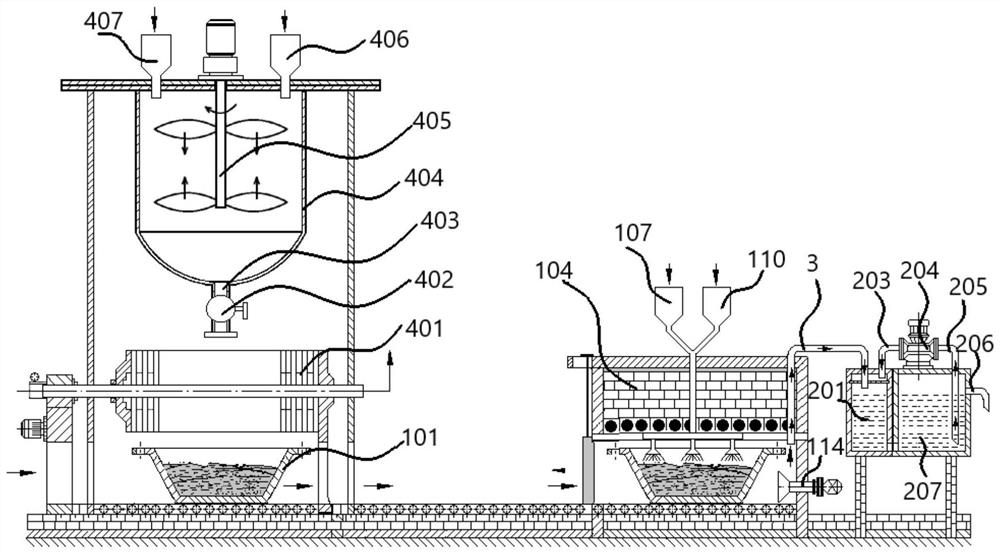

Integrated production line and method for removing chloride ions and regenerating dechlorinating agent from dechlorination residues

A chloride ion and dechlorination agent technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of complex dechlorination process, high cost, large amount of waste water, etc., to simplify the dechlorination process, reduce Process cost and effect of reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

