A method for recycling waste lithium sub-batteries to prepare lithium-sulfur battery cathode materials

A technology for lithium sub-battery and positive electrode material is applied in the field of recycling waste lithium sub-battery to prepare lithium-sulfur battery positive electrode material. Broad application prospects and easy-to-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for recycling waste lithium sub-batteries to prepare lithium-sulfur battery cathode materials, the operation steps are as follows:

[0029] (1) Disassemble the discarded lithium thionyl chloride battery (ER14250) after discharge, and collect 5 g of the sulfur / carbon black mixture of the positive electrode;

[0030] (2) the 5g sulfur / carbon black mixture that step (1) collects is cleaned with ethanol, collects filter residue after filtering;

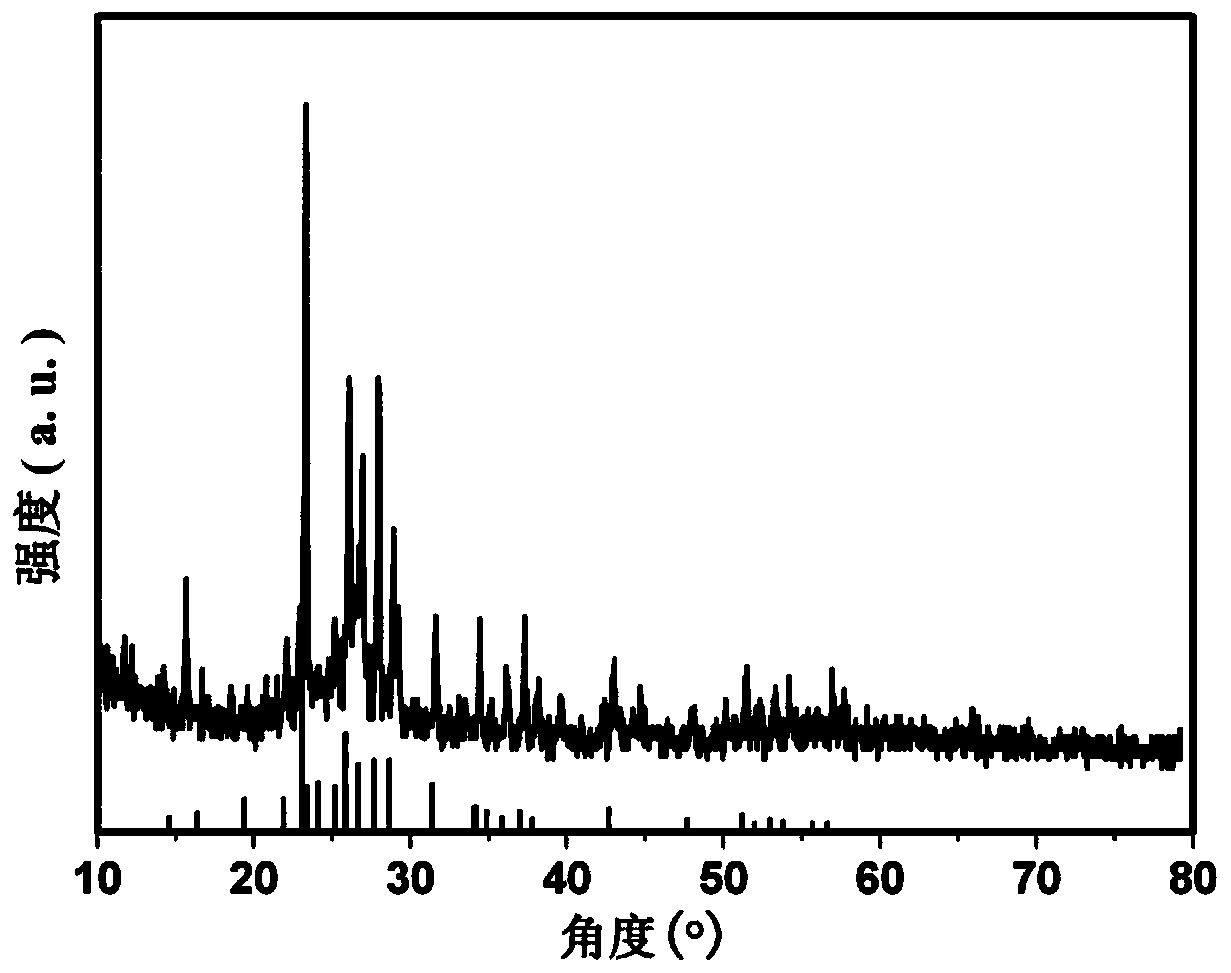

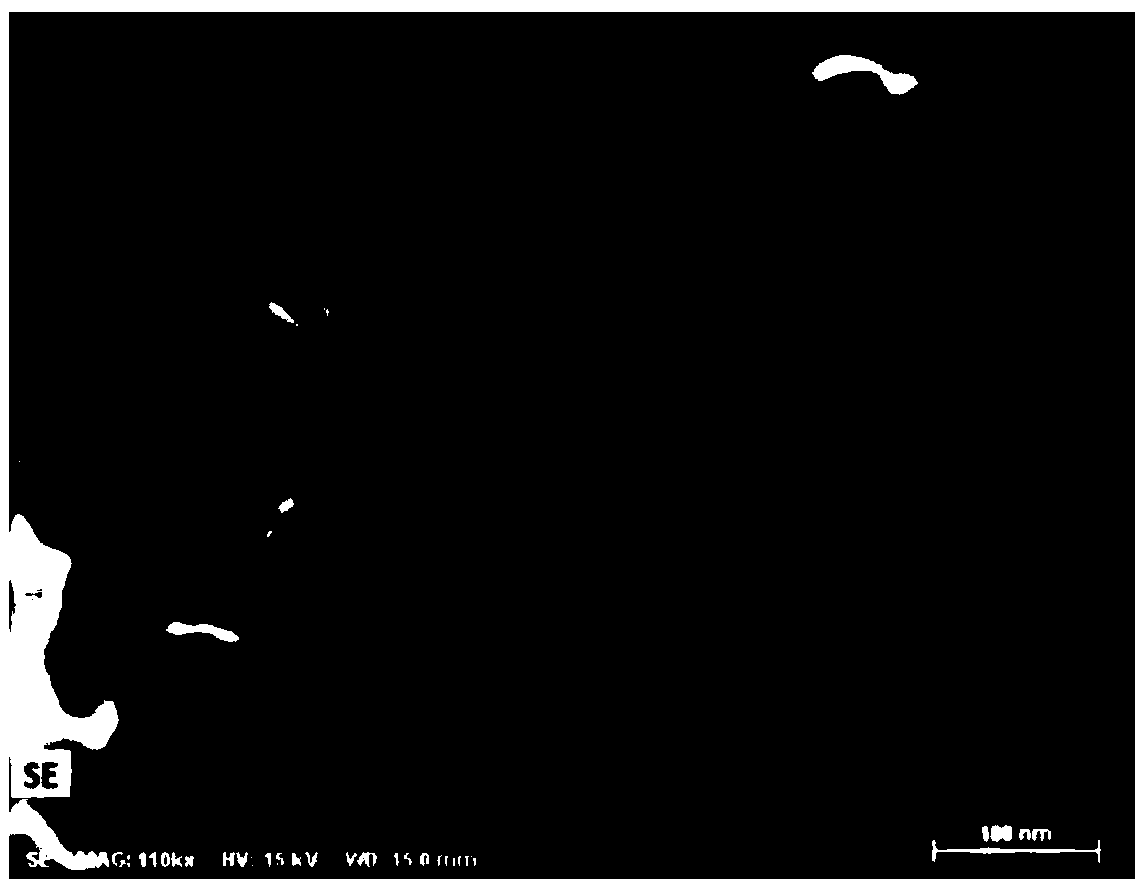

[0031] (3) Add 5g of the filter residue collected in step (2), that is, the sulfur / carbon black mixture, into 100mL of mixed acid (the mixed acid is 1mol / L hydrochloric acid + 1mol / L nitric acid, the volume ratio of the two is 1:1) , heated and stirred at 50°C for 3 hours, filtered, washed the filter residue with deionized water until the eluate was neutral, dried and collected the sample, which was the positive electrode material of lithium-sulfur battery; the obtained sample was subjected to X-ray diffraction, scanning e...

Embodiment 2

[0033] A method for recycling waste lithium sub-batteries to prepare lithium-sulfur battery cathode materials, the operation steps are as follows:

[0034] (1) Disassemble the discarded lithium thionyl chloride battery after discharge, and collect the sulfur / carbon black mixture of the positive electrode;

