Recycling method for copper smelting slag

A recovery method and technology of copper smelting slag, which is applied in the field of metallurgical engineering, can solve the problems of reducing the quality of copper matte, increasing the pressure of impurity removal, waste of resources, etc., achieving high recovery rate, avoiding pollution, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

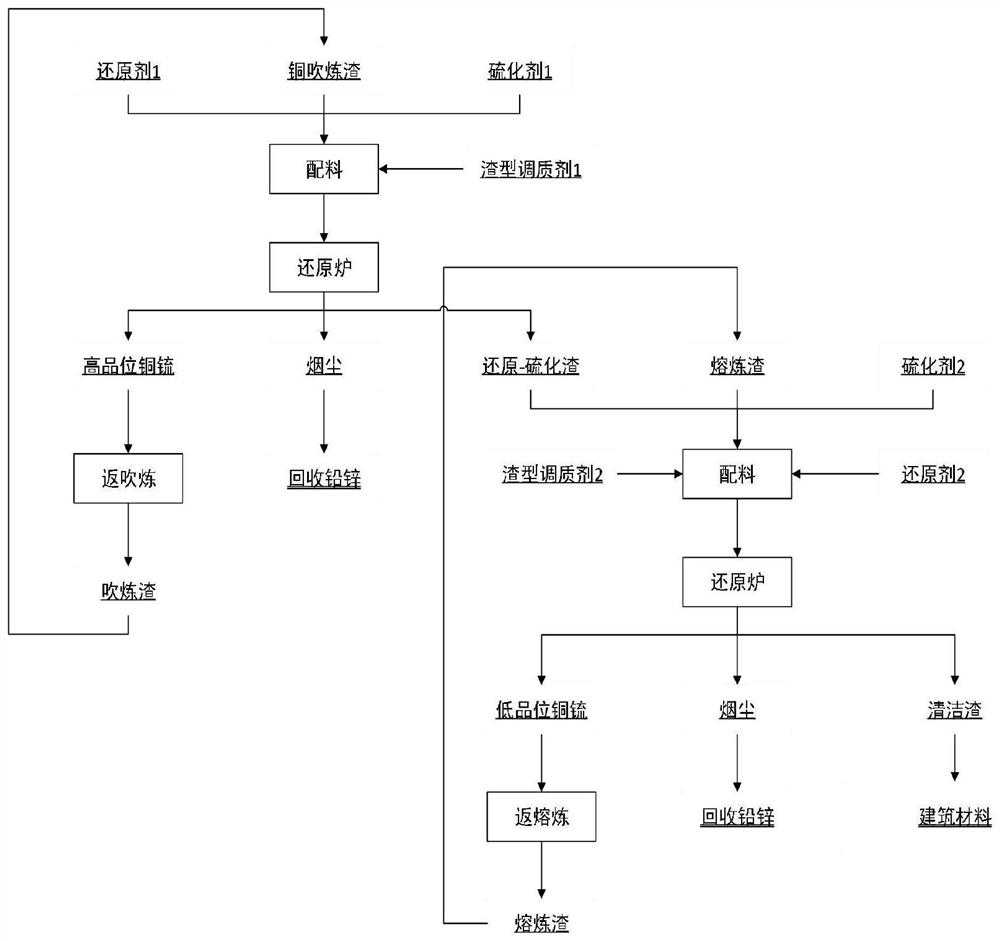

[0061] Such as figure 1 Shown, a kind of resource recovery method of copper smelting slag, comprises the following steps:

[0062] (1) With 200g copper flash blowing slag as raw material, its main chemical composition includes Cu25.5%, Pb10.6%, Zn2.29%, Fe28.9%, SiO 2 1.01%, CaO8.95%. Put the blowing slag into the reduction furnace 1, raise the temperature to 1350°C, add 5% calcium sulfate and 4% quartz to the molten copper blowing slag through the feeding device, and inject 5% calcium sulfate into the high-temperature melt by the powder spraying device After standing for 2.5 hours at heat preservation, high-grade copper matte phase, sulfidation-reduction slag (as the raw material melt in the next step, the temperature is 1250°C-1300°C) and flue gas are produced. The copper grade of the high-grade copper matte phase is 78.3%, the contents of lead and zinc are 18.8% and 0.1% respectively, and the high-grade copper matte phase returns to the blowing system. After calculation,...

Embodiment 2

[0067] Such as figure 1 Shown, a kind of resource recovery method of copper smelting slag, comprises the following steps:

[0068] (1) With 200g copper flash blowing slag as raw material, its main chemical composition includes Cu20.4%, Pb8.2%, Zn3.2%, Fe30.1%, SiO 2 1.34%, CaO9.04%. Put the blowing slag into the reduction furnace 1, raise the temperature to 1350°C, add 10% calcium sulfate and 8% quartz to the molten copper blowing slag through the feeding device, and spray 10% calcium sulfate into the high-temperature melt by the powder spraying device After standing for 3 hours, high-grade copper matte phase, sulfidation-reduction slag (as the raw material melt in the next step, the temperature is 1250°C-1300°C) and flue gas will be produced. The copper grade of the high-grade copper matte phase is 77.4%, the contents of lead and zinc are 18.4% and 0.93% respectively, and the high-grade copper matte phase returns to the blowing system. After calculation, the recovery rates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com