Patents

Literature

113results about How to "Solve the crystallization problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vulcanization-induced failed lead-acid storage battery repair method

ActiveCN102522601ASolve the crystallization problemExtended service lifeSecondary cells servicing/maintenanceCharge and dischargePower flow

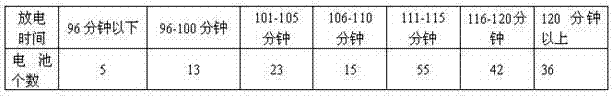

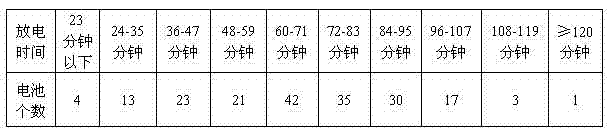

The invention relates to a lead-acid storage battery repair method, in particular to a vulcanization-induced failed lead-acid storage battery repair method. The vulcanization-induced failed lead-acid storage battery repair method is characterized in that the method comprises the following steps of: visually inspecting a fault, detecting, precharging, judging whether polar plate active matters become slurry or not, filling in dilute acid or repaid liquid, statically placing the battery, recording initial capacity, recording discharge time and over-discharge time, determining repaid charge capacity and a charge and discharge process flow, and repairing according to different battery capacities. Through the steps, the vulcanization-induced failed lead-acid storage battery repair method fundamentally solves the problem that lead sulfate is crystallized, not only can the vulcanization removal rate be reach more than 90 percent, but also the repaid success rate of the battery failed because of vulcanization can reach more than 95 percent, the service life of the battery is prolonged by more than 80 percent, the polar plate lead sulfate crystals which are though to be inevitable by the traditional theory are dissolved, and the capacities of most lead-acid storage batteries can be restored and the lead-acid storage batteries can be reused as long as the waste batteries are not visually damaged and deformed and do not have hard faults.

Owner:HANGZHOU CHUYUNFENG TECH

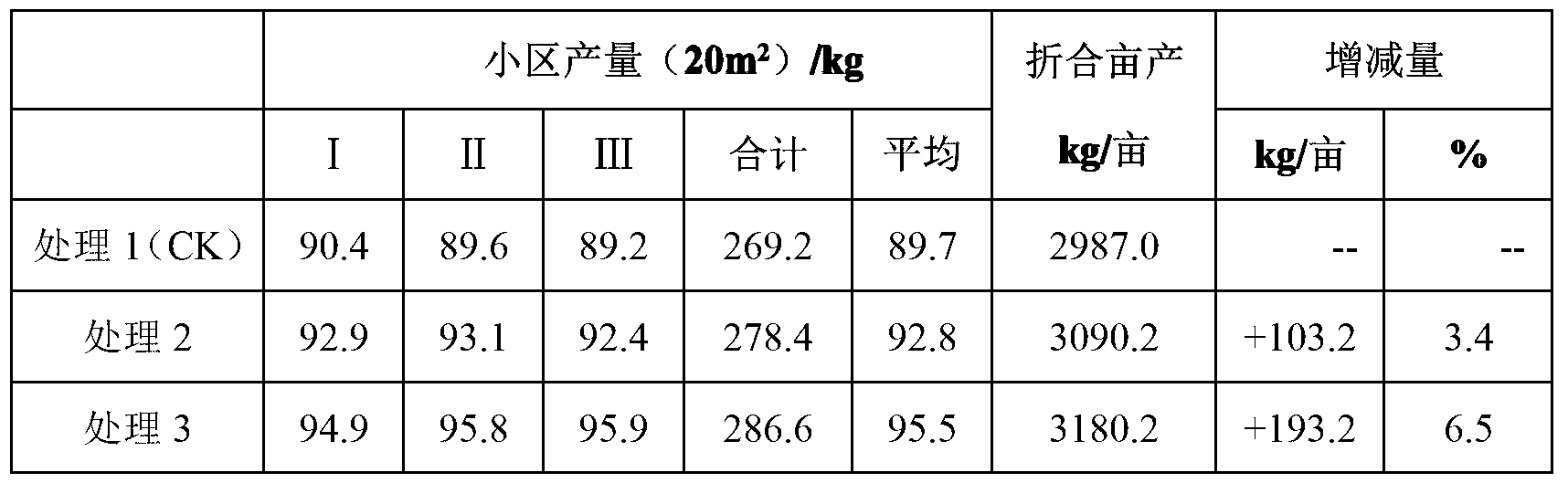

Paste type water-soluble fertilizer with potassium fulvic acid serving as matrix

InactiveCN103265368AFast dissolutionIncrease contentFertilizer mixturesPotassium nitrateAdditive ingredient

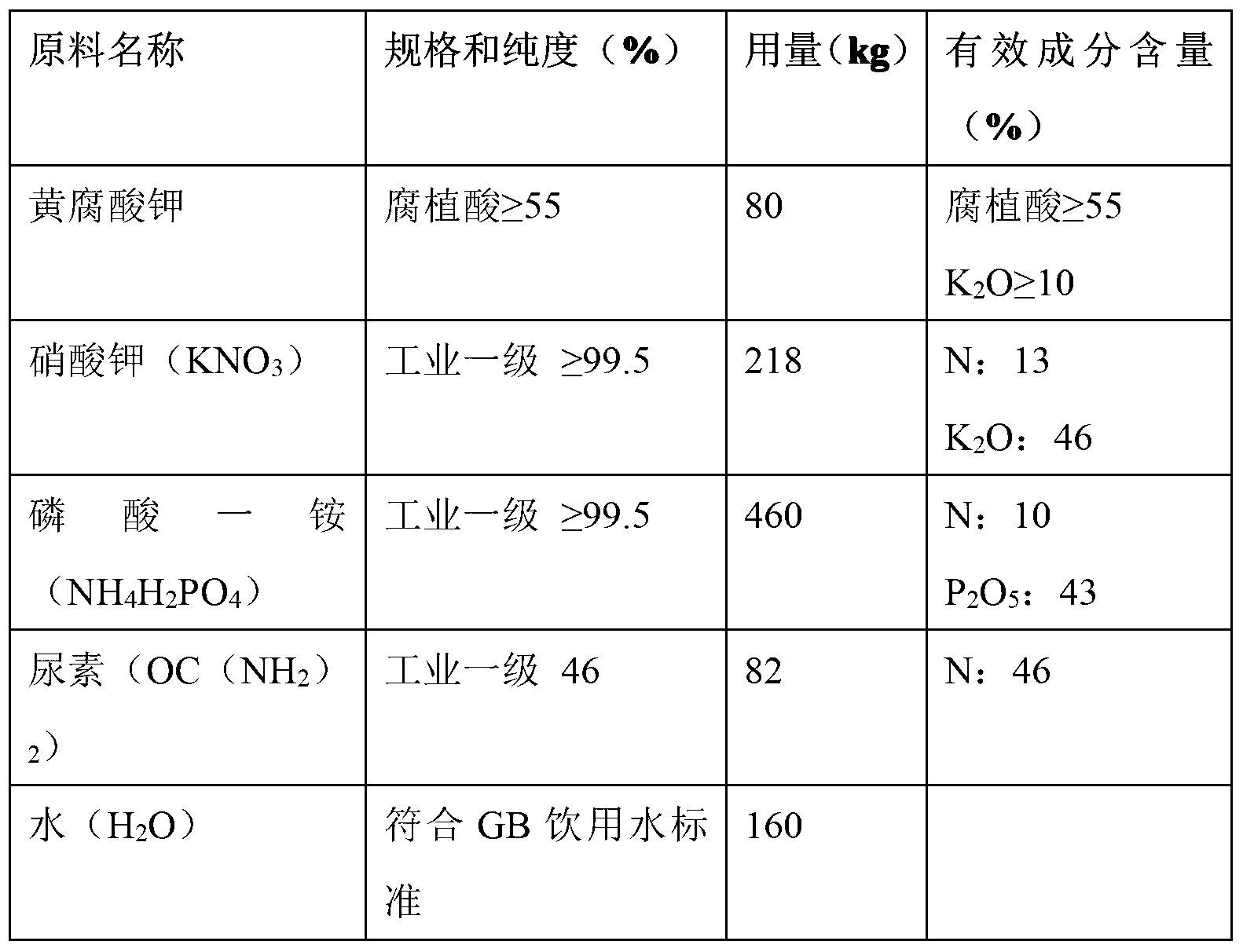

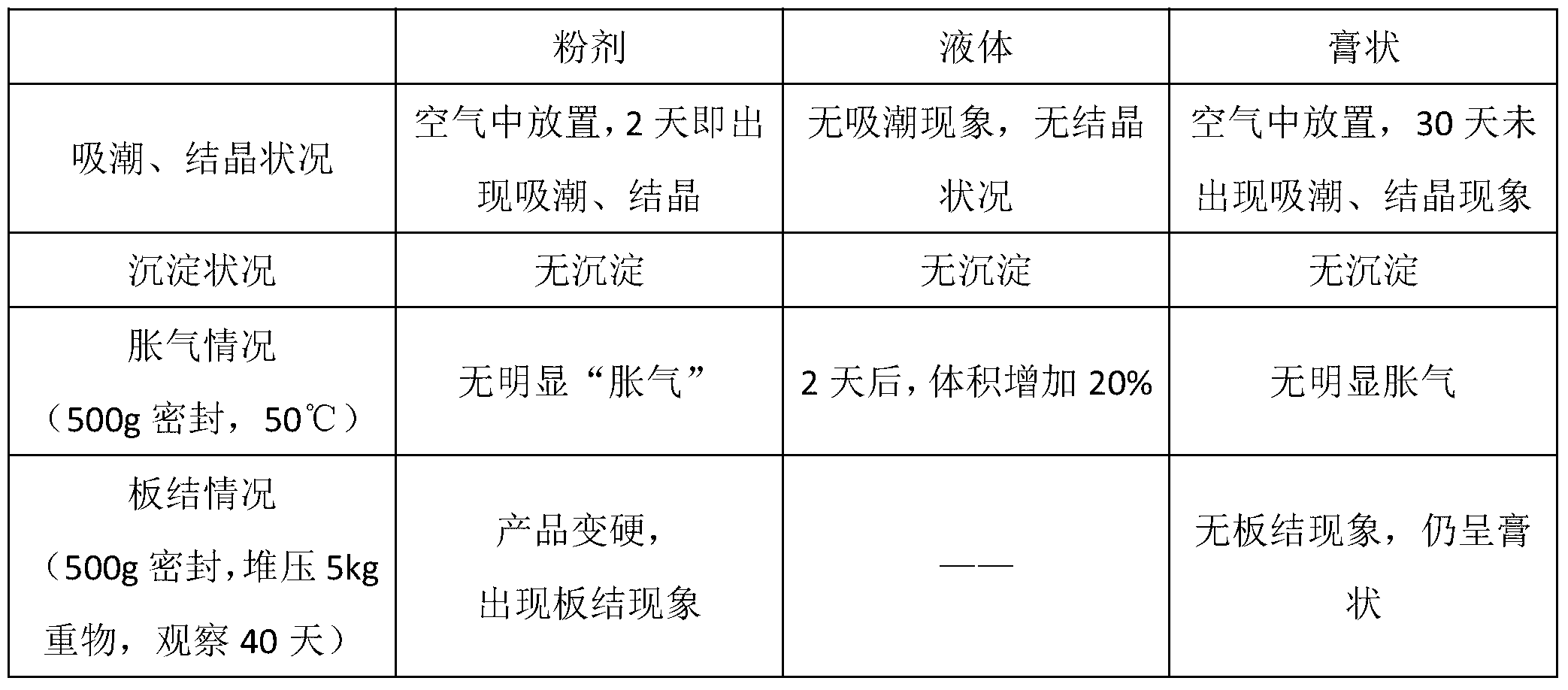

The invention discloses a paste type water-soluble fertilizer with potassium fulvic acid serving as a matrix. The paste type water-soluble fertilizer comprises the following components in parts by weight: 80 to 100 parts of potassium fulvic acid, 200 to 650 parts of potassium nitrate, 100 to 460 parts of monoammonium phosphate, 60 to 90 parts of urea, 130 to 160 parts of water, 2.1 to 3.8 parts of calcium magnesium phosphate fertilizer, 1.6 to 2.4 parts of manganese sulfate, 0.7 to 1.2 parts of ferrous sulfate, 0.8 to 1.3 parts of zinc sulfate, 0.8 to 1.4 parts of copper sulfate, and 0.6 to 1.2 parts of ammonium molybdate. A paste type water-soluble material with potassium fulvic acid serving as the matrix can bring the colloid effect, complexing effect, acid-base equilibrium effect for all components, and interspersion effect for all material of the potassium fulvic acid into full play in the whole compound fertilizer, so that the dissolution velocity of all the materials during being diluted with water can be increased, and the content of each nutritional ingredient in the fertilizer is increased; and the paste type water-soluble fertilizer has the characteristics of being free of precipitating, hardening, crystallizing and bleeding, and can be applied to foliage spray, fertigation, etc.

