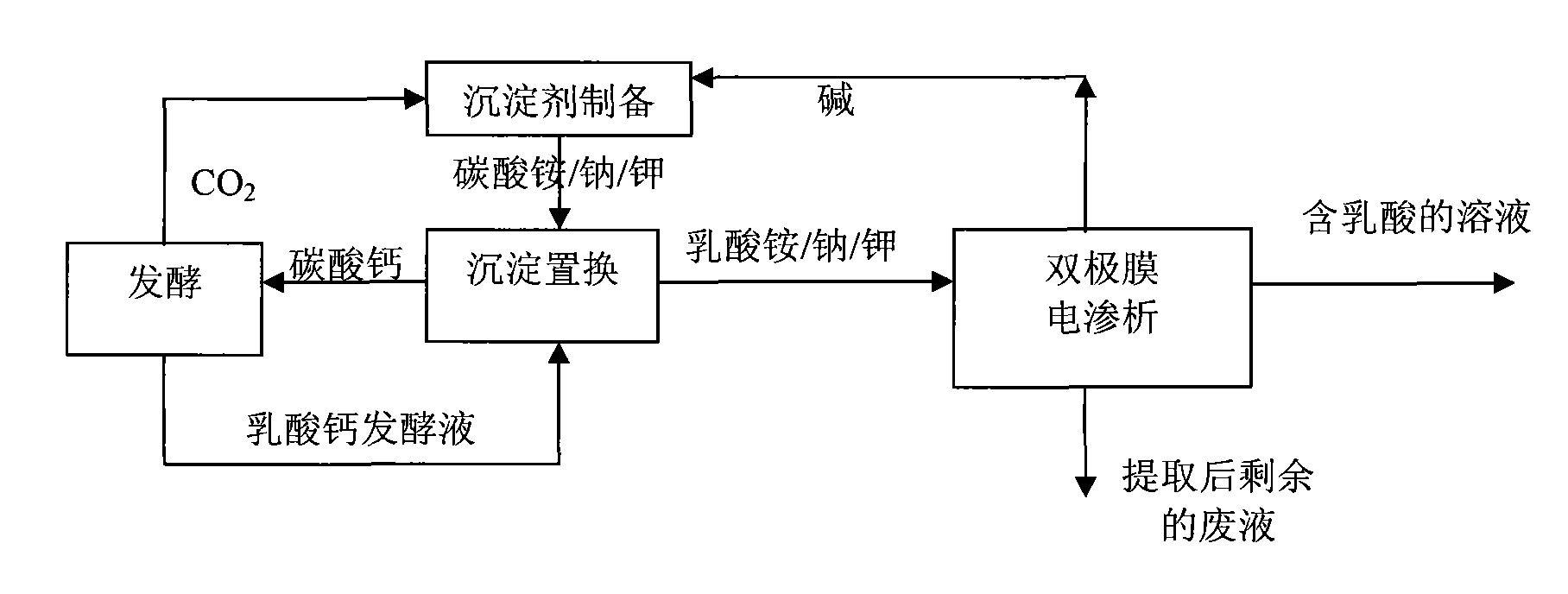

Calcium salt method-electrodialysis coupling technology-based lactic acid cleaner production method

A technology of clean production and electrodialysis, applied in the direction of microorganism-based methods, biochemical equipment and methods, separation/purification of carboxylic acid compounds, etc., to achieve the effect of closed-circuit recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Step 1) Preparation of lactic acid fermentation broth:

[0083] The microorganism strain used was Lactobacillus paracasei (Lactobacillus paracasei, NERCB0401 (Industrial Microorganisms, 2007, Vol. 37, Issue 4, 1-5)), and the above-mentioned strains were used for fed-batch fermentation. There are two kinds of media used:

[0084] (1) Seed culture medium: glucose 40g / L, peptone 10g / L, beef extract 10g / L, yeast powder 5g / L, diammonium hydrogen citrate 2g / L, sodium acetate 5g / L, dipotassium hydrogen phosphate 2g / L, Tween 801mL / L, magnesium sulfate 0.6g / L, manganese sulfate 0.25g / L.

[0085] (2) Fermentation medium: glucose 60g / L, peptone 10g / L, beef extract 6g / L, yeast powder 10g / L, sodium chloride 0.03g / L, ferrous sulfate 0.01g / L, sodium acetate 4g / L , Citrate diamine 2g / L, potassium dihydrogen phosphate 2g / L, Tween-801mL / L, magnesium sulfate 0.2g / L, manganese sulfate 0.2g / L.

[0086] Two kinds of media were prepared according to the above formula, sterilized at 121°C for 15 mi...

Embodiment 2

[0094] Step 1) Preparation of lactic acid fermentation broth: same as step 1) of Example 1, to obtain about 3.4 liters of calcium lactate-containing fermentation broth with a lactic acid concentration of 160 g / L.

