Patents

Literature

88results about How to "Achieve high value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for clean production of lactic acid by calcium salt process

InactiveCN102220388AAvoid defectsAvoid it happening againMicroorganism based processesFermentationSlagSulfate

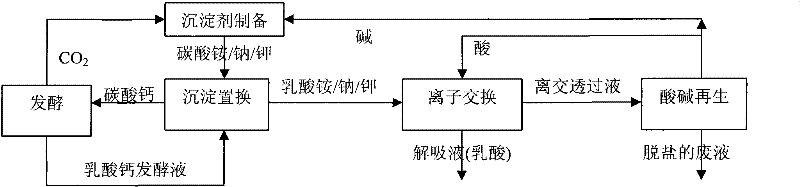

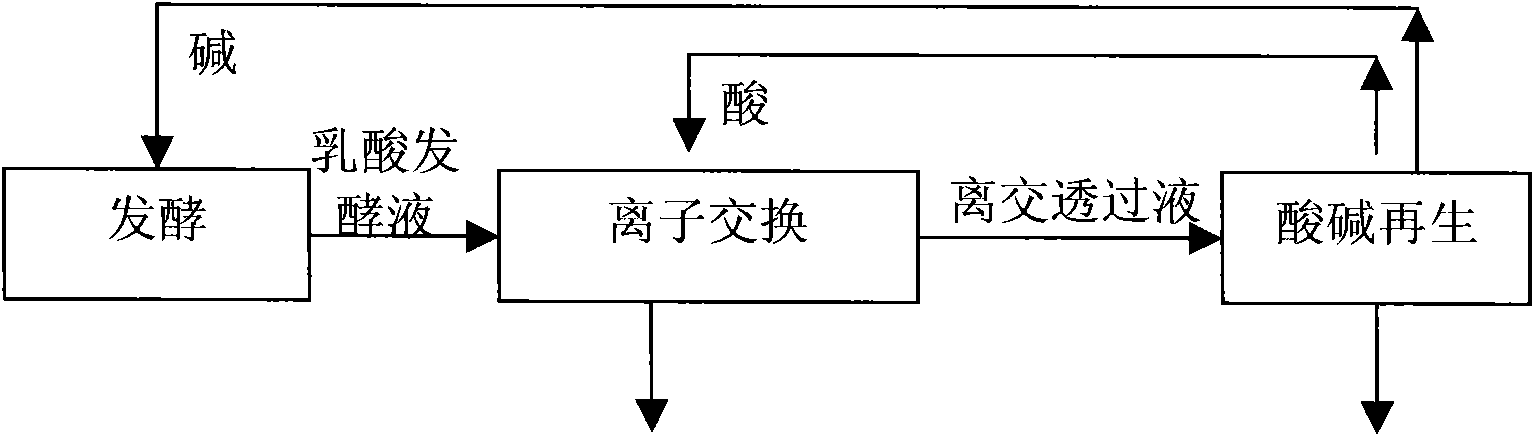

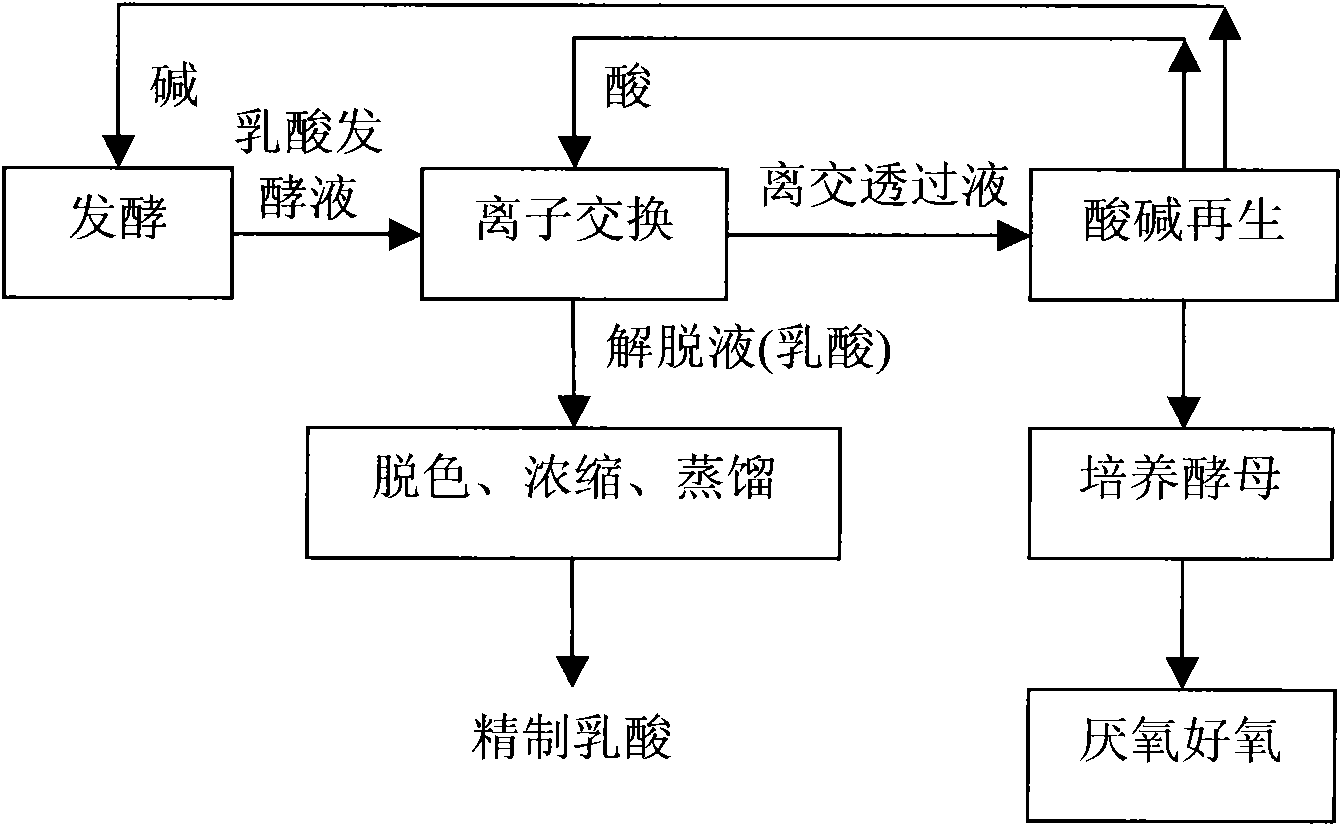

The invention relates to a method for clean production of lactic acid by a calcium salt process, which comprises: regulating the pH value of fermentation liquid by using CaCO3; adding carbonate to perform a precipitation displacement reaction to obtain solution of soluble lactate and a CaCO3 precipitate; loading the solution of soluble lactate on an anion exchange column, so that lactates are absorbed onto the column and ion exchange permeate passing through the anion exchange column is obtained; eluting the anion exchange column with acid to obtain extrication liquid containing lactic acid; and subjecting the ion exchange permeate to bipolar membrane electrodialysis to obtain regenerated acid, alkali and desalted waste solution. The method for clean production of lactic acid by the calcium salt process completely overcome the drawback of production of calcium sulfate waste slag in production of lactic acid by the conventional production technique and can be connected with the conventional lactic acid fermentation step directly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for cleanly producing lactic acid by fermentation method

ActiveCN101607887ASolve the crystallization problemImplement resourcesFermentationCarboxylic compound separation/purificationSulfate radicalsNitrate

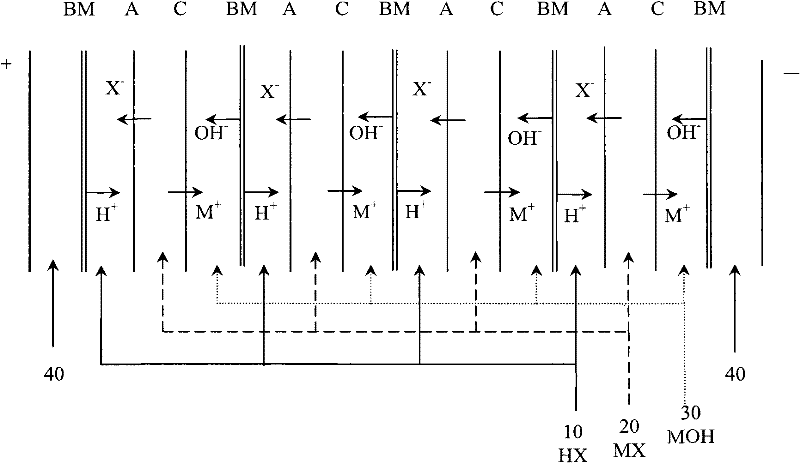

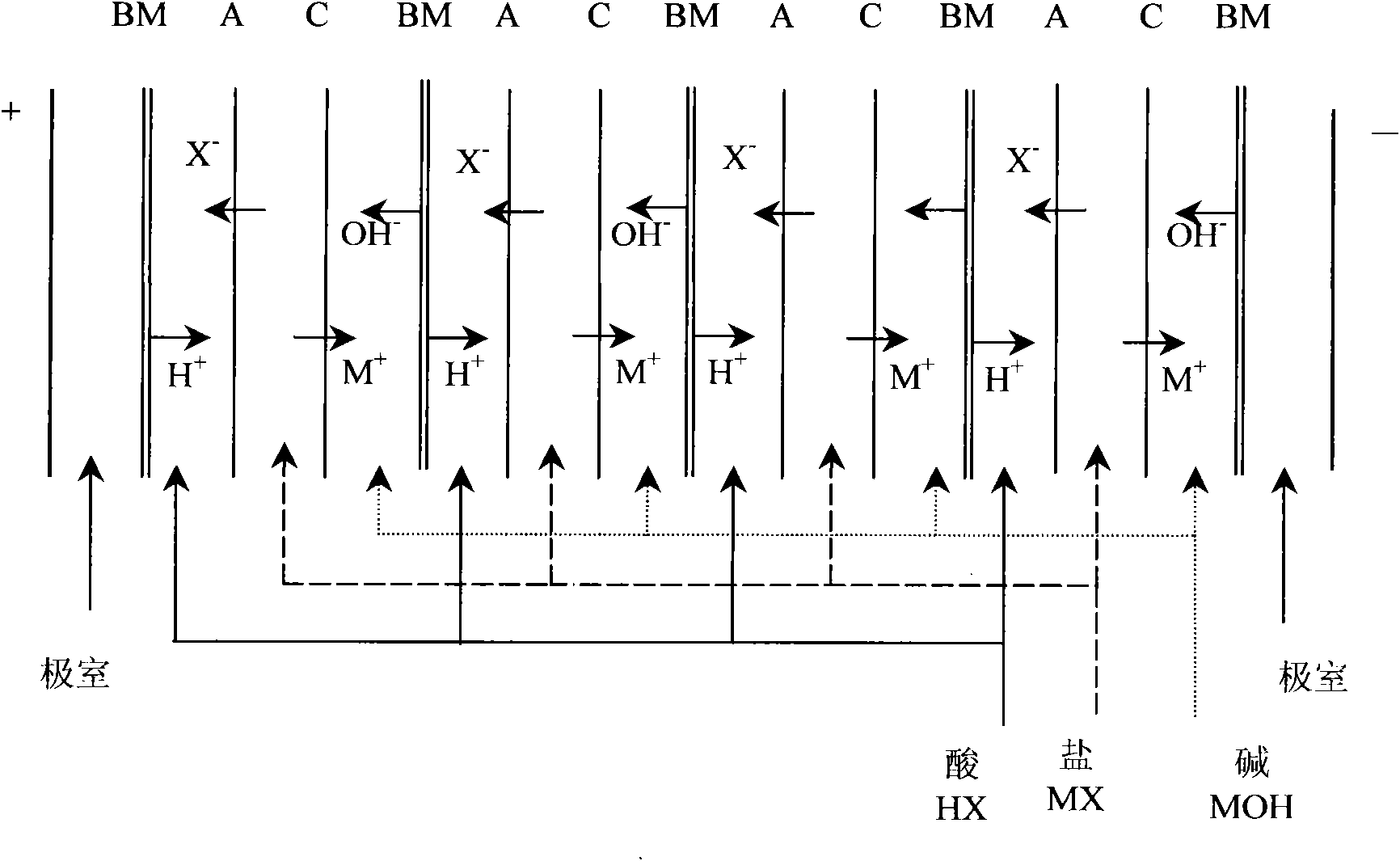

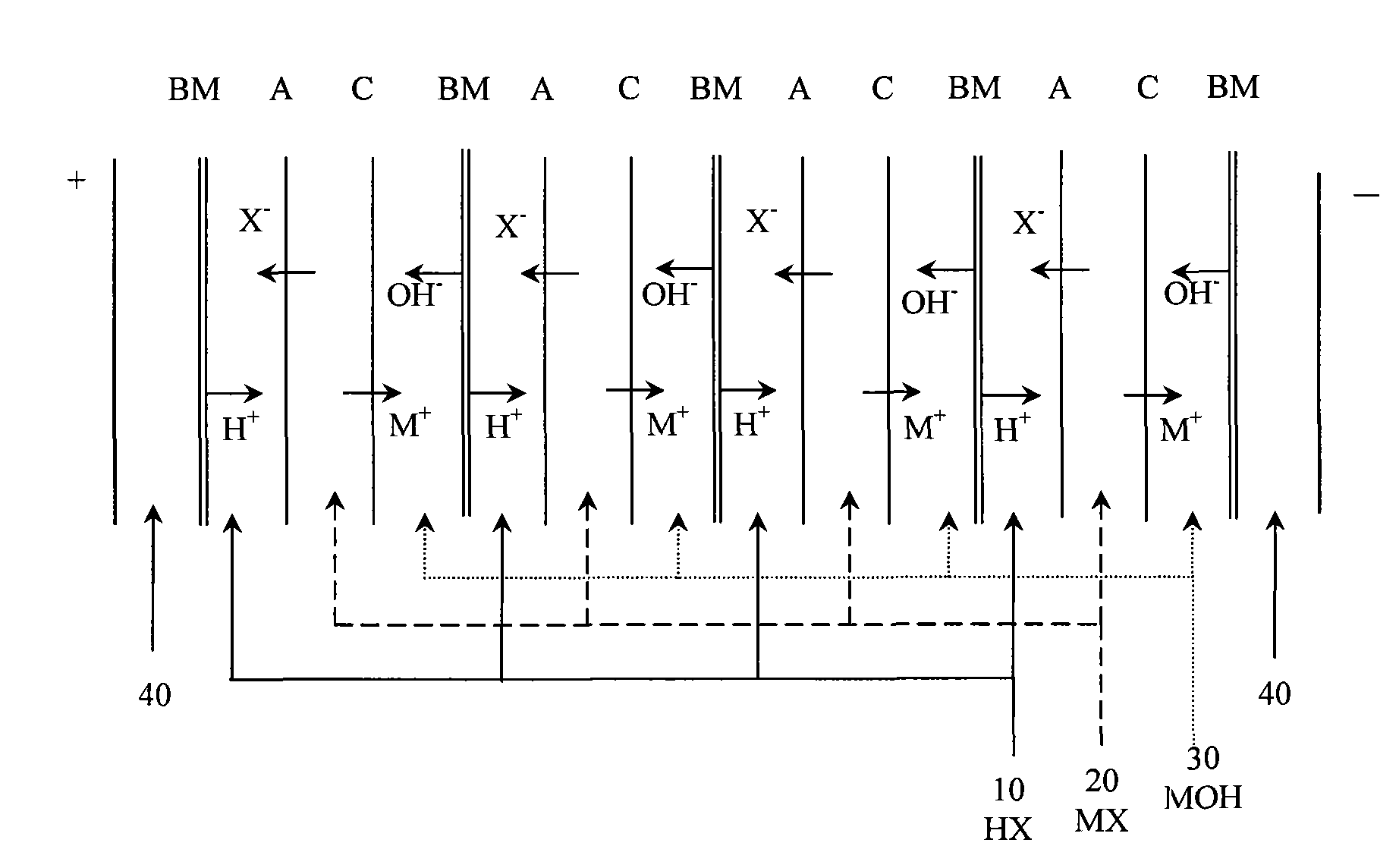

The invention relates to a method for cleanly producing lactic acid by a fermentation method. The method comprises the following steps that: during the fermentation of the lactic acid, solution of NH3 and NaOH or solution of KOH is used for adjusting the pH value of fermentation solution, the obtained fermentation solution of the lactic acid passes through a C1 typed, sulfate radical typed or nitrate radical typed anion-exchange column, lactate radical in the fermentation solution of the lactic acid is exchanged and adsorbed by C1-, SO42- or NO3-, and simultaneously ionic exchange permeating solution of hydrochloride, sulfate or nitrate containing NH4+, Na+ or K+ and permeating the ionic exchange column is obtained; the lactic acid adsorbed on the ionic exchange column and exchanged and adsorbed by the lactate radical is eluted by hydrochloric acid, sulfuric acid or nitric acid, an eluent containing the lactic acid is obtained, and the ionic exchange column is regenerated simultaneously during eluting; the ionic exchange permeating solution is filled in a bipolar membrane electrodialyzer to obtain regenerated hydrochloric acid, sulfuric acid or nitric acid; the regenerated hydrochloric acid, the sulfuric acid or the nitric acid is used for eluting the lactic acid adsorbed on the ionic exchange column, and the regenerated solution of the NH3 and the NaOH or the solution of the KOH is used for adjusting the pH value of the fermentation solution when the lactic acid is fermented.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