[0035] (2) The 5g sulfur / carbon black mixture collected in step (1) is cleaned with a mixture of organic solvent ether, acetone and n-hexane (the mixture of the three in a volume ratio of 1:1:1), and the filter residue is dried after filtering;

[0036] (3) Add 5g of filter residue obtained after drying in step (2), sulfur / carbon black mixture into 10ml of nitric acid solution with a concentration of 8mol / L, heat and stir at 35°C for 24 hours, filter, and wash the filter residue with deionized water until washed out The solution is neutral, and the sample collected by drying is the positive electrode material of lithium-sulfur battery.

Embodiment 3

[0038] A method for recycling waste lithium sub-batteries to prepare lithium-sulfur battery cathode materials, the operation steps are as follows:

[0039] (1) Disassemble the discarded lithium thionyl chloride battery after discharge, and collect the sulfur / carbon black mixture of the positive electrode;

[0040] (2) the 5g sulfur / carbon black mixture that step (1) collects is cleaned with organic solvent ethyl acetate, and filter residue is dried after filtering;

[0041] (3) Gained 5g filter residue after drying in step (2), sulfur / carbon black mixture joins 1000ml concentration and is the hydrochloric acid solution of 0.5mol / L and the nitric acid solution mixture (the nitric acid solution of 0.5mol / L hydrochloric acid solution and 0.5mol / L Solution volume ratio 1:1 mixed), heated and stirred at 80°C for 1 hour, filtered, washed the filter residue with deionized water until the eluate was neutral, dried and collected the obtained sample, which was the positive electrode mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com