[0095] Sterilization: pass the fermentation broth obtained in step 1) through a 0.2 μm microfiltration membrane of Tianjin Membrane Engineering Technology Co., Ltd. to obtain 3 liters of fermentation broth with a lactic acid concentration of about 160 g / L.

[0096] Step 2) Precipitation replacement: Add 5.1 mol / L of sodium carbonate solution to the sterilized fermentation broth with a volume ratio of about 5:1, stir and mix thoroughly to make the reaction complete; filter to obtain solid calcium carbonate and lactic acid concentration of 134g / The fermentation broth containing sodium lactate is about 3.5L.

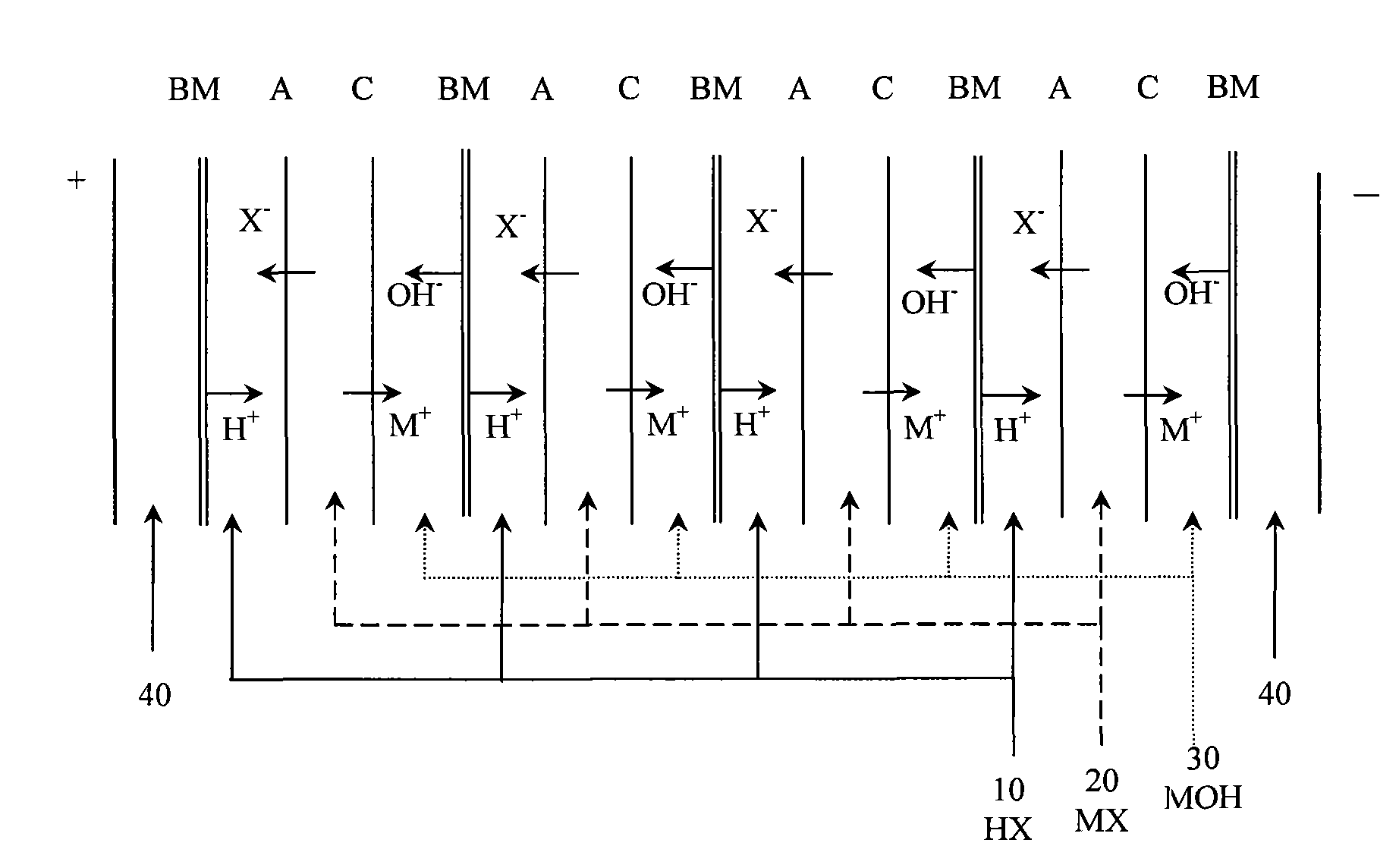

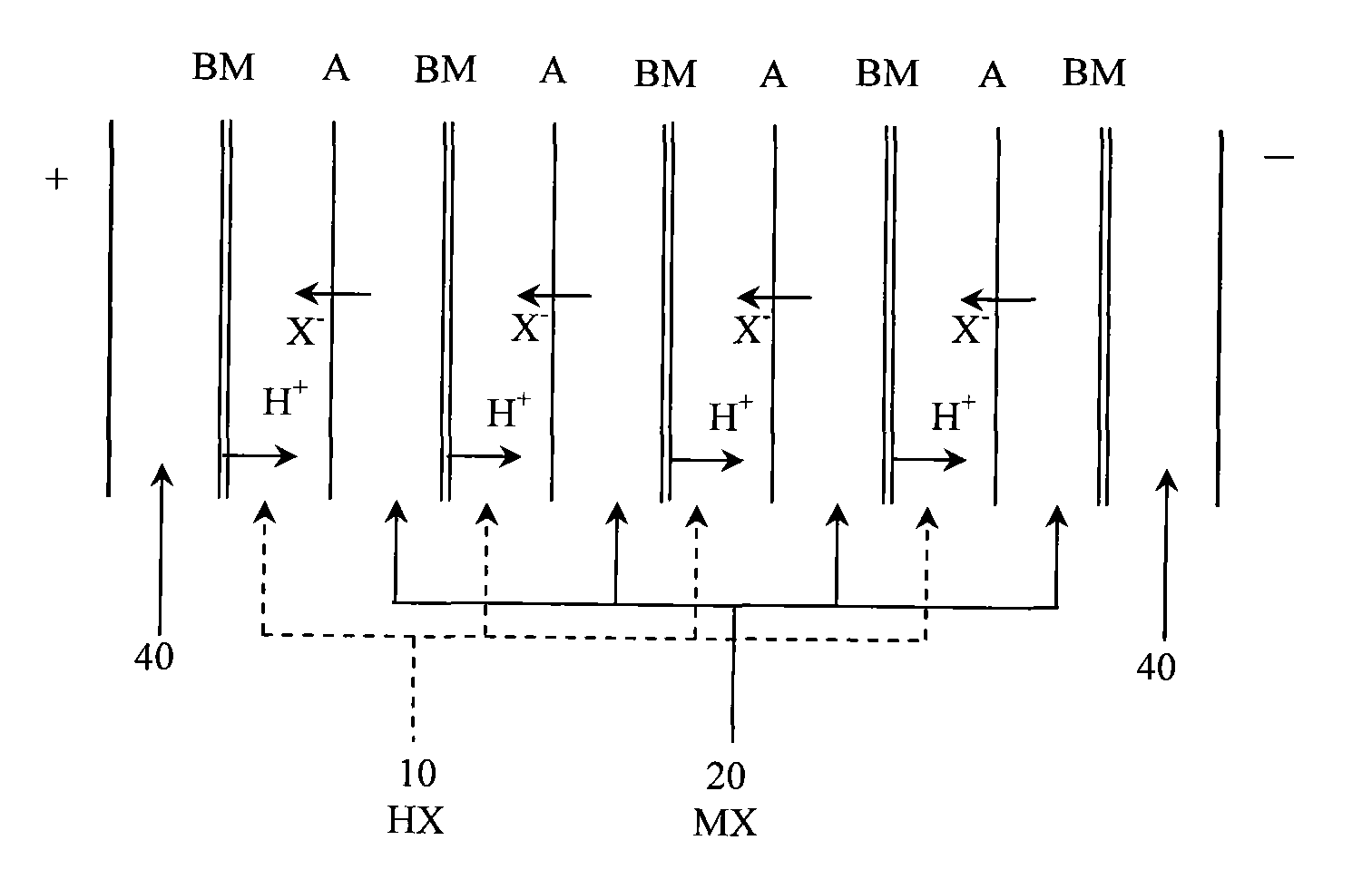

[0097] Step 3) Bipolar membrane electrodialysis regenerates acid and alkali from fermentation broth containing sodium lactate:

[0098] The bipolar membrane electrodial...

Embodiment 3

[0101] Step 1) Preparation of lactic acid fermentation broth: same as step 1) of Example 1, to obtain about 3.4 liters of calcium lactate-containing fermentation broth with a lactic acid concentration of 164 g / L.

[0102] Sterilization: Pass the fermentation broth obtained in step 1) through a 0.2 μm microfiltration membrane of Tianjin Membrane Engineering Technology Co., Ltd. to obtain about 3.0 liters of fermentation broth with a lactic acid concentration of about 164 g / L.

[0103] Step 2) Precipitation replacement: Add 5.0 mol / L potassium carbonate solution to the sterilized fermentation broth with a volume ratio of about 4.98:1, stir and mix thoroughly to make the reaction complete; filter to obtain solid calcium carbonate and lactic acid concentration of 137g / The fermentation broth containing potassium lactate of L is about 3.6L.

[0104] Step 3) Bipolar membrane electrodialysis regenerates acid and alkali from fermentation broth containing potassium lactate:

[0105] The bipola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com