Method for improving anaerobic fermentation effect of synthesis gas by using carbon material

An anaerobic fermentation and carbon material technology, which is applied in the field of environmental protection and comprehensive resource utilization, can solve the problems of long start-up time, unstable anaerobic fermentation system, etc., and achieve accelerated degradation, accelerated electron transfer, degradation rate and methane production rate Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

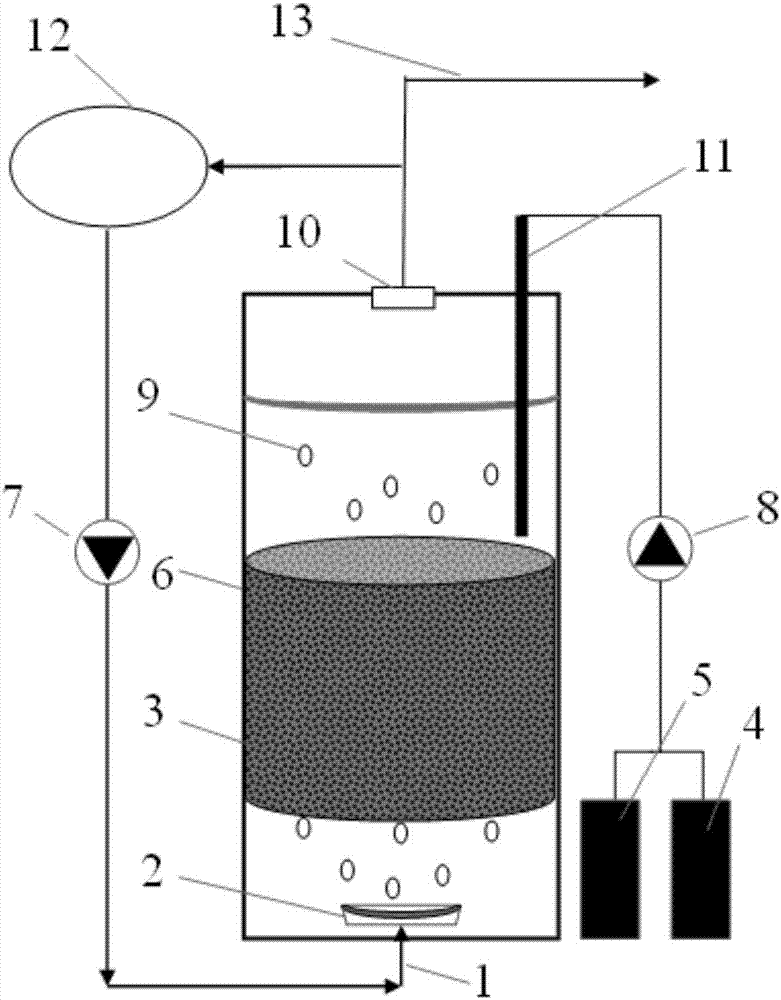

[0025] The structure of the anaerobic reactor adopted in this embodiment is as follows: figure 1 As mentioned above, it is a closed upflow anaerobic reactor. An air inlet 1 is provided at the bottom of the anaerobic reactor 6, an aeration head 2 is arranged above the air inlet 1, microorganisms 3 are filled inside the anaerobic reactor 6, and an air outlet 10 is provided at the top of the anaerobic reactor 6, An air bag 12 filled with syngas is arranged outside the anaerobic reactor 6, and the air bag 12 communicates with the air inlet 1 through the air inlet pipe, and a circulating pump 7 is arranged on the air inlet pipe, and a return pipe and an air outlet pipe are drawn from the air outlet 10 13. The return pipe communicates with the air bag 12, and the air outlet pipe 13 directly leads into the atmosphere.

[0026] After the syngas enters from the air inlet 1, it forms many bubbles 9 through the aeration head 2, and the bubbles 9 will pass through the microorganisms 3, a...

Embodiment 2

[0035] In this embodiment, the method for improving the anaerobic fermentation effect of syngas by using carbon materials, the steps are as follows:

[0036] (1) Anaerobic granular sludge was used as the starting agent, the dosage of sludge was 60g, and its TS and VS were 12% and 73% respectively. According to the quality of sludge VS: the quality of activated carbon is approximately equal to 1:1 adding 5 grams of activated carbon. The particle size of activated carbon is 75-150 microns, and the specific surface area is 644m 2 / g.

[0037] (2) The volume filling rate of activated carbon in the anaerobic reactor is 0.7%.

[0038] (3) if figure 1, in the closed up-flow anaerobic reactor, the syngas is pumped into the reactor from the air bag by the circulation pump, and finally returns to the same air bag, the reflux rate is 100%, and the gas in the air bag is replaced once every two days. The content of carbon monoxide in the synthesis gas in the reactor increases successiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com