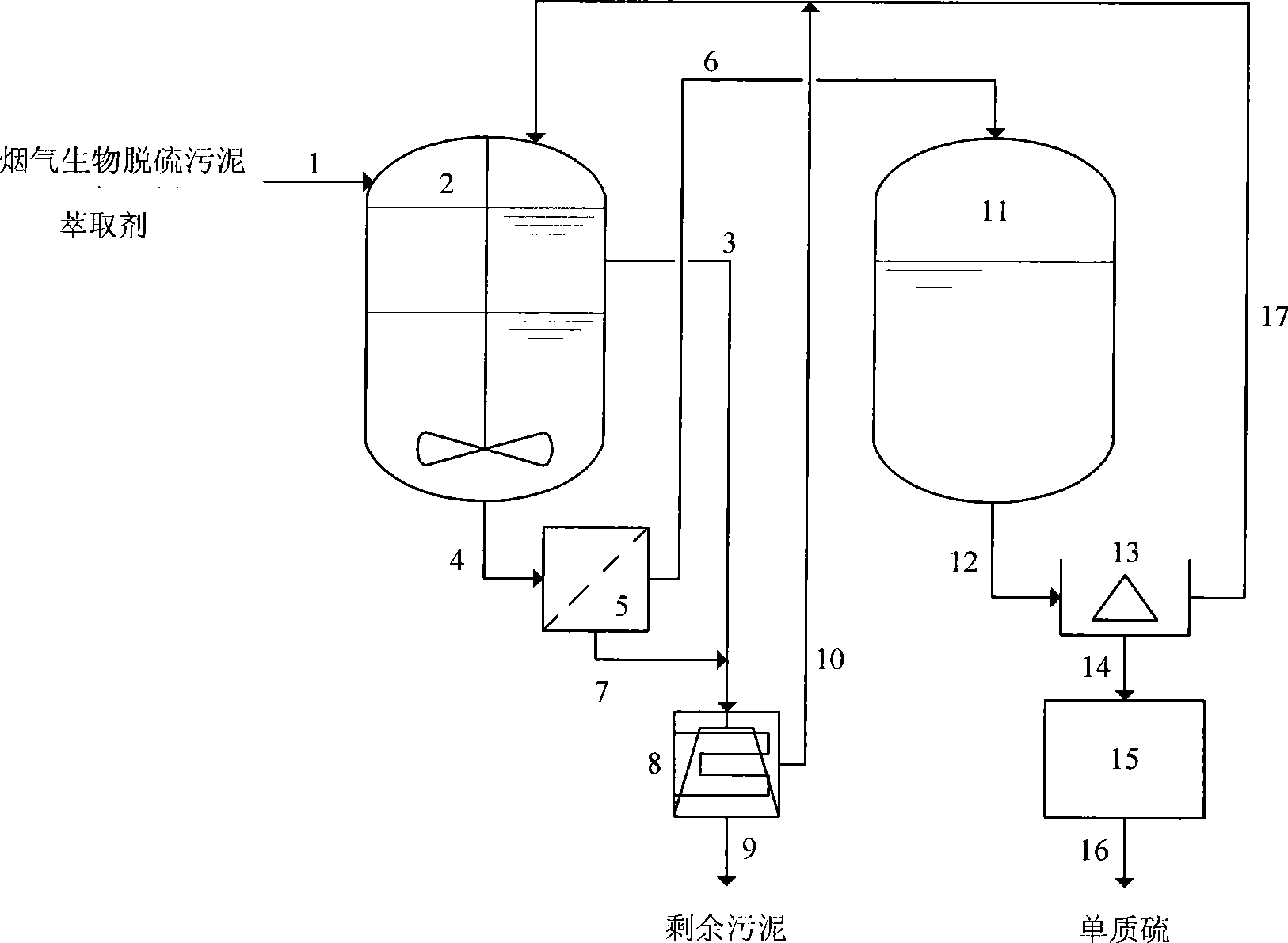

Method for recycling and purifying elemental sulfur from flue gas biological desulphurization sludge

The invention provides a method for recycling and purifying simple substance sulfur from flue gas biological desulphurization mud. The method takes halogenated hydrocarbon, alkyl or aryl-disulfide, or the mixture of alkyl naphthalene and Naphtha solvent as an extracting agent, extracts and recycles elemental sulfur from the biological desulphurization mud by heating, and purifies the elemental sulfur by cooling and crystallizing. The technique method has high coefficient of recovery of the elemental sulfur (more than 90 percent), the elemental sulfur has high purity (more than 98 percent), the extracting agent can be used in a circulating way, and the consumption is low.

Owner:TSINGHUA UNIV

Method for preparing shrimp paste by using low-value shrimp and shrimp offal

ActiveCN104256479AReduce pollutionGuaranteed naturalAcidic food ingredientsShrimp/lobster processingMaillard reactionHydrolysate

The invention relates to a method for preparing shrimp paste by using low-value shrimp and shrimp offal. The method comprises the following steps of washing the low-value shrimp; removing impurities; grinding; adding water for homogenizing; carrying out autolysis; adding protease to carry out enzymolysis; adding reducing sugar and amino acids to carry out a Maillard reaction by using a enzymatic hydrolysate as a base material; cooling a reaction liquid to a room temperature; adding shrimp flavor substances; and regulating to obtain the shrimp paste. The shrimp flavor substances are obtained by using shrimp offal such as shrimp heads and shrimp shells as raw materials and extracting by using supercritical carbon dioxide extraction technology. The method prepares the shrimp paste by using the low-value shrimp and shrimp offal, effectively reduces source waste and environment pollution, has significant social importance and considerable economic benefits, and guarantees that the sources of the raw materials are natural, nutritional and safe. In cooperative with a modern technology, a natural and healthy seasoning item with realistic fragrance and thick shrimp flavor can be produced by the method, thereby solving the defects existing in present products.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

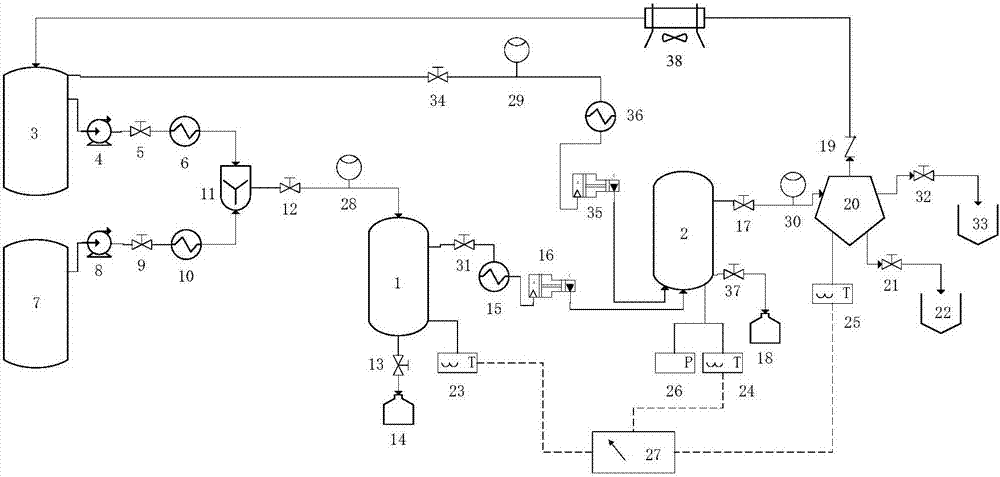

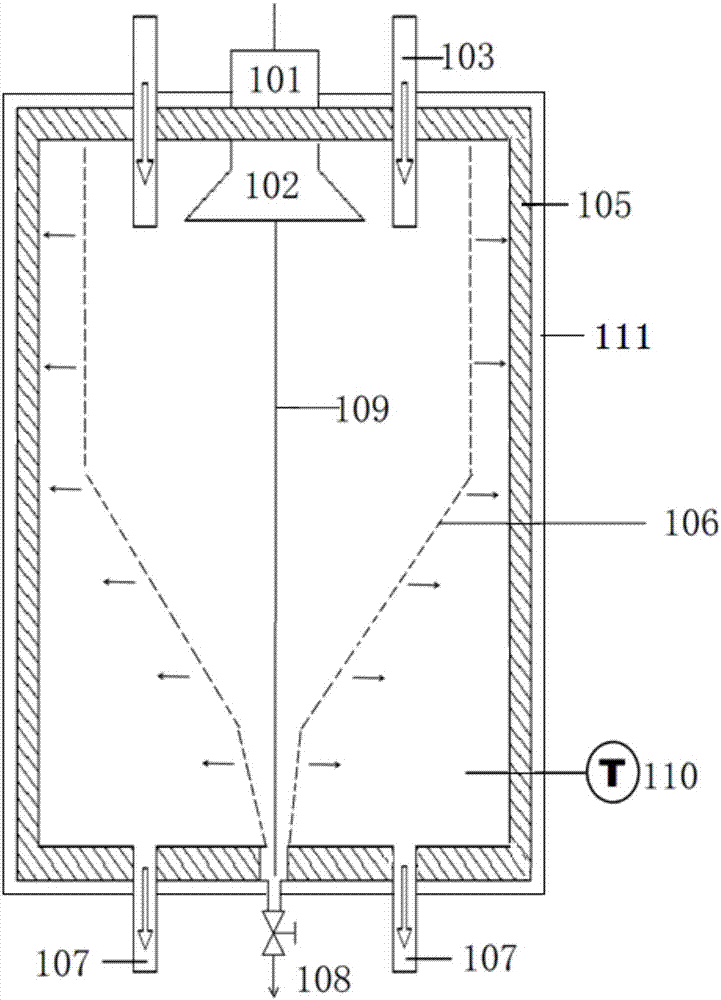

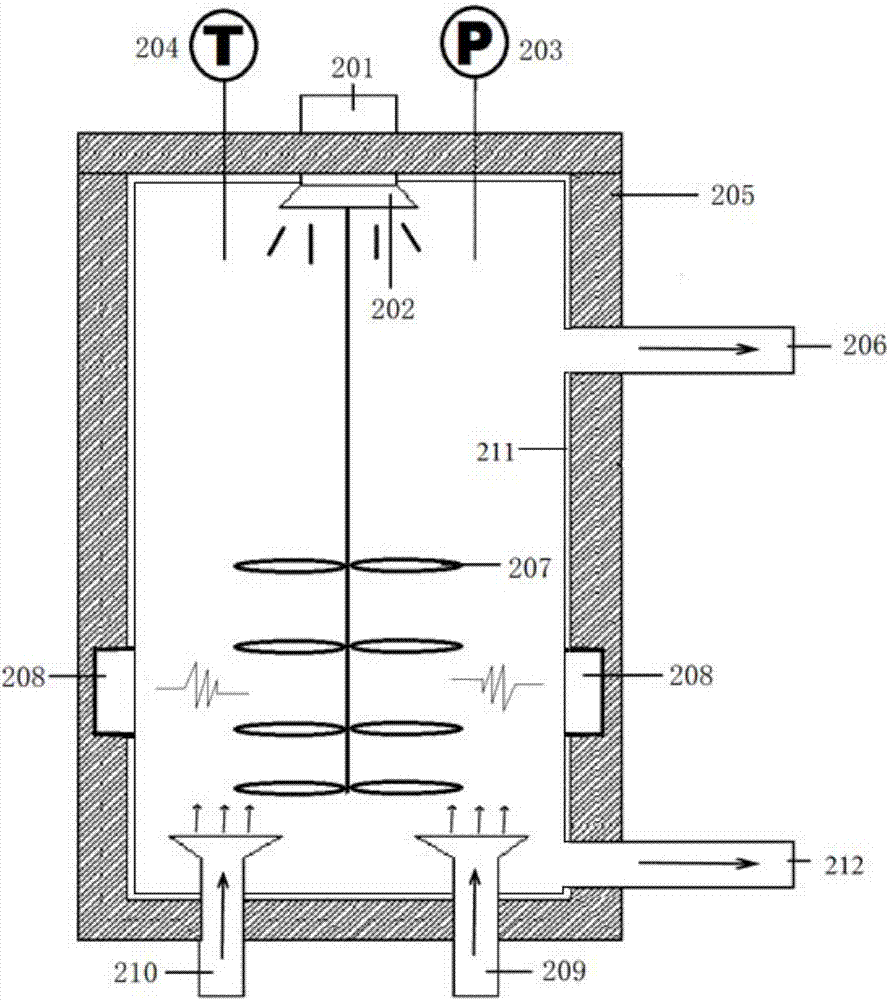

Catalytic cracking oil slurry pretreatment system and pretreatment method by utilization of system

ActiveCN106929096AAvoid wastingAchieve high valueTreatment with plural serial refining stagesProcess equipmentPretreatment method

A catalytic cracking oil slurry pretreatment system and a pretreatment method by the utilization of the system are disclosed. The invention relates to the field of comprehensive utilization of catalytic cracking oil slurry, specifically to a catalytic cracking oil slurry pretreatment device, a system thereof and a pretreatment method. The invention aims to solve the problem of low efficiency during the process of catalytic cracking oil slurry pretreatment. The system comprises a solvent tank, a catalytic cracking oil slurry tank, a mixer, an ultrasonic centrifuge device, an ultrasound-assisted microwave-enhanced supercritical extraction device, a separator, a solid particle gathering tank, a heavy components collector and a light components collector. Through a raw material mixing unit, a solid-liquid separation unit, a solvent extraction unit, a components separation unit and a solvent recovery unit, catalyst granules and oil slurry are separated, and separation of light and heavy components of oils and precision cutting extraction are realized. The method has advantages of simple process equipment and good separation effect.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

