Preparation method of 3D printing building material aggregate

A building material and 3D printing technology, applied in the field of 3D printing, can solve the problems of inability to popularize and use, immature research, high strength, and achieve the effect of being suitable for popularization, low cost, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

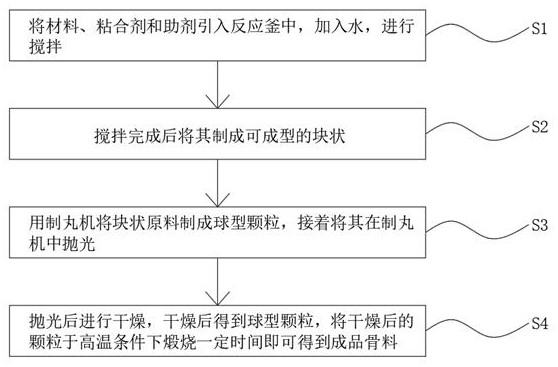

[0022] Example: such as figure 1 As shown, the present invention provides technical scheme, a kind of preparation method of 3D printing building material aggregate, comprises the following steps:

[0023] S1. Introduce materials, adhesives and additives into the reactor, add water, and stir;

[0024] S2, after the stirring is completed, it is made into a formable block;

[0025] S3, making the bulk raw material into spherical particles with a pelletizing machine, and then polishing it in the pelletizing machine;

[0026] S4. Drying is carried out after polishing, and spherical particles are obtained after drying, and the dried particles are calcined at high temperature for a certain period of time to obtain the finished aggregate.

[0027] According to the above technical scheme, the raw materials in S1 include red mud, coal gangue, fly ash, blast furnace slag, sludge incineration waste residue, desulfurized gypsum, tailings, smelting slag, and ceramic industrial waste; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com