Collagen polypeptide rich in glycine and formaldehyde scavenger prepared therefrom

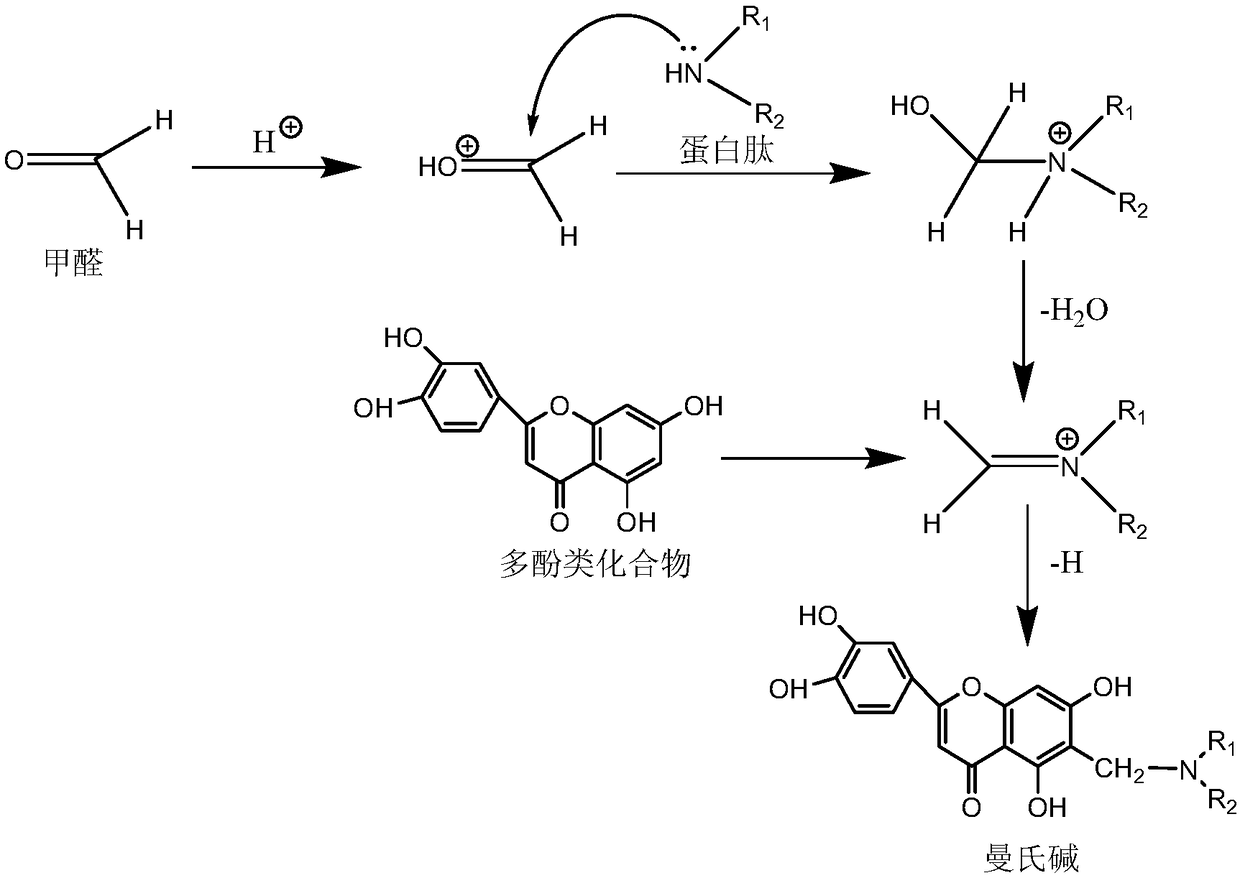

A technology of formaldehyde scavenger and collagen polypeptide, which is applied in the field of functional polypeptides, can solve problems such as potential safety hazards and limited effect of formaldehyde removal, and achieve the effects of production safety, short validity period, secondary pollution and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

