Enteromorpha wood and plastic floor and preparation method thereof

A technology of wood-plastic flooring and enteromorpha, applied in the field of wood-plastic flooring, can solve the problems of large selection and high production costs, and achieve the effects of protecting the environment, reducing production costs, and protecting the marine ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

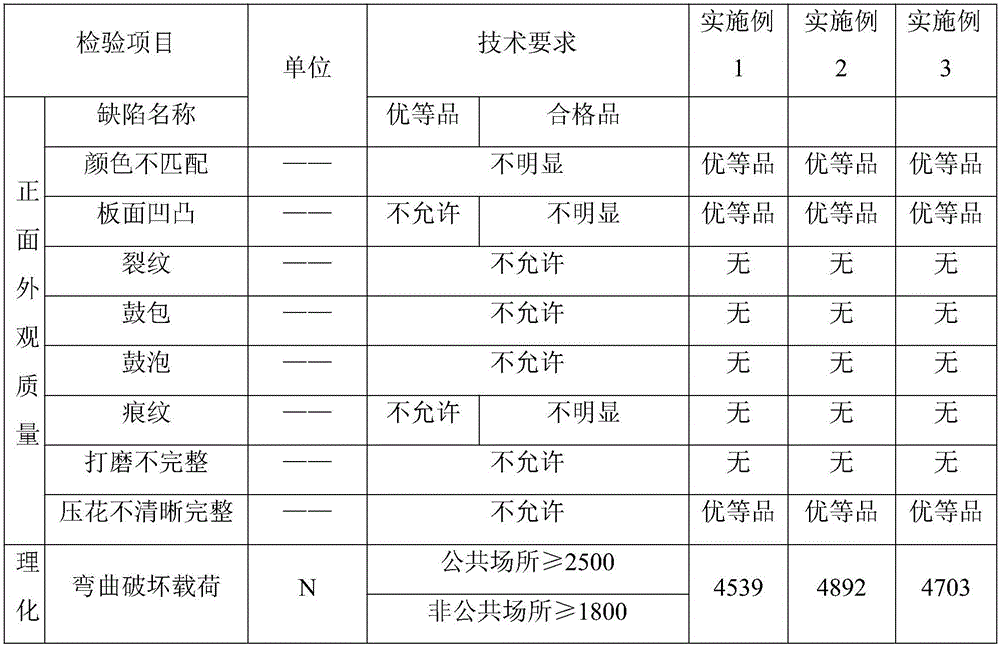

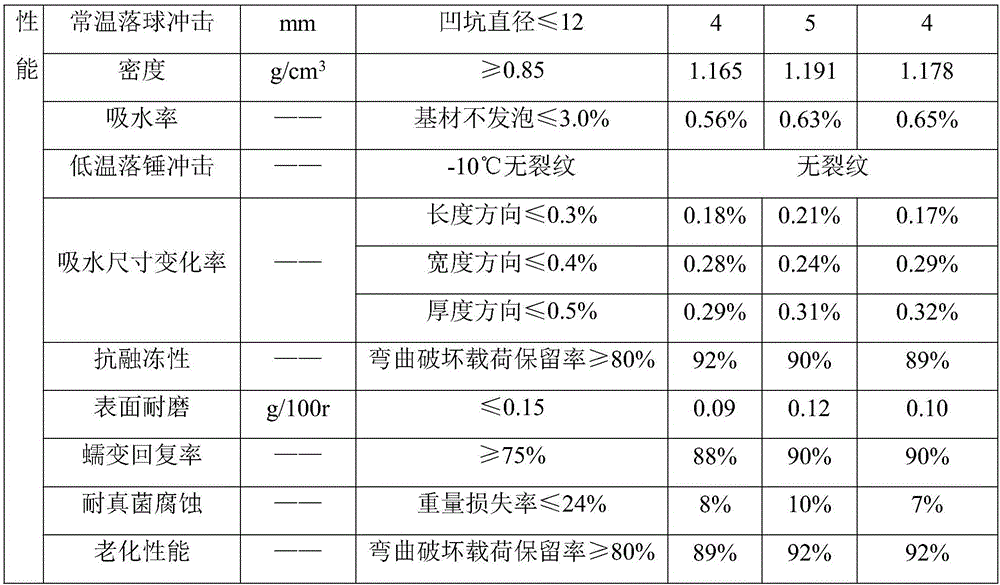

Examples

Embodiment 1

[0028] An Enteromorpha wood-plastic floor, the components and parts by weight of the Enteromorpha wood-plastic floor are: 30 parts of Enteromorpha dry powder, 10 parts of tea meal, 10 parts of straw powder, 10 parts of shell powder, and 30 parts of recycled plastic , 10 parts of polyvinyl chloride, 0.5 parts of titanate coupling agent, 0.3 parts of silane coupling agent, 5 parts of medical stone, 0.4 parts of AC foaming agent, 0.3 parts of toughening agent, 0.3 parts of stabilizer, propionic acid Calcium 1 part, zinc stearate 1 part.

[0029] The preparation method of the enteromorpha wood-plastic floor comprises the following steps:

[0030] 1) After drying the tea meal, grind and pulverize to obtain the tea meal powder, which is set aside;

[0031] 2) After the medical stone is mixed and coarsely crushed, heated at high temperature for 1 hour, then placed in cold water to quench, and then crushed, passed through a 200-mesh sieve to obtain medical stone powder;

[0032] 3) ...

Embodiment 2

[0036] An Enteromorpha wood-plastic floor, the components and parts by weight of the Enteromorpha wood-plastic floor are: 50 parts of Enteromorpha dry powder, 20 parts of tea meal, 20 parts of straw powder, 20 parts of shell powder, and 50 parts of recycled plastic , 20 parts of polyvinyl chloride, 1.5 parts of titanate coupling agent, 0.5 parts of silane coupling agent, 15 parts of medical stone, 0.8 parts of AC foaming agent, 0.5 parts of toughening agent, 0.5 parts of stabilizer, propionic acid 2 parts of calcium, 3 parts of zinc stearate.

[0037] The preparation method of the Hutai wood-plastic floor of this embodiment is the same as that of the embodiment.

Embodiment 3

[0039] An Enteromorpha wood-plastic floor, the components and parts by weight of the Enteromorpha wood-plastic floor are: 40 parts of Enteromorpha dry powder, 15 parts of tea meal, 15 parts of straw powder, 15 parts of shell powder, and 40 parts of recycled plastic 15 parts of polyvinyl chloride, 1 part of titanate coupling agent, 0.4 parts of silane coupling agent, 10 parts of medical stone, 0.6 parts of AC foaming agent, 0.4 parts of toughening agent, 0.4 parts of stabilizer, propionic acid 1.5 parts of calcium, 2 parts of zinc stearate.

[0040] The preparation method of the Hutai wood-plastic floor of this embodiment is the same as that of the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com