Condensing washing method of polyvinylidene fluoride emulsion

A technology of polyvinylidene fluoride and polyvinylidene fluoride resin, which is applied in the field of post-treatment of polymer emulsions, can solve problems such as unfavorable washing and small particle size, achieve good demulsification effect, increase solubility, and reduce water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

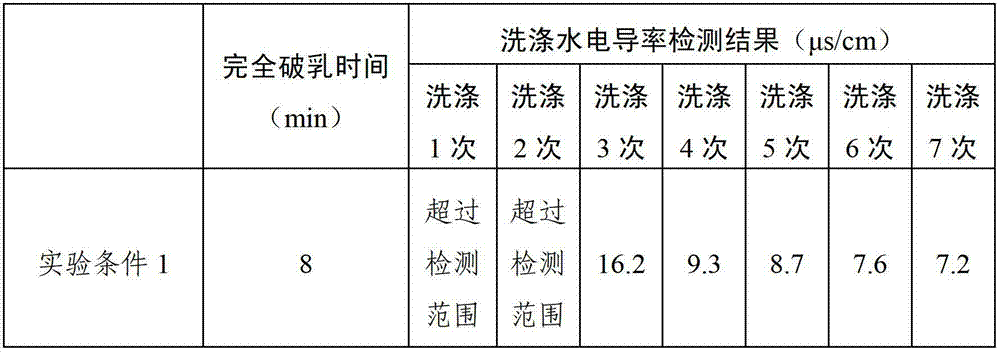

Embodiment 1

[0027] (1) Add deionized water at a temperature of 8°C to 500mL polyvinylidene fluoride emulsion to adjust the specific gravity of the emulsion to 1.08;

[0028] (2) Turn on the stirring, the stirring speed is controlled at 1400 rpm, and the complete demulsification time is 8 minutes; the average particle size of the PVDF emulsion before coagulation is about 20 μm, and the average particle size after coagulation is 230 μm;

[0029] (3) The polyvinylidene fluoride resin precipitated by coagulation and demulsification is washed with deionized water at a temperature of 80°C for 5 minutes each time (the volume ratio of the polyvinylidene fluoride resin precipitated in the previous step to deionized water is Both are 1:2), washed repeatedly 7 times, measured the conductivity of the deionized water after washing, if it is lower than 10μs / cm, it is qualified (4 times of washing meets the requirements), PVDF is white powder after washing.

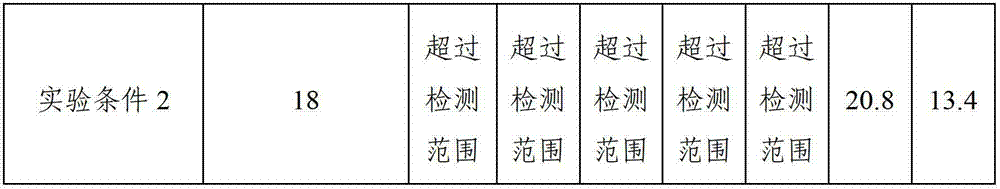

Embodiment 2

[0031] (1) Add deionized water at a temperature of 10°C to 500mL polyvinylidene fluoride emulsion to adjust the specific gravity of the emulsion to 1.06;

[0032] (2) Turn on the stirring, the stirring speed is controlled at 1600 rpm, and the complete demulsification time is 5 minutes; the average particle size of the PVDF emulsion before coagulation is about 20 μm, and the average particle size after coagulation is 180 μm;

[0033] (3) The polyvinylidene fluoride resin precipitated by coagulation and demulsification is washed with deionized water at a temperature of 70°C for 8 minutes each time (the volume ratio of the polyvinylidene fluoride resin precipitated in the previous step to deionized water is Both are 1:1.18), washed repeatedly 4 times, measured the conductivity of the deionized water after washing, if it is lower than 10μs / cm, it is qualified, and the PVDF is white powder after washing.

Embodiment 3

[0035] (1) Add deionized water at a temperature of 5°C to 500mL polyvinylidene fluoride emulsion to adjust the specific gravity of the emulsion to 1.12;

[0036] (2) Turn on the stirring, the stirring speed is controlled at 1200 rpm, and the complete demulsification time is 10 minutes; the average particle size of the PVDF emulsion before coagulation is about 20 μm, and the average particle size after coagulation is 200 μm;

[0037] (3) The polyvinylidene fluoride resin precipitated by coagulation and demulsification is washed with deionized water at a temperature of 90°C for 4 minutes each time (the volume ratio of the polyvinylidene fluoride resin precipitated in the previous step to deionized water is Both are 1:6), wash repeatedly 4 times, measure the conductivity of the deionized water after washing, if it is lower than 10μs / cm, it is qualified, and the PVDF is white powder after washing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com