Iron-chromium-aluminum alloy casting integrated device and method

An iron-chromium-aluminum alloy and alloy technology, which is used in casting equipment, metal processing equipment, casting melt containers, etc., can solve the problems of continuous casting nodules and low cleanliness, improve cleanliness, solve oxidation problems, realize integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

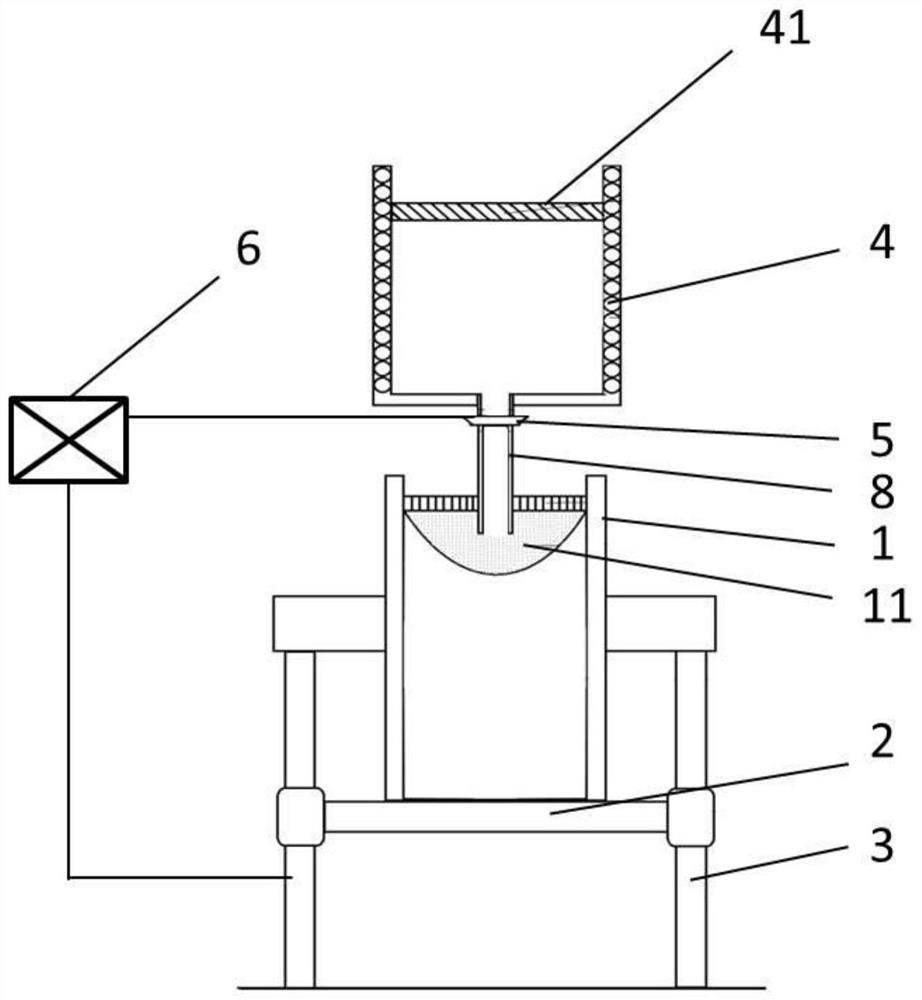

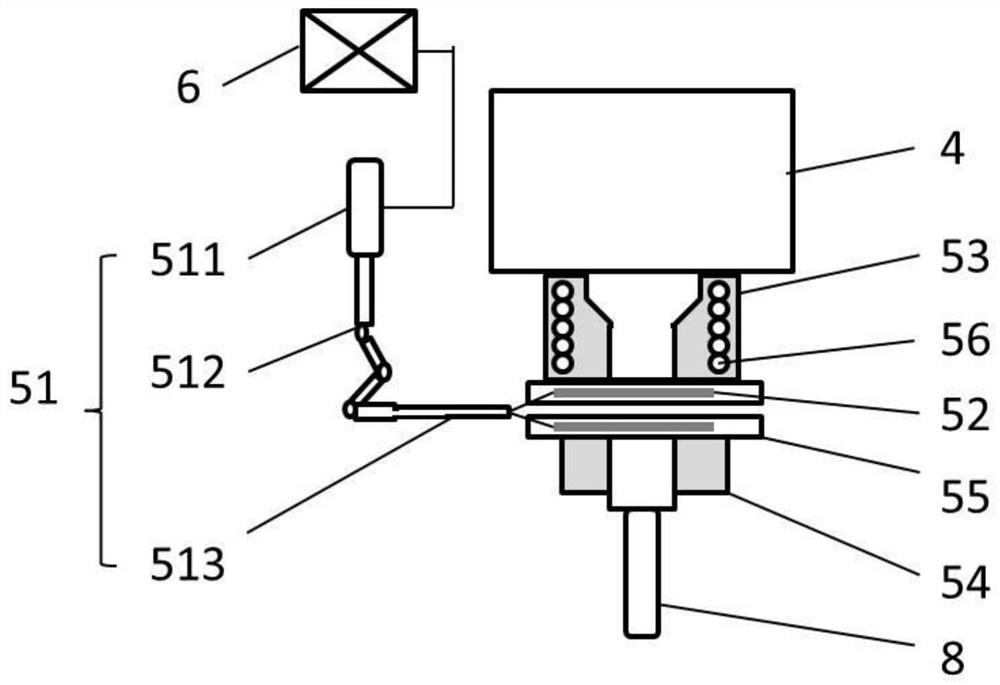

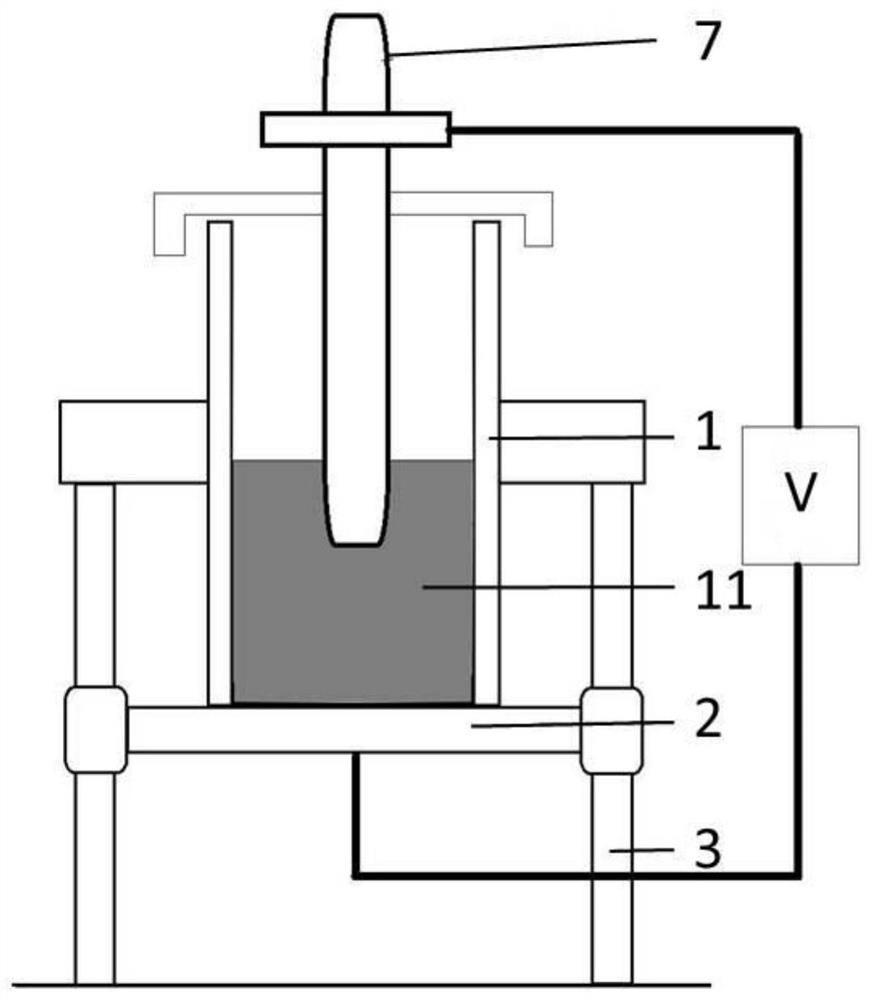

[0027] Such as figure 1 As shown, an iron-chromium-aluminum alloy melting and casting integrated device includes a water-cooled crystallizer 1, a bottom water tank 2, a screw lifting platform 3, an induction furnace 4 and a PLC controller 6, and the bottom of the induction furnace 4 is provided with a sliding nozzle 5 , the alloy liquid can enter the sliding nozzle 5 from the induction furnace 4, and the lower nozzle of the sliding nozzle 5 is connected with a long nozzle 8, and the alloy liquid can pass through the sliding nozzle 5 and the long nozzle 8 in sequence, and the long nozzle 8 is in a sealed state to prevent air from infiltrating and preventing When the alloy liquid enters the water-cooled crystallizer 1 from the induction furnace 4, it contacts with the outside, which avoids the entry of impurities and can play a good role in protecting the alloy fluid. The bottom of the long nozzle 8 extends into the water-cooled crystallizer 1, and the The water-cooled crystalli...

Embodiment 2

[0040] Such as figure 1 As shown, an iron-chromium-aluminum alloy melting and casting integrated device includes a water-cooled crystallizer 1, a bottom water tank 2, a screw lifting platform 3, an induction furnace 4 and a PLC controller 6, and the bottom of the induction furnace 4 is provided with a sliding nozzle 5 , the alloy liquid can enter the sliding nozzle 5 from the induction furnace 4, and the lower nozzle of the sliding nozzle 5 is connected with a long nozzle 8, and the alloy liquid can pass through the sliding nozzle 5 and the long nozzle 8 in sequence, and the long nozzle 8 is in a sealed state to prevent air from infiltrating and preventing When the alloy liquid enters the water-cooled crystallizer 1 from the induction furnace 4, it contacts with the outside, which avoids the entry of impurities and can play a good role in protecting the alloy fluid. The bottom of the long nozzle 8 extends into the water-cooled crystallizer 1, and the The water-cooled crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com