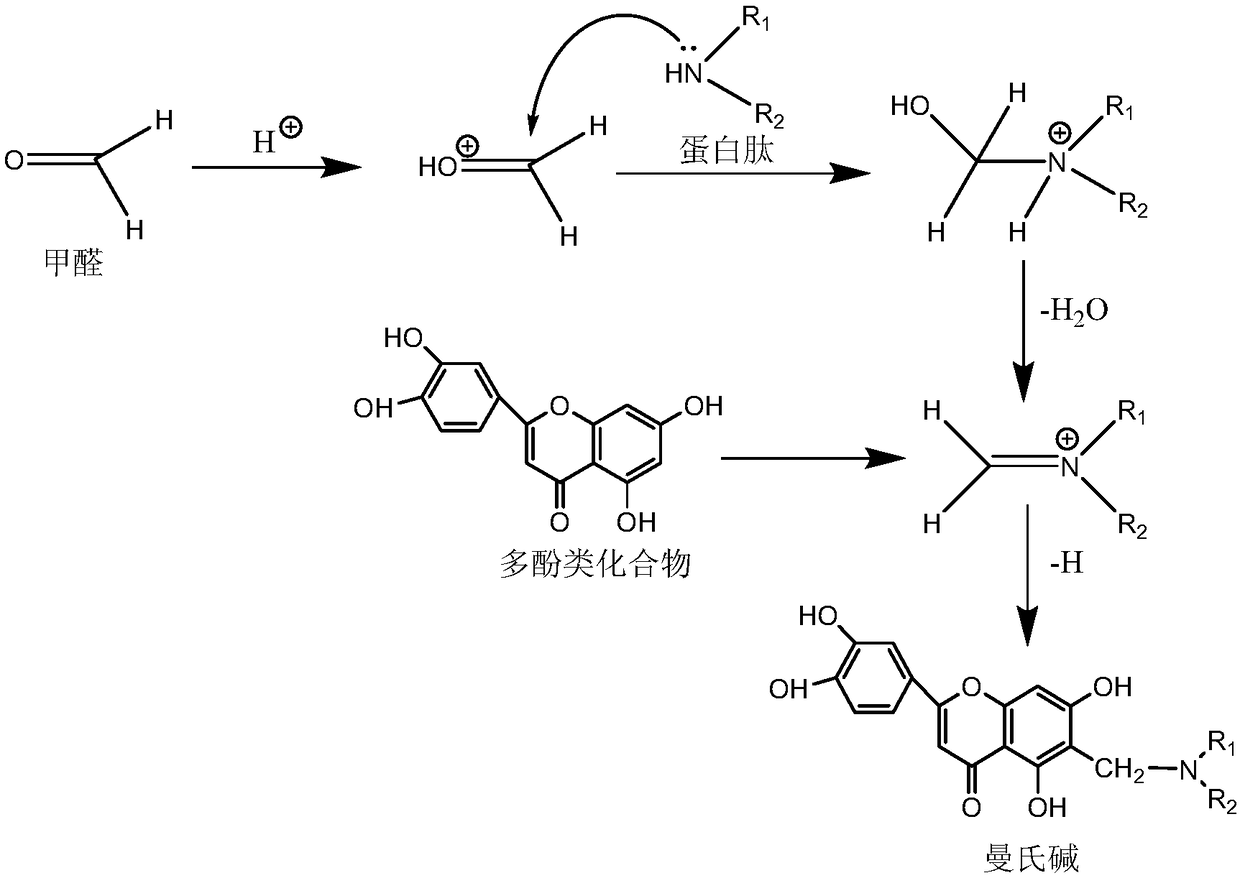

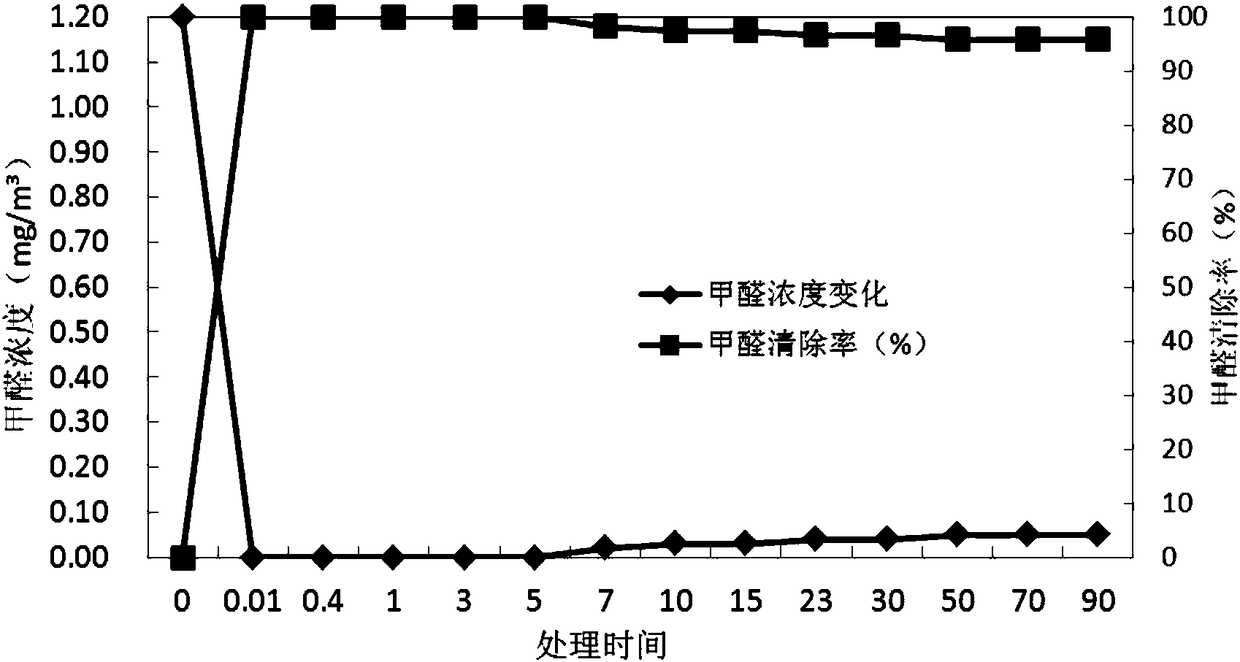

Collagen polypeptide rich in glycine and formaldehyde scavenger prepared therefrom

InactiveCN108130355AAchieve high valueHigh viscosityConnective tissue peptidesDispersed particle separationGlycineFormaldehyde product

The invention belongs to the technical field of functional polypeptides and discloses a collagen polypeptide rich in glycine and a formaldehyde scavenger prepared therefrom. The collagen polypeptide is prepared from the following steps: extracting collagens by means of a hot water extraction method; and then preparing the collagen polypeptide rich in glycine by enzymolysis of the collagens by means of protease by taking Tilapia mossambica waste as a raw material. By being combined with plant polyphenol compounds, the quick, long-acting, safe and edible formaldehyde scavenger is prepared. The formaldehyde removal rate of the formaldehyde scavenger can reach 95% or above within 10 min, so that the problem that a single amino acid is not ideal in removing formaldehyde is solved. A colloid film which is 2-10 microns can be formed on the surface of an object such as furniture if being dried to inhibit further release of formaldehyde. The formaldehyde removal rate can be kept at 95% or abovewithin three months, an effect of removing formaldehyde for a long time is achieved, and the problem that existing formaldehyde removal products are rebound in effect and short in effective period issolved.

Owner:SOUTH CHINA UNIV OF TECH

Method for extracting celluloses, hemicelluloses and lignins from pennisetum hydridum

The invention discloses a method for extracting celluloses, hemicelluloses and lignins from pennisetum hydridum. The method includes: (1) adding benzene-alcohol mixed liquid into the pennisetum hydridum to realize dewaxing, adding water into dewaxed pennisetum hydridum, extracting, filtering, and drying to obtain pretreated pennisetum hydridum; (2) sequentially adding NaOH-H2O2 mixed solution and tetraacetylethylenediamine into the pretreated pennisetum hydridum, treating for 1-4h at the temperature of 55-95 DEG C, filtering, and drying filter residues to obtain the celluloses; (3) adjusting a pH value of filtrate with the celluloses extracted to 5.0-5.5, adding ethyl alcohol to realize precipitation of hemicelluloses, and centrifugally separating to obtain the hemicelluloses; (4) recovering the ethyl alcohol in supernatant obtained after centrifugal separation at the step (3), adjusting a pH value of raffinate with ethyl alcohol recovered to 1.5-2.5, and centrifugally separating to obtain the lignins. By adoption of the method, the celluloses, the hemicelluloses and the lignins can be sequentially and effectively extracted in the same process, high extraction rate is realized, and high-value utilization of wood fibers in the pennisetum hydridum is improved.

