Process for extracting residual oil from oil-tea cake

A technology of camellia oleifera cake and residual oil, which is applied in the direction of fat oil/fat refining and fat production, which can solve the problems of no extraction and poor quality of oil products, and achieve the effects of improved extraction rate, low raw material cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

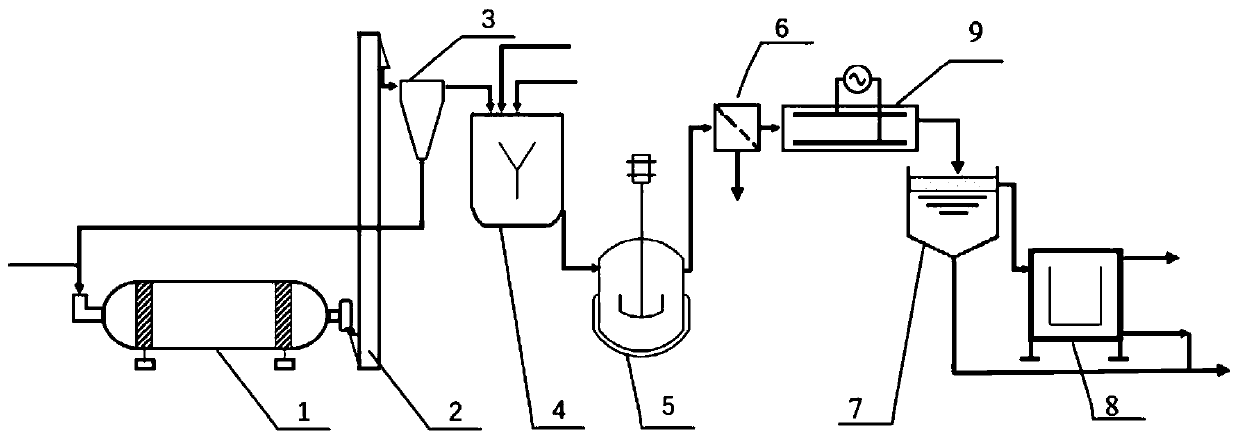

[0036] The present embodiment provides a kind of technique of extracting residual oil from Camellia oleifera cake, comprises the following steps,

[0037] Put the Camellia oleifera cake after cleaning with distilled water and removing impurities, put it into the pulverizer 1 with a rotating speed of 150r / min, and pulverize it for 30min. The diameter is not greater than 0.3mm powder, wherein, the filling rate of camellia oleifera cake in the pulverizer is 15%, and the filling rate of the grinding medium is 15%.

[0038] Accurately weigh 0.5 kg of pulverized Camellia oleifera cake and 4.5 kg of water, mix them in the mixer 4, and prepare a mixed liquid for subsequent use.

[0039] Add the mixed solution into the ultrasonic reactor 5 with temperature control and stirring for ultrasonic stirring, extract the residual oil, and disperse the residual oil in the camellia oleifera cake into water under the action of ultrasonic; the ultrasonic temperature is 80°C, and the ultrasonic tim...

Embodiment 2

[0045] The present embodiment provides a kind of technique of extracting residual oil from Camellia oleifera cake, comprises the following steps,

[0046] Put the Camellia oleifera cake after cleaning with distilled water and removing impurities into the pulverizer 1 with a rotating speed of 200r / min for pulverization for 40min, and then send it to the powder separator 3 through the hoist 2 for sieving, and sieve to the particle size. The diameter is not greater than 5mm powder, wherein, the filling rate of camellia oleifera cake in the pulverizer is 20%, and the filling rate of the grinding medium is 18%.

[0047] Accurately weigh 1 kg of pulverized Camellia oleifera cake and 4 kg of water, mix them in the mixer 4, and prepare a mixed liquid for subsequent use.

[0048] Add the mixed solution into the ultrasonic reactor 5 with temperature control and stirring for ultrasonic stirring, extract the residual oil, and disperse the residual oil in the camellia oleifera cake into wate...

Embodiment 3

[0053] The present embodiment provides a kind of technique of extracting residual oil from Camellia oleifera cake, comprises the following steps,

[0054] The camellia cake after cleaning with distilled water and removing impurities is put into the pulverizer 1 with a rotating speed of 160r / min for pulverization for 40min, and then sent to the powder classifier 3 through the hoist 2 for sieving, and sieves to a fine grain size. The diameter is not greater than 6mm powder, wherein, the filling rate of the oil tea cake in the pulverizer is 16%, and the filling rate of the grinding medium is 23%.

[0055] Accurately weigh 1.5 kg of pulverized camellia oleifera cake and 3.5 kg of water, mix them in the mixer 4, and prepare a mixed liquid for subsequent use.

[0056] Add the mixed solution into the ultrasonic reactor 5 with temperature control and stirring for ultrasonic stirring, extract the residual oil, and disperse the residual oil in the camellia oleifera cake into water under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com