Direct type millimeter wave signal detection instrument of silicon slot coupled T junctions

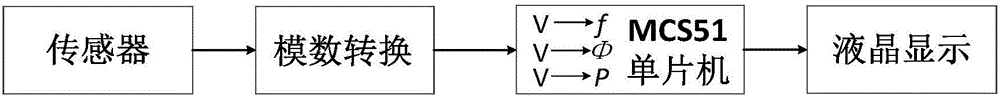

A signal detection and millimeter wave technology, which is applied in the field of direct millimeter wave signal detection instruments, can solve the problems that the range of millimeter wave detection technology is not very large, is particularly perfect from time to time, and has a complex structure, and achieves high potential application value and simple structure Novel, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

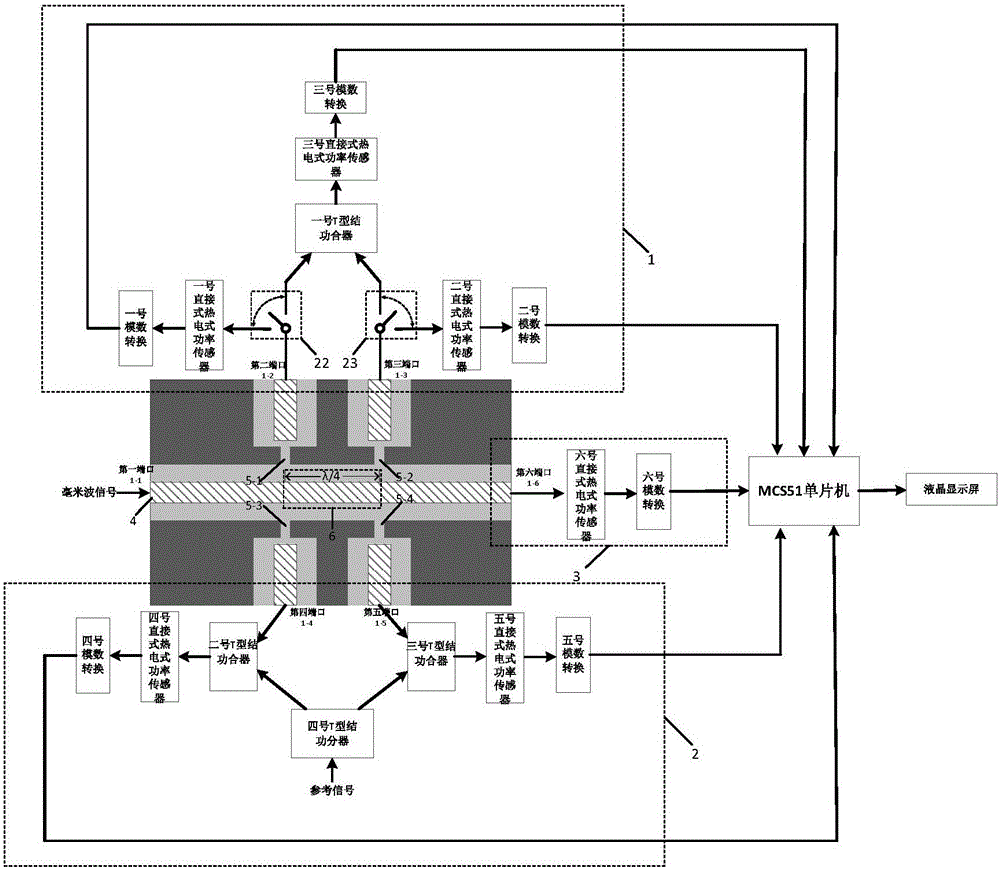

[0033] specific implementation plan

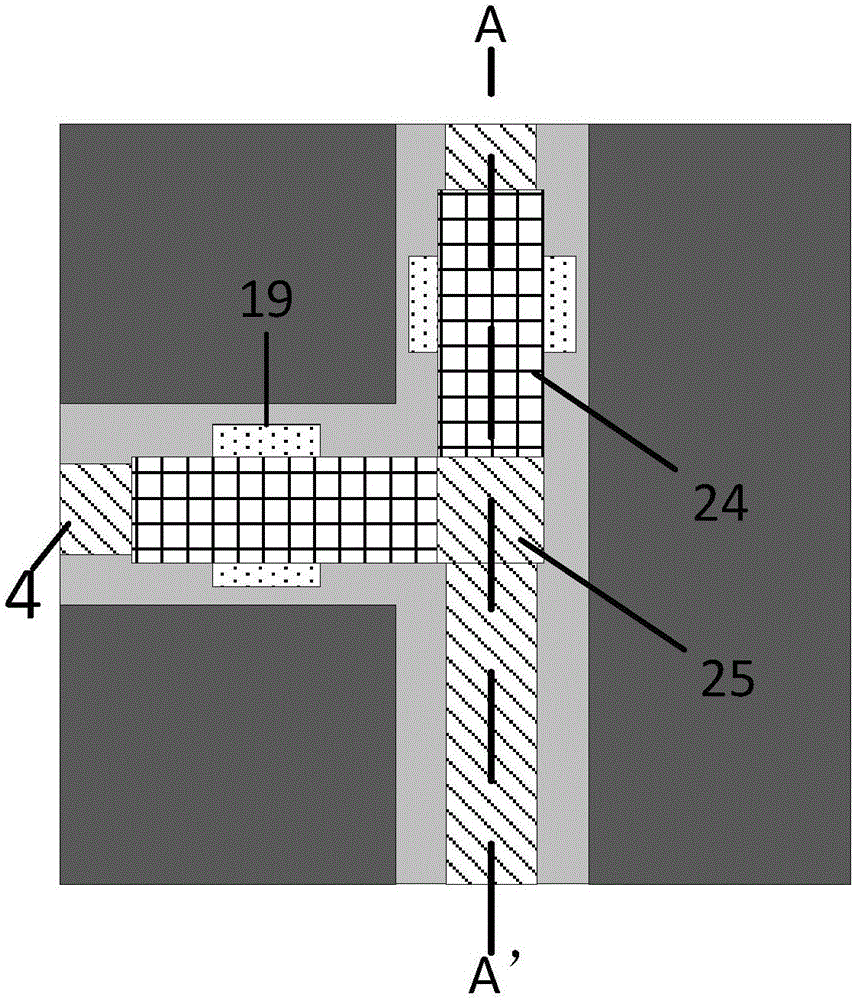

[0034] The sensor part of the silicon-based gap-coupled T-junction direct millimeter-wave signal detection instrument of the present invention is based on a high-resistance Si substrate 7, which consists of a coplanar waveguide transmission line 4 and a No. 1 slot coupling structure 5-1 , No. 2 slot coupling structure 5-2, No. 3 slot coupling structure 5-3, No. 4 slot coupling structure 5-4, phase shifter 6, No. 1 SPDT switch 22, No. 2 SPDT switch 23, one It is composed of T-junction power splitter, three T-junction power combiners and six direct thermoelectric power sensors.

[0035] The structure of the T-junction power divider and the T-junction power combiner is the same, mainly composed of a coplanar waveguide transmission line 4, two fan-shaped defect structures 9 and three air bridges 10, and the fan-shaped defect structure 9 is located at two input The fan-shaped defect ground structure at the port, and the air bridge 10 is a beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com