Water-in-oil demulsification method for oil field

A water-in-oil emulsion and water-in-oil technology, which is applied in the fields of hydrocarbon oil dehydration/demulsification, dehydration/demulsification by chemical method, dehydration/demulsification by mechanical method, etc. Problems such as limited effect, increased water content and total liquid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

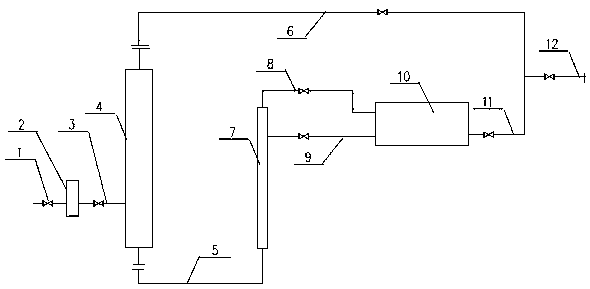

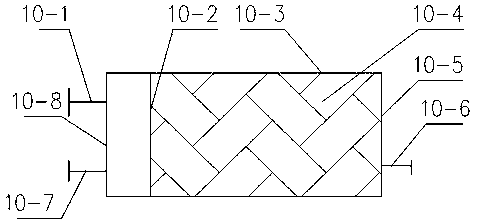

[0018] Such as figure 1 Shown, a kind of method for the water-in-oil demulsification of oilfield; It is characterized in that: comprise at least, filter 2, stabilizer 4, cyclone demulsifier 7, coalescing demulsifier 10; After the emulsion is filtered from the liquid inlet pipe 1 through the filter 2 to remove impurities in the liquid, it enters the flow stabilizer 4 through the connecting pipeline 3, and the water-in-oil emulsion is stabilized, buffered, and gas-liquid separated through the flow stabilizer 4. The associated gas enters the gas pipeline 6 at the top of the flow stabilizer 4 and is output; the separated oil-water enters the bottom inlet of the cyclone demulsifier 7 through the emulsified oil-water pipeline 5; , through the cyclone demulsifier 7, the oil outlet pipeline 8 and the oily sewage outlet pipe 9 respectively enter the coalescing demulsifier 10, and after the coalescing demulsifier 10 performs rectification and demulsification, the water-in-oil emulsion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com