibers of Suaeda salsa

InactiveCN108192719AImprove oil yieldHigh yieldPeptide preparation methodsFermentationFiberEnzymatic hydrolysis

The invention especially relates to a comprehensive preparation method for the seed oil, crude proteins and crude fibers of Suaeda salsa, belonging to the technical field of vegetable fat extraction.The comprehensive preparation method comprises the following steps: ultrasonic enzymatic hydrolysis pretreatment of raw materials; supercritical extraction; secondary enzymatic hydrolysis treatment; preparation of a total nutrient solution for composite demulsifying bacteria; demulsification; and preparation of the crude proteins; and preparation of the crude fibers. The preparation method of theinvention can prepare the seed oil, the crude proteins and the crude fibers of Suaeda salsa at the same time, and greatly improves the oil yield of the seeds of Suaeda salsa and the yield of the crudeproteins and the crude fibers.

Owner:WEIFANG YOURONG IND

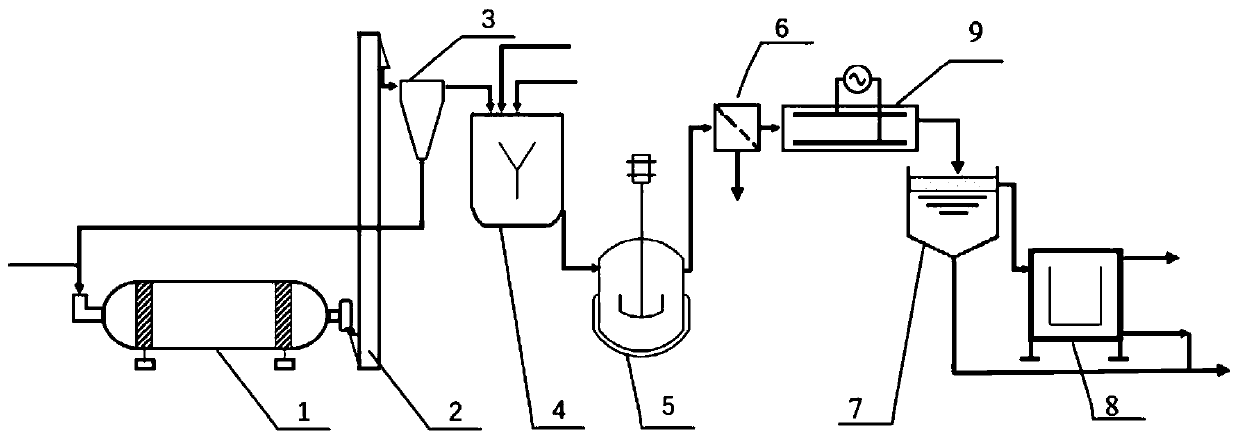

Process for extracting residual oil from oil-tea cake

PendingCN111187662AHigh extraction rateFix poor qualityFatty-oils/fats refiningFatty substance recoveryCamellia oleiferaEmulsion

The invention belongs to the technical field of tea oil extraction, and particularly relates to a process for extracting residual oil from a tea-oil cake. The process comprises the following steps: crushing oil tea cakes, carrying out sieving, and adding water to prepare a mixed solution for later use; carrying out ultrasonic stirring on the mixed solution obtained in the step (1), and conductingfiltering to obtain an emulsion; and carrying out demulsification and centrifugal separation on the emulsion to obtain an oil product. According to the method, ultrasonic stirring and demulsificationare matched for use, the tea oil cake with low oil content can be further extracted, and the extraction rate of residual oil in the tea oil cake is 75-80%; compared with a traditional method, the extraction rate of the residual oil is increased by 5-10%, and the method is short in extraction time, high in extraction efficiency and low in energy consumption. According to the method, water is used as a solvent, so the extracted oil product does not contain an organic solvent, the problem that the quality of oil products become poor due to the fact that hexane is used as the solvent in the priorart is solved, and the problems of environmental pollution and the like caused by separating hexane from the oil products in a later period are avoided.

Owner:JIANGXI UNIV OF SCI & TECH

Anti-rutting asphalt and preparation method thereof

The invention discloses anti-rutting asphalt and a preparation method thereof, and relates to the technical field of asphalt preparation, and the anti-rutting asphalt is prepared from the following raw materials: matrix asphalt, a basic emulsifier, a co-emulsifier, rubber powder, a plasticizer, a stabilizer, an accelerant, epoxy resin, naphthenic oil, an anti-aging agent, modified bentonite, sulfur and an anti-slip agent. The emulsifier used by the modified emulsified asphalt is formed by compounding and combining the basic emulsifier and the co-emulsifier, and then adding a certain amount of stabilizer to enhance the stability of the emulsified asphalt, so that the finally produced emulsified asphalt product has good performance and high storage stability, and has the characteristics of short demulsification time, high storage stability and the like when being used for pavement construction projects, and high adhesion performance with aggregate and the like; and the anti-rutting asphalt is simple in preparation process, low in cost, large in density, high in strength, good in anti-rutting effect, free of additional anti-rutting additives and the like, capable of effectively preventing the problems of upheaval, waves and upheaval, and high in high-temperature stability.

Owner:胡杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com