Polymer, and preparation method and use thereof

A technology of polymer and polymerization reaction, applied in the field of polymers, can solve the problems of poor compatibility of lubricating oil, etc., achieve good demulsification effect, short demulsification time, and reduce interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

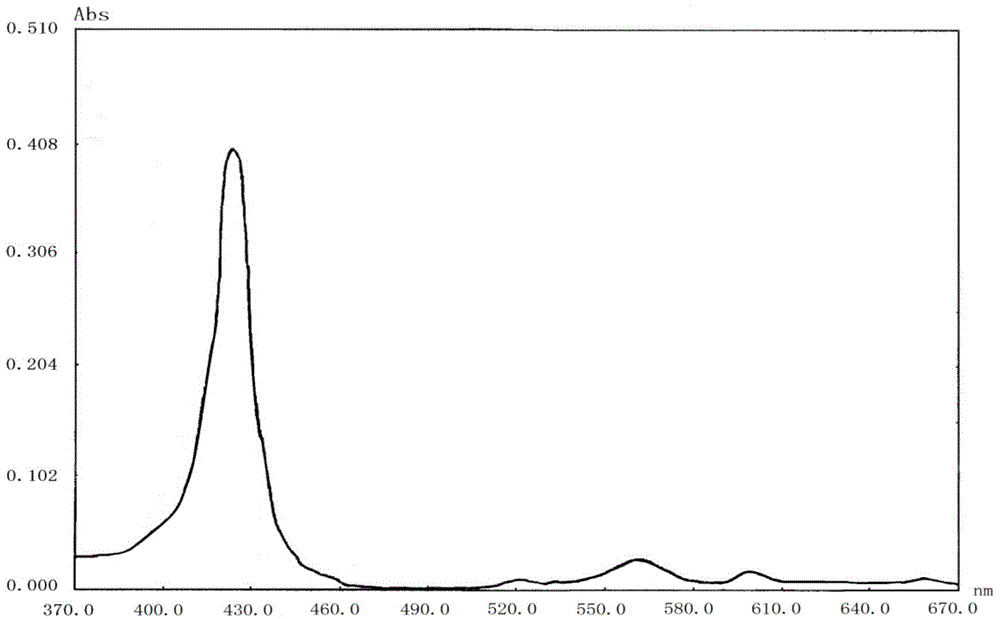

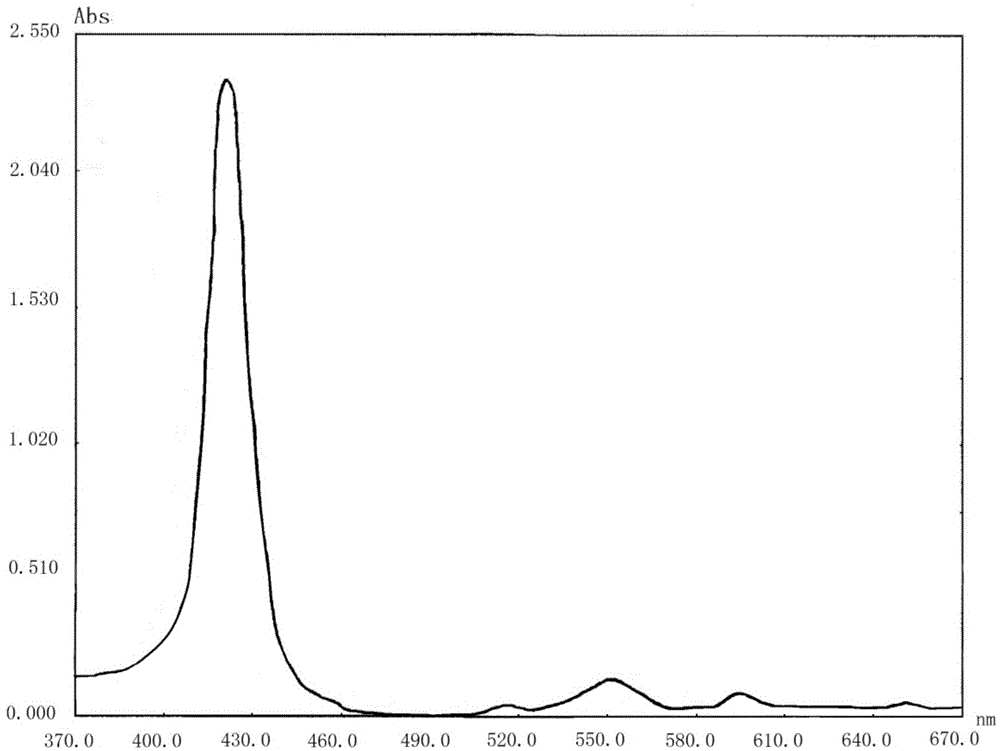

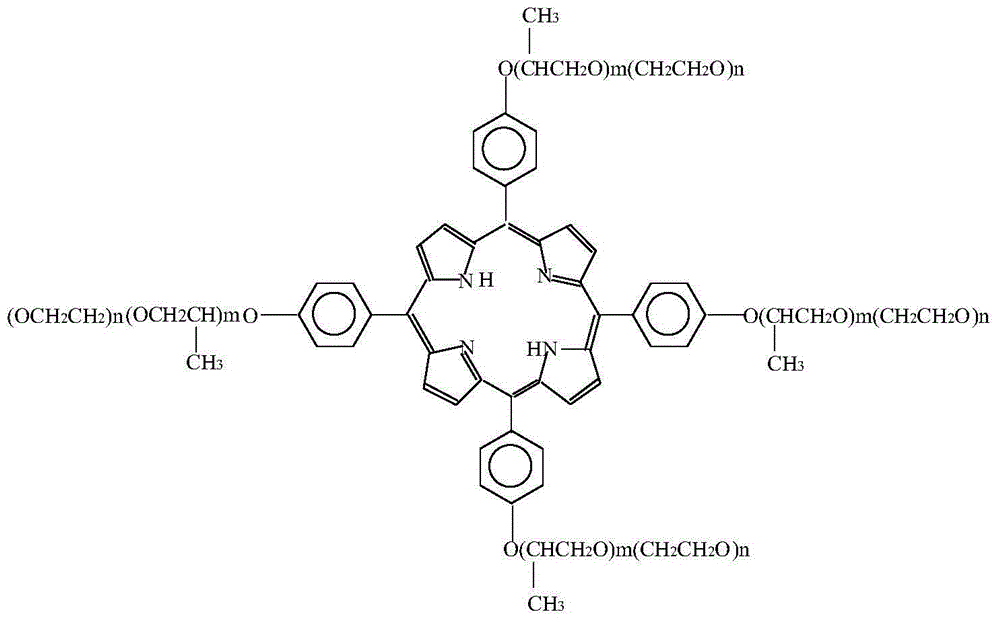

Embodiment 1

[0048] In a 250 milliliter autoclave with a motor stirrer, condensation and heating jacket, add 4.5 grams of tetrakis (4-hydroxyphenyl) porphyrin (M=678.7, 0.0066mol), add 1.5 grams of potassium hydroxide (0.027mol ), then the temperature was raised to 90°C after nitrogen replacement three times; 30 grams of propylene oxide (0.52mol) was started to be added dropwise in the autoclave, and the reaction pressure was controlled at 0.6MPa, and the reaction temperature was 125°C for 3 hours; Add 14 grams (0.32mol) of ethylene oxide dropwise, control the reaction pressure 0.5MPa, and the reaction temperature is 125°C, and react for 2 hours; add 10 grams of toluene after the reaction is completed, transfer the material to a 200ml beaker, and add 10% sulfuric acid 50 milliliters of solutions neutralize the residual potassium hydroxide in the reaction product, and wash twice with deionized water until the reaction product is neutral; the oil layer in the material is put into a vacuum dis...

Embodiment 2

[0050] In 250 milliliters of autoclaves with motor stirrer and condensation, heating mantle, add tetrakis (4-hydroxyphenyl) porphyrin 5 grams (M=678.7, 0.0074mol), 1.25 grams of sodium hydroxide (0.031mol), Then, after replacing with nitrogen three times, the temperature was raised