Method for recycling and purifying elemental sulfur from flue gas biological desulphurization sludge

A technology of biological desulfurization and elemental sulfur, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of no good method for biological desulfurization sludge treatment, no recovery and purification of elemental sulfur, etc. The effect of resource utilization, convenient production and reasonable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

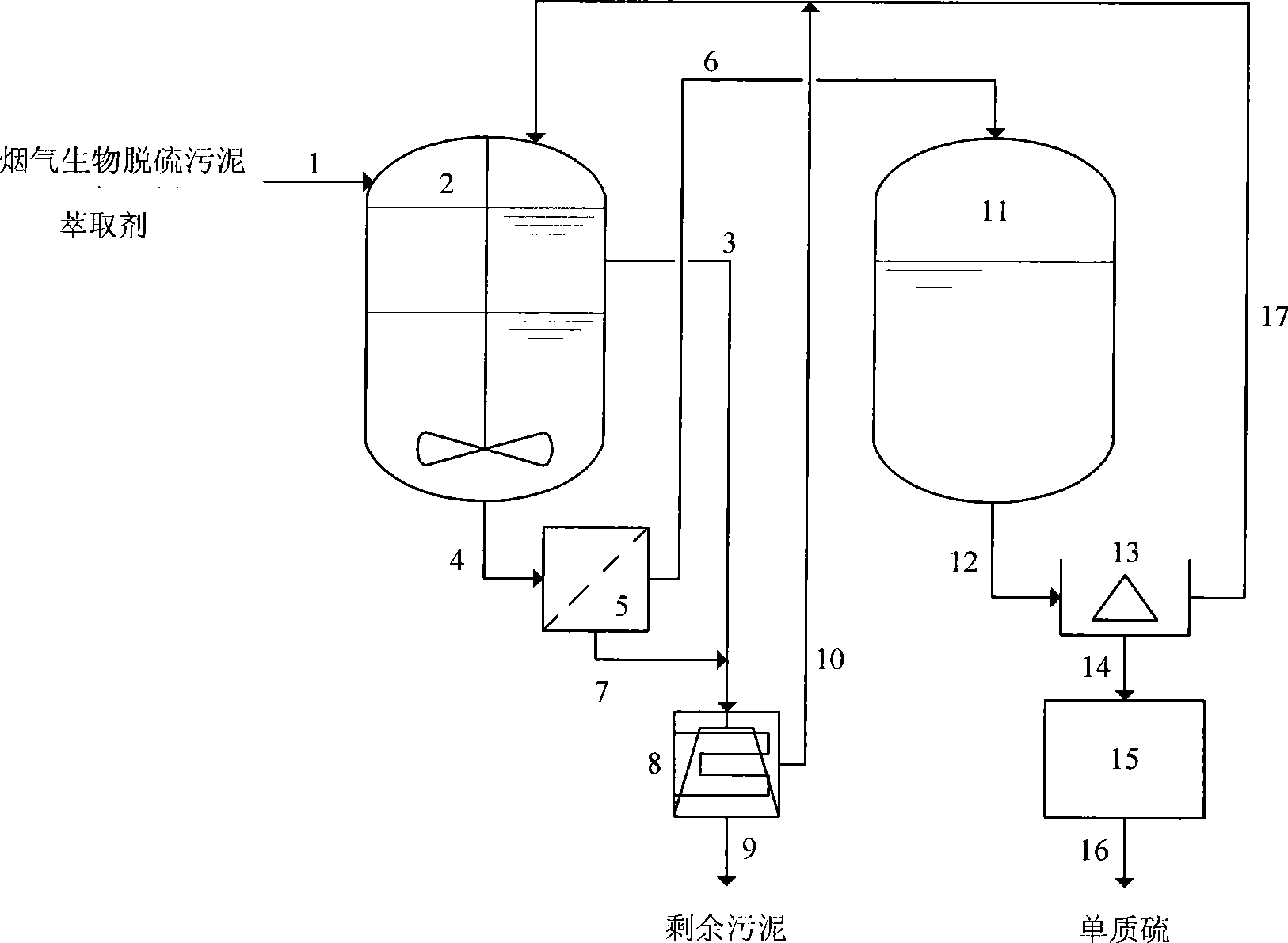

[0045] Such as figure 1 As shown, the mud cake with a water content of 60.3% was mixed with tetrachlorethylene at a mass ratio of 1:12, the mixture was heated to 80°C, and fully stirred for 10 minutes for extraction, and then the mixture was left to stand for 10 minutes to make the sulfur The perchlorethylene and the sludge-containing aqueous phase are separated. In this example, a heated centrifuge is used to centrifuge the sulfur-containing tetrachlorethylene solution at 80° C. to separate the sulfur-containing tetrachlorethylene solution and a small amount of solid sludge impurities contained therein. The water phase and sludge impurities are recovered by rapid flash evaporation to recover tetrachlorethylene.

[0046]The tetrachlorethylene solution from which impurities have been removed is cooled to 25°C. Since the solubility of elemental sulfur in tetrachlorethylene decreases significantly with the decrease of temperature, the elemental sulfur dissolved in tetrachlorethy...

Embodiment 2

[0048] Such as figure 1 As shown, the flue gas biological desulfurization sludge is centrifuged or plate-and-frame press-filtered to obtain a sulfur-containing mud cake with a moisture content of 60-80%; then the further dried mud cake (moisture content 90%, and the purity of elemental sulfur is >98%, which can meet the requirements of elemental sulfuric acid and other industries for elemental sulfur raw materials.

Embodiment 3

[0050] Process flow such as figure 1 As shown, the basic process is the same as in Example 1, except that the extractant used is diphenyl disulfide, the mass ratio of mud cake to extractant is 1:10, the extraction temperature is 80°C, and the extraction time is 30 minutes. The cooling crystallization temperature is 20°C.

[0051] In this example, the recovery rate of elemental sulfur is >90%, and the purity of elemental sulfur is >98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com