Preparation method of calcium ferrite

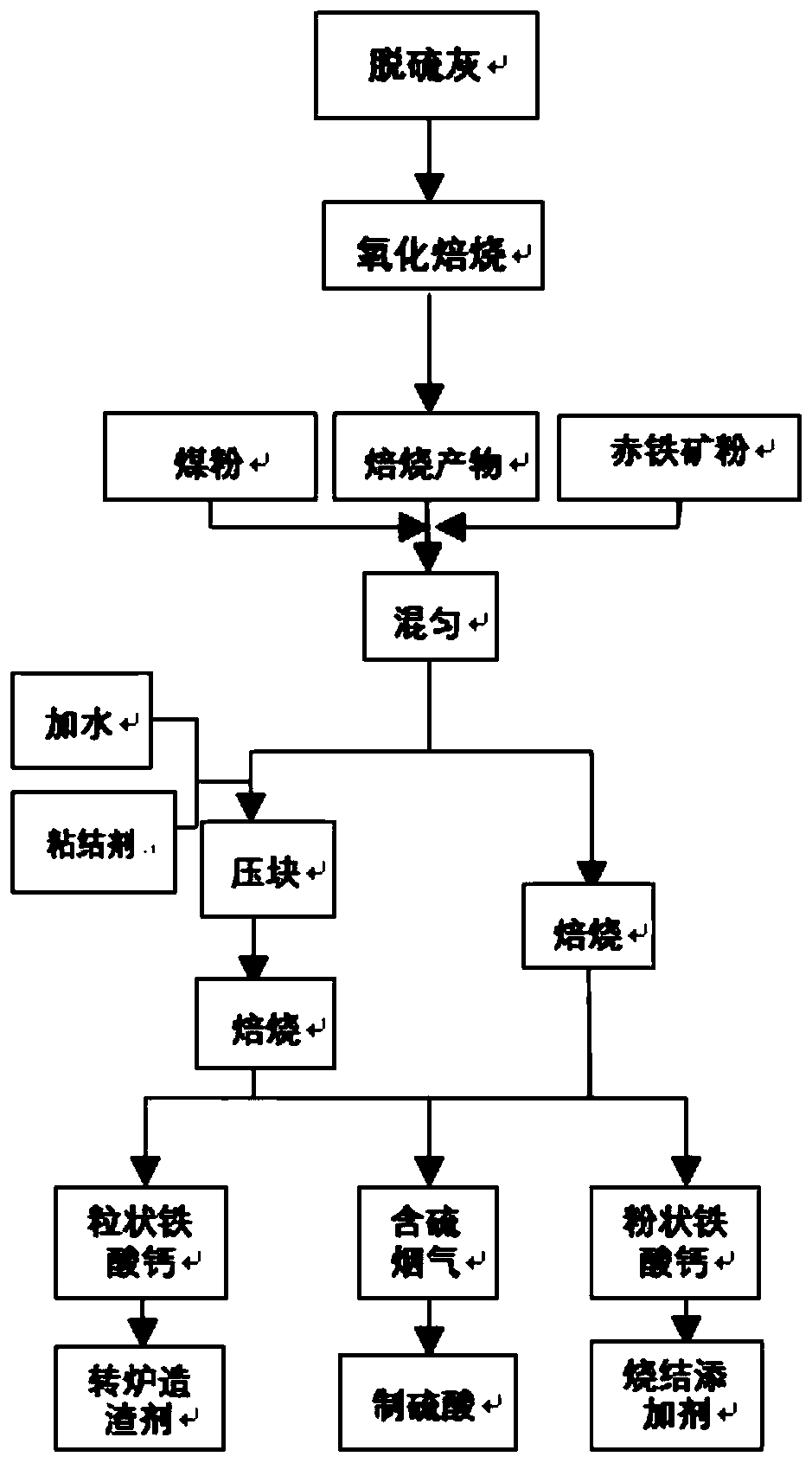

A technology of calcium ferrite and iron ore powder, applied in the field of metallurgy, can solve the problems of waste of resources, environmental pollution, etc., and achieve the effects of speeding up slagging and dephosphorization, high product value and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 calcium ferrite

[0026] (1) Oxidation Roasting Fresh desulfurized ash was taken and roasted in an air atmosphere at a roasting temperature of 600°C for a roasting time of 20 minutes. After the roasting was complete, the product was cooled.

[0027] (2) Mixing

[0028] Add bituminous coal and hematite to the product obtained in the previous step and mix, S element in desulfurization ash: Fe element in iron ore powder: C element in carbon powder = 1:0.5-2:0-2, stir and mix for 30 minutes, made into mixed powder;

[0029] (3) Briquetting

[0030] The powder after mixing is used briquetting machine, and briquetting pressure is 20MPa, and sample diameter is 3cm, and height is 2cm, and weight is the block shape of 3g.

[0031] (4) Heating and roasting The mixed powder obtained in step (2) or the block sample obtained in step (3) is heated and roasted in an electric rotary kiln, and the specific steps are as follows:

[0032] S1 opens the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com