Owner:中化化肥有限公司烟台作物营养与植物保护研究中心

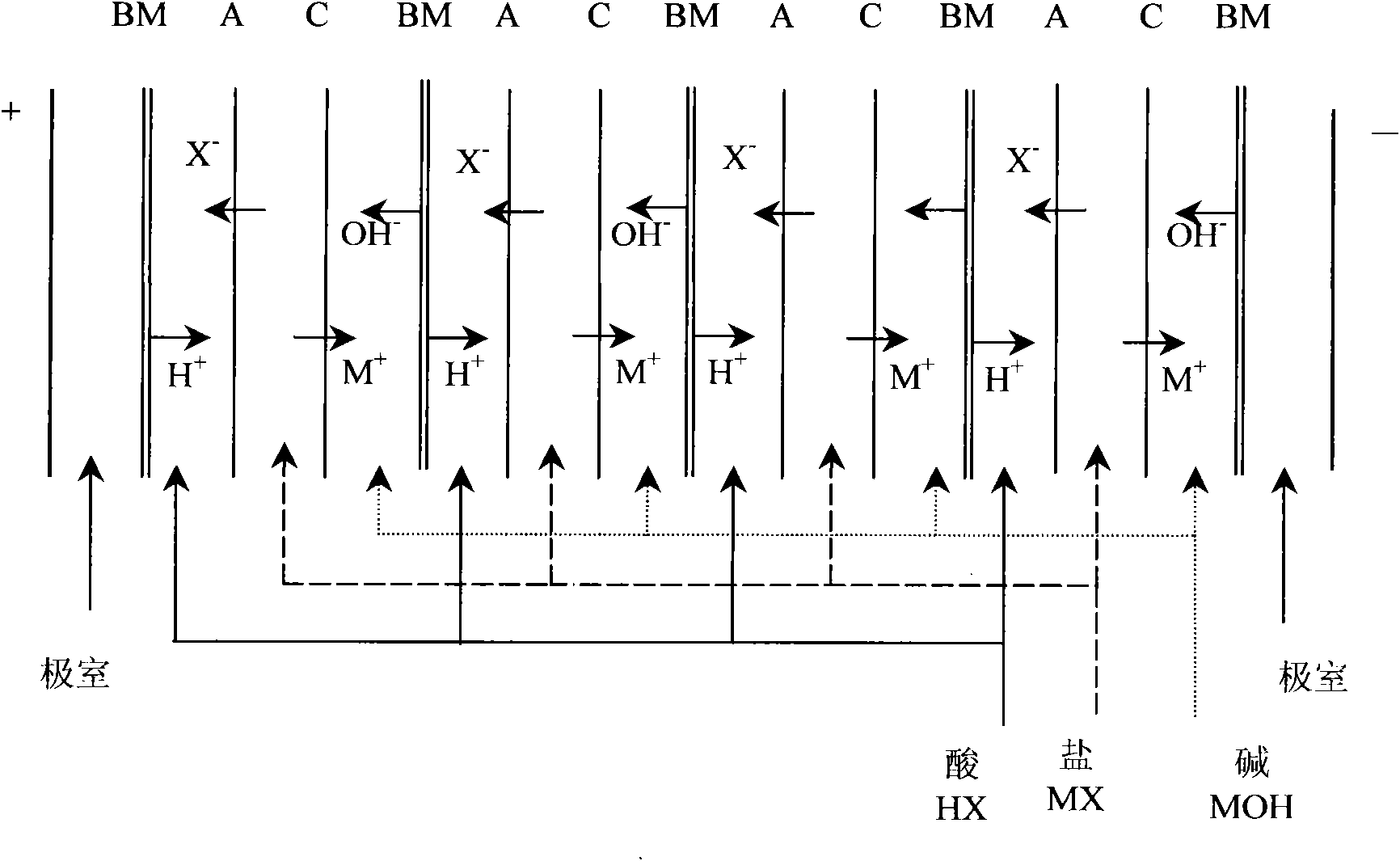

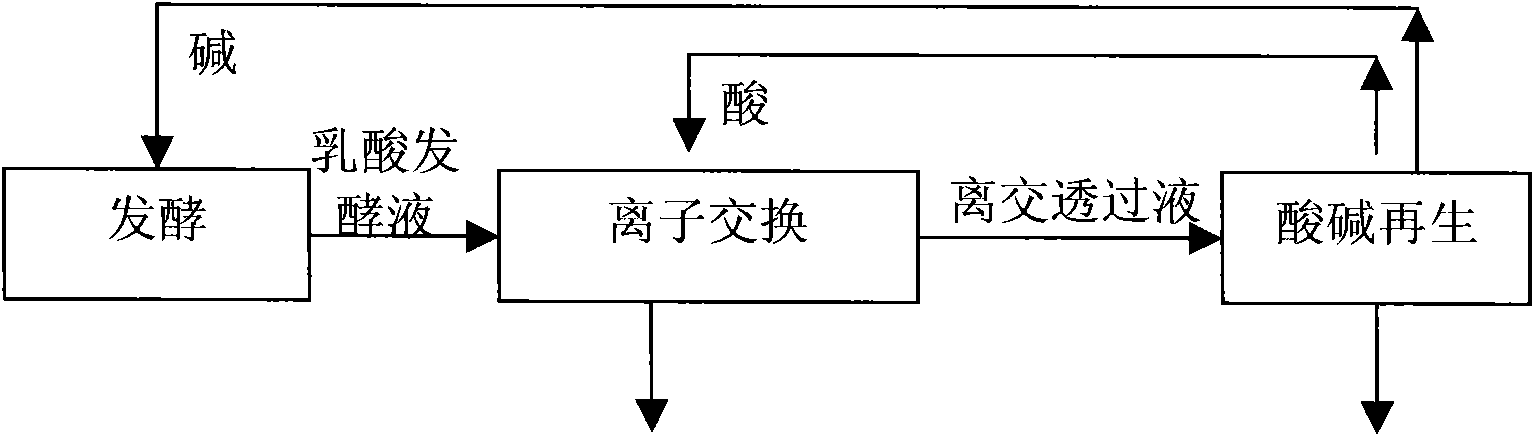

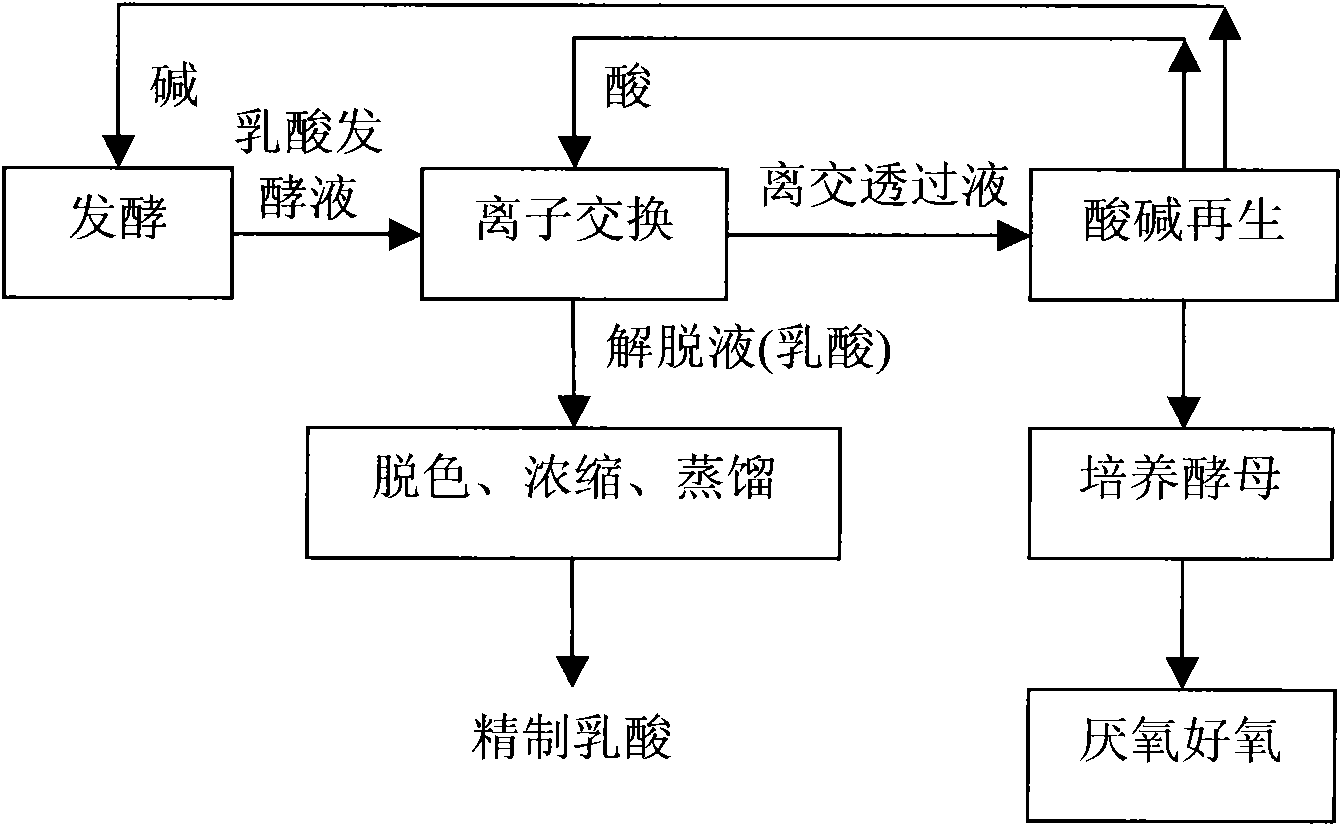

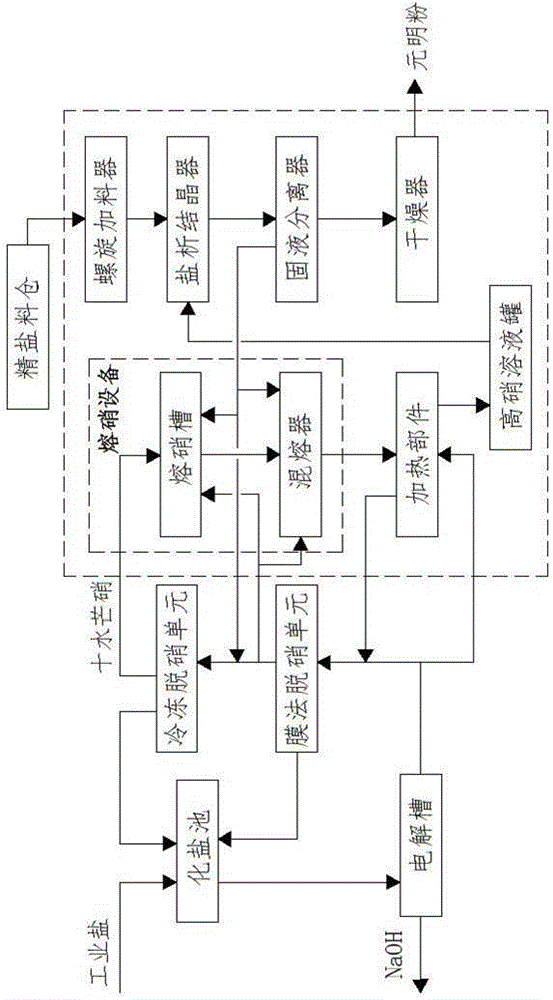

Method for cleanly producing lactic acid by fermentation method

ActiveCN101607887ASolve the crystallization problemImplement resourcesFermentationCarboxylic compound separation/purificationSulfate radicalsNitrate