Owner:QILU UNIV OF TECH

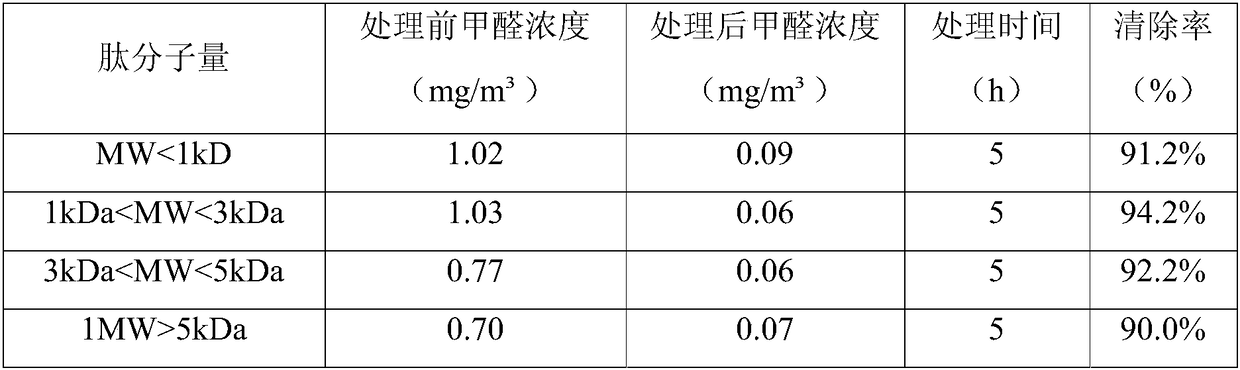

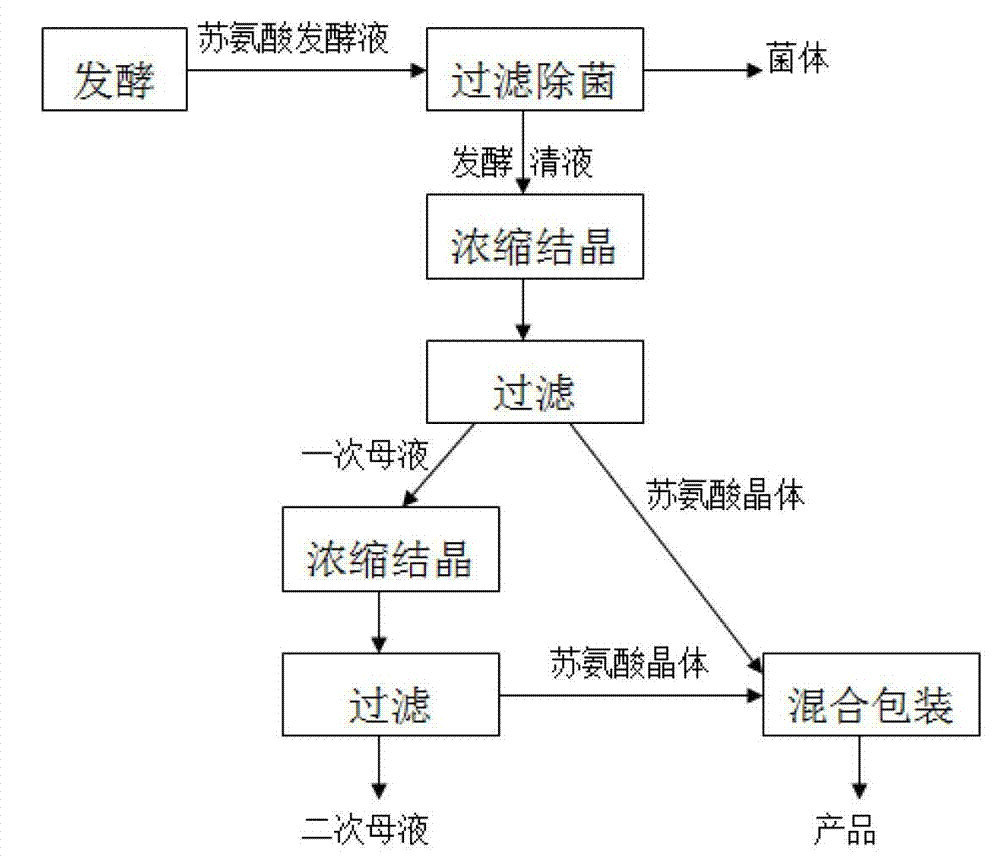

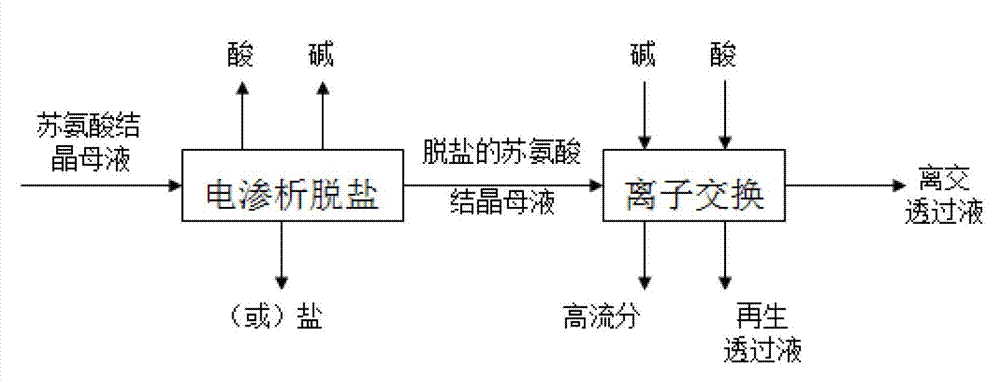

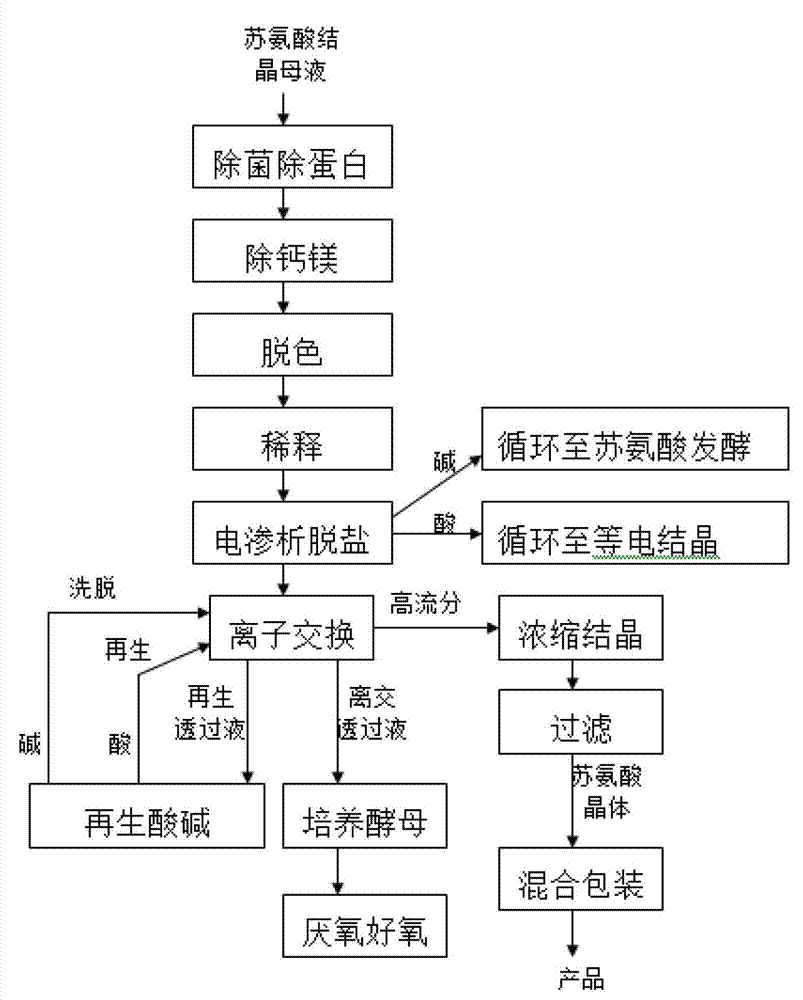

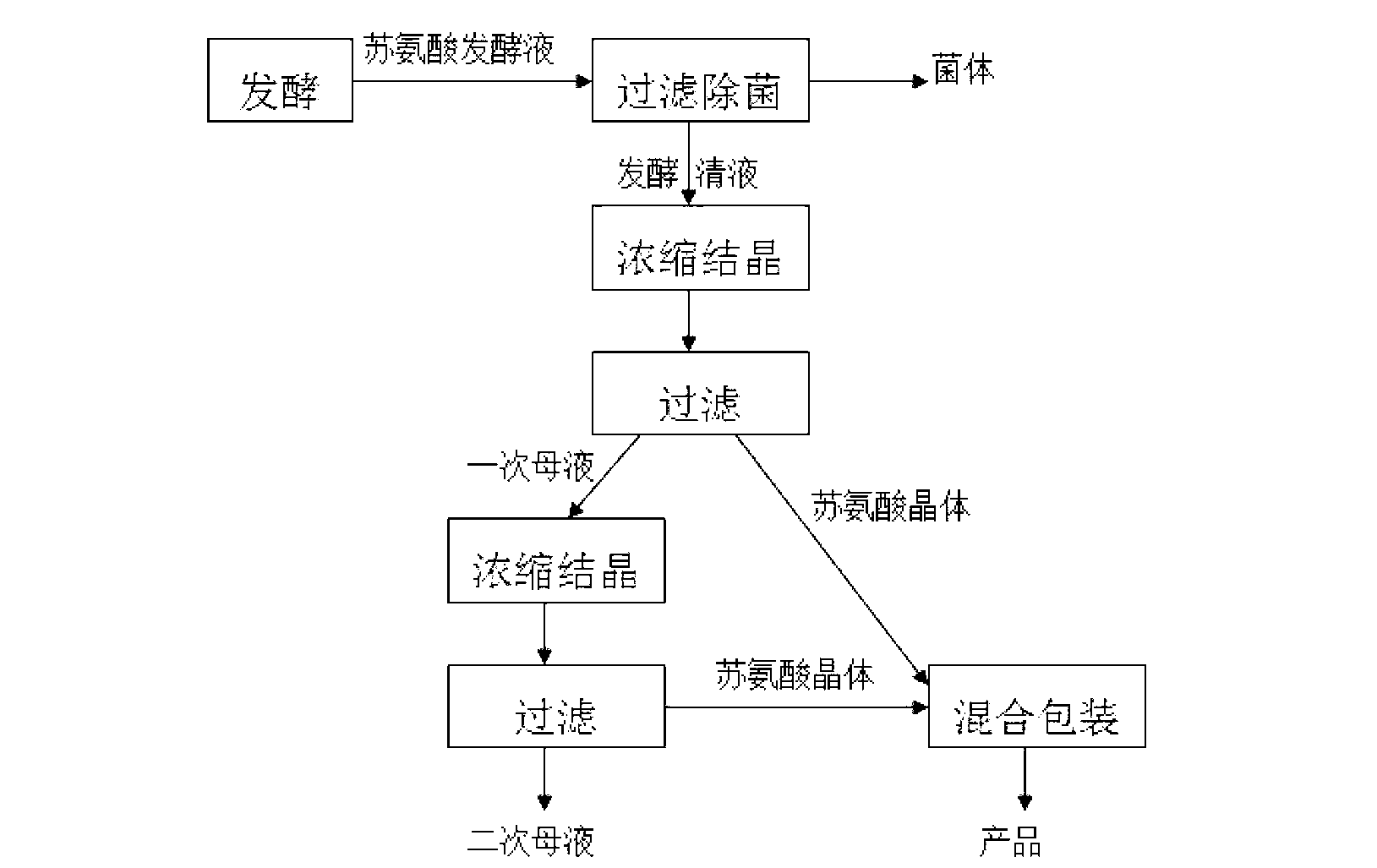

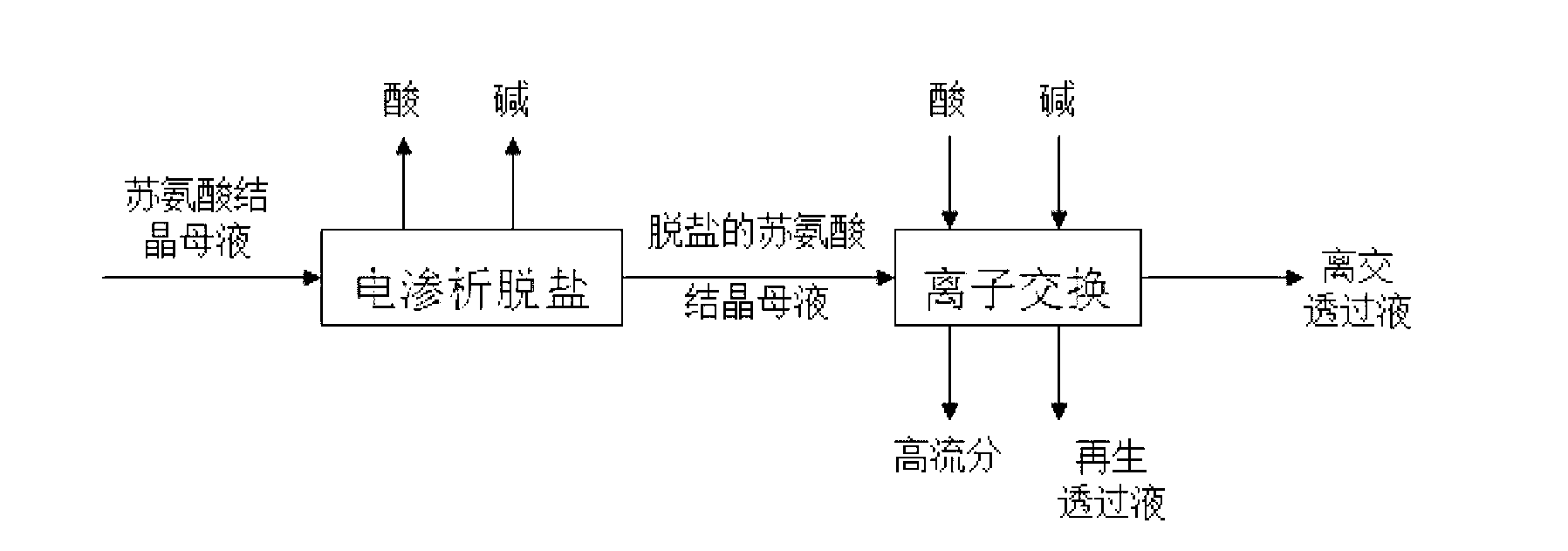

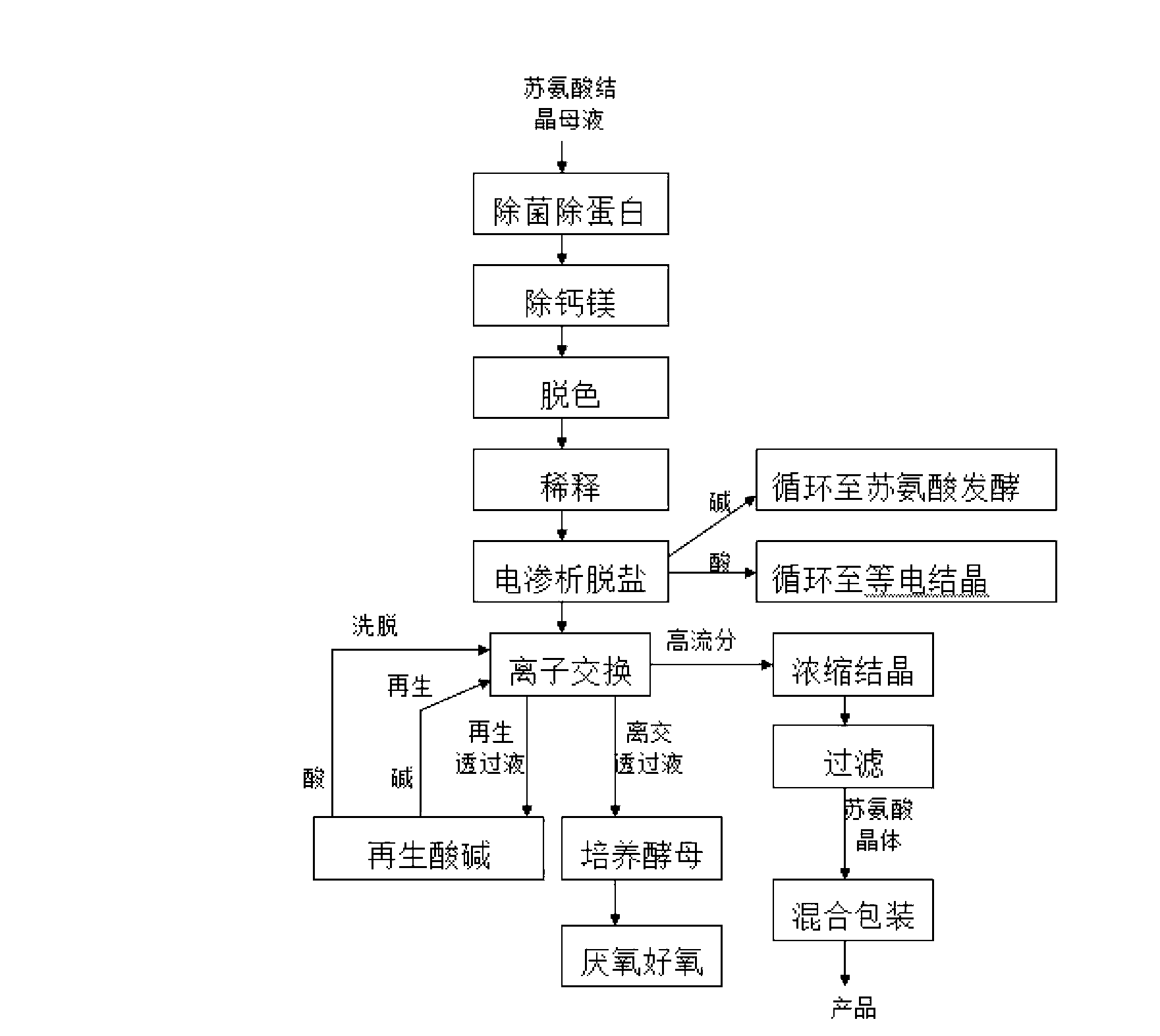

Method for recovering threonine from threonine crystallization mother liquor

InactiveCN103071389AHigh recovery rateImplement resourcesSemi-permeable membranesOrganic compound preparationInorganic saltsBiotechnology

The present invention relates to the field of amino acid production, particularly to a method for recovering threonine from a threonine crystallization mother liquor. The method comprises the following steps: 1) adopting a bipolar membrane electrodialysis technology or a common electrodialysis technology to remove inorganic salts from a threonine crystallization mother liquor to obtain an inorganic salt-removed threonine crystallization mother liquor, wherein the bipolar membrane electrodialysis technology is an acid-salt-alkali three-chamber bipolar membrane electrodialysis technology; and 2) adopting a cation exchange method to recover threonine from the inorganic salt-removed threonine crystallization mother liquor. With the present invention, recovery of the threonine from the threonine crystallization mother liquor is achieved, a threonine extraction yield is increased, complete utilization of various components in the threonine crystallization mother liquor can be further achieved, and the residue liquid can be treated by using the existing mature biotechnology so as to achieve standard discharge, and reduce pollution emission.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

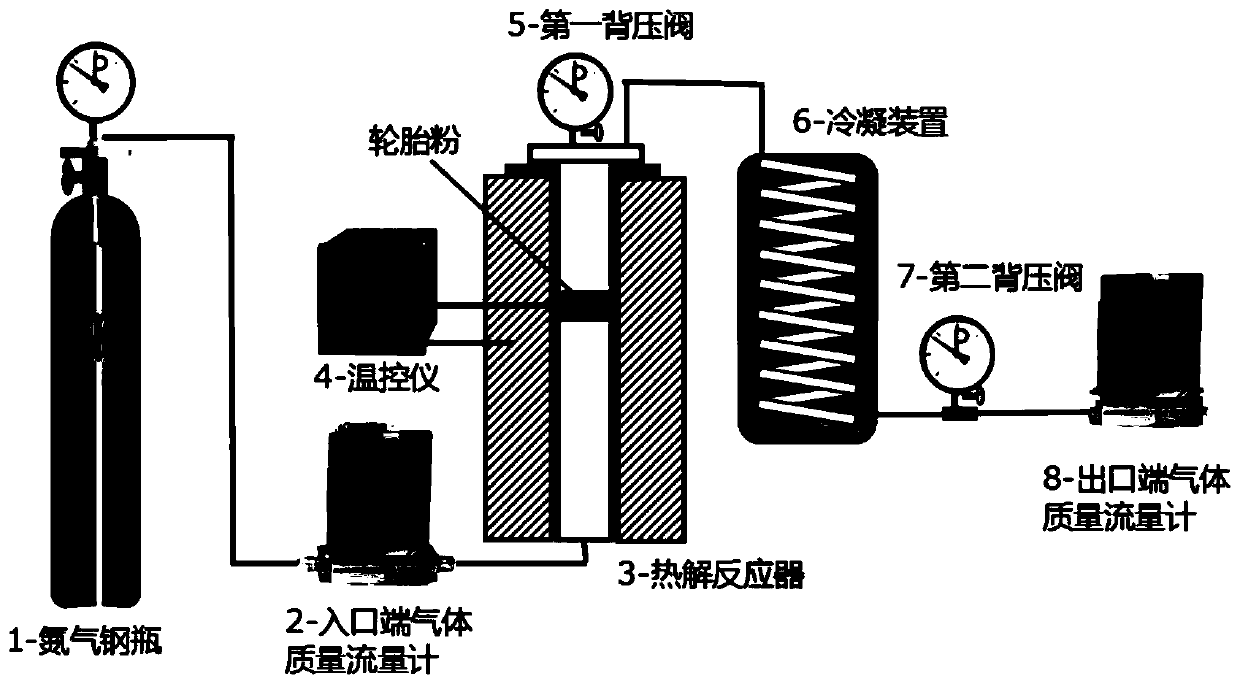

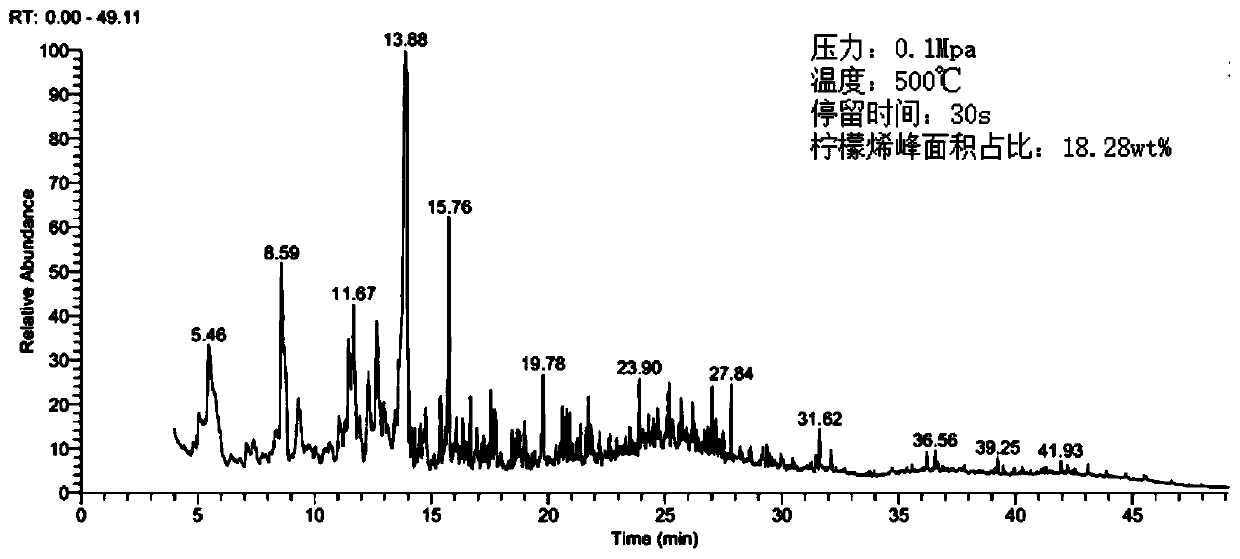

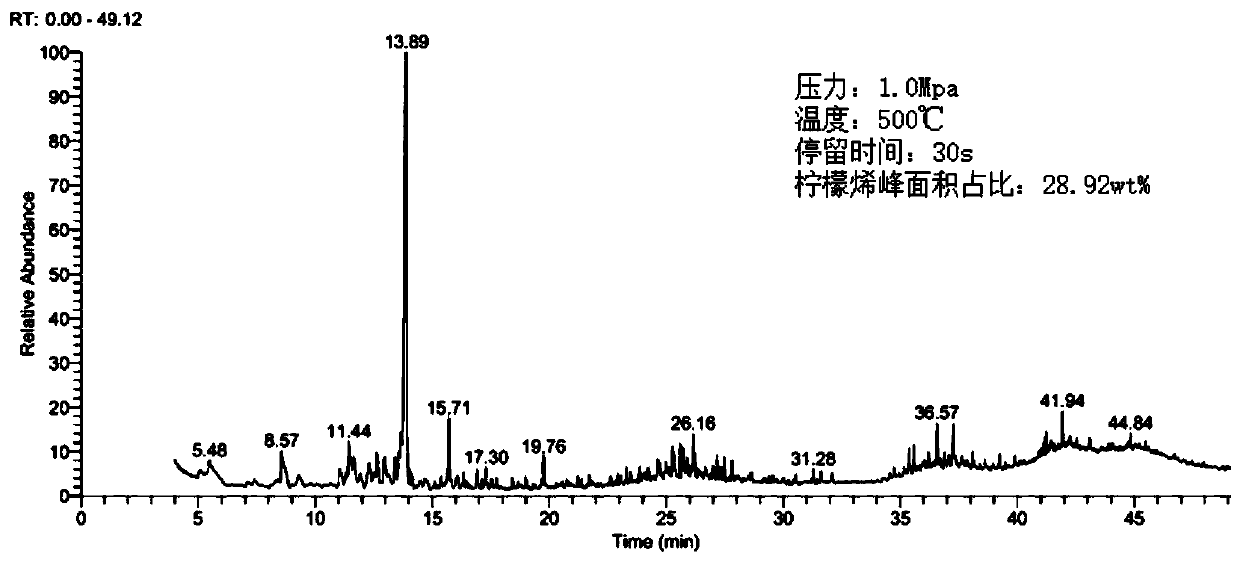

Method for preparing pyrolytic tar and limonene by pressurizing and pyrolyzing waste tires

ActiveCN110938450AIncrease the mass ratioIncrease concentrationProductsReagentsProcess engineeringLimonene

The invention discloses a method for preparing pyrolytic tar by pressurizing and pyrolyzing waste tires. The method comprises the following steps: putting crushed waste tires into a pyrolysis reactor,continuously introducing a protective gas at a preset flow rate, controlling the reaction pressure at 0.5-2.0 Mpa, heating to fully pyrolyze the waste tires, and collecting a pyrolysis product to obtain limonene-containing pyrolytic tar. The invention also provides a preparation method of limonene, which comprises the following steps: preparing the limonene-containing pyrolytic tar by using the above method, and separating and purifying to obtain limonene. According to the method disclosed by the invention, the pyrolytic reaction of the waste tires is controlled to be carried out in a properpressure interval, so that the mass ratio of limonene in the pyrolytic tar is effectively increased, and the concentration of limonene in the pyrolytic tar product is remarkably increased compared with normal-pressure and vacuum pyrolysis at the same temperature.

