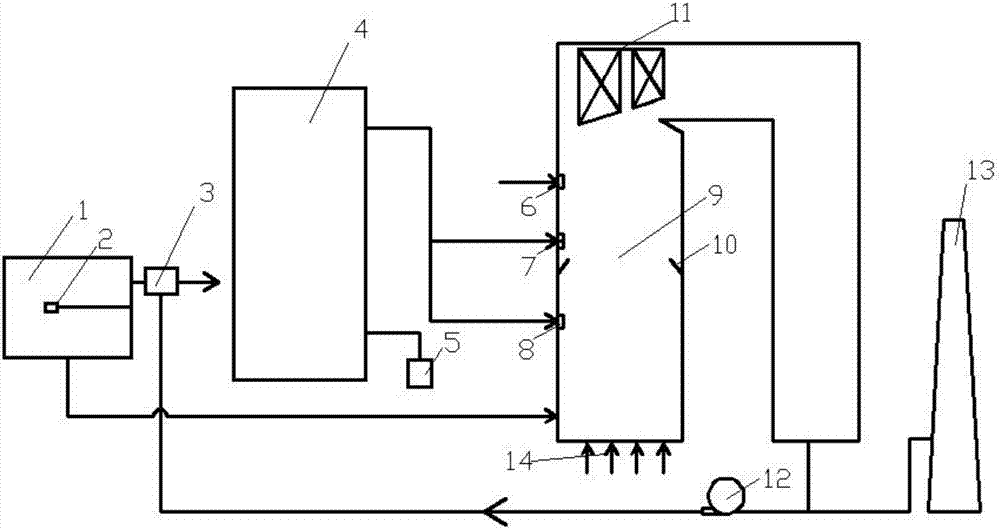

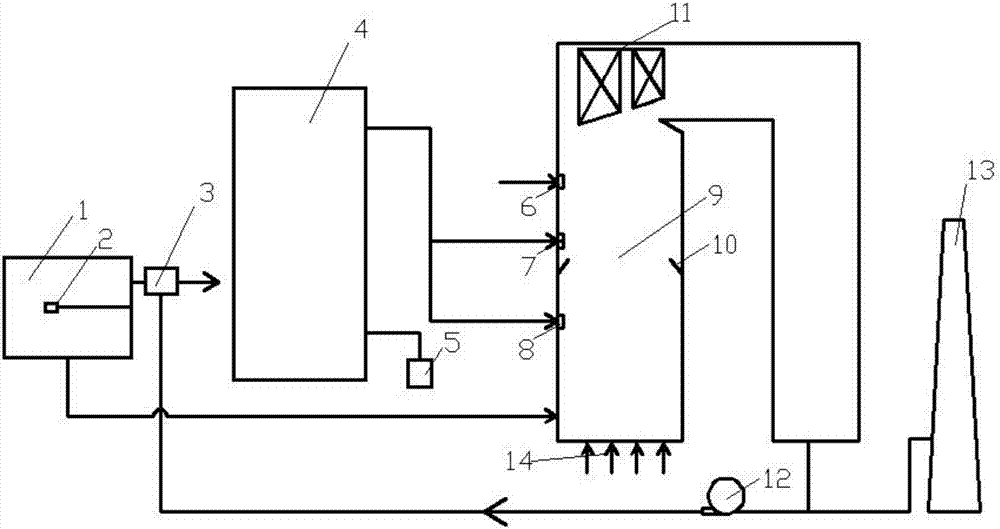

Device and method for co-producing carbon by coupling biomass direct combustion boiler with biomass gasification

A technology of biomass gas and biomass, which is applied in the direction of combustion method, transportation of non-flammable liquid/gas, combustion of block fuel and gaseous fuel, etc., which can solve the problem that the device cannot operate stably for a long time and the gasification of biomass is unstable , slagging and other issues, to achieve the effect of improving comprehensive utilization efficiency, realizing diversification and high value, and reducing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

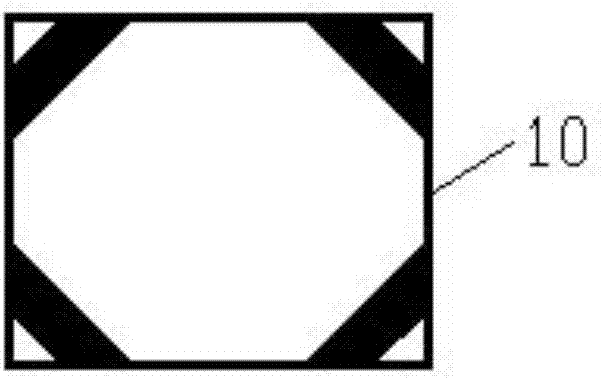

Method used

Image

Examples

Embodiment 1

[0035] Example 1: The raw materials are rice straw and bamboo chips, and the ratio of two kinds of biomass fixed carbon and ash is detected by raw material analyzer, wherein, the ratio of rice straw fixed carbon to ash is 0.91, and the ratio of bamboo chip fixed carbon to ash for 10.1. After screening, the rice straw is sent to the direct-fired boiler for combustion with the primary air with an air coefficient of 0.85. Bamboo slices are dried to 28% moisture after boiler exhaust gas drying, and then sent to the charcoal-gas cogeneration device for gasification, and bamboo charcoal about 15% of the raw material weight of bamboo chips is collected, and the charcoal-gas cogeneration device produces Biomass gas is sent to the direct-fired boiler for combustion. 60% of the biomass gas enters the furnace for combustion from the gas inlet in the lower part of the furnace, and 40% of the biomass gas enters the furnace for combustion from the gas inlet in the middle of the furnace. Th...

Embodiment 2

[0036] Embodiment 2: raw material is leaf, wheat straw, wood chip, utilizes raw material analyzer to detect the ratio of the fixed carbon of three kinds of biomass and ash content, wherein, the ratio of the fixed carbon of leaf, wheat straw, wood chip and ash content is respectively 0.8, 0.92, 9.5. After screening, the leaves and wheat stalks are fed into the direct-fired boiler and burned with primary air with an air coefficient of 0.9. After the wood chips are dried by the boiler exhaust gas, the water content is 25%, and then sent to the charcoal-gas cogeneration device for gasification, and wood chip charcoal about 14% of the raw material weight of bamboo chips is collected. The biomass produced by the charcoal-gas cogeneration device The gas is sent to the direct-fired boiler for combustion, 50% of the biomass gas enters the furnace for combustion from the gas inlet in the lower part of the furnace, and 50% of the biomass gas enters the furnace for combustion from the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com