The invention relates to a method for cleanly producing lactic acid by a fermentation method. The method comprises the following steps that: during the fermentation of the lactic acid, solution of NH3 and NaOH or solution of KOH is used for adjusting the pH value of fermentation solution, the obtained fermentation solution of the lactic acid passes through a C1 typed, sulfate radical typed or nitrate radical typed anion-exchange column, lactate radical in the fermentation solution of the lactic acid is exchanged and adsorbed by C1-, SO42- or NO3-, and simultaneously ionic exchange permeating solution of hydrochloride, sulfate or nitrate containing NH4+, Na+ or K+ and permeating the ionic exchange column is obtained; the lactic acid adsorbed on the ionic exchange column and exchanged and adsorbed by the lactate radical is eluted by hydrochloric acid, sulfuric acid or nitric acid, an eluent containing the lactic acid is obtained, and the ionic exchange column is regenerated simultaneously during eluting; the ionic exchange permeating solution is filled in a bipolar membrane electrodialyzer to obtain regenerated hydrochloric acid, sulfuric acid or nitric acid; the regenerated hydrochloric acid, the sulfuric acid or the nitric acid is used for eluting the lactic acid adsorbed on the ionic exchange column, and the regenerated solution of the NH3 and the NaOH or the solution of the KOH is used for adjusting the pH value of the fermentation solution when the lactic acid is fermented.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

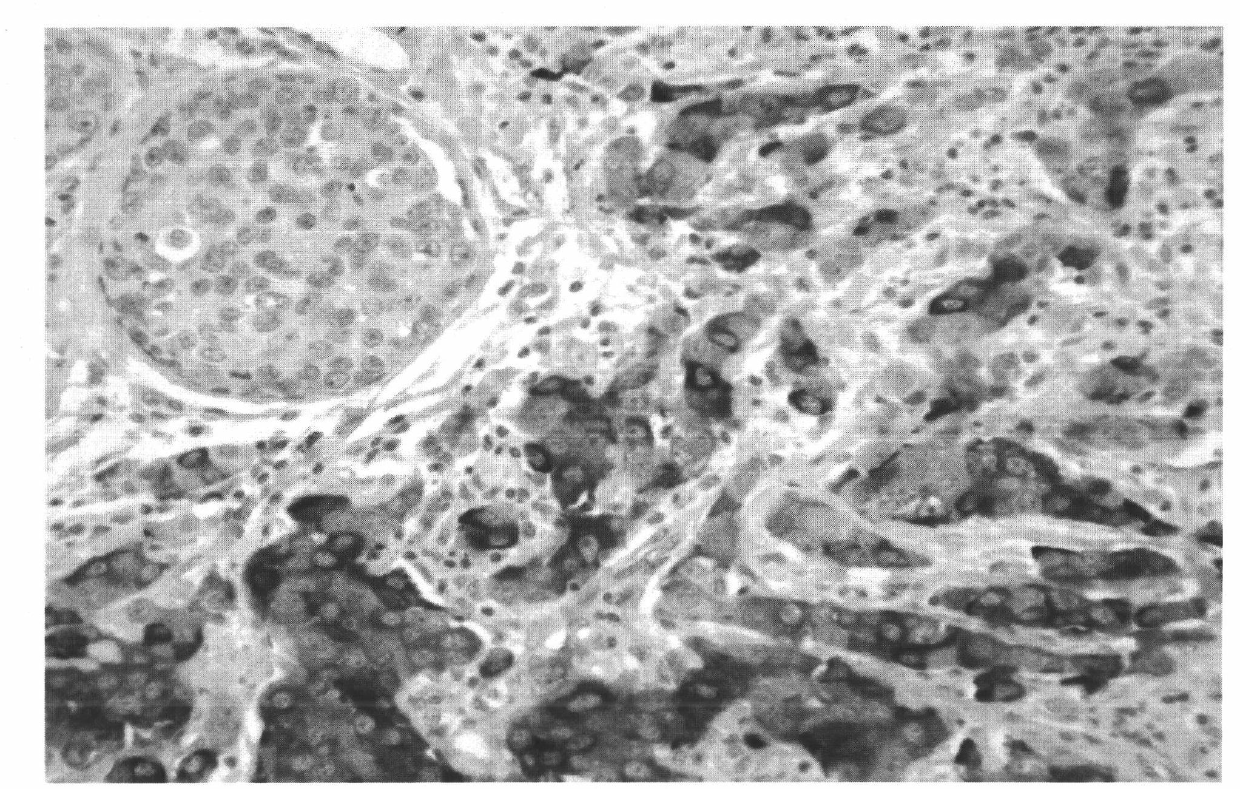

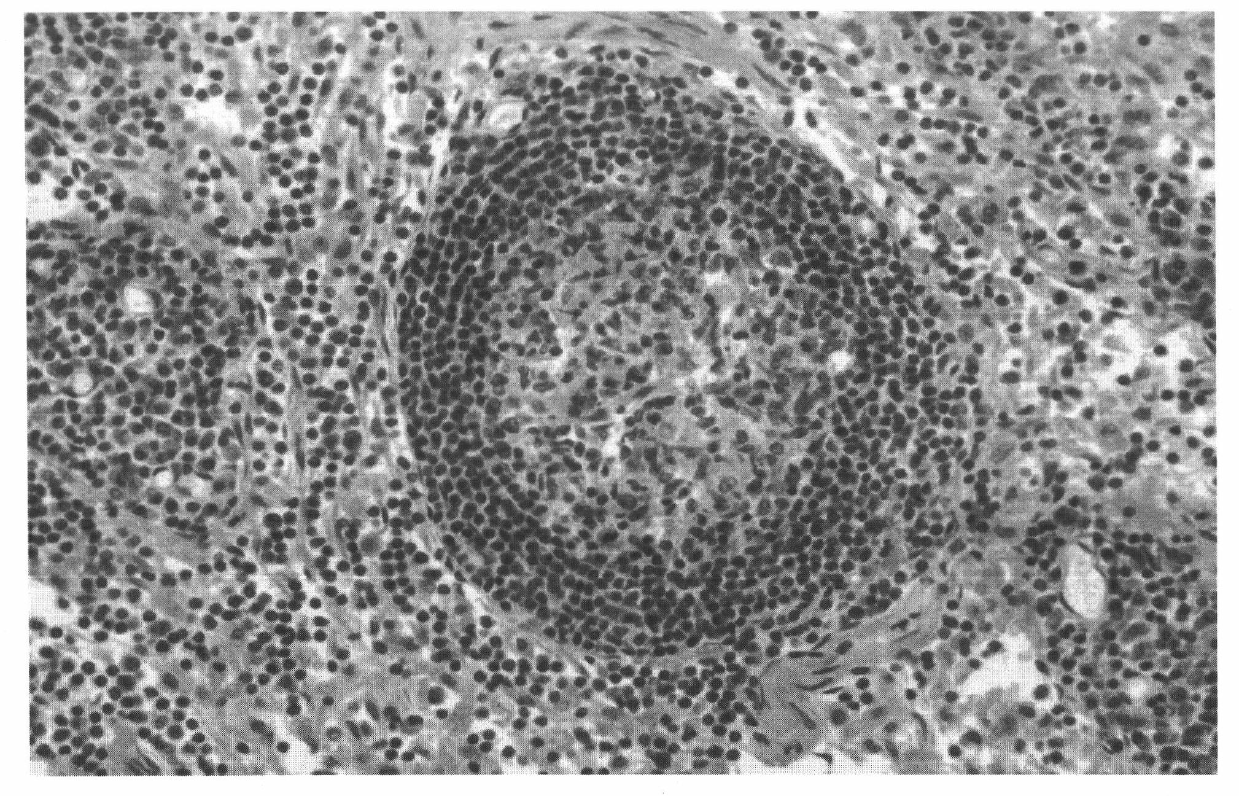

Mercury-free environment-friendly hematoxylin staining solution

InactiveCN102167914AEasy doseSolve the crystallization problemPreparing sample for investigationMordantsAcetic acidAluminium sulfate

The invention provides a mercury-free environment-friendly hematoxylin staining solution, which comprises the following components in portions by volume: 100-300 portions of 3-10 percent hematoxylin absolute ethyl alcohol solution, 1500-2000 portions of 2-6 percent aluminum sulfate aqueous solution, 60-100 portions of .05-2 percent periodic acid aqueous solution, and 15-30 portions of glacial acetic acid. Non-toxic and innocuous chemical reagents are adopted for the mercury-free environment-friendly hematoxylin staining solution, and a histological section staining experiment shows that the nucleus is clearly stained and the structures of the chromatin, nuclear membrane and nucleolus are clear.

