Device for demulsifying emulsified oil product and method thereof

A technology for demulsification and oil products, which is applied in the fields of hydrocarbon oil dehydration/demulsification, petroleum industry, etc. It can solve the problems of complex method equipment, high energy consumption for repeated heating, and low demulsification efficiency, so as to improve the demulsification efficiency and shorten the Demulsification time, the effect of solving secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

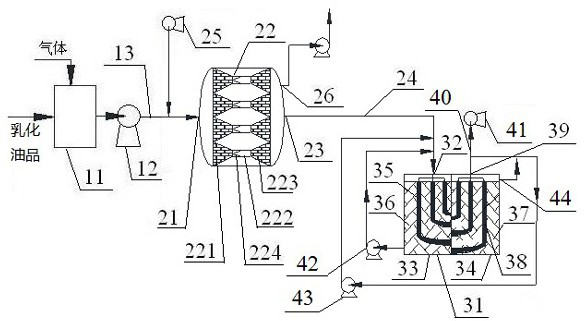

[0056] A device for demulsifying emulsified oil products, including a dissolved air system, a primary demulsification system and a secondary demulsification system, such as figure 1 Shown:

[0057] The gas dissolving system includes a material mixing tank 11 and a microbubble generator 12 connected thereto; the material mixing tank 11 is provided with an emulsified oil raw material inlet and a gas inlet for mixing the two.

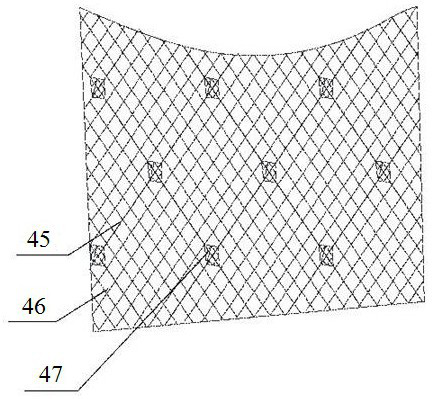

[0058] The discharge pipeline I13 of the microbubble generator 12 is connected to the primary demulsification system through the feed port I21, including four parallel primary demulsifiers 22 connected to the end of the discharge pipeline I13, and the primary demulsifier The upper part of the demulsifier 22 is provided with a first-stage demulsifier gas outlet 26, and the first-stage demulsifier 22 is successively divided into a diameter-reducing section 221, a straight cylinder section 222, and a diameter-expanding section 223 from the feed end, and the i...

Embodiment 2

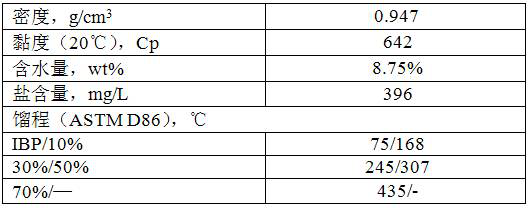

[0063] Demulsification of the emulsified oil product using the device of Example 1: Table 1 shows the properties of the raw material of the emulsified oil product, and the emulsified oil product is severely emulsified.

[0064] Table 1.

[0065]

[0066] Add the above-mentioned emulsified oil raw material and gas into the material mixing tank 11 through the emulsified oil raw material inlet and the gas inlet connected to the material mixing tank 11, mix the two, and transport them to the microbubble generator 12 for mixing and dissolving. Dissolve and disperse the gas into the emulsified oil to obtain the gas-in-oil mixed material, enter the primary demulsifier 22 through the discharge pipeline I13 from the feed inlet I21, and pass through the shrinking section 221, the straight section 222 and the expanding section in sequence Section 223, in the diameter-reducing section 221 and the diameter-expanding section 223, the mesh corrugated plate filler is filled. In the diamete...

Embodiment 3

[0070] Demulsification of the emulsified oil product using the device of Example 1: Table 2 shows the properties of the raw material of the emulsified oil product, and the emulsified oil product is severely emulsified.

[0071] Table 2.

[0072]

[0073] The gas flow rate added to the emulsified oil raw material in the material mixing tank (Nm 3 / h) and emulsified oil raw material (m 3 / h) The volume ratio is 1:120, and the gas volume in it is based on the gas volume in the standard state. The operating conditions of the dissolved gas system are as follows: the temperature is 90°C and the pressure is 3.0MPa. In the discharge pipeline I13, high-pressure nitrogen is added to the material through the pressurization tank 25 pressurization equipment. The operating temperature of the pressurization tank 25 is 90°C and the pressure is 5.0MPa. The operating temperature is 90°C and the pressure is 3.0MPa, and the operating temperature of the straight section 222 and the enlarged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com