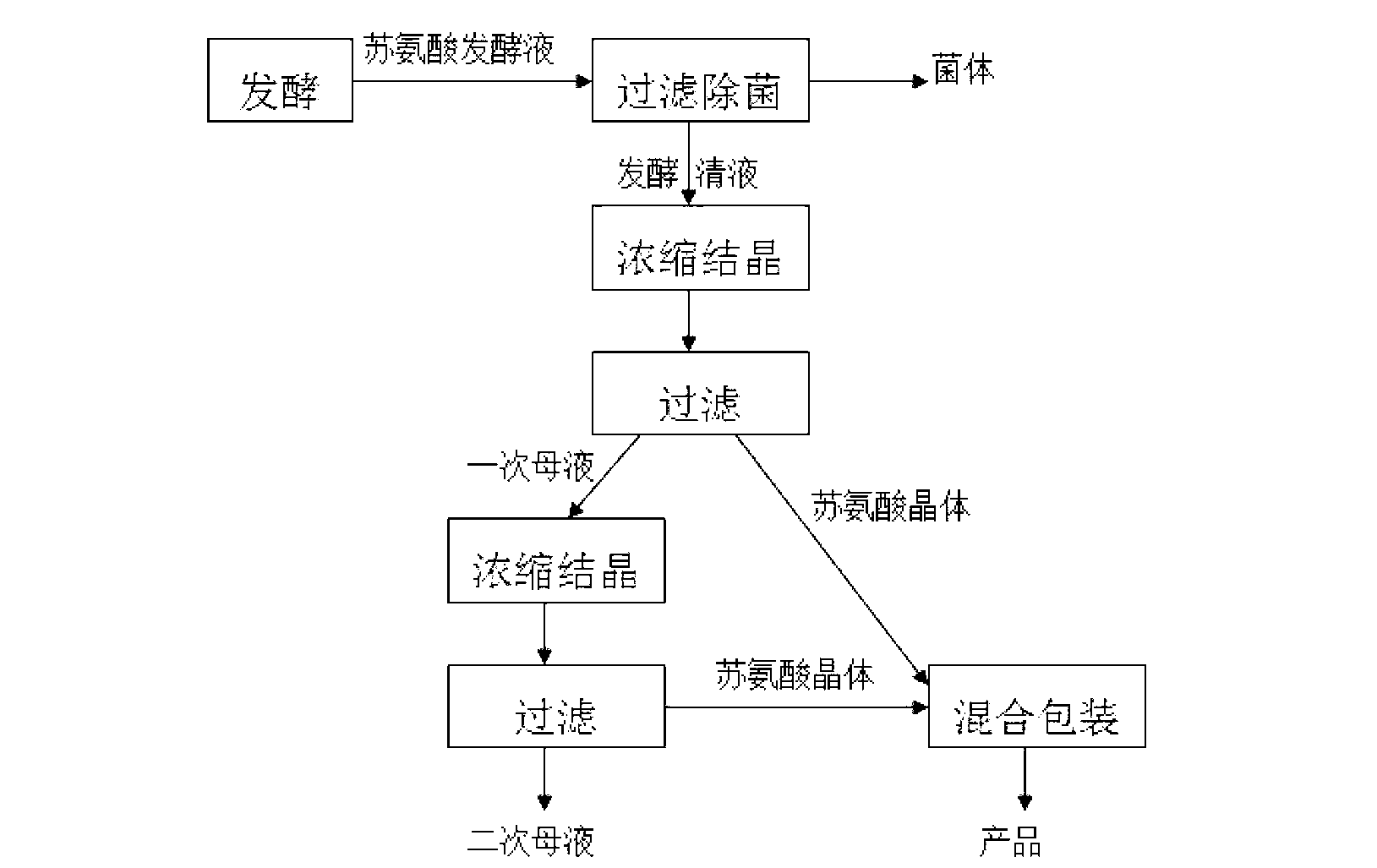

Method for recycling threonine from threonine crystallization mother liquid

A technology for crystallizing mother liquor and threonine, which is applied in the field of recycling threonine and can solve problems such as difficulty in utilization and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