Owner:HARBIN GREEN SPECIMEN TECH DEV

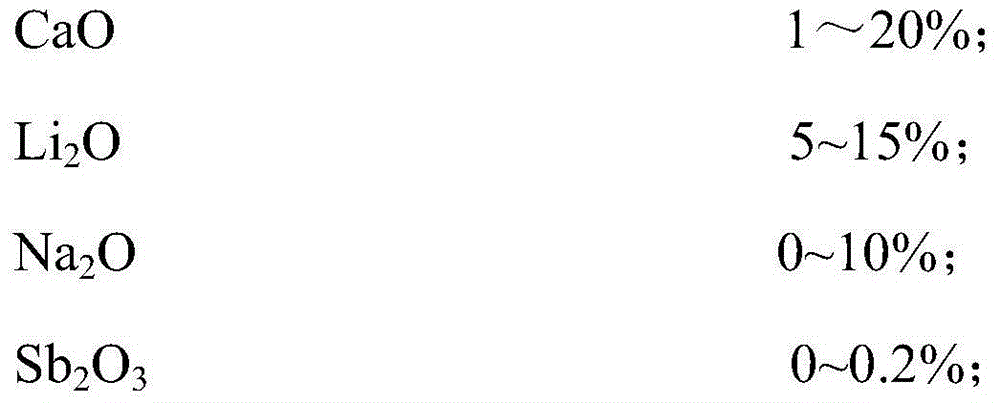

Optical glass

The invention provides optical glass. The optical glass comprises the following components (measured by oxide) in percentage by weight: 30-40% of SiO2, 1-10% of B2O3, 33-45% of SiO2+B2O3, 0-10% of La2O3, 25-40% of Nb2O5, 60-75% of Nb2O5+SiO2, 3-10% of ZrO2, 1-20% of CaO, 5-15% of Li2O, 0-10% of Na2O and 0-0.2% of Sb2O3, wherein 3<= SiO2 / B2O3<=14 and 0.65<=Nb2O5 / SiO2<=1.3; the optical glass does not contain TiO2, ZnO, BaO, Th, Pb, As, Cd, Hg, GeO2, TeO2, Ta2O5 and Yb2O3; and the refractive index nd of the optical glass is within the range of 1.70-1.75, and the Abbe number upsilon d is within the range of 32-38. The optical glass is low in devitrification tendency, high in transmittance, low in maximum crystallization temperature and suitable for mass production, and is mainly used for digital products, cameras, liquid crystal projectors and the like.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

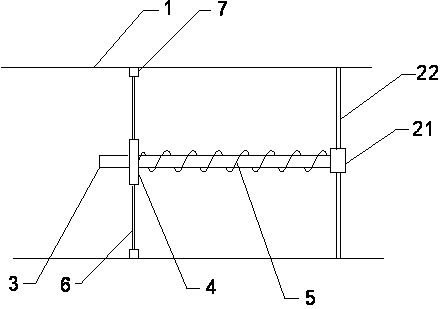

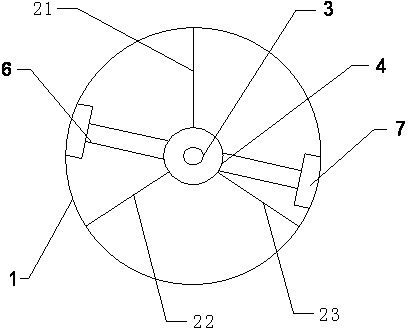

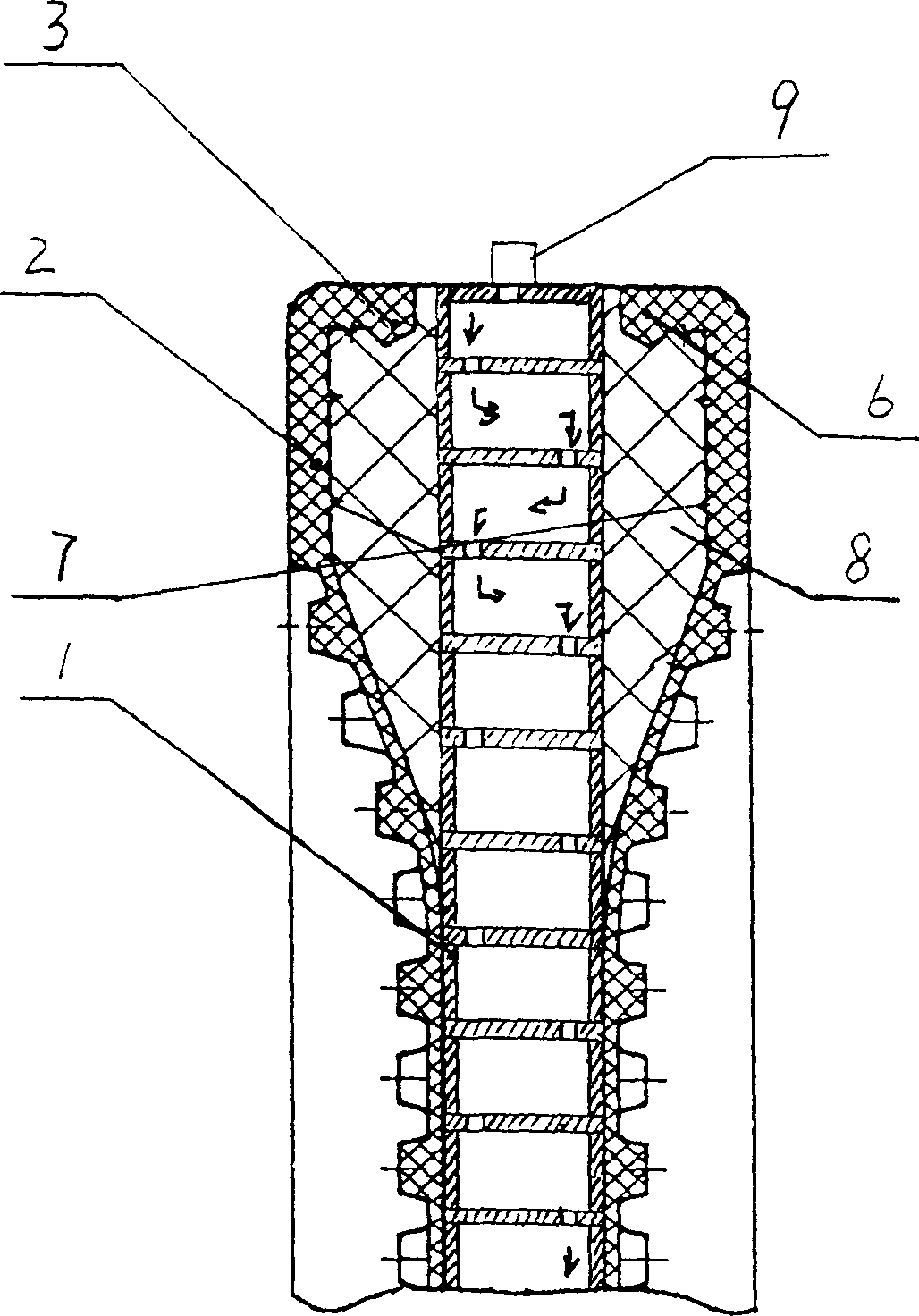

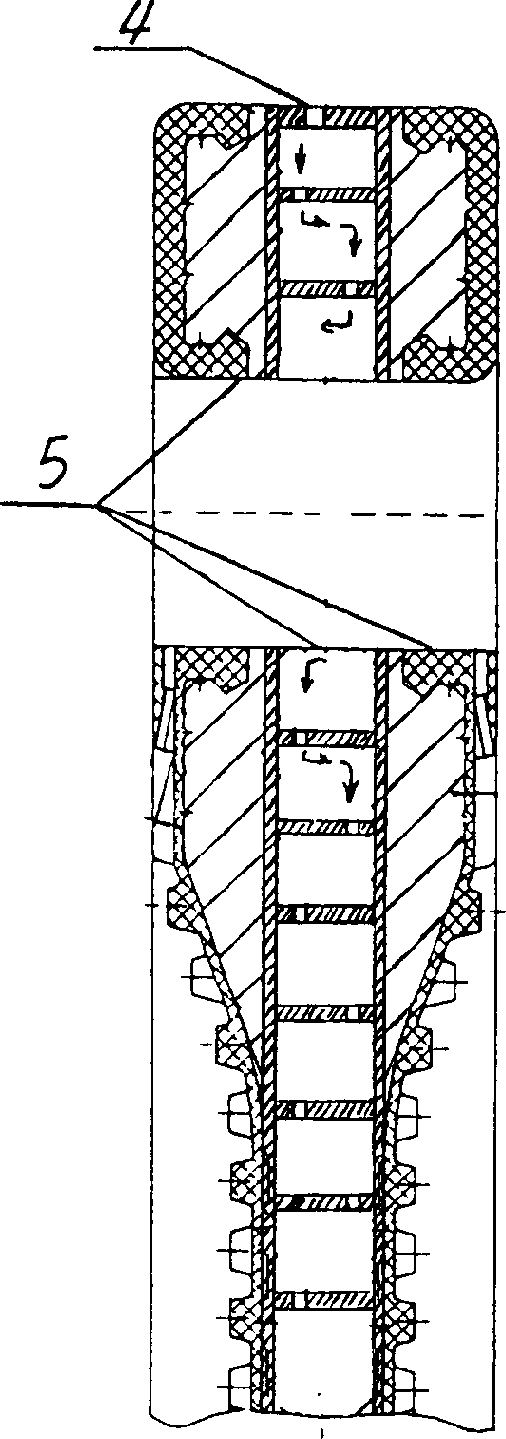

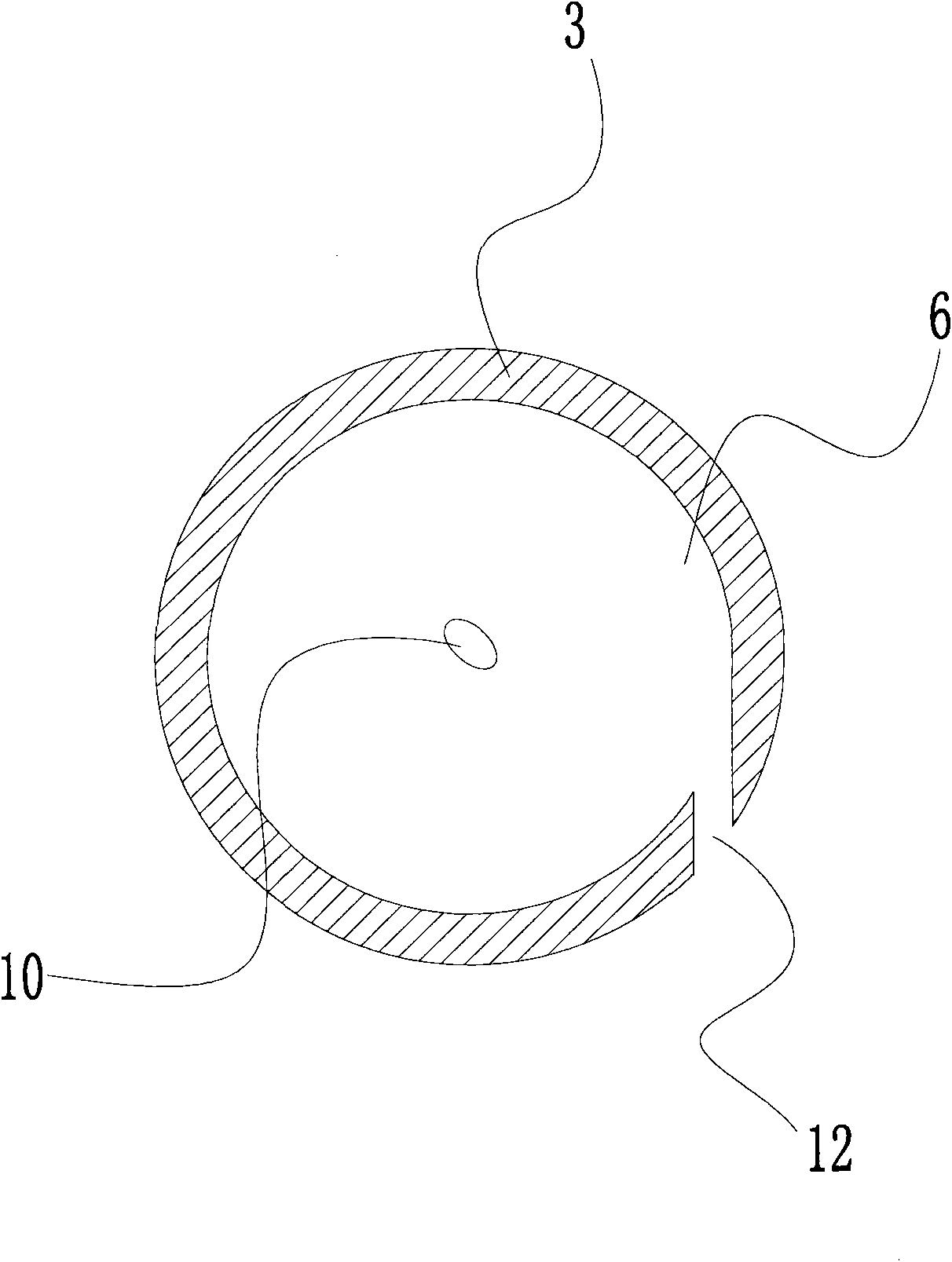

Automatic crystal removing structure of tunnel drainage pipeline and tunnel drainage system with same

ActiveCN104196565ASimple structureSolve the crystallizationHollow article cleaningDrainageWater seepageWater leakage

Disclosed are an automatic crystal removing structure of a tunnel drainage pipeline and a tunnel drainage system with the same. The automatic crystal removing structure of the tunnel drainage pipeline comprises a drain pipe, a base fixedly connected with the drain pipe is arranged inside the drain pipe, a threaded shaft is arranged in the middle of the base, the threaded shaft is arranged in the length direction of the drain pipe, a stress piece is movably arranged on the threaded shaft, an elastic piece is arranged between the stress piece and the base, supporting rods are arranged on the stress piece, the tail ends of the supporting rods are provided with brushes, and the brushes make contact with the inner wall of the drain pipe. The automatic crystal removing structure is simple and capable of effectively solving the problem of crystallization of a tunnel drain pipe, thereby reducing the water seepage and water leakage phenomena of tunnels in limestone areas; the automatic crystal removing structure is good in effect, low in cost and suitable for application and popularization.

