Method for comprehensively utilizing multi-metal acidic wastewater of non-ferrous metal mine

A technology for acidic wastewater and non-ferrous metals, which is applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, and water pollutants. , to avoid waste of resources, to achieve the effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

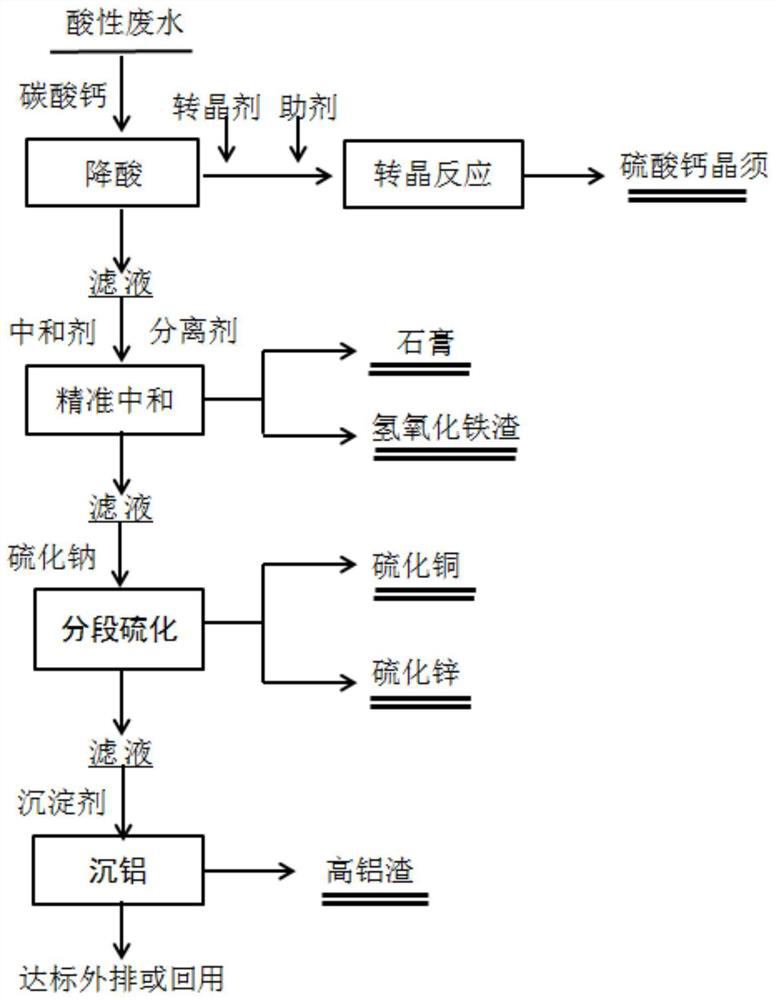

[0026] This embodiment provides a method for the comprehensive utilization of polymetallic acid wastewater from non-ferrous metal mines, such as figure 1 As shown, it specifically includes the following steps:

[0027] S1, reducing acid to prepare calcium sulfate whiskers:

[0028] Calcium carbonate is added to the acid waste water to reduce the acid, and after thickening, a polymetallic acidic solution A (filtrate) and gypsum slurry (filter residue) containing copper, iron, zinc, and aluminum will be produced; the amount of calcium carbonate added is 0.8% of the theoretical amount of acid neutralization. -1.2 times; pump the gypsum slurry into the reactor for crystal transformation reaction, add water to the reactor according to the mass ratio of gypsum slurry and water of 1:7-35, and add crystal modifier, during the reaction React for 60-180min under the technological conditions of temperature 90-140℃ and stirring speed 150-180rpm, then perform flash evaporation and separat...

Embodiment 2

[0038] Acidic pit water produced during the mining process of a polymetallic sulfide mine, containing H 2 SO 4 10g / L, Cu 2+ 0.37g / L, Zn 2 + 0.27g / L, Al 3+ 1.6g / L, TFe 7.2g / L, Fe 3+ 6.6g / L, SO 4 2- 30-35g / L, pH=1.35.

[0039] The main implementation steps are as follows:

[0040] (1) Calcium sulfate whisker is prepared by reducing acid: measure 10 liters of acid waste water in the reaction tank, add 110g limestone (CaCO in limestone) under normal temperature stirring condition 3 The content is 94wt%, the same below) for neutralization, stirring and reacting for 20min, and the end point pH=2.25. After the reaction is finished, filter to obtain a polymetallic acidic solution A (filtrate) containing copper, iron, zinc and aluminum and gypsum slurry. Put all the gypsum slurry into the reaction kettle, add water to the reaction kettle according to the ratio of gypsum slurry and water quality of 1:9, add 0.08wt% sodium nitrate, and mix the mixture at a reaction temperature ...

Embodiment 3

[0050] The quality of the acid pit water produced in the mining process of a certain polymetallic sulfide mine is the same as that of Example 1.

[0051] The main implementation steps are as follows:

[0052] (1) Preparation of calcium sulfate whiskers by reducing acid: measure 10 liters of acidic wastewater into the reaction tank, add 110 g of limestone under normal temperature stirring conditions for neutralization, stir for 20 minutes, and the final pH is 2.25. After the reaction is finished, filter to obtain a polymetallic acidic solution A containing copper, iron, zinc and aluminum and gypsum slurry. Put all the gypsum slurry into the reaction kettle, add water into the reaction kettle according to the ratio of gypsum slurry and water quality of 1:7, add 0.02wt% sodium nitrate, at the reaction temperature of 140°C and the stirring speed of 150rpm The crystal transformation reaction is carried out for 60 minutes under the technological conditions, followed by flash evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com