Method of reel-to-reel preparation of large-area micro-nano structured generator membrane

A micro-nano structure, large-area technology, applied in the field of micro-nano science, can solve the problems of product area limited by size, complex preparation process of micro-nano structure generator film, etc., to achieve high repeatability, low cost and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

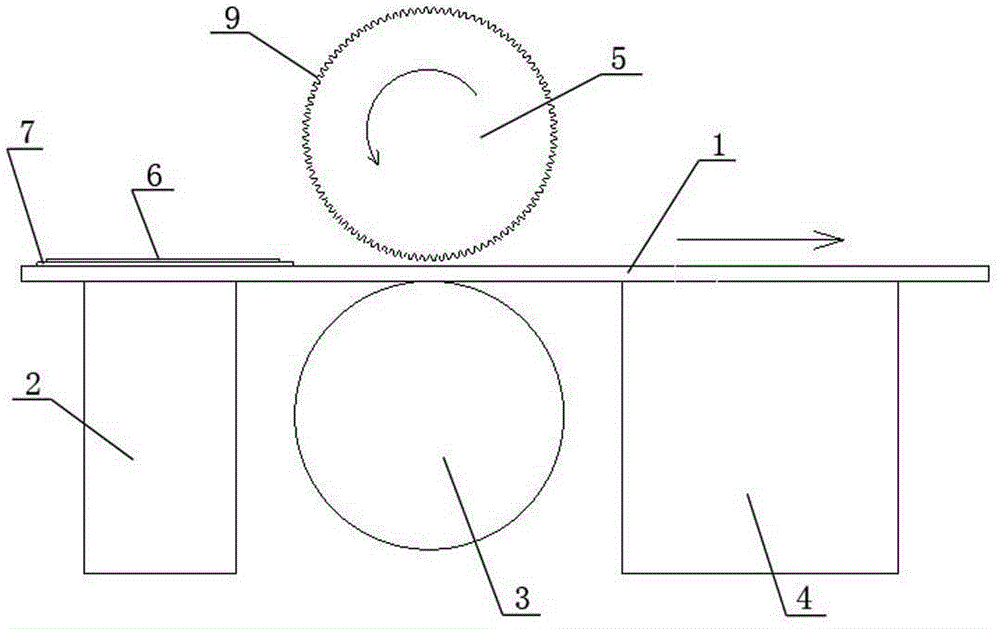

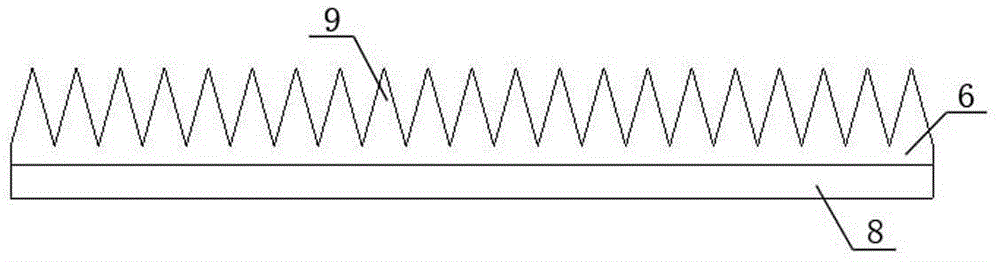

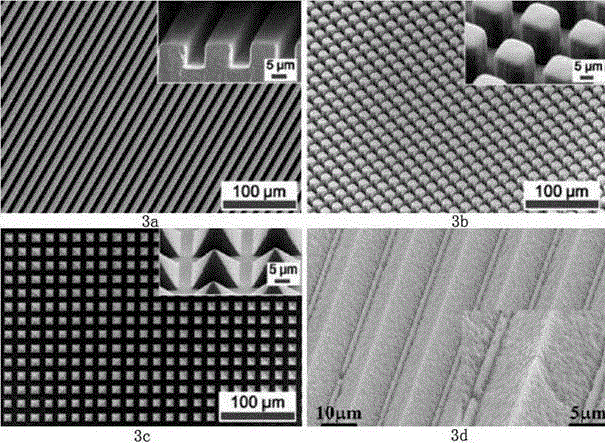

[0023] 3) Preparation of the plastic polymer embossed film: first, the plastic polymer 6 obtained in step 2) is coated on the flat substrate 7, and the flat substrate 7 is placed on the conveyor belt 1 above the first heater 2, The first heater 2 preliminarily shapes the plastic polymer 6 on the planar substrate 7, the heating temperature of the first heater 2 is 60-65°C, and the initial molding time is 50-60min; then, the planar substrate 7 is passed through embossing Roller 5, the plastic polymer 6 preliminarily formed on the flat substrate 7 is embossed with a regular micro-nano concave-convex structure 9 by the embossing roller 5; then, the flat substrate 7 is transferred to the top of the second heater 4 through the conveyor belt 1, and the second The second heater 4 solidifies and shapes the plastic polymer 6 embossed with the micro-nano concave-convex structure 9 on the planar substrate 7, the heating temperature of the second heater 4 is 75-80° C., and the curing and se...

Embodiment 1

[0028] A roll-to-roll method for preparing a large-area micro-nano structure generator film, comprising the steps of:

[0029] 1) Preparation of the preparation device: the preparation device includes a conveyor belt 1, the first heater 2, the support roller 3 and the second heater 4 are sequentially installed under the conveyor belt 1, and the position above the conveyor belt 1 is installed directly opposite the support roller 3 There is an embossing roller 5, and the surface of the embossing roller 5 is provided with a regular micro-nano concave-convex structure 9;

[0030] 2) Preparation of plastic polymer: Take carbon nanotubes and piezoelectric particles and mix them evenly at a mass ratio of 1:13, then put the mixed particles into alcohol for ultrasonic treatment for 18 minutes, then put them in a drying oven to dry for 1.5 hours, and then The dried mixed particles were added to the liquid PDMS, stirred evenly and vacuumed to remove air bubbles, the mixed particles and l...

Embodiment 2

[0035] A roll-to-roll method for preparing a large-area micro-nano structure generator film, comprising the steps of:

[0036] 1) Preparation of the preparation device: the preparation device includes a conveyor belt 1, the first heater 2, support roller 3 and second heater 4 are installed in sequence under the conveyor belt 1, and the position above the conveyor belt 1 is installed directly opposite the support roller 3 There is an embossing roller 5, and the surface of the embossing roller 5 is provided with a regular micro-nano concave-convex structure 9;

[0037] 2) Preparation of plastic polymers: Take carbon nanotubes and piezoelectric particles and mix them evenly at a mass ratio of 1:10, then put the mixed particles into alcohol for ultrasonic treatment for 20 minutes, then put them in a drying oven to dry for 2 hours, and then dry them The final mixed particles were added to liquid PDMS, stirred evenly and vacuumed to remove air bubbles, mixed particles and liquid PDM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com