Owner:HUAZHONG UNIV OF SCI & TECH

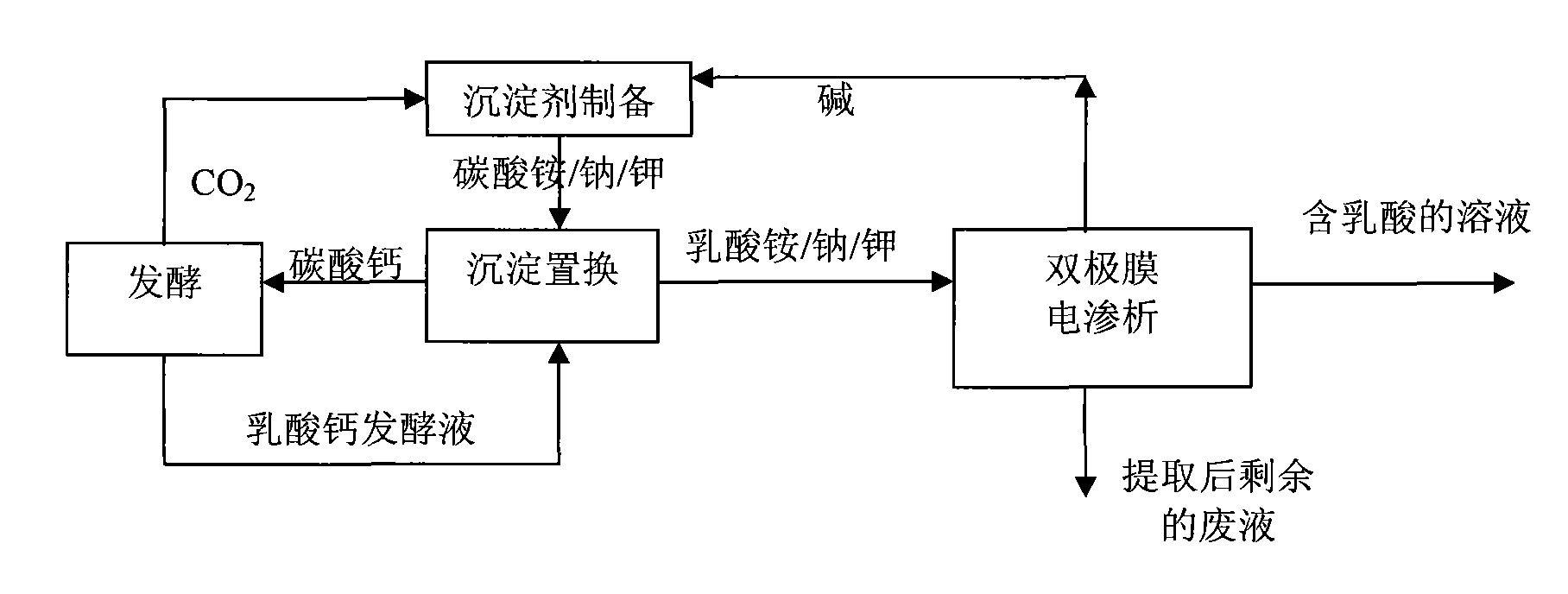

Calcium salt method-electrodialysis coupling technology-based lactic acid cleaner production method

InactiveCN102250973AAvoid defectsRealize closed loop useMicroorganism based processesFermentationSodium lactateDisplacement reactions

The invention relates to a calcium salt method-electrodialysis coupling technology-based lactic acid cleaner production method. The method comprises the following steps that 1, the pH value of fermentation broth is still adjusted through CaCO3 in a lactic acid fermentation stage; 2, calcium lactate-containing lactic acid fermentation broth and ammonium carbonate, sodium carbonate or potassium carbonate undergo a precipitation displacement reaction to form fermentation broth containing ammonium lactate, sodium lactate or potassium lactate, and calcium carbonate precipitates; and 3, the fermentation broth containing ammonium lactate, sodium lactate or potassium lactate is treated into lactic acid-containing solution and regenerated NH3 solution, NaOH solution or KOH solution through a bipolar membrane electrodialysis technology. The method provided by the invention can overcome the defect that calcium sulfate waste residues can be produced in the existing production technology-based lactic acid production, be directly linked up with the existing lactic acid fermentation step (adopting calcium carbonate to adjust a pH value), and realize closed cycle use of materials.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method for foamed polypropylene

The invention provides a preparation method for foamed polypropylene. The method comprises: carrying out mixing, melting and extruding on raw materials to obtain the foamed polypropylene, wherein the raw materials comprise polypropylene, a reaction additive, and an initiator, the weight ratio is 100:(0.5-50):(0.01-10), the reaction additive comprises at least a C5 fraction, and a mole ratio of olefin to alkane in the reaction additive is 1:(2-50). According to the present invention, the C5 fraction is directly utilized to prepare the foamed polypropylene, the olefin in the C5 fraction provides an effect of a cross-linking agent during the reaction process, and the olefin component can be grafted on the polypropylene main chain by using the double bond of the olefin so as to increase the melt strength of the polypropylene, and improve the foaming performance of the polypropylene; the alkane in the C5 fraction mainly provides the effect of the physical foaming agent; the method provideshigh compressive utilization rate for the C5 fraction, such that the high value utilization of the C5 fraction is achieved; in addition, with the method of the present invention, the cheap price C5 fraction is adopted as the reaction additive, such that the production cost is reduced.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for improving anaerobic fermentation effect of synthesis gas by using carbon material

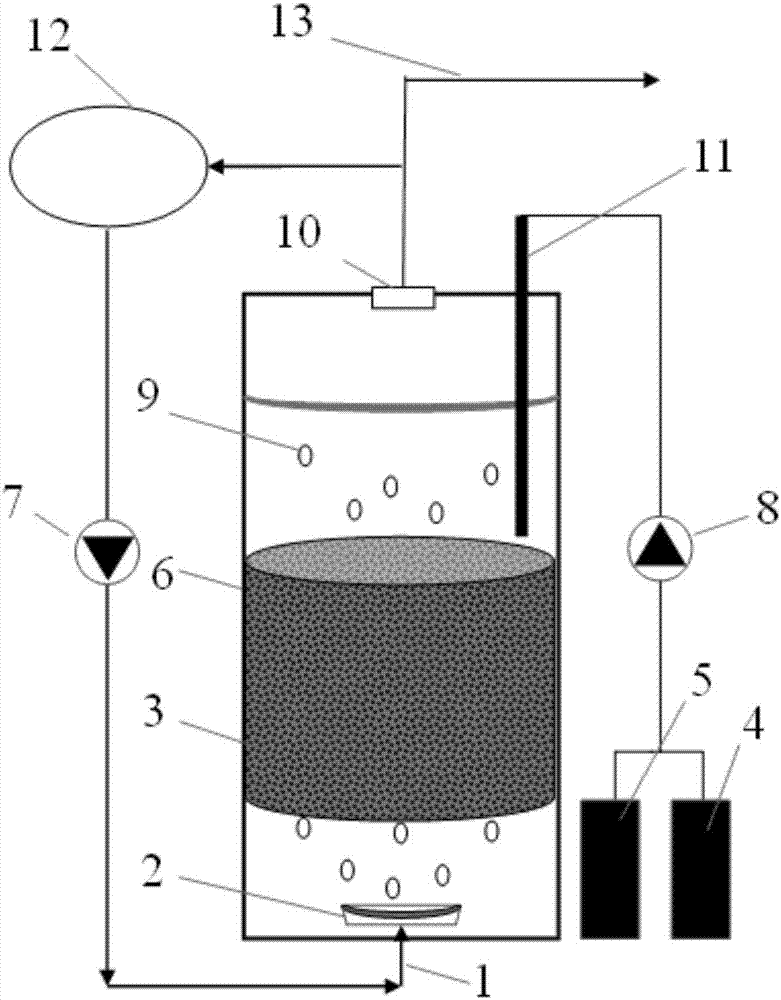

ActiveCN107130003APromote growthTo promote metabolismWaste based fuelFermentationStart timeMicrobial agent

The invention relates to a method for improving anaerobic fermentation of synthesis gas by using a carbon material. The method comprises the following steps: (1) adding the carbon material into an anaerobic reactor which takes anaerobic sludge as a starting microbial agent; (2) carrying out anaerobic fermentation in a way of aeration by taking the synthesis gas as a carbon source. Compared with the prior art, the method takes the carbon material as an additive, thus shortening the starting time of the anaerobic fermentation of the synthesis gas and obviously increasing a carbonic oxide degradation rate and a methane production rate. The method is simple to operate, and a device is simple. The synthesis gas and the carbon material are respectively used as the carbon source and the additive in a microbial anaerobic fermentation process, so that the biological refining and high-value utilization of waste can be realized.

Owner:TONGJI UNIV

Method for recycling threonine from threonine crystallization mother liquid

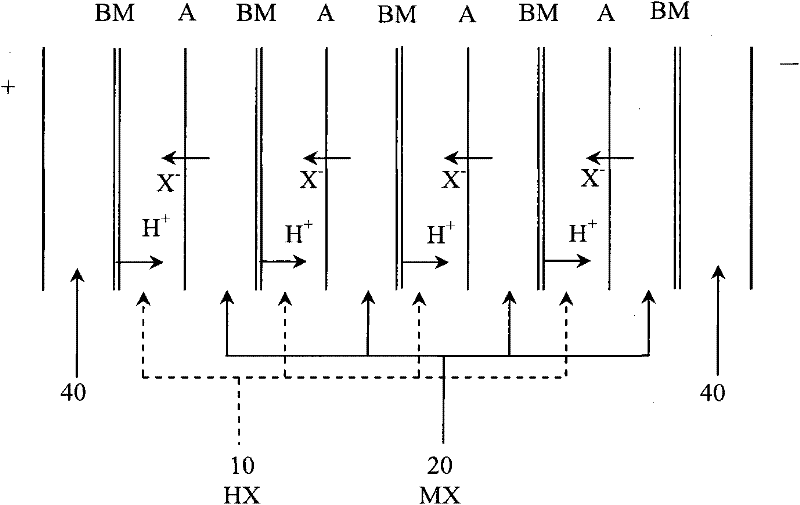

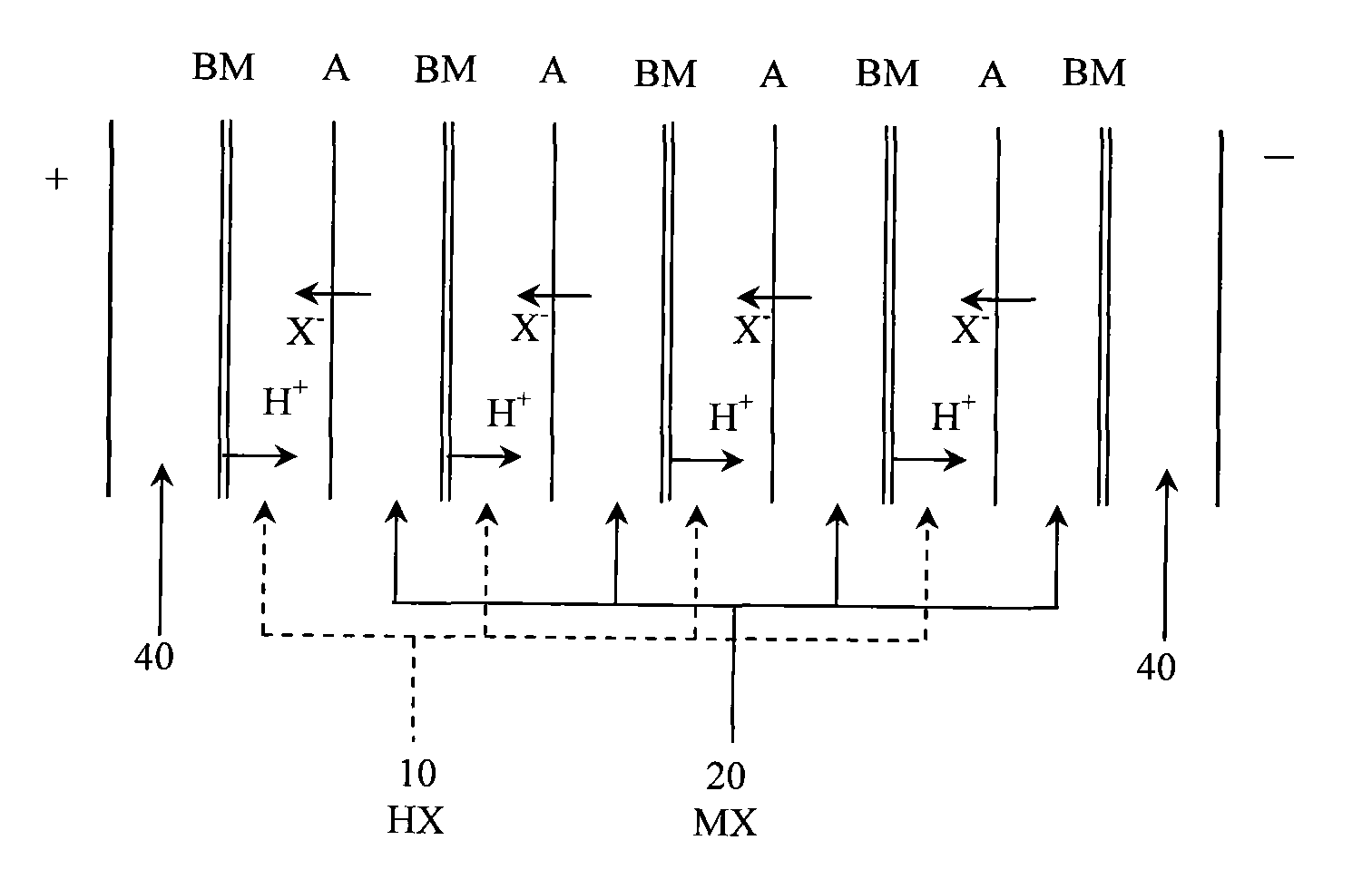

ActiveCN102698602AHigh recovery rateImplement resourcesSemi-permeable membranesOrganic compound preparationInorganic saltsThreonine

The invention relates to the field of amino acid production and particularly relates to a method for recycling threonine from threonine crystallization mother liquid. The method includes the following steps that 1) the bipolar membrane electrodialysis technology is adopted to remove inorganic salt from the threonine crystallization mother liquid to obtain the threonine crystallization mother liquid free of inorganic salt, wherein the bipolar membrane electrodialysis technology is the 'acid-salt' double-chamber bipolar membrane electrodialysis technology; and 2) an anion exchange method is utilized to recycle threonine from the threonine crystallization mother liquid free of inorganic salt. The method achieves the effect that the threonine is recycled from the threonine crystallization mother liquid, improves extraction yield of the threonine, further completely utilizes components in the threonine crystallization mother liquid, enables residual liquid to be subjected to the existing full-blown biological technological treatment and reach the standard and reduces pollution discharge.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

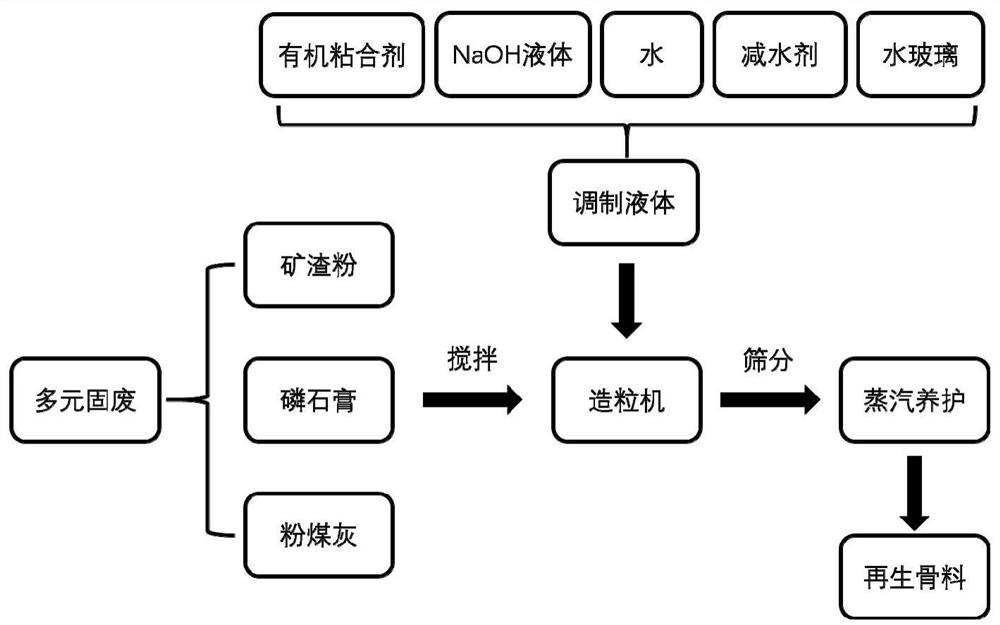

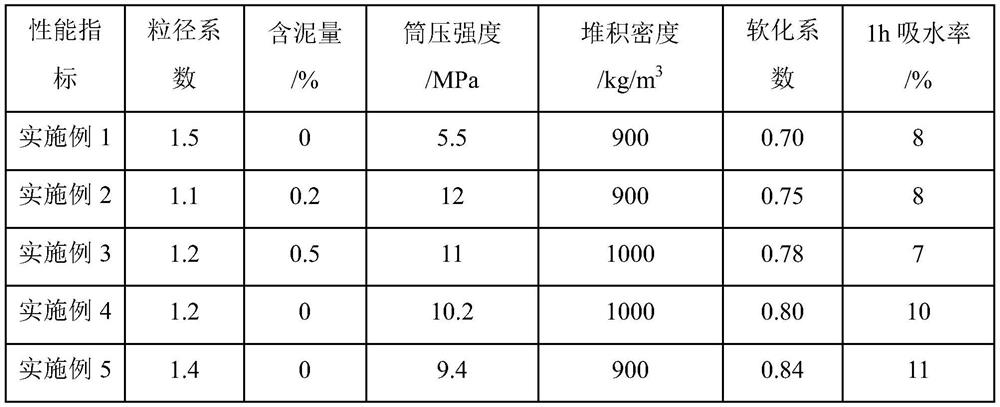

Multi-element solid waste recycled aggregate and preparation process thereof

The invention discloses a multi-element solid waste recycled aggregate and a preparation process thereof. The multi-element solid waste recycled aggregate is prepared by taking ardealite, fly ash, slag powder and a water reducing agent as raw materials and utilizing an alkaline activator, an active silicon-aluminum mineral admixture and an organic adhesive through a disc granulation balling process. Through carrying out a disc granulation pelletizing technology and natural hydration to generate ettringite and C-S-H gel to wrap and bond the remaining undissolved ardealite and the admixture together, thereby obtaining the novel building material. After the recycled aggregate is naturally hydrated and formed, the primarily formed aggregate is put into a steam curing box with the temperature being 100 + / -2 DEG C and the humidity being 95% or above so as to accelerate generation of C-S-H particles. The hydration rate is increased, the performance of the recycled aggregate is improved, the water absorption rate of the recycled aggregate is reduced, the water consumption of the recycled concrete is reduced, the strength of the recycled aggregate concrete is obviously improved, and the utilization rate of the recycled aggregate in the concrete is increased.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