Owner:CHONGQING GUOXIANG NEW MATERIAL

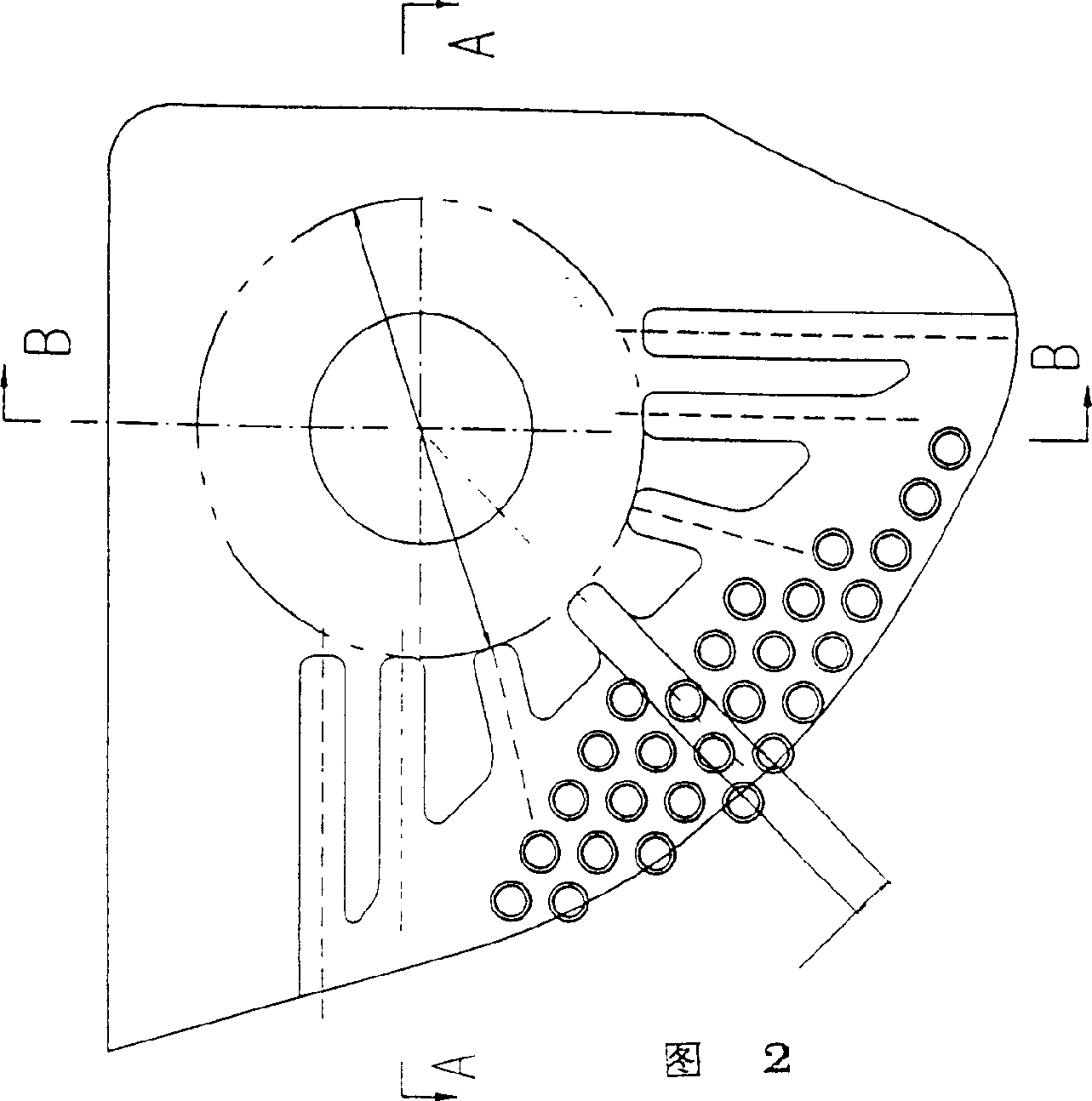

Lateral embedded type diaphragm filter plate constructed from controllable constant temperature plate core and assembling process

InactiveCN1429642AImprove prestress strength and service lifeAutomateFiltration separationEngineeringPre stress

A laterally embedded diaphragm filter plate made of constant-temp. plate core is composed of a constant-temp. plate core and a diaphragm whose joint part is fixed to the lateral surface of the constant-temp. plate core in the shrink fet mode. Its advantages are no fluid leakage, high pressure strength and long service life of plate core, high productivity and quality of product, and no crystallizing and chemical modification of material during filtration.

Owner:朱兴源

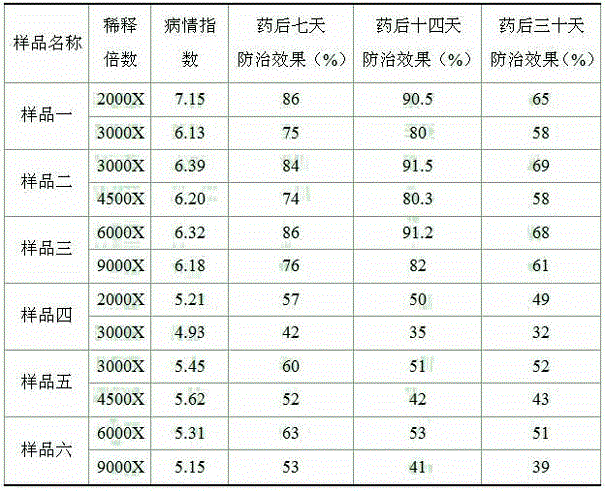

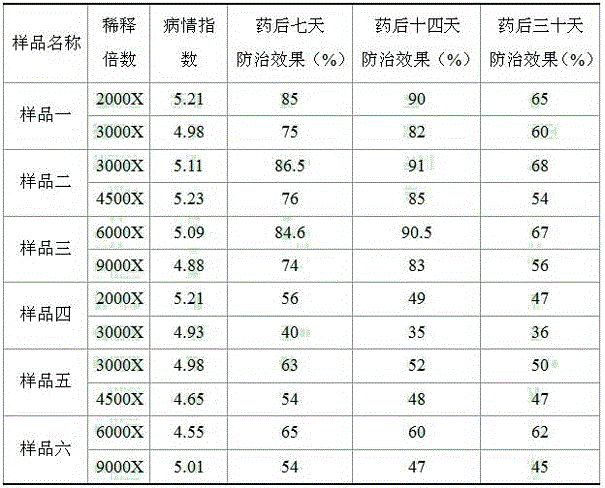

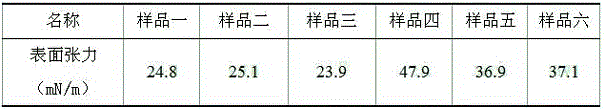

Pyraclostrobin synergistic water suspension agent and preparation method thereof

InactiveCN106259391ASolve the crystallization problemAddress particle size growthBiocideDead animal preservationFoaming agentAnti freezing

The invention relates to a pyraclostrobin synergistic water suspension agent. The pyraclostrobin synergistic water suspension agent is prepared from the following components in percentage by weight: 20 percent to 60 percent of pyraclostrobin, 2 percent to 4 percent of a grain-diameter increasing inhibitor, 3 percent to 6 percent of a dispersing wetting agent, 0.1 percent to 1 percent of a thickener, 0.1 percent of a preservative, 3 percent to 5 percent of an anti-freezing agent, 0.1 percent of a de-foaming agent, 2 percent to 6 percent of a synergist and the balance of water. The pyraclostrobin, the grain-diameter increasing inhibitor, the dispersing wetting agent, the thickener, an emulsifier, the synergist and the water are pre-mixed and sheared, and then are subjected to two-grade sanding to form a finished product. The pyraclostrobin synergistic water suspension agent provided by the invention is low in surface tension and good in pharmacological effect; a preparation process is simple and an application method is simple; a field experiment shows that the pyraclostrobin synergistic water suspension agent has remarkable sterilization and treatment, and protection effects.