to 90°C; 20 grams of propylene oxide (0.34mol) was added dropwise to the autoclave, the reaction pressure was controlled at 0.6MPa, the reaction temperature was 122°C, and the reaction was carried out for 2.5 hours; Ethylene oxide 10.5 grams (0.24mol), control reaction pressure 0.5MPa, reaction temperature is 125 ℃, reacts for 2 hours; Add 20 grams of xylenes after reaction finishes, material is transferred in the 200ml beaker, adds the sulfuric acid solution of 10% 50 milliliters of sodium hydroxide remained in the neutralization reaction product, and washed twice with deionized water until the reaction product was neutral; the oil layer in the material was put into a vacuum distillation device, and...

Embodiment 3

[0052] Add 4.4 grams of tetrakis (4-hydroxyphenyl) porphyrin (M=678.7, 0.0065mol) in 250 milliliters of autoclaves with motor stirrer and condensation, heating jacket, then add 1.6 grams of potassium hydroxide (0.029mol ), the temperature was raised to 90°C after nitrogen replacement three times; 35 grams of propylene oxide (0.60mol) was added dropwise to the autoclave, the reaction pressure was controlled at 0.6MPa, the reaction temperature was 126°C, and the reaction was carried out for 3.5 hours; 12 grams (0.27mol) of ethylene oxide, control the reaction pressure 0.5MPa, the reaction temperature is 125 ° C, and react for 2.5 hours; after the reaction, add 90 ° C ~ 120 ° C petroleum ether, transfer the material to a 200 ml beaker, add 10% 50 ml of sulfuric acid solution neutralizes the residual potassium hydroxide in the reaction product, and washes it twice with deionized water until the reaction product is neutral; put the oil layer in the material into a vacuum distillatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com