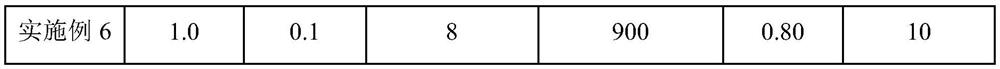

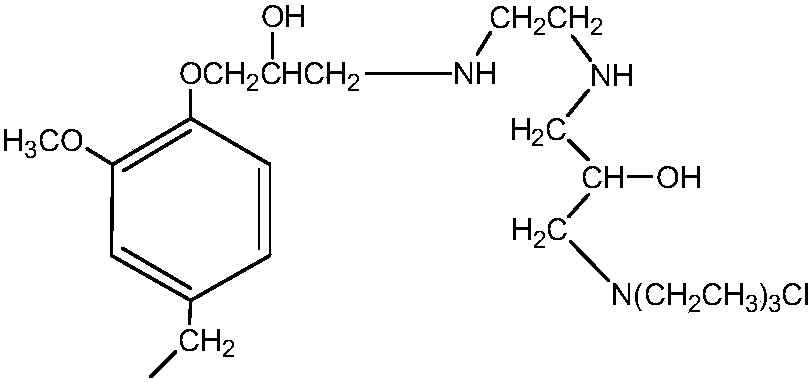

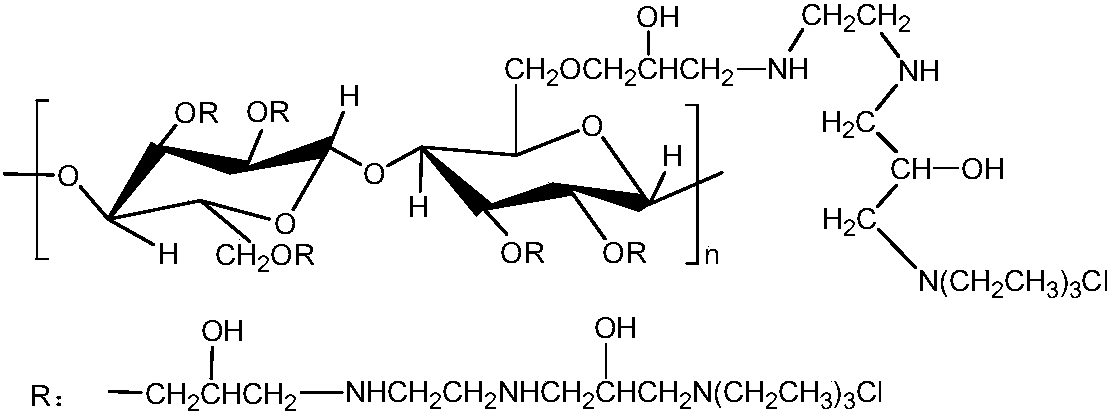

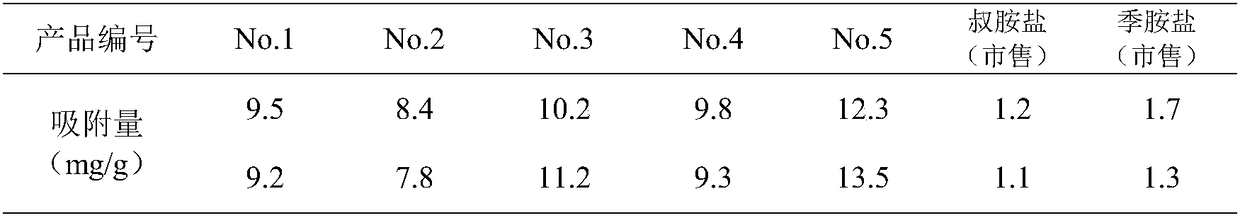

Preparation method of multi-functional group antibacterial biogas residue adsorbent for adsorbing heavy metals and anions

InactiveCN108160044AAntibacterial biogas residue adsorbent with large adsorption capacityImprove antibacterial propertiesOther chemical processesWater contaminantsCross-linkEthylenediamine

The invention relates to a preparation method of a multi-functional group antibacterial biogas residue adsorbent for adsorbing heavy metals and anions. The method comprises that with a biogas residueproduced by crop straw fuel formation and epoxy chloropropane as main raw materials, with ethylenediamine, triethylamine, hexamethylenediamine, diethylenetriamine, triethylene tetramine, or diethylaminopropylamine as cross-linking agents, the adsorbent is prepared in the presence of an N,N-dimethyl formamide medium; the prepared novel multi-functional group antibacterial biogas residue-based adsorbent has the advantages of simple production process, low cost, easy modification, large mechanical strength, wide use range, good adsorption effect, strong antibacterial property, low secondary pollution, large adsorption capacity, high adsorbing capacity specially for copper ions, nickel ions, nitrate radicals, phosphate radicals, dichromate radicals and anion dye ions, even attachment of chemical functional groups, large specific surface area and strong adhesion power. The adsorbent can be widely applied in all kinds of polluted water bodies containing various heavy metal ions and anions, such as industrial wastewater, eutrophic water bodies, chromium-containing wastewater, printing and dyeing wastewater or other polluted water bodies.

Owner:SHANDONG UNIV

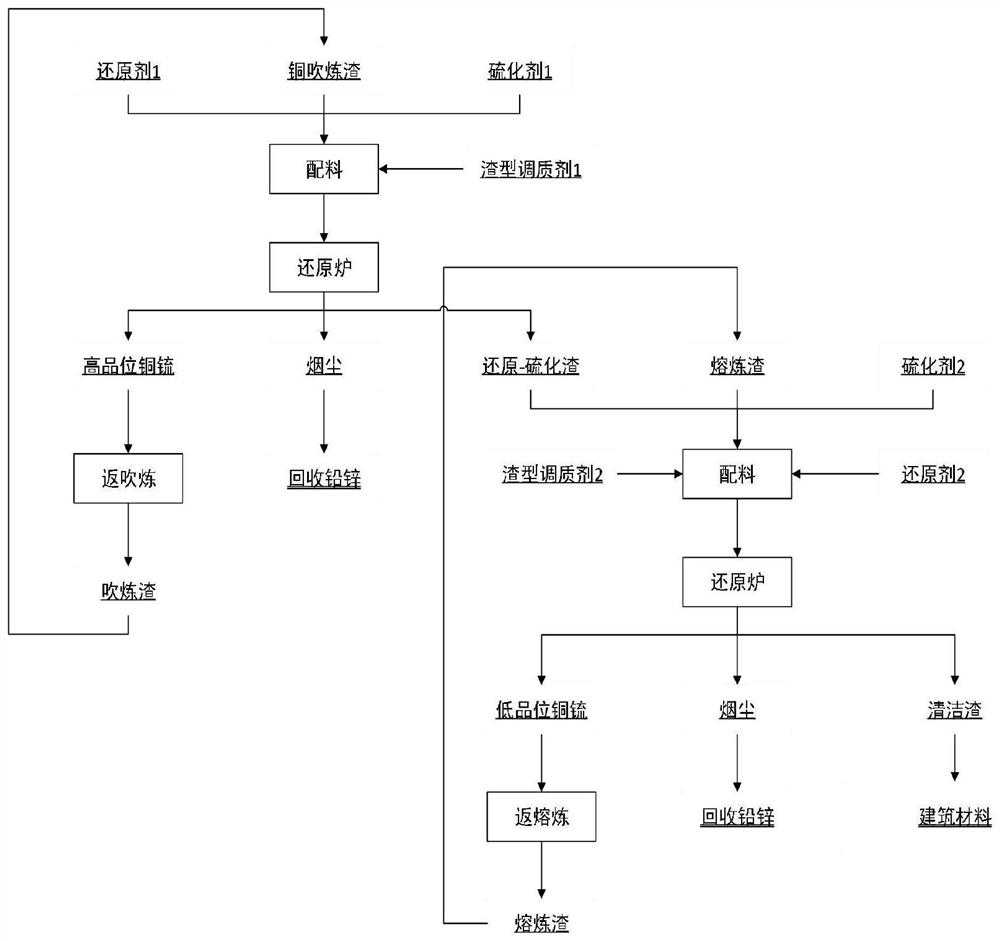

Recycling method for copper smelting slag

The invention discloses a recycling method for copper smelting slag. The recycling method comprises the following steps: (1) mixing copper blowing slag, a vulcanizing agent 1, a slag type modifying agent 1 and a reducing agent for smelting to obtain high-grade copper sulfur, flue gas and vulcanizing-reducing slag, wherein the high-grade copper sulfur is blown to recycle copper; (2) mixing the vulcanizing-reducing slag, the copper smelting slag, a vulcanizing agent 2, a slag type tempering agent 2 and a reducing agent 2 for smelting to obtain low-grade copper sulfur, flue gas and furnace slag,wherein the low-grade copper sulfur is smelted to recycle copper; and (3) collecting dust of flue gas in the step (1) and the step (2) to obtain smoke dust rich in lead and zinc, wherein lead and zincare recycled from the smoke dust rich in lead and zinc through a lead and zinc recycling system. The copper blowing slag and the copper smelting slag are cooperatively treated, so that efficient enriching and recycling for valuable metals such as copper, lead and zinc in the copper smelting slag are achieved, and thus, environmental pollution and resource waste caused by stock-piling are avoided.

Owner:CENT SOUTH UNIV

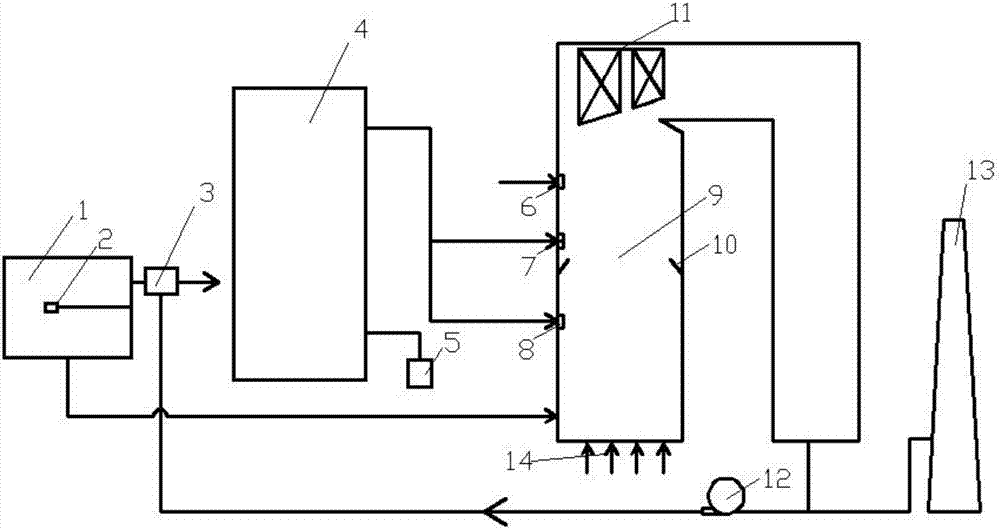

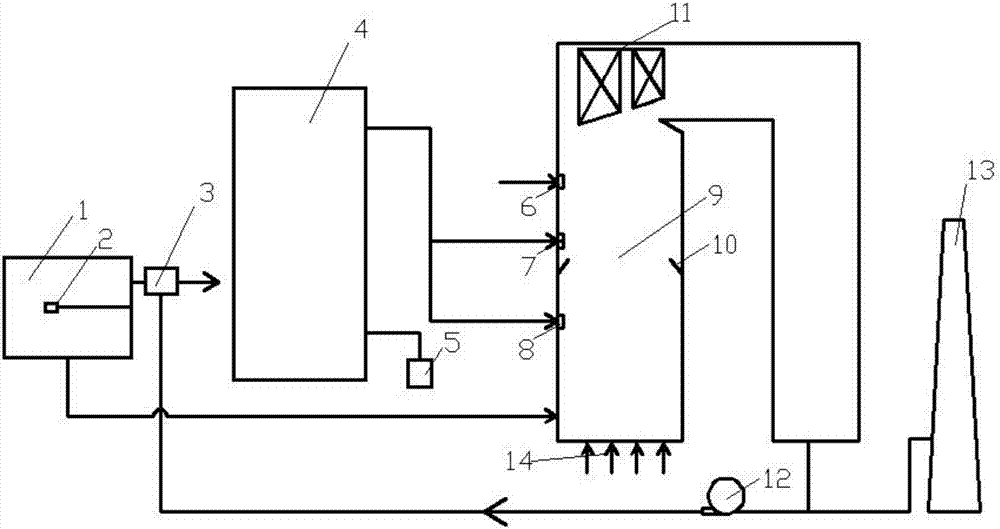

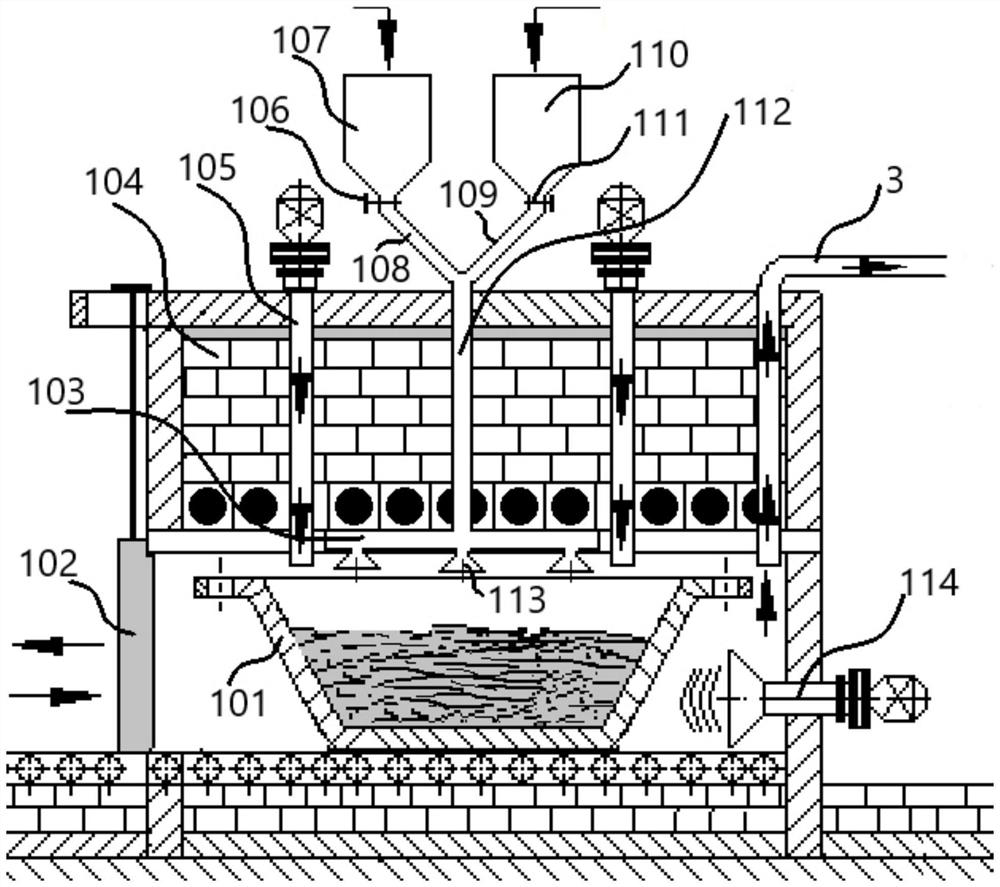

Device and method for co-producing carbon by coupling biomass direct combustion boiler with biomass gasification

InactiveCN108003937AImprove utilization efficiencyAchieve diversificationGasification processes detailsNon-combustible gases/liquids supplyBiomass carbonDirect combustion

The invention provides a device and a method for co-producing carbon by coupling a biomass direct combustion boiler with biomass gasification. The device comprises a carbon gas co-production device; abiomass raw material storehouse is arranged on one side of the carbon gas co-production device; a raw material detection device is arranged in the biomass raw material storehouse; a biomass direct combustion boiler hearth is arranged on one side of the carbon gas co-production device; the outlet of biomass gas generated by the carbon gas co-production device is connected with a middle gas nozzleand a middle lower part gas nozzle of the biomass direct combustion boiler hearth; a carbon collecting device is arranged on the lower side of the carbon gas co-production device; and biomass carbon produced by the carbon gas co-production device is collected by the carbon collecting device. The biomass raw materials are divided into two kinds which are suitable for gasification and suitable for direct combustion correspondingly, so multi-stage utilization and value gradient utilization of the biomass are realized and diversification and high value of the biomass products are realized; and dueto substance and energy exchange between the carbon gas co-production device and the direct combustion boiler, the comprehensive utilization efficiency of the biomass is further improved.