Owner:HEBEI VEYONG BIO CHEM

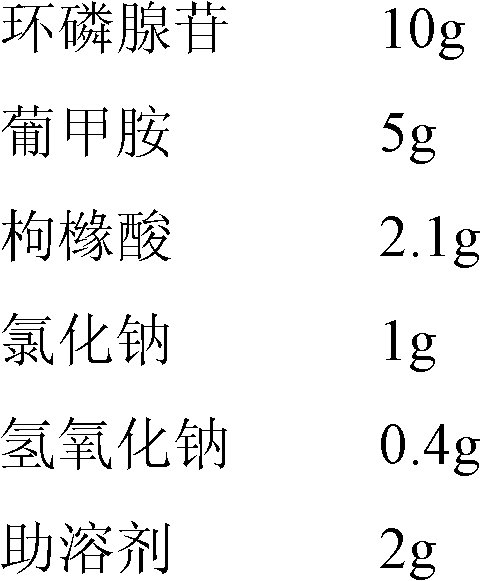

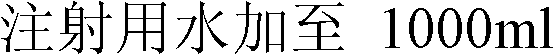

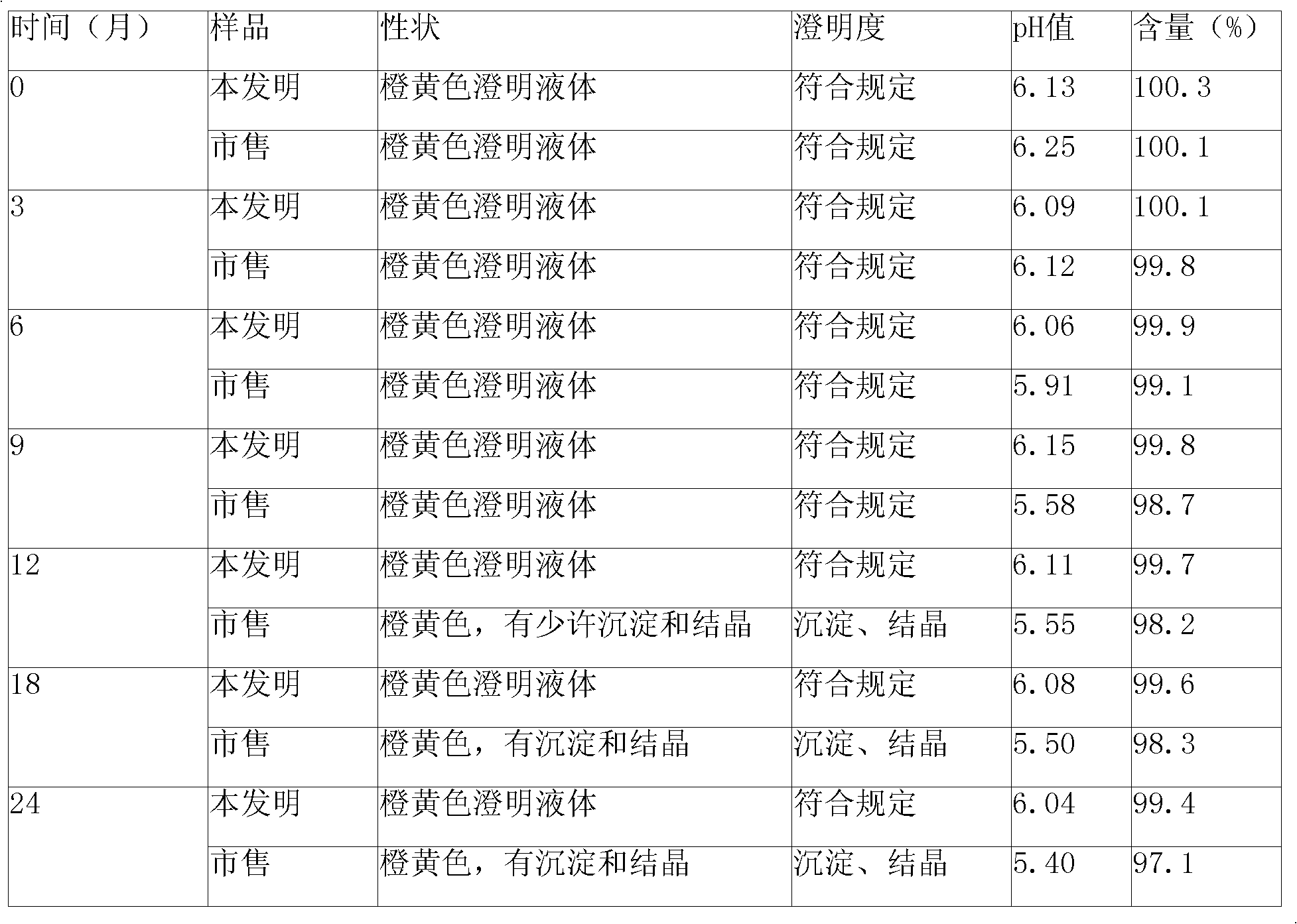

Meglumine adenosine cyclophosphate composition injection and preparation method thereof

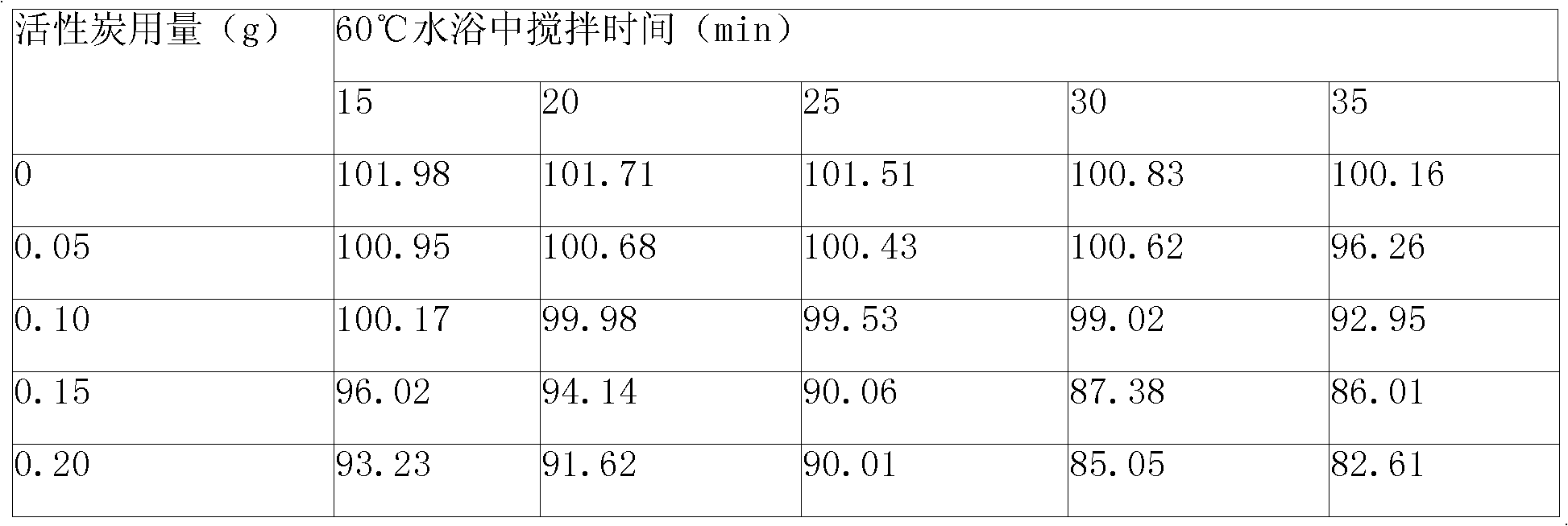

InactiveCN102600070ASolve the crystallization problemFix stability issuesOrganic active ingredientsPharmaceutical delivery mechanismAdenosineAdditive ingredient

The invention relates to a preparation method of chemical medicine, in particular to meglumine adenosine cyclophosphate composition injection and a preparation method thereof. The meglumine adenosine cyclophosphate composition injection comprises the following ingredients in part by weight: 5 to 15 parts of adenosine cyclophosphate, 3 to 10 parts of meglumine, 2.0 to 2.2 parts of citric acid, 0.6 to 0.8 parts of sodium hydroxide, 2 to 4 parts of sodium chloride and 2 to 5 parts of water for injection. The preparation method comprises the following steps that the citric acid is mixed and dissolved in the water for injection, the pH value of the mixed solution is adjusted to 5.9 to 6.5 by the sodium hydroxide to form buffering solution, then the sodium chloride and latent solvent are added into the buffering solution to be stirred and dissolved, the water for injection is added, the adenosine cyclophosphate and meglumine are slowly added while the solution is stirred, active carbon is added and stirred in the solution after the adenosine cyclophosphate and the meglumine are completely dissolved, and the mixed solution is filtered and reflowed to prepare colorless clear and bright liquid. The clarity of the injection is good, the stability is good, and the injection is safe to use.

