A kind of underwater concrete repair reinforcement material and preparation method thereof

A technology of underwater concrete and reinforced materials, which is applied in the field of building materials to achieve the effects of convenient construction, strong stability and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

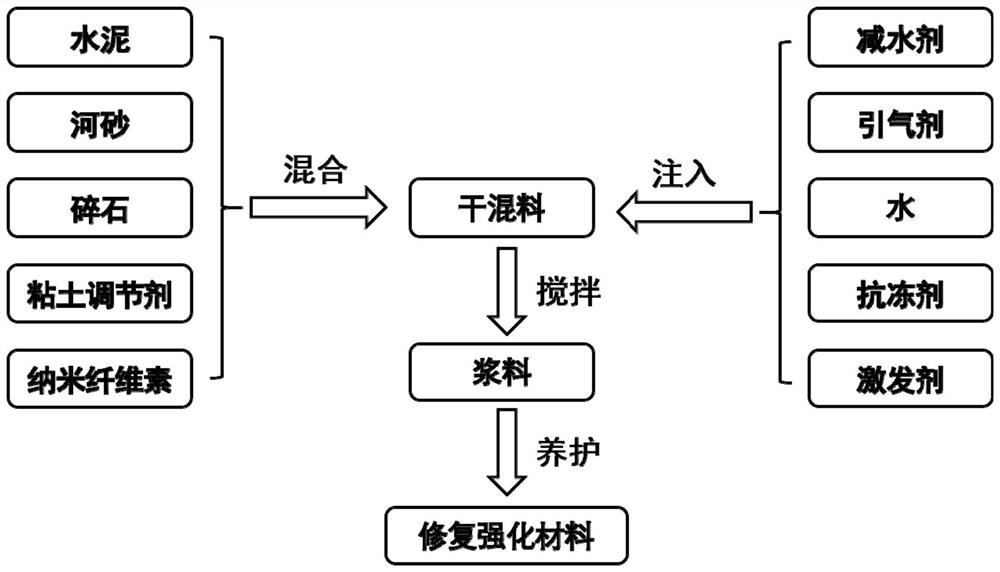

[0028] like figure 1 As shown, an underwater concrete repair strengthening material and a preparation method thereof include the following raw materials in terms of mass percentage: 10%-20% of cement, 10%-15% of fly ash, 15%-25% of river sand, and 15% of crushed stone -20%, clay conditioner 1%-3%, nanocellulose 1%-3%, polycarboxylate superplasticizer 0.3-0.5%, flocculant 0.3-0.5%, antifreeze agent 0.3-0.5%, air-entraining agent 0.3-0.5%, alkaline activator 3-5%, etc., the balance is water, and the sum of the mass percentages of the above components is 100%. The underwater concrete repair strengthening material prepared by the invention has good fluidity, cohesiveness and filling property, and can quickly set when being constructed in an underwater environment and ensure the strength and stability of concrete.

[0029] The present invention provides a kind of preparation method of underwater concrete repair reinforcing material, according to the above-mentioned mass percentage...

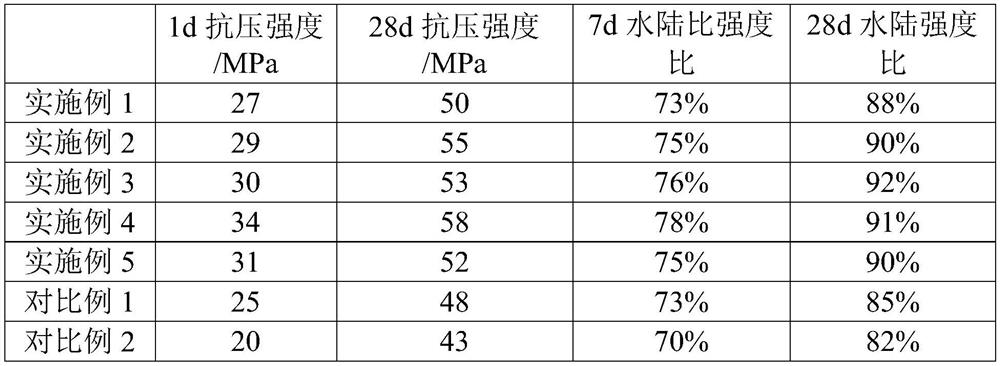

Embodiment 1

[0036] The following raw materials are included in terms of mass percentage: 10% cement, 15% fly ash, 25% river sand, 20% gravel, 1% clay conditioner, 1% nanocellulose, 0.3% polycarboxylate superplasticizer, flocculant 0.3%, antifreeze 0.3%, air-entraining agent 0.3-0.5%, alkaline activator 3%, etc., and the rest is water. The sum of the mass percentages of the above components is 100%.

[0037] Preparation process steps:

[0038] S1. Stir cement, fly ash, river sand, gravel, clay modifier, nanocellulose, etc. in a mixer for 1 to 2 minutes, and mix evenly to obtain a dry mix;

[0039] S2. Add water, water reducing agent, flocculant, antifreeze agent, air-entraining agent and alkaline activator to the dry mixture prepared in step S1, and mix and stir for 2 to 5 minutes until the mixture has good fluidity. Prepare the slurry;

[0040] S3, pouring the slurry prepared in step S2 into a mold, vibrating evenly, finishing and plastering the surface, and obtaining a green body after...

Embodiment 2

[0043]An underwater concrete repair strengthening material and a preparation method thereof, comprising the following raw materials in terms of mass percentages: 12% cement, 12% fly ash, 20% river sand, 15% crushed stone, 2% clay regulator, and 2% nanocellulose %, 0.3% polycarboxylate superplasticizer, 0.3% flocculant, 0.3% antifreeze, 0.3% air-entraining agent, 4% alkaline activator, etc., and the rest is water. The sum of the mass percentages of the above components is 100%.

[0044] The preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com