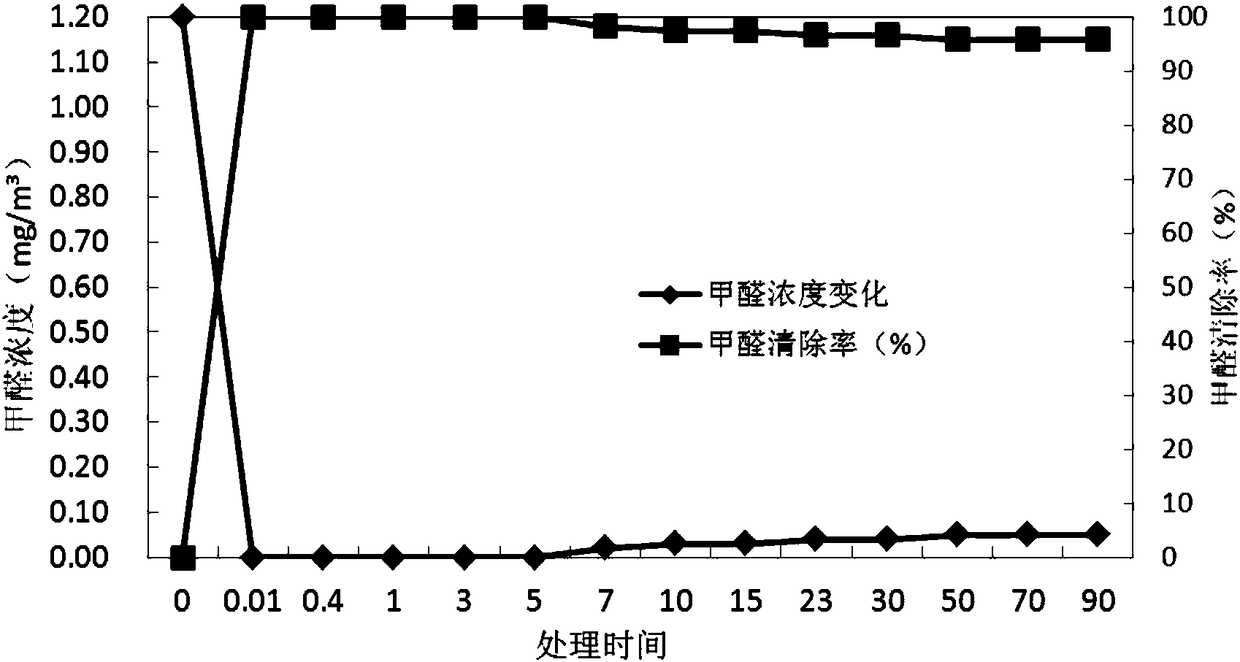

Examples

Embodiment 1

[0037] A preparation method of a glycine-rich collagen polypeptide in this embodiment, the specific preparation steps are as follows:

[0038] (1) After cleaning the tilapia skin with deionized water, cut it into pieces of 1 × 1cm size, then add the fish skin pieces into a 100mL conical flask, add 0.8mmol / L NaOH solution (fish skin: solution =1:7, g / mL), soak for 2 hours to remove impurity proteins, then rinse with deionized water repeatedly until neutral. Add 0.6wt.% HCl, soak for 1h (fish skin: solution = 1:7, g / mL), and then rinse repeatedly with deionized water until neutral to obtain washed fish skin.

[0039] (2) Add sterile water and mix with the washed fish skin, the ratio of material to liquid is 1:15 (g / mL), extract at a constant temperature of 40-60°C for 12 hours, and then centrifuge (10000r / min, 20min), the obtained supernatant Freeze-dried, that is, collagen.

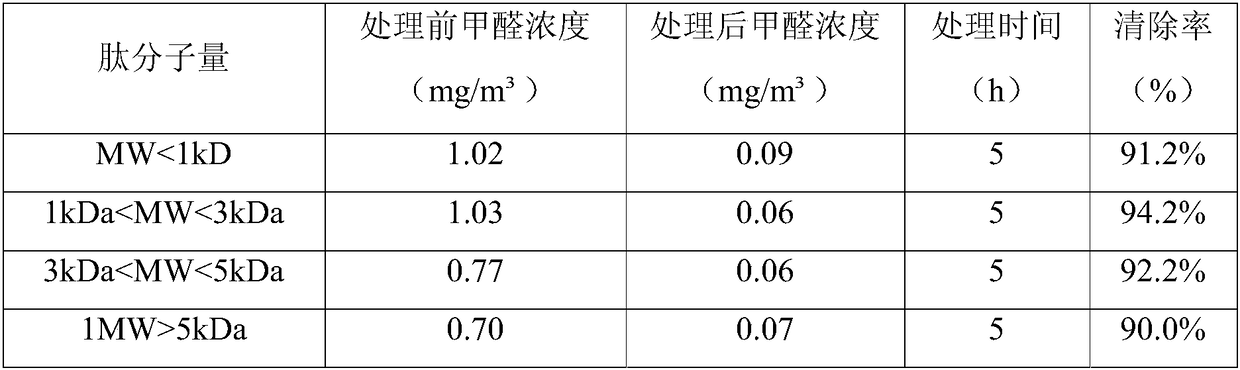

[0040] (3) Enzyme hydrolyze collagen with protease, collagen substrate concentration is 10wt.%, enzym...

Embodiment 2

[0051] A formaldehyde scavenger of the present embodiment is composed of: using deionized water as a solvent, containing 8wt.% collagen polypeptide with a molecular weight of 1kDa<MW<3kDa obtained in Example 1, and 2wt.% apple polyphenols (commercially purchased) .

Embodiment 3

[0053] A kind of formaldehyde scavenging agent of the present embodiment, its composition is: take deionized water as solvent, containing 10wt.% the collagen polypeptide that the molecular weight obtained in embodiment 1 is 1kDa<MW<3kDa, 2wt.% red grape polyphenol (commercially purchased ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com