Owner:湖北安邦医药有限公司

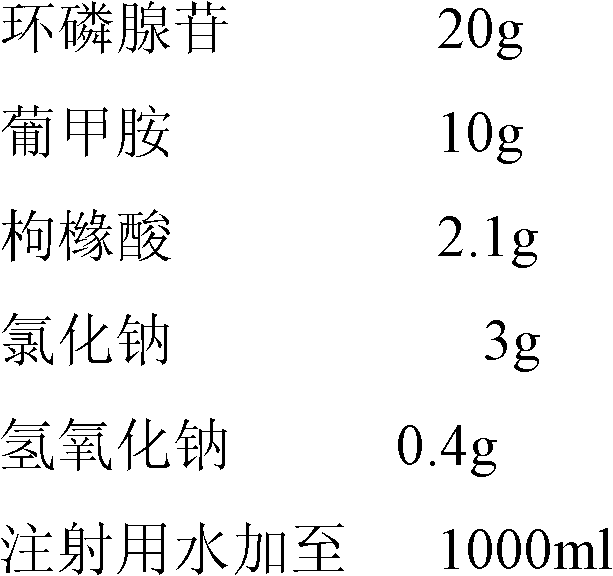

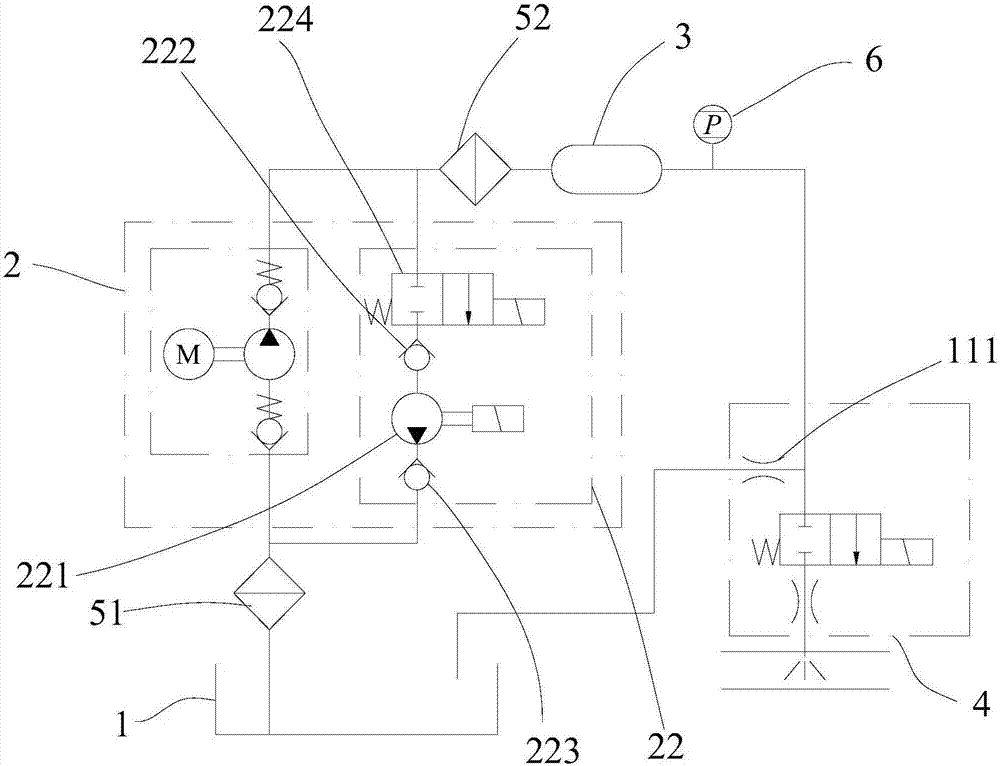

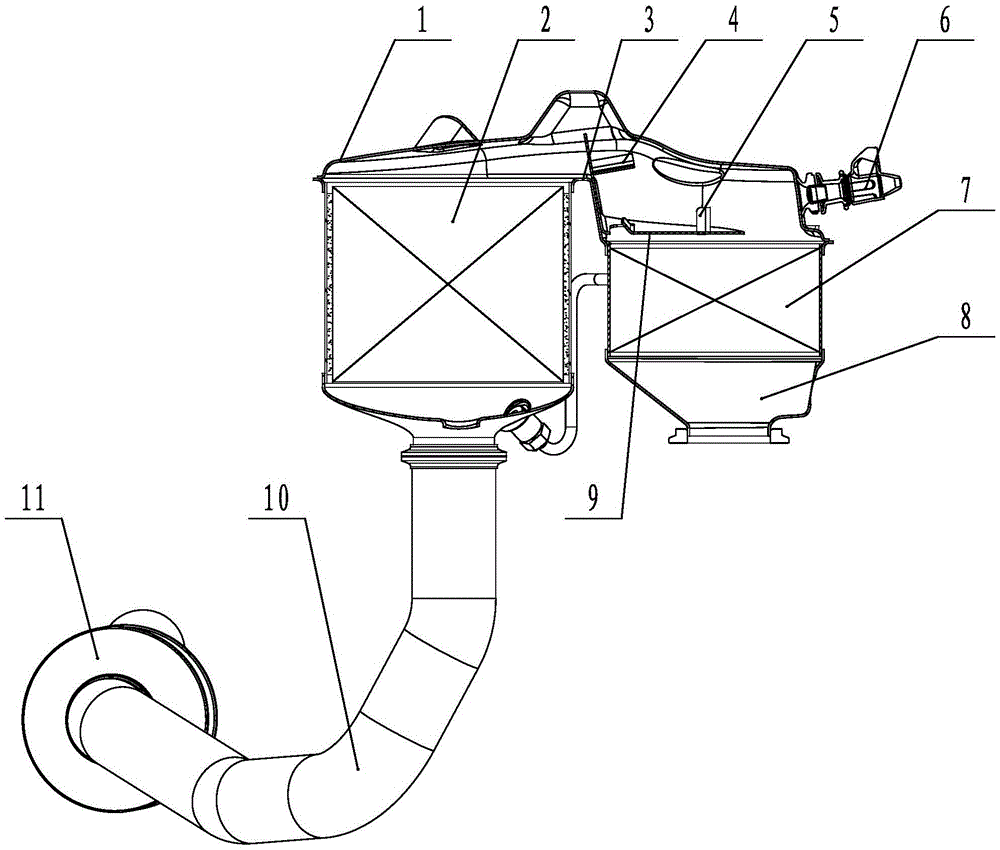

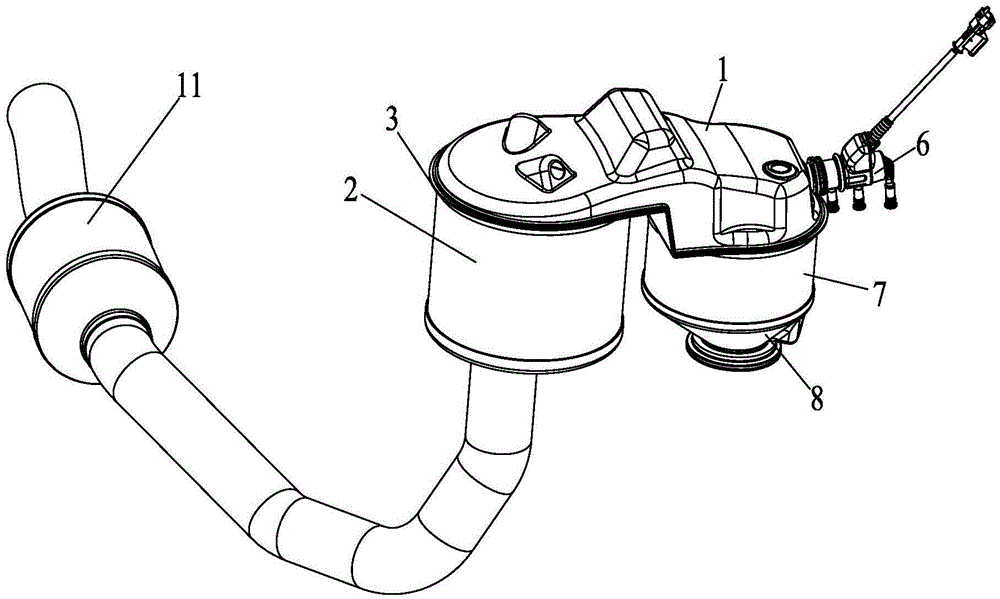

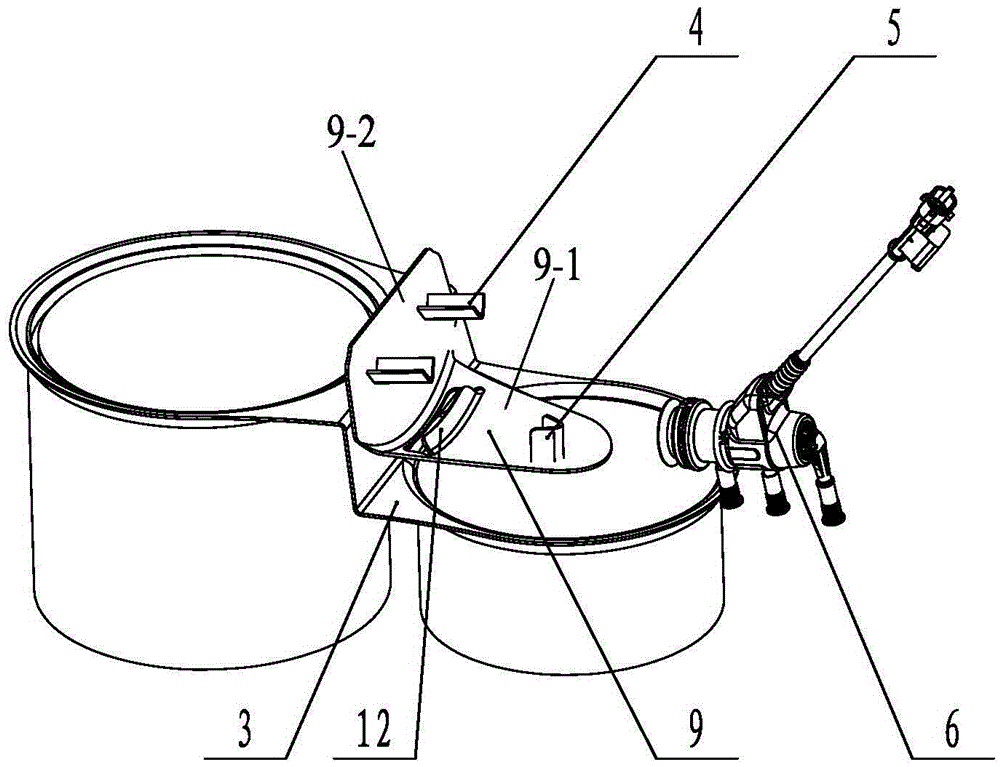

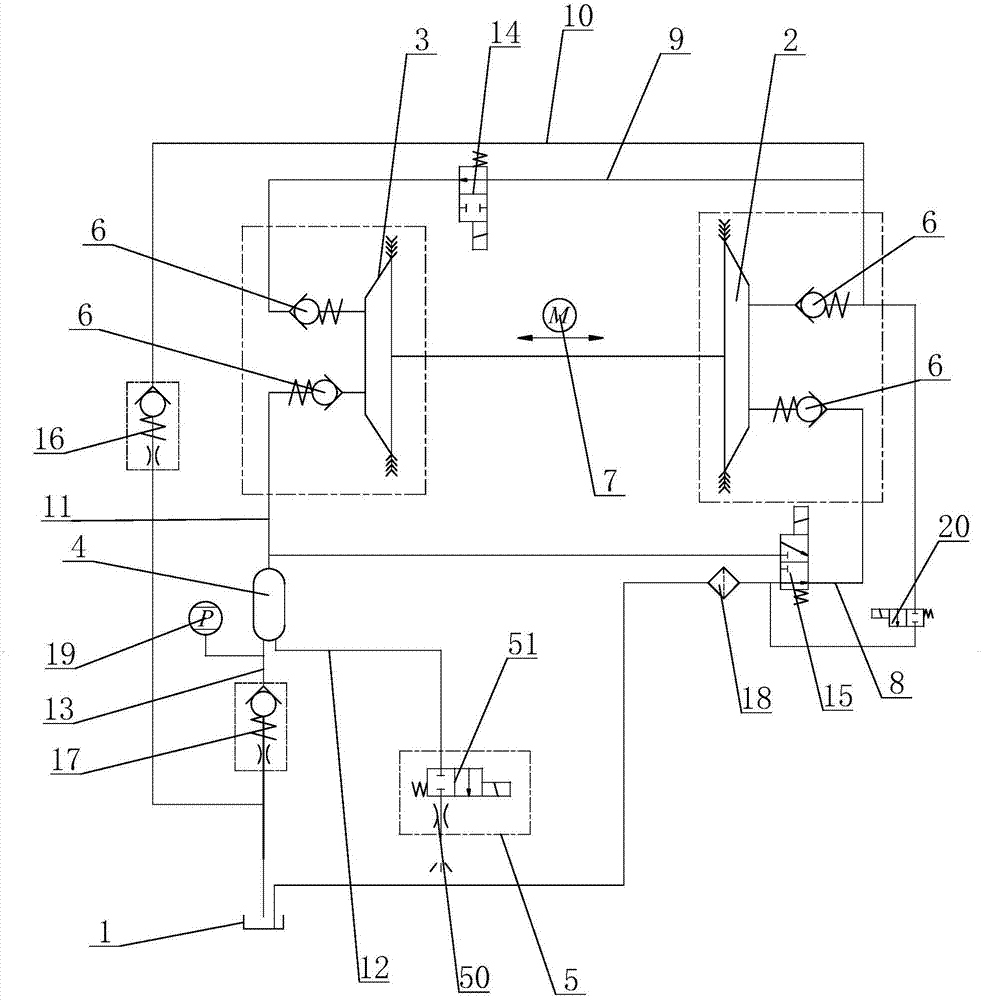

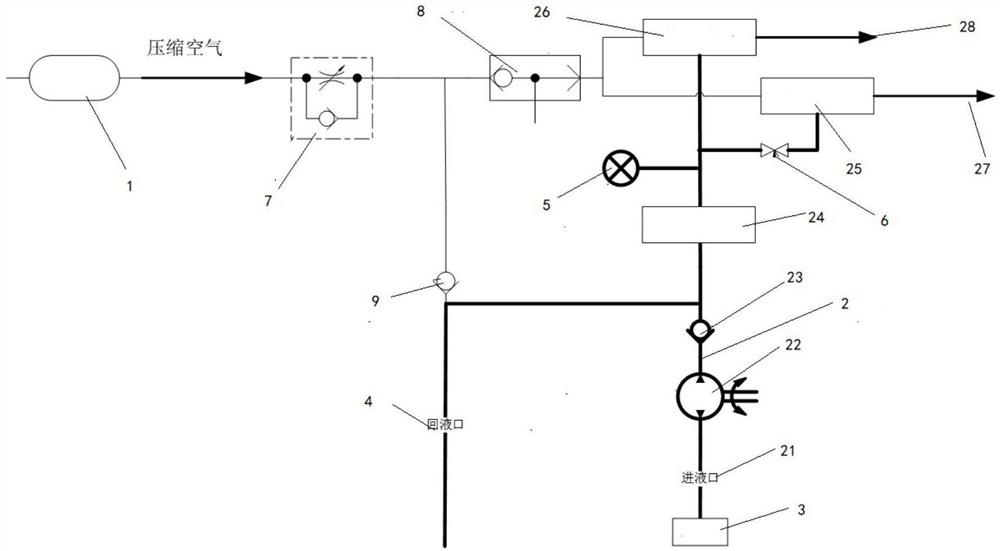

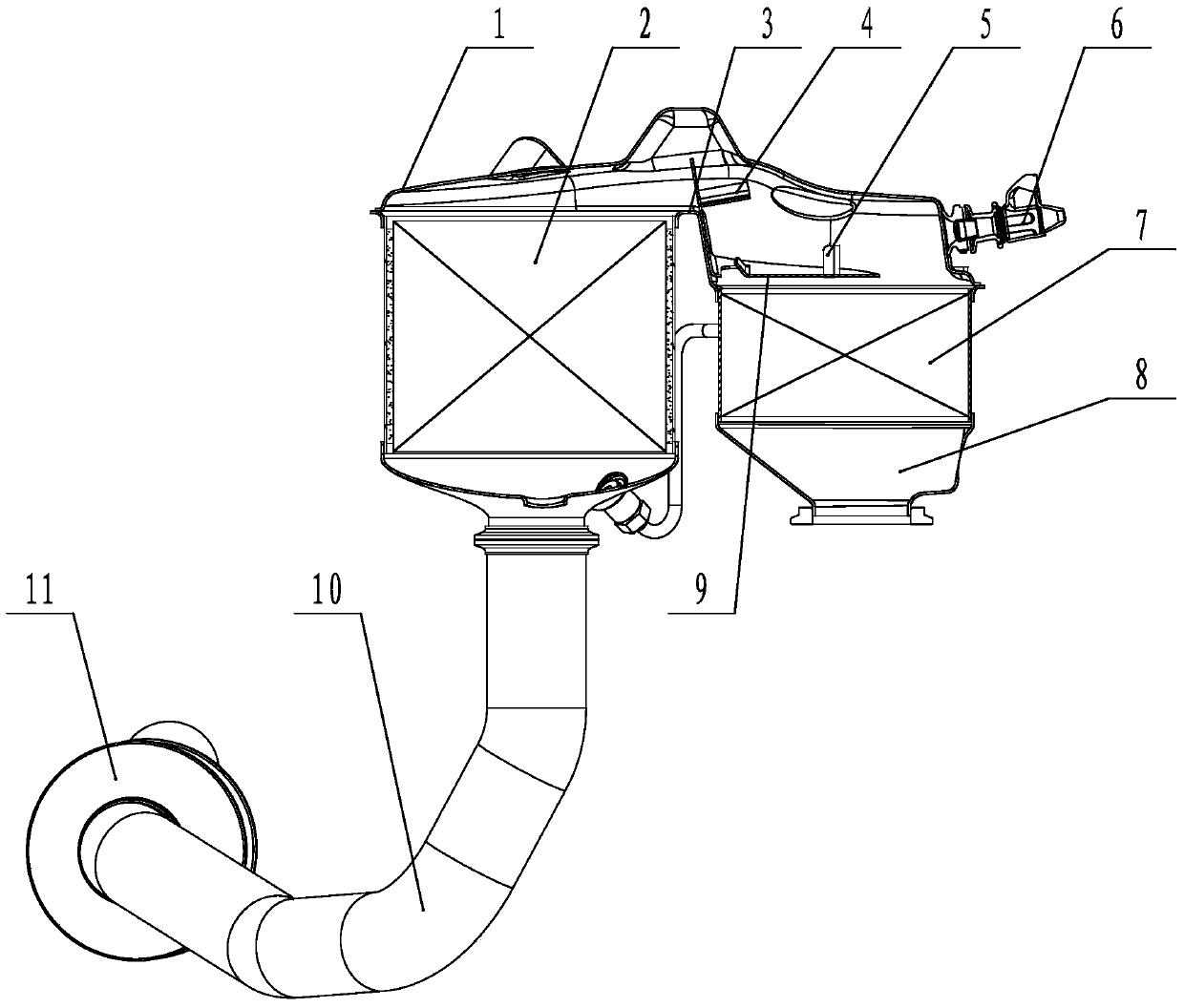

Urea pumping system

PendingCN107246302AResolve residual crystalsSolve the problem of blocked pipesExhaust apparatusSilencing apparatusRefluxElectromagnetic valve

The invention discloses a urea pumping system. The urea pumping system comprises a urea box, a urea pump module, an energy accumulator and a nozzle module which are sequentially connected through a pipeline, wherein the urea pump module comprises a main pump used for pumping a liquid in the urea box to the nozzle module, and an auxiliary pump used for reversely sucking a liquid in the pipeline back into the urea box; the nozzle