Owner:苏玉臻 +1

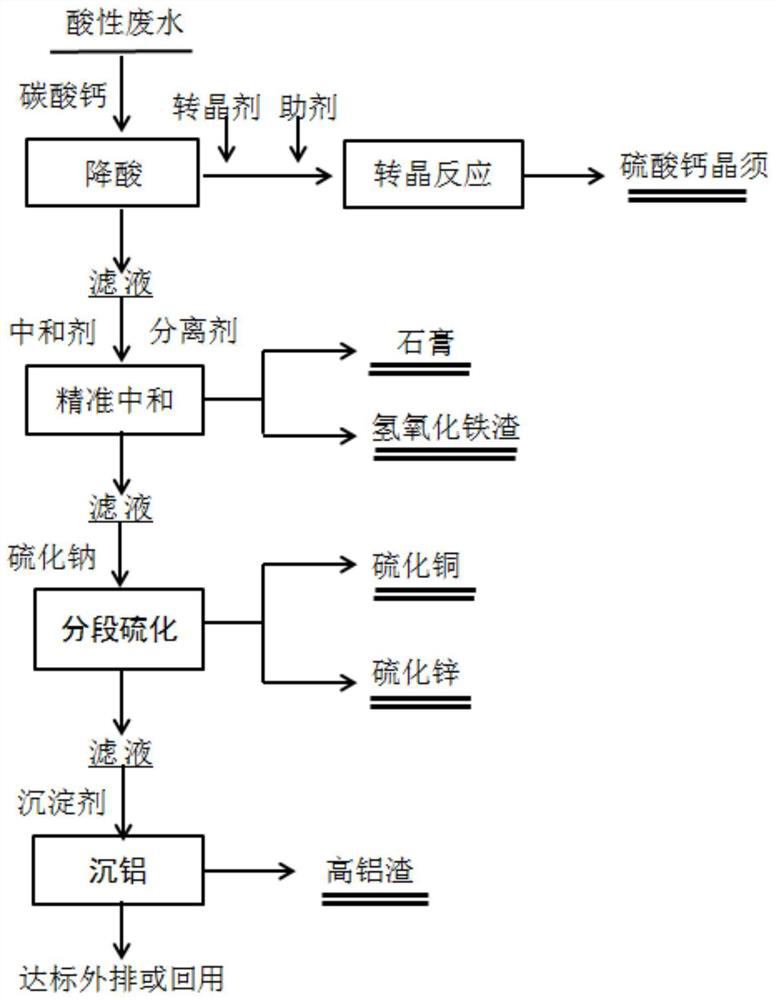

Method for comprehensively utilizing multi-metal acidic wastewater of non-ferrous metal mine

ActiveCN111777224AAchieve reductionRealize resource utilizationIron oxides/hydroxidesWater contaminantsSlagNon-ferrous metal

The invention discloses a method for comprehensively utilizing multi-metal acidic wastewater of non-ferrous metal mine, which realizes recovery of sulfate radicals in the acid wastewater and production of calcium sulfate whiskers by neutralizing and controlling the acidity of the solution so as to realize high value of products. Ferric hydroxide and gypsum generated in the neutralization process are efficiently separated in a physical mode, ferric hydroxide slag and gypsum products are obtained, reduction of the neutralization slag is achieved, and high-valued utilization is achieved. Copper,zinc and aluminum products are selectively separated and recycled through a stepped precipitation method, so that the recovery rates of copper, zinc and aluminum are larger than or equal to 90%, larger than or equal to 95% and larger than or equal to 85% respectively, resource utilization of valuable metal is achieved, and the problems of resource waste of a traditional neutralization process andsecondary pollution to the environment in neutralization slag stockpiling are solved.

Owner:ZIJIN MINING GROUP +1

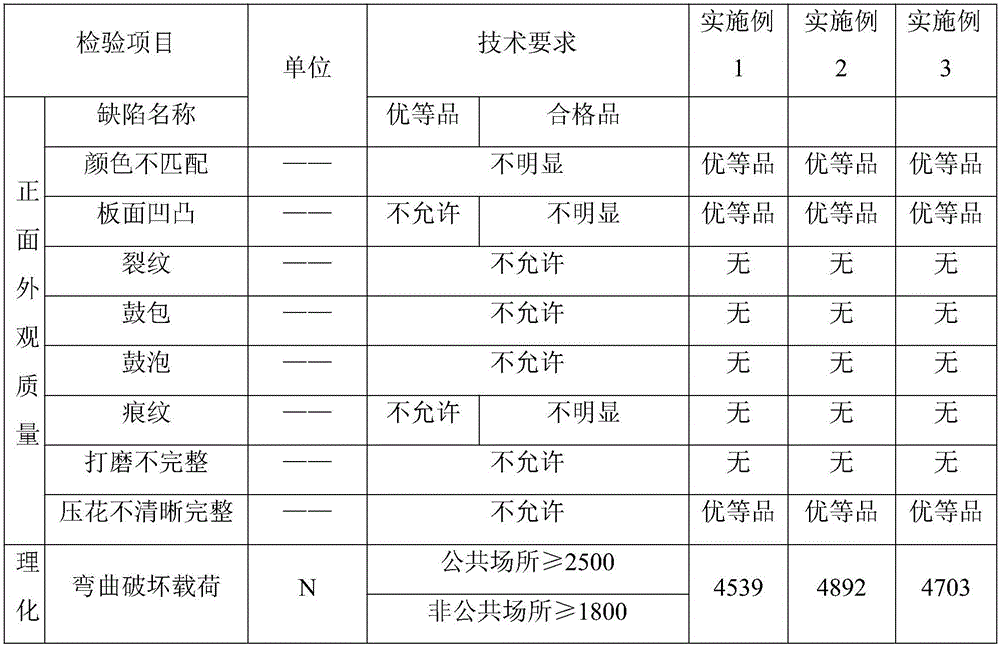

Enteromorpha wood and plastic floor and preparation method thereof

The invention relates to an enteromorpha wood and plastic floor and a preparation method thereof. The enteromorpha wood and plastic floor is prepared from the following components in parts by weight: 30 to 50 parts of enteromorpha dry powder, 10 to 20 parts of tea meal, 10 to 20 parts of straw powder, 10 to 20 parts of shell powder, 30 to 50 parts of recycled plastic, 10 to 20 parts of polyvinyl chloride, 0.5 to 1.5 parts of titanate coupling agent, 0.3 to 0.5 part of silane coupling agent, 5 to 15 parts of medical stone, 0.4 to 0.8 part of AC foaming agent, 0.3 to 0.5 part of toughening agent, 0.3 to 0.5 part of stabilizer, 1 to 2 parts of calcium propionate, and 1 to 3 parts of zinc stearate. The product provided by the invention has the advantages of environmental protection, wide raw material source, reasonable use of resources, low cost, good quality, low shrinkage rate and expansion rate, low density, light weight, and convenience in transport and installation.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

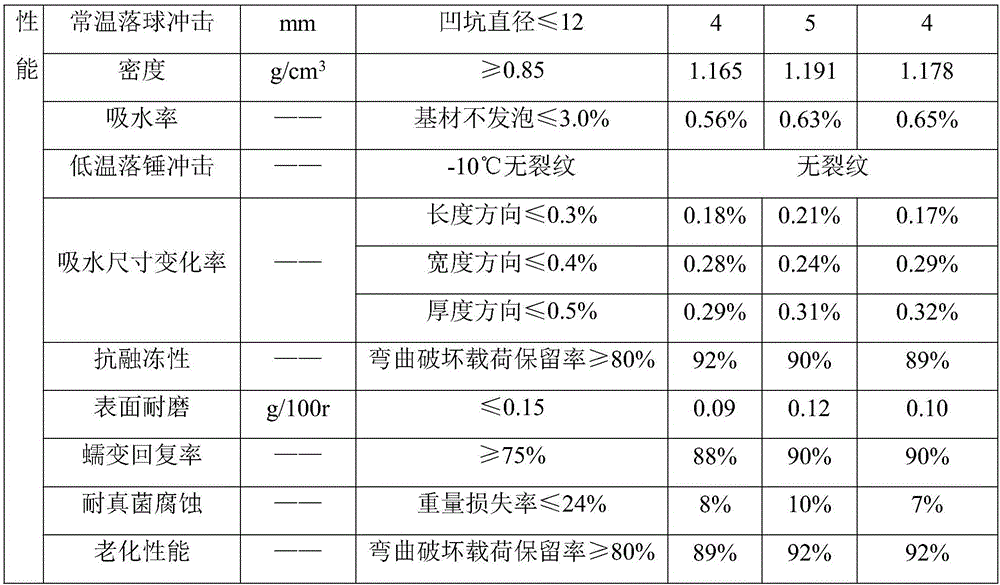

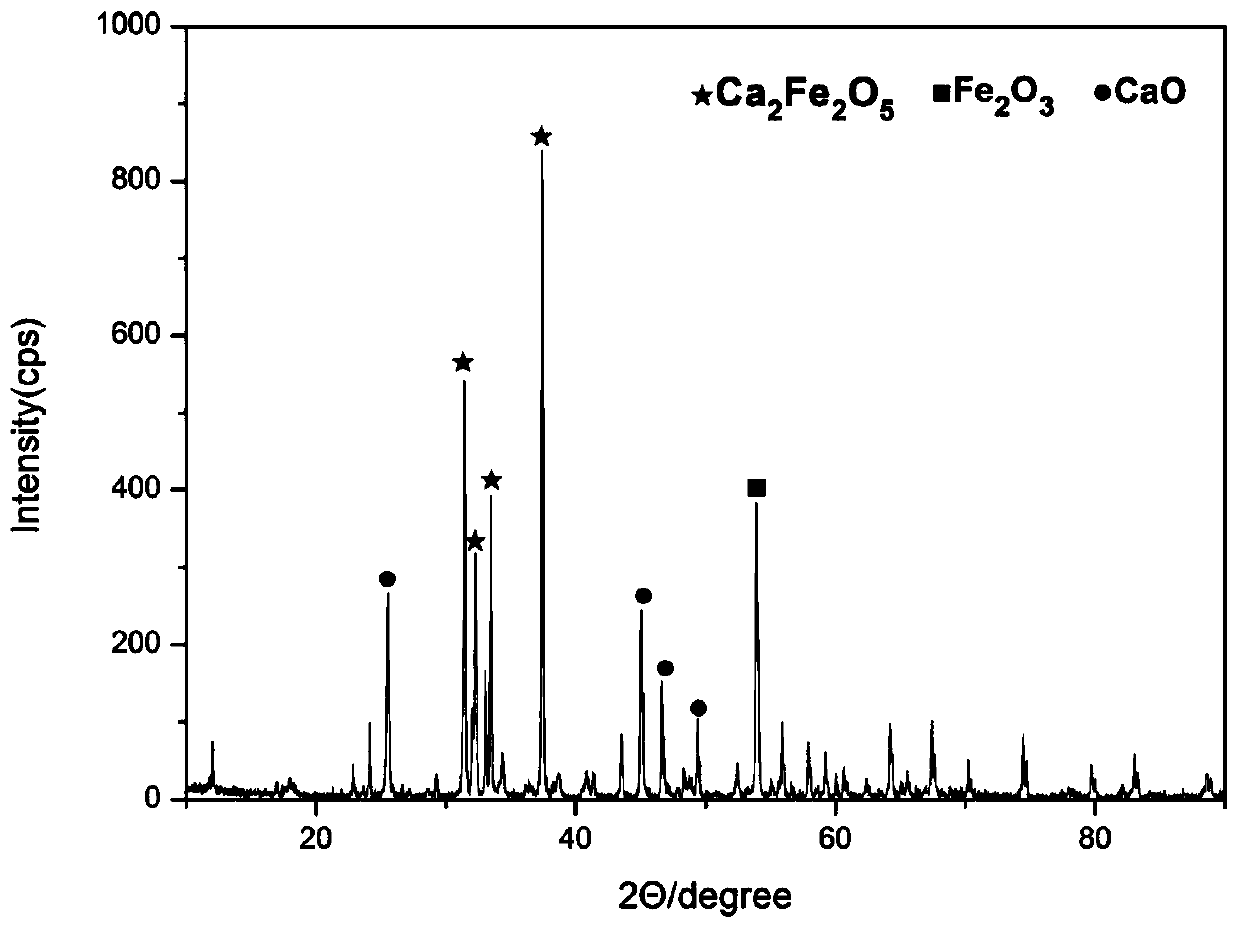

Preparation method of calcium ferrite

InactiveCN110372042AIncrease valueRealize resource utilizationSulfur compoundsIron compoundsSlagSulfur

The invention relates to a preparation method of calcium ferrite. The conditions of large amount, difficult storage, difficult disposition, seriously pollution of desulfurized fly ash in a raw material factory are aimed at, firstly the desulfurized ash is heated for a period of time at oxidizing atmosphere, then coal powder, coke powder, iron ore powder are added as raw materials, crushing, mixing, water adding briquetting, hot pressing, heating roasting and other steps are conducted, a product with the calcium ferrite as the main component is prepared after desulfuration, and removed sulfur is prepared to sulfuric acid and recovered by an absorption tower. The preparation method of the calcium ferrite is advanced in process method, simple in operation and high in desulfurization rate, thepurity of a produced product is high, and the preparation method can be used as a sintering additive or a converter slag making agent to realize recycling of waste.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Alkaline type rapid brewing method of low-salt fish sauce

InactiveCN104642998AShorten the fermentation cycleImprove fermentation efficiencyFood preparationProtein proteinFermented fish

The invention discloses an alkaline type rapid brewing method of low-salt fish sauce. The method comprises the following steps: mixing marine fishes with general drinking water; adding table salt; uniformly mixing; adjusting pH to be 7.0 to 11.0 through an alkaline regulator; maintaining the temperature to ferment; agitating once every two days to promote rapid degrading of protein of the fish bodies; continuously fermenting the product obtained by the constant temperature fermenting for 30 to 60 days; agitating once at every 5 to 10 days to obtain completely fermented fish sauce; filtering to remove residues of the completely fermented fish sauce; after-ripening; removing the upper grease of the fish sauce to obtain the after-ripened and de-greased fish sauce; heating for sterilizing; filtering to remove incompletely-fermented protein and other impurities to obtain clear and transparent low-salt fish sauce which has a good taste. The method is short in fermenting cycle, high in fermenting efficiency, and low in salt in the fish sauce, and the value of low-value marine fishes is increased.

Owner:JIMEI UNIV

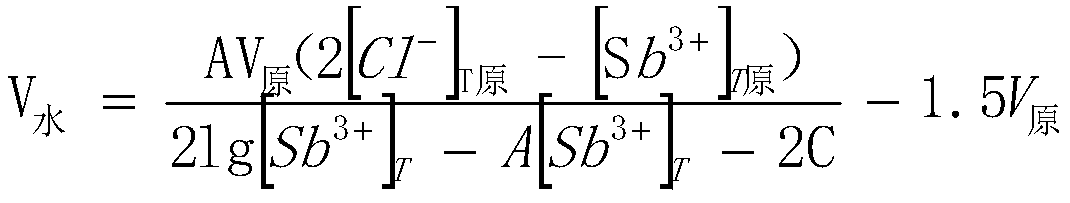

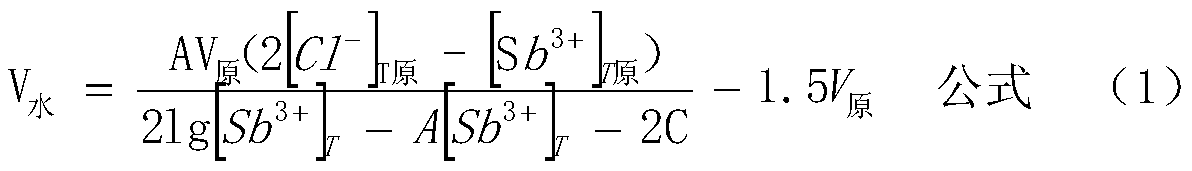

Antimony sulfide concentrate smelting process

ActiveCN110016575ANo emissionsRealize closed loopSulfur preparation/purificationProcess efficiency improvementMelting tankElectrolysis

The invention discloses an antimony sulfide concentrate smelting process. The antimony sulfide concentrate smelting process comprises the steps of controlling potential strengthening leaching, hydrolyzing, controlling potential arsenic precipitation, dechlorination, strengthening reduction smelting; firstly, the antimony sulfide concentrate is subjected to strengthening leaching through a controlled potential shear to obtain a leachate and leached residues, the leachate is restored and then cooled to precipitate elemental sulfur, carrying out dilute hydrolysis on the sulfur-removed leachate toobtain the antimony oxychloride and the hydrolyzed liquid, after the hydrolyzed liquid is subjected to the controlling potential arsenic precipitation to remove arsenic and then returning to the hydrolytic liquid for use, removing chlorine from the antimony oxychloride to obtain crude antimony oxide and dechlorinated liquid, the dechlorinated liquid is electrolyzed by a diaphragm to obtain caustic soda and chlorine, the caustic soda is reused for dechlorination of crude antimony oxychloride, the chlorine is used for controlling potential leaching, the crude antimony oxide is subjected to intensified reduction smelting by adopting a low-temperature molten pool to obtain refined antimony, or is treated by a plasma furnace to obtain the high-purity antimony oxide. According to the antimony sulfide concentrate smelting process, the low-concentration SO2 pollution can be eliminated from the source, the generation of arsenic alkali residue is avoided, and the process has the characteristicsof cleanness and environmental protection.