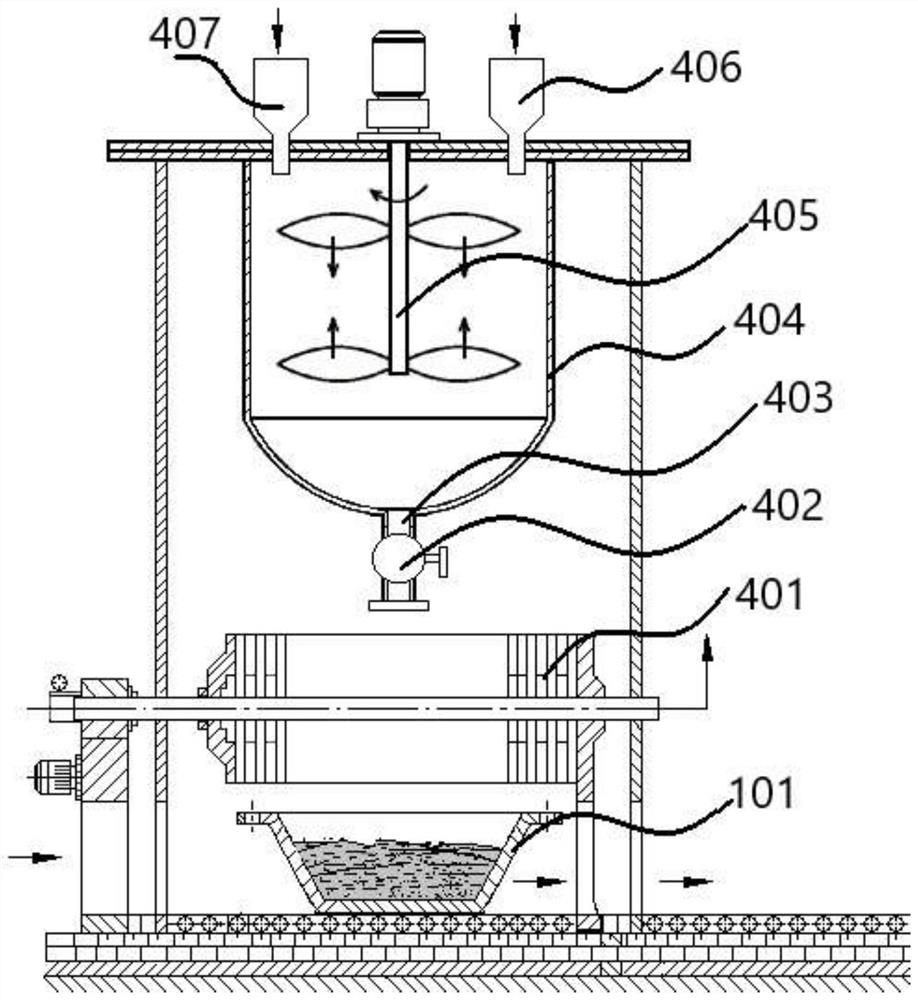

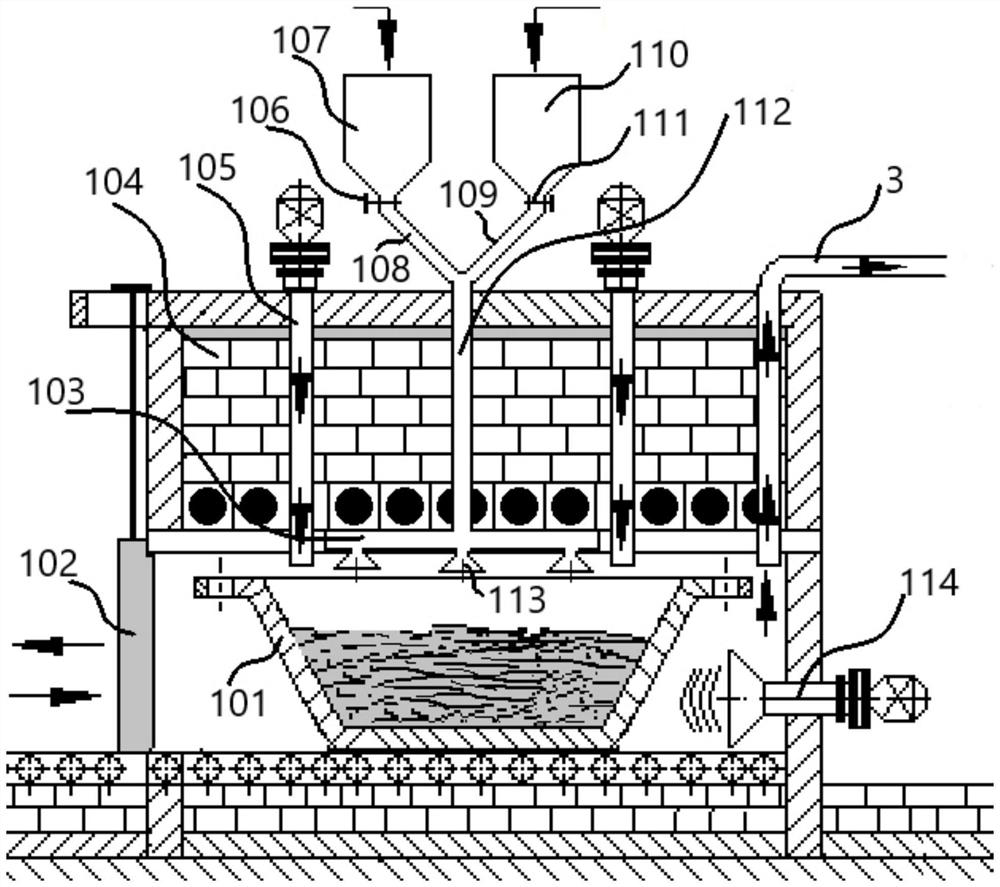

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1, the method for chlorine ion removal and chlorine removal slag regeneration chlorine removal agent for chlorine ion in power plant wastewater

[0058] In this embodiment, the dilute sulfuric acid solution of stannous sulfate is used as the chlorine removal agent, wherein the concentration of tin ions is 200g / L, and the concentration of sulfuric acid is 100g / L; The pH value of the wastewater is 9-10, and the chloride ion concentration in the wastewater is 800mg / L.

[0059] The specific implementation of this embodiment includes the following steps:

[0060] The first step is to obtain chlorine removal residue.

[0061] Measure the dechlorination agent according to 1.5% (volume ratio) of the total amount of wastewater to be treated, and dechlorinate the wastewater under the condition of constant stirring, which can reduce the chlorine ions in the wastewater to below 100mg / L. The dechlorination principle is:

[0062] sn 2+ +Cl - +H 2 O=Sn(OH)Cl↓+H +

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com