Multi-element solid waste recycled aggregate and preparation process thereof

A recycled aggregate and preparation technology, which is applied in the field of building materials, can solve the problems of poor durability and low strength, and achieve the effects of improved bonding performance, large specific surface area, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

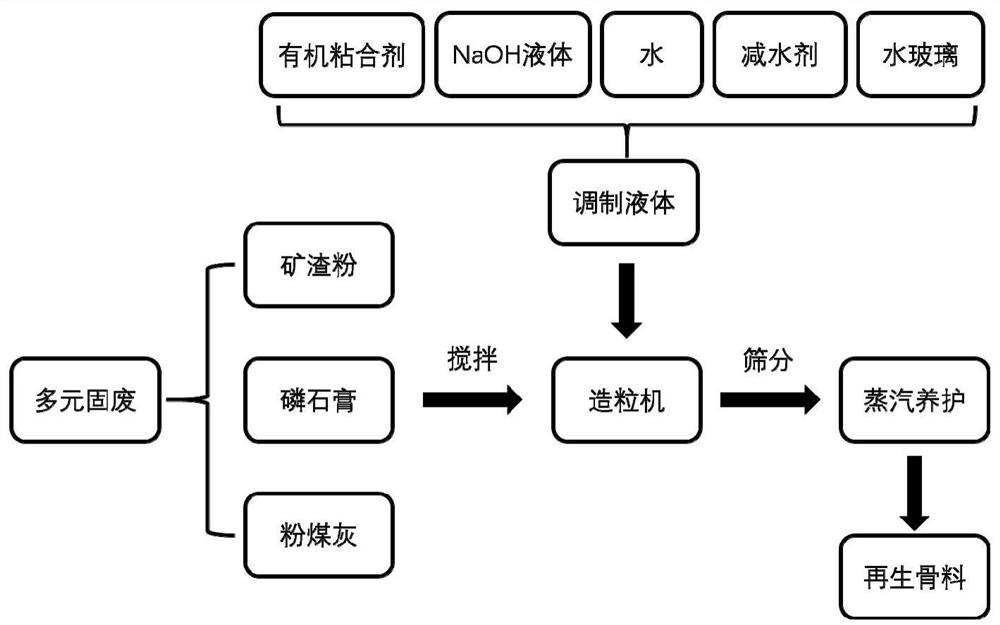

[0030] The invention provides a preparation process of multi-component solid waste regenerated aggregate, the preparation process flow chart is as follows figure 1 As shown, by the above parts by weight, comprising the following steps,

[0031] Weigh phosphogypsum, fly ash, and slag powder, stir in a mixer, and mix evenly to obtain a dry mixture;

[0032] Stir the water reducer, NaOH aqueous solution, water glass solution, water, and organic binder in a container evenly, and mix thoroughly to obtain a mixed liquid;

[0033] Put the dry mixture into the disc granulator, adjust the speed of the disc granulator and the water spray mode, spray the mixed liquid into the disc granulator, wet the dry mixture, and let it pass through the disc granulator. Dry blends form spherical particles;

[0034] Spherical particles are taken out, and 90-100% of the residue is sieved through the three-stage sieve tray to obtain raw materials with a pore size of 4.75mm;

[0035] Further sieve 95-...

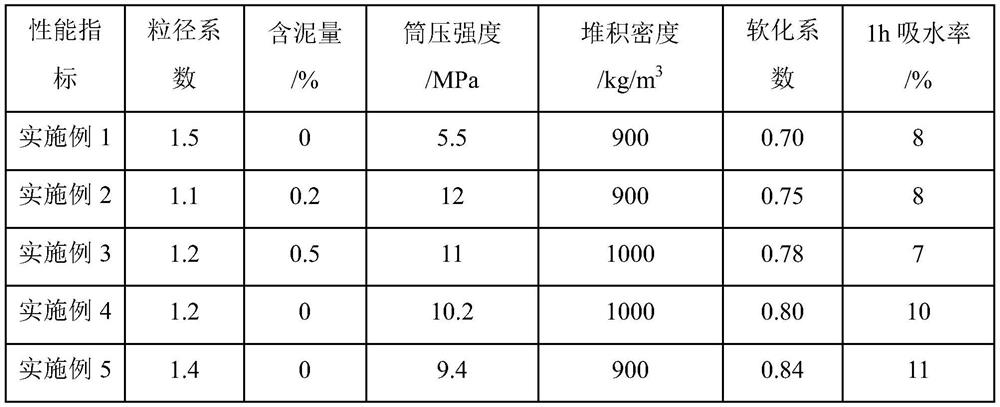

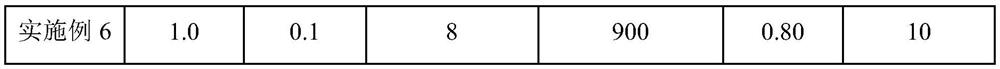

Embodiment 1

[0041] A multi-component solid waste regenerated aggregate formula, which is composed of the following raw materials in parts by weight: 30 parts of phosphogypsum, 20 parts of fly ash, 20 parts of slag powder, 0.5 parts of water reducing agent, and 40% NaOH aqueous solution with a mass fraction of 2 parts, 2 parts of water glass solution with a mass fraction of 10%, 15 parts of water and 5 parts of silicone.

[0042] The above-mentioned preparation process of a multi-component solid waste recycled aggregate comprises the following steps,

[0043] S1. According to the weight ratio of raw materials, weigh phosphogypsum, fly ash, and slag powder and stir them in the mixer, and mix them evenly to obtain a dry mixture;

[0044] S2. Stir water, water reducing agent, NaOH aqueous solution with a mass fraction of 40%, water glass solution with a mass fraction of 10%, and silicone in a capacity bucket, and mix thoroughly to obtain a mixed liquid;

[0045]S3, put the dry blend prepared...

Embodiment 2

[0051] A multi-component solid waste regenerated aggregate formula, which is composed of the following raw materials in parts by weight: 35 parts of phosphogypsum, 23 parts of fly ash, 23 parts of slag powder, 0.7 parts of water reducing agent, and 2.3 parts of NaOH aqueous solution with a mass fraction of 40%. 2.3 parts of water glass solution with a mass fraction of 10%, 20 parts of water and 8 parts of polyurethane.

[0052] The above-mentioned preparation process of a multi-component solid waste recycled aggregate comprises the following steps,

[0053] S1. According to the weight ratio of raw materials, weigh phosphogypsum, fly ash, and slag powder and stir them in the mixer, and mix them evenly to obtain a dry mixture;

[0054] S2. Stir water, water reducing agent, NaOH aqueous solution with a mass fraction of 40%, water glass solution with a mass fraction of 10%, and polyurethane in a capacity bucket, and mix thoroughly to obtain a mixed liquid;

[0055] S3, put the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com