Method for extracting soybean oil compound breakdown emulsion by virtue of aqueous enzymatic method

A technology of compound demulsification and soybean oil, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of enhanced Brownian motion, low demulsification rate, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

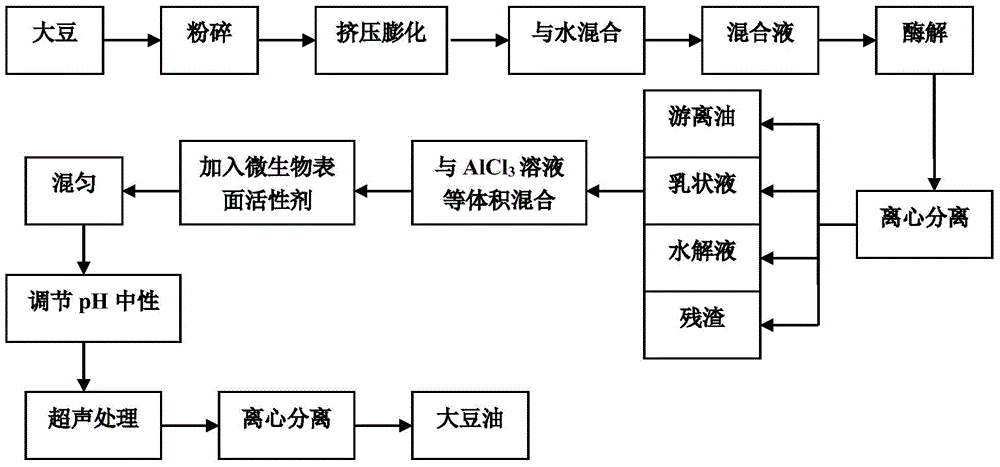

Embodiment 1

[0021] Soybeans are crushed and subjected to extrusion and puffing treatment to obtain puffed materials, the puffed materials are mixed with water to obtain a mixed solution, alkaline protease is added to the mixed solution for enzymolysis, and after enzymolysis, centrifuged to obtain free oil, emulsion, hydrolyzate and Residue; mix the emulsion with AlCl at a concentration of 0.2mol / L 3 Mix the solutions in equal volumes, then add 2% microbial surfactant, adjust the pH neutrality after mixing; at an ultrasonic power of 40W and an ultrasonic temperature of 80°C, perform ultrasonic treatment on the treated emulsion for 25 minutes, and then centrifuge That is soybean oil. The demulsification rate of the method is 91.77%, and the obtained soybean oil has high purity and good quality.

Embodiment 2

[0023] Soybeans are crushed and subjected to extrusion and puffing treatment to obtain puffed materials, the puffed materials are mixed with water to obtain a mixed solution, alkaline protease is added to the mixed solution for enzymolysis, and after enzymolysis, centrifuged to obtain free oil, emulsion, hydrolyzate and Residue; the emulsion and the concentration of 0.4mol / L AlCl 3 Mix the solutions in equal volumes, then add 1.5% microbial surfactant, adjust the pH neutrality after mixing; at an ultrasonic power of 30W and an ultrasonic temperature of 75°C, ultrasonically treat the processed emulsion for 20 minutes, and then centrifuge That is soybean oil. The demulsification rate of the method is 89.91%, and the obtained soybean oil has high purity and good quality.

Embodiment 3

[0025] Soybeans are crushed and subjected to extrusion and puffing treatment to obtain puffed materials, the puffed materials are mixed with water to obtain a mixed solution, alkaline protease is added to the mixed solution for enzymolysis, and after enzymolysis, centrifuged to obtain free oil, emulsion, hydrolyzate and Residue; mix the emulsion with AlCl with a concentration of 0.3mol / L 3 Mix the solutions in equal volumes, then add 2.5% microbial surfactant, adjust the pH neutrality after mixing; at an ultrasonic power of 50W and an ultrasonic temperature of 85°C, ultrasonically treat the processed emulsion for 30 minutes, and then centrifuge That is soybean oil. The demulsification rate of the method is 90.59%, and the obtained soybean oil has high purity and good quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com