module comprises a first electromagnetic valve and an atomization nozzle; the first electromagnetic valve is connected with the energy accumulator and the atomization nozzle through the pipeline; a reflux pipeline which communicates with the urea box is arranged on the pipeline between the first electromagnetic valve and the energy accumulator; and a first damping hole is formed in the reflux pipeline. According to the urea pumping system, an airfree auxiliary structure is adopted, double-pump parallel connection is adopted, when a urea solution is injected, the main pump is started, the urea solution is pumped from the urea box to the nozzle module, after injection, the auxiliary pump sucks the urea solution remaining in the system back into the urea box, and the problems of urea crystallization and pipeline blocking are solved.

Owner:HUST WUXI RES INST +1

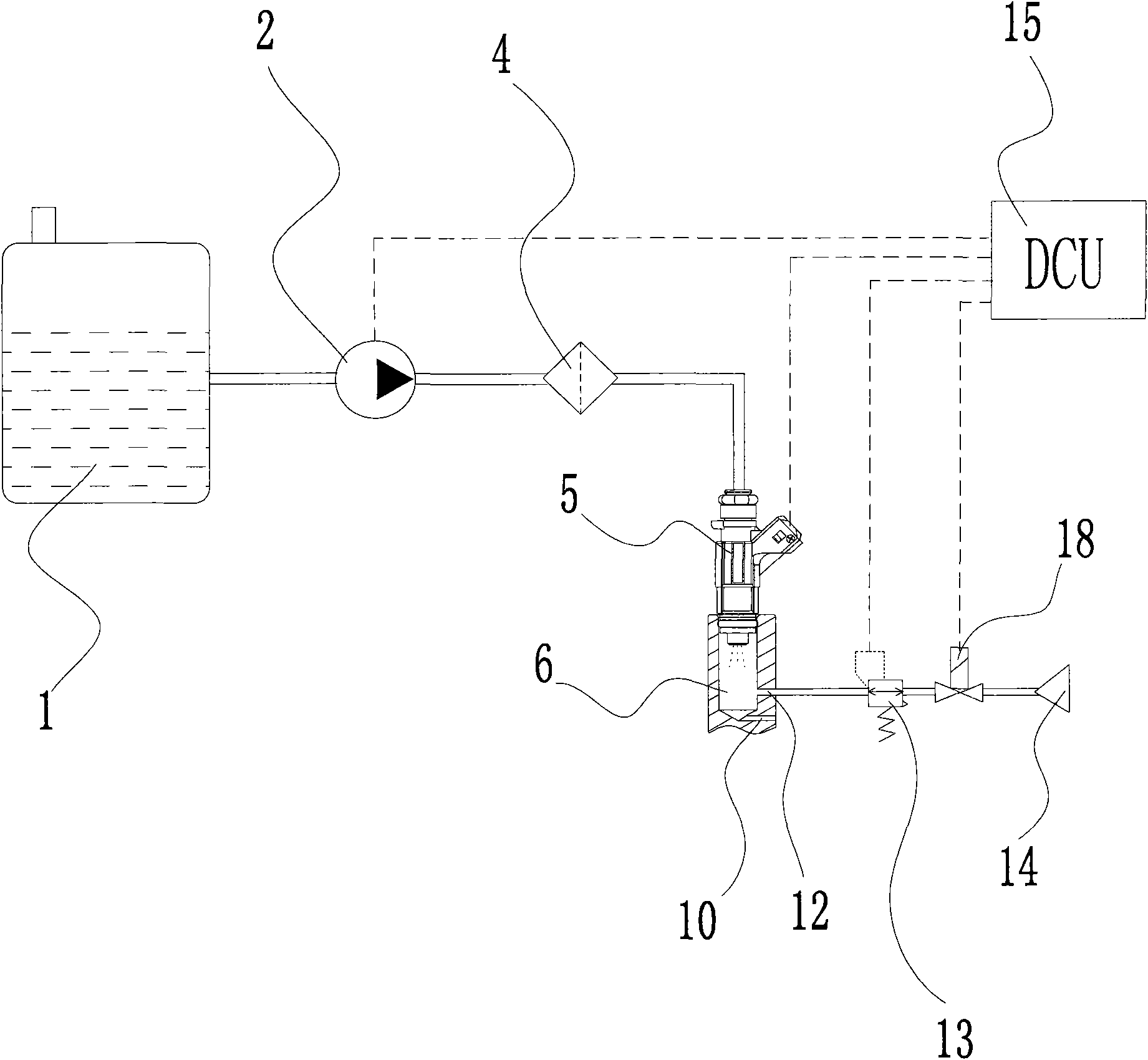

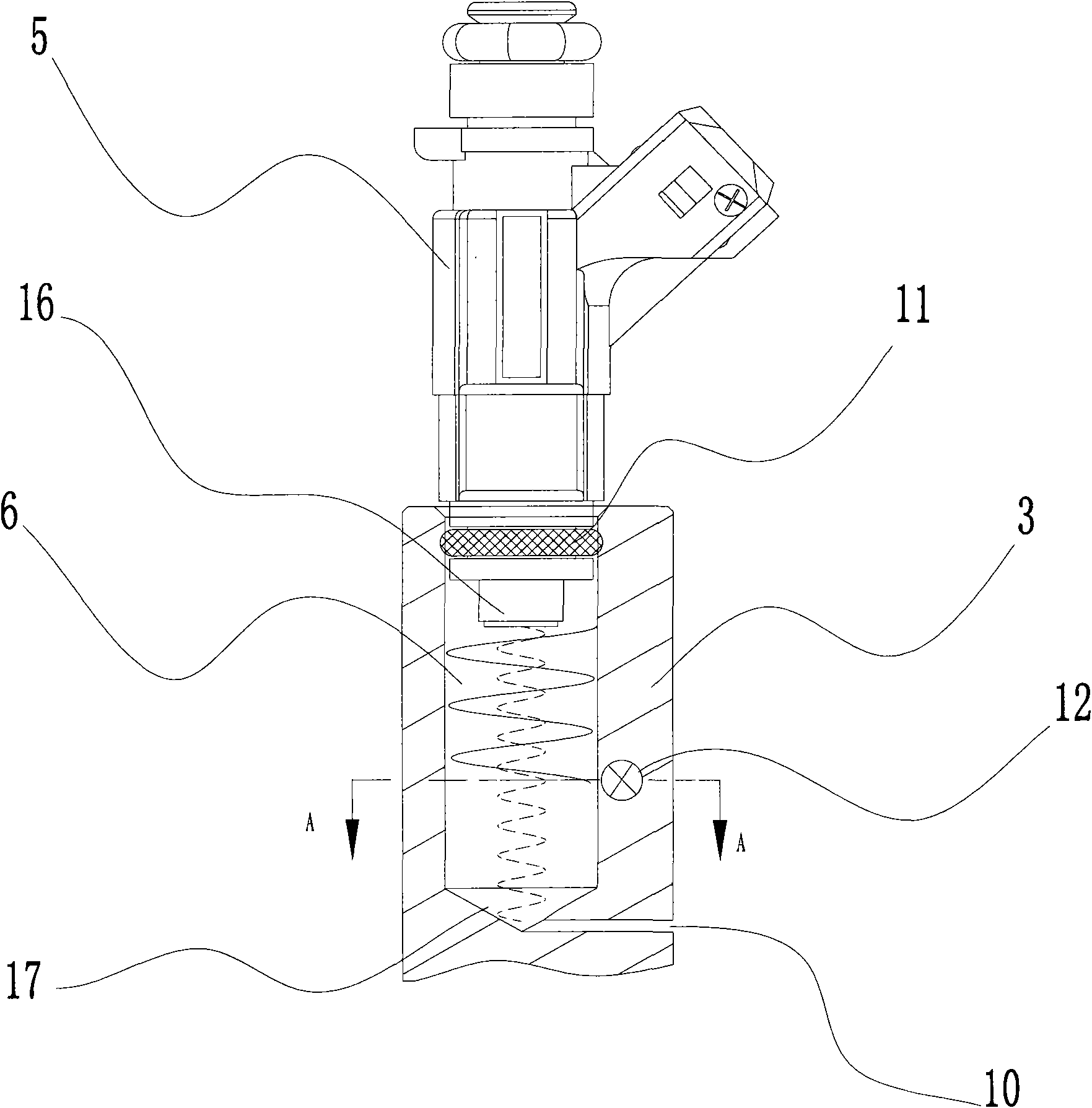