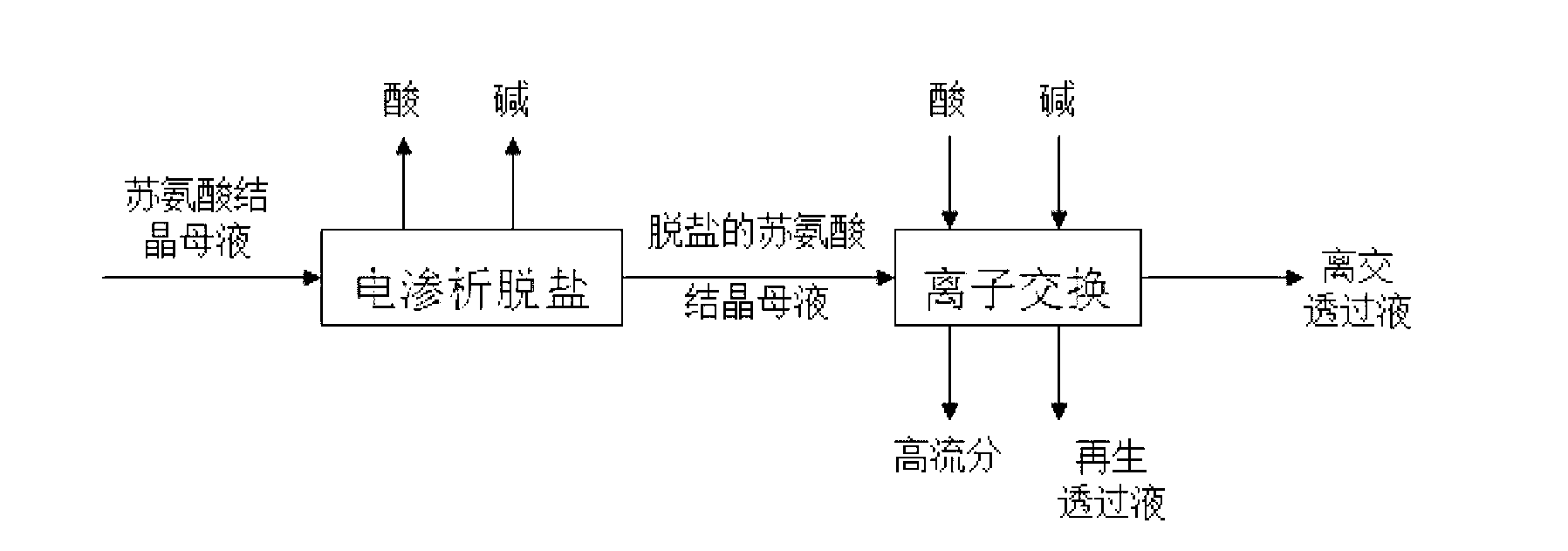

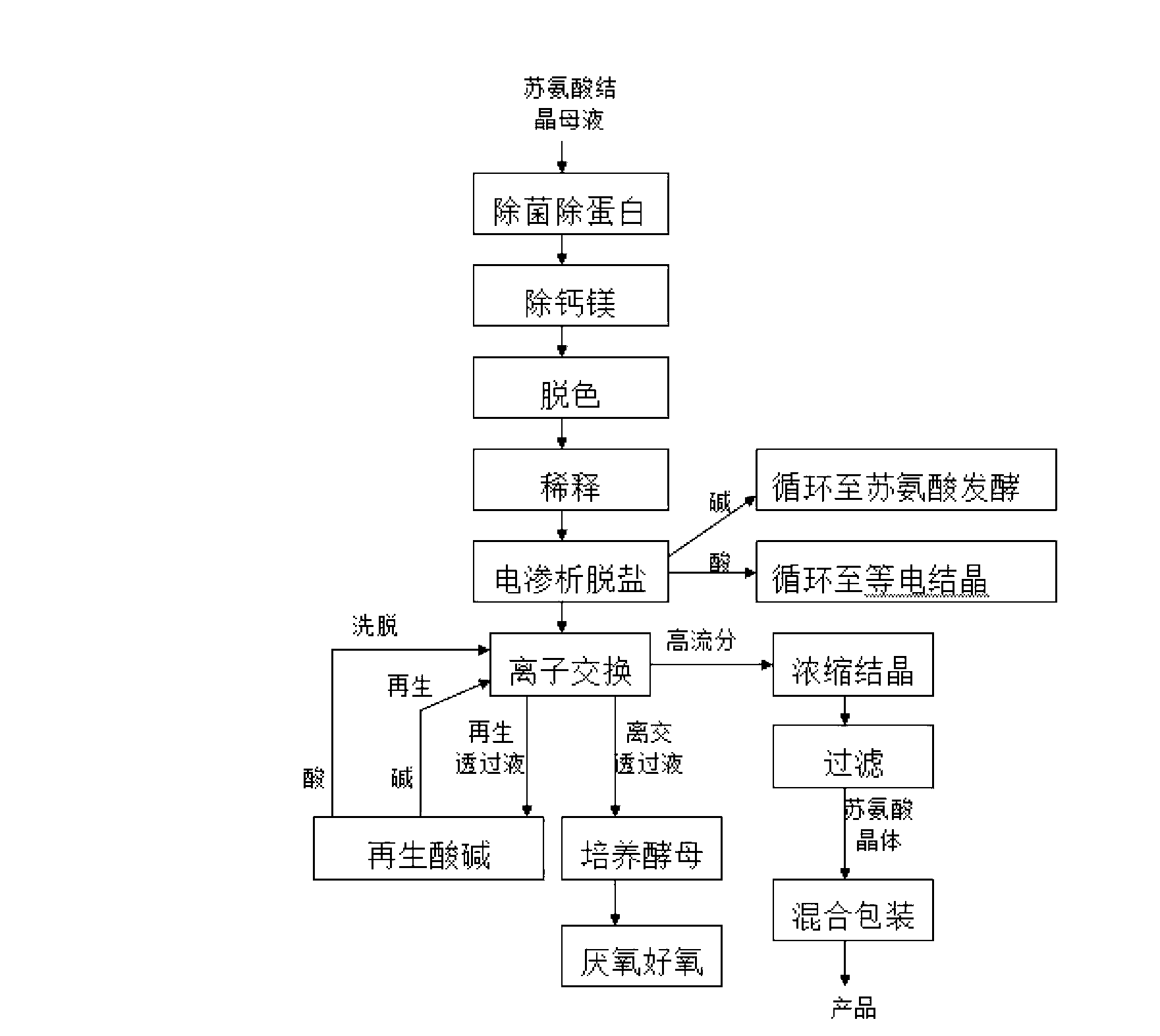

Method used

Image

Examples

Embodiment 1

[0089] Step 1: Removal of inorganic salts

[0090] The bipolar membrane electrodialyzer is a one-stage, two-chamber bipolar membrane electrodialyzer that operates independently, and the liquid flow direction in adjacent compartments adopts a parallel flow form. The area of the ion exchange membrane is 210mm×62mm, using BP-1 type bipolar membrane and JAM-10 type anion exchange membrane. The bipolar membrane and anion exchange membrane form a two-compartment membrane stack structure (such as Figure 4 Shown) Repeat for 5 pairs. A titanium-coated ruthenium electrode is used as the anode plate, and a stainless steel electrode is used as the cathode plate. Both the partition and the net are polypropylene materials, the partition is a non-loop partition, and the partition is a woven mesh type.

[0091] Pass 3.0L of threonine crystallization mother liquor of 17g / L ammonium sulfate and 90g / L threonine from China Ningxia Yipin Biotechnology Co., Ltd. into the salt chamber; the ini...

Embodiment 2

[0100] Step 1: Removal of inorganic salts

[0101] Bipolar membrane electrodialyzer is the same as embodiment 1.

[0102] Pass 2.26L of threonine crystallization mother liquor containing 13.2g / L ammonium chloride and 88g / L threonine into the salt chamber; It is 1.0L, 0.25mol / L sodium sulfate solution.