Owner:CENT SOUTH UNIV

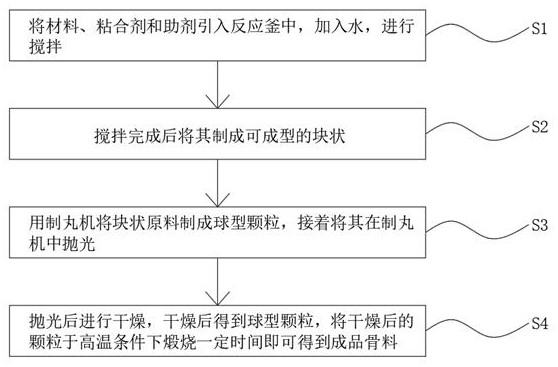

Preparation method of 3D printing building material aggregate

ActiveCN111635156ASolve the scaleSolve high valueAdditive manufacturing apparatusAdhesiveArchitectural engineering

The invention discloses a preparation method of 3D printing building material aggregate. The preparation method comprises the following steps: S1, introducing a material, an adhesive and an assistantinto a reaction kettle, adding water, and stirring; S2, after stirring is completed, manufacturing the mixture into a moldable block; S3, preparing the blocky raw materials into spherical particles byusing a pill making machine, and then polishing the spherical particles in the pill making machine; S4, drying after polishing, drying to obtain spherical particles; calcining the dried particles fora certain time under a high-temperature condition to obtain a finished product aggregate; the structure is scientific and reasonable, the preparation method of the 3D printing building material aggregate is simple, safe and convenient to use, a new preparation scheme of the 3D printing building material aggregate is provided, a new choice is provided for 3D printing building materials, solid waste is recycled, and large-scale, high-valued and resourceful treatment of the solid waste is achieved.

Owner:SHANGHAI RUIHUI ENVIRONMENTAL PROTECTION TECH

Method for preparing rich xylobiose to xylotetraose from eucalyptus hydrothermal pretreatment liquid

PendingCN109680024ARealize high-value utilizationIncrease contentFermentationFood scienceCalcium hydroxideActivated carbon

The invention discloses a method for preparing rich xylobiose to xylotetraose from eucalyptus hydrothermal pretreatment liquid. The eucalyptus hydrothermal pretreatment liquid is sequentially treatedwith calcium hydroxide, activated carbon adsorption and endo-xylanase to obtain xylooligosaccharide-rich sugar liquid. Then, the sugar liquid is treated with membrane dialysis and freeze-dried to obtain xylooligosaccharide powder rich in xylobiose to xylotetraose. By means of the method of the invention, the operating cost of equipment in the process of refining xylooligosaccharide can be effectively reduced, the environmental pollution load can be alleviated, the yield and purity of the xylooligosaccharide can be increased, the high-value utilization of the hydrothermal pretreatment liquid isrealized, and the market price of the xylooligosaccharide is reduced to a certain extent.

Owner:QILU UNIV OF TECH

New mode duck manure harmless and resource utilization method

PendingCN111517838AAchieve full utilizationAchieve high valueBio-organic fraction processingClimate change adaptationAnimal scienceHermetia

The invention provides a new mode duck manure harmless and resource utilization method which comprises the following steps that 1, duck manure and auxiliary materials are mixed, the mixture of the duck manure and the auxiliary materials is sheared to enable the mixture of the duck manure and the auxiliary materials to be in a semi-fluid state, hermetia illucens larva associated microbial inoculants are added, the mixture is mixed to be uniform, and a duck manure mixture is obtained for use; 2, the duck manure mixture obtained in the step 1 is flatly laid, then 3-year-old hermetia illucens larvae are inoculated into duck manure to be treated for 5-7 days, fresh insects are screened to be separated from duck manure residues, and the fresh insects are processed to be used as livestock, poultry and pet feed; 3, the duck manure residues are uniformly mixed with auxiliary materials, a fermentation inoculant is added and stacked, and static aerobic composting fermentation is performed; and 4,after composting fermentation treatment, aging is performed to be used as an organic fertilizer. According to the method, hermetia illucens is used for biologically converting the duck manure into insect protein, the moisture content of the duck manure is reduced, biological composting is better facilitated, and the problems that the duck manure harmless treatment cost is high, and the resource utilization benefit is low are solved.

Owner:HEZE BRANCH QILU UNIV OF TECH(SHANDONG ACAD OF SCI

Preparation method of novel salt-free Chinese sauerkraut

InactiveCN111789243ALight in massEasy to storeFood thermal treatmentClimate change adaptationBiotechnologyCellulose

The invention discloses a preparation method of novel salt-free Chinese sauerkraut. The novel salt-free Chinese sauerkraut is prepared from raw materials in parts by weight as follows: 10-20 parts ofround radish leaves, 0.1-0.2 part of lactobacillus yeast powder and 100-200 parts of distilled water. According to the process, the traditional Chinese sauerkraut preparation technology is optimized,and the prepared finished product is light in mass, easy to store and convenient to eat, has unique flavor and appetizing and grease-relieving effects, is rich in cellulose, meets the health requirement for low-salt food on the market, provides theoretical basis and support for further development and utilization of green vegetables and promotes development of deep processing industry of vegetables in China.

Owner:湖南海霸食品有限公司

Recycled aggregate based on metakaolin slurry soaking and modification method of recycled aggregate

The invention belongs to the technical field of building materials, and relates to a modification method of a recycled aggregate based on metakaolin slurry soaking. The modification method mainly comprises the following steps of: preparing raw materials, specifically, separately weighing 60-90 parts by weight of metakaolin, 30-65 parts by weight of fly ash, 30-65 parts by weight of silica fume, 0.5-1.5 parts by weight of a water reducing agent, 2-3.5 parts by weight of an alkali activator, 2-3 parts by weight of a water glass solution and 35-60 parts by weight of water; uniformly mixing and stirring the metakaolin, the fly ash and the silica fume according to proportions to obtain a dry mixture; mixing water, a water reducing agent, an alkaline exciting agent and a water glass solution in proportion, and uniformly stirring to obtain a mixed solution; mixing the dry mixture with the mixed solution in proportion, and uniformly stirring to obtain metakaolin slurry; pretreating recycled coarse aggregate, soaking the recycled coarse aggregate in the metakaolin slurry, filtering out the recycled coarse aggregate after the recycled coarse aggregate absorbs water to be saturated, and drying to obtain the modified recycled aggregate. According to the method, existing waste can be utilized to the maximum extent, and resource utilization of industrial waste can be achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

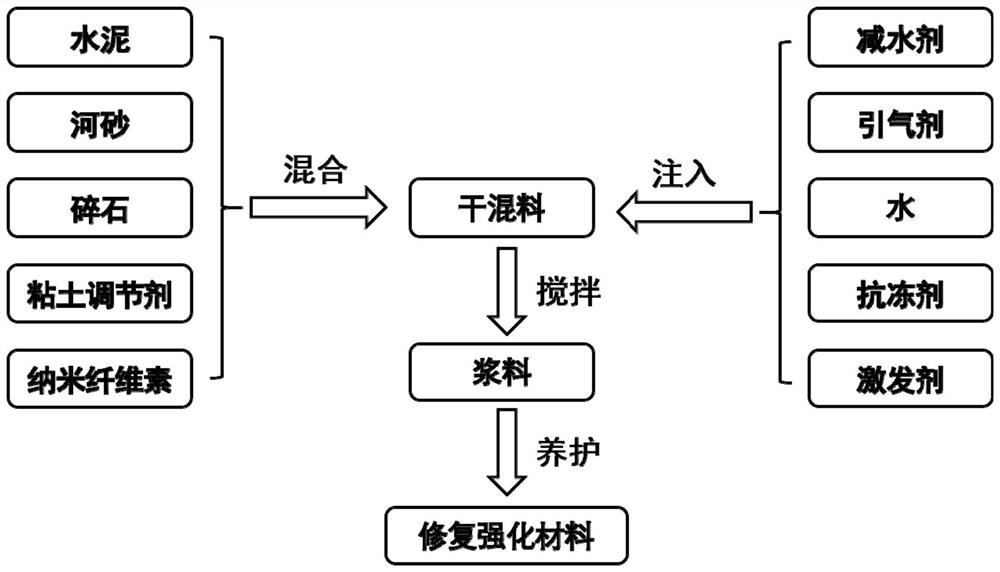

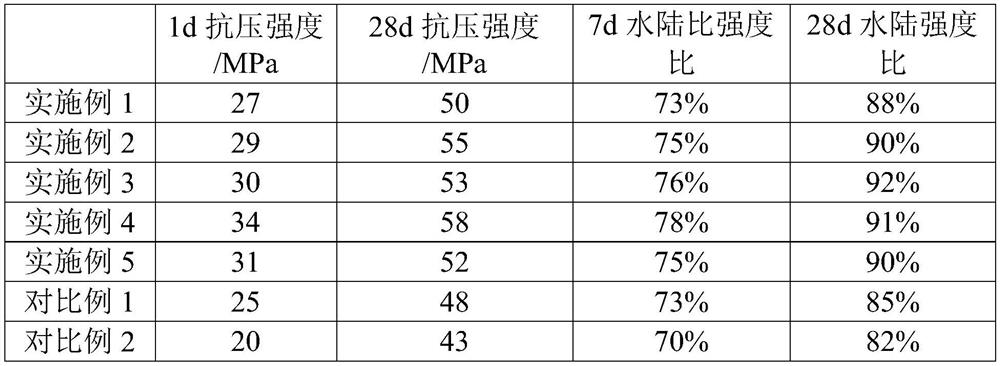

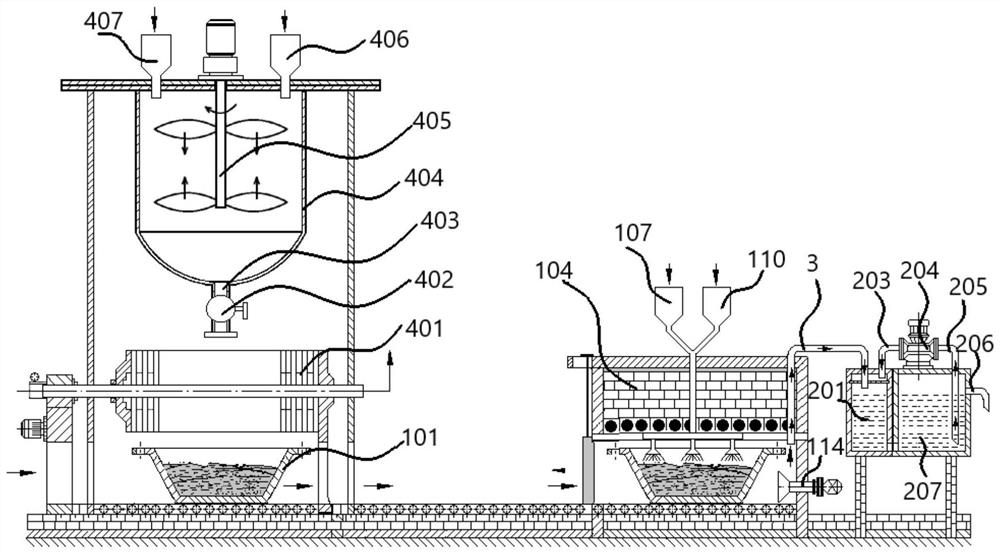

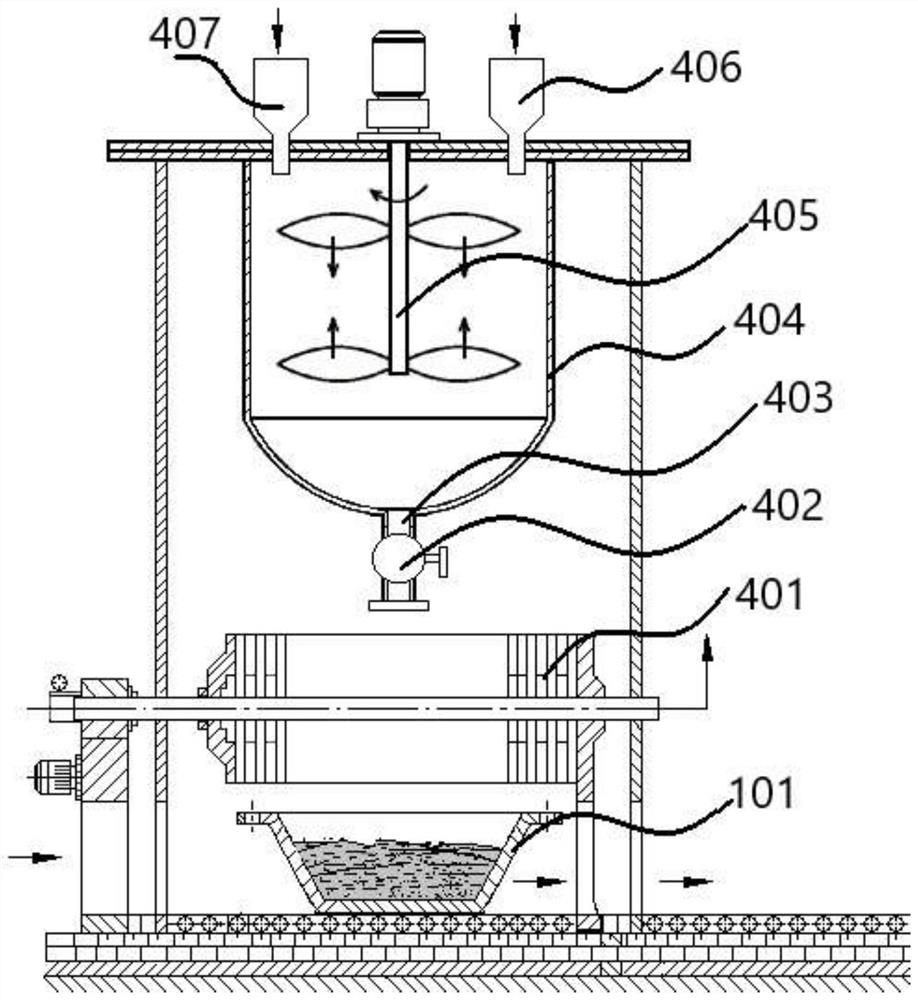

A kind of underwater concrete repair reinforcement material and preparation method thereof

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for extracting lignin from biomass by liquid nitrogen coupled microwave pretreatment

InactiveCN108316037ARetain structureReduce damagePaper material treatmentBulk chemical productionMicrowave powerPre treatment

The invention discloses a method for extracting lignin from biomass by liquid nitrogen coupled microwave pretreatment. The method comprises the following steps: crushing biomass raw materials, passingthrough a sieve with 20 to 100 meshes and then using liquid nitrogen treatment; then adjusting the water content of materials to 20 to 40 weight percent and standing for 1 to 6 hours; putting into amicrowave device for treating, wherein microwave power is 1 to 10 kW and the treating time is 30 to 600s; repeating for 2 to 6 times; leaching and filtering the materials subjected to microwave treatment to obtain filter residues and supernatant; adjusting the pH value of the supernatant by using hydrochloric acid, then centrifuging and drying the obtained sediment to obtain the lignin. Accordingto the method for extracting the lignin from the biomass by the liquid nitrogen coupled microwave pretreatment, disclosed by the invention, biomass is pretreated by using the liquid nitrogen coupled microwave, so that a biomass pretreatment process is optimized and the extraction efficiency and the purity of the lignin are effectively improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Integrated production line and method for removing chloride ions and regenerating dechlorinating agent from dechlorination residues

ActiveCN114314928AAchieve removalRealize activation and reuseWater contaminantsDispersed particle separationPtru catalystDechlorinator

The invention discloses a chloride ion removal and dechlorination slag regeneration dechlorination agent integrated production line and method, the production line comprises a chloride ion removal system, a dechlorination slag regeneration system and a tail gas purification system, the dechlorination slag regeneration system comprises a dechlorination slag regeneration furnace, a hot blast stove, a regenerated catalyst container, a pH regulator container and a medicament adding pipe, one side of the chlorine slag removal regeneration furnace is provided with a furnace door through which a chlorine slag removal material boat enters and exits, the regenerated catalyst container and the pH regulator container are respectively converged and communicated with one end of a medicament adding pipe through a regenerated catalyst adding branch pipe and a pH regulator adding branch pipe, and the other end of the medicament adding pipe extends into the chlorine slag removal regeneration furnace; a regenerated catalyst adding valve and a pH regulator adding valve are respectively arranged on the regenerated catalyst adding branch pipe and the pH regulator adding branch pipe; and the chlorine slag removal regeneration furnace is communicated with a tail gas purification system through a tail gas exhaust pipe. The method has the advantages of simple process, low cost and small wastewater amount.

Owner:湖南烯富环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com