[0103] Control current density 30mA / cm during operation 2 , the linear velocity of liquid flow in each compartment is 3cm / s, and the temperature of feed liquid in each compartment is 30°C. Air is introduced into the feed tank of the salt chamber, and the regenerated ammonia is blown out with air at a blowing volume of 1.0 liters per minute. The ammonia blown out from the salt chamber is passed into a stainless steel coil placed in a -60°C refrigerator, and at the other end of the coil. Obtain about 9.6 grams of liquid ammonia in the receiving bottle. Measure the conductivity value of the feed liquid in the salt chamber every 10 minutes, and stop the electrodialysis operatio...

Embodiment 3

[0114] Step 1: Removal of inorganic salts

[0115] Bipolar membrane electrodialyzer is the same as embodiment 1.

[0116] Pass 2.92L of threonine crystallization mother liquor containing 19.6g / L ammonium nitrate and 89g / L threonine into the salt chamber; 1.0L, 0.25mol / L sodium sulfate solution.

[0117] Control current density 30mA / cm during operation 2 , the linear velocity of liquid flow in each compartment is 3cm / s, and the temperature of feed liquid in each compartment is 30°C. Air is introduced into the material tank of the salt chamber, and the regenerated ammonia is blown out with air at a blowing volume of 1.5 liters per minute. The ammonia blown out from the salt chamber is absorbed in another container with 0.2L of water to obtain ammonia water with a mass concentration of about 5%. . Measure the conductance value of the feed liquid in the salt chamber every 10 minutes, and stop the electrodialysis operation when the conductance value drops to 1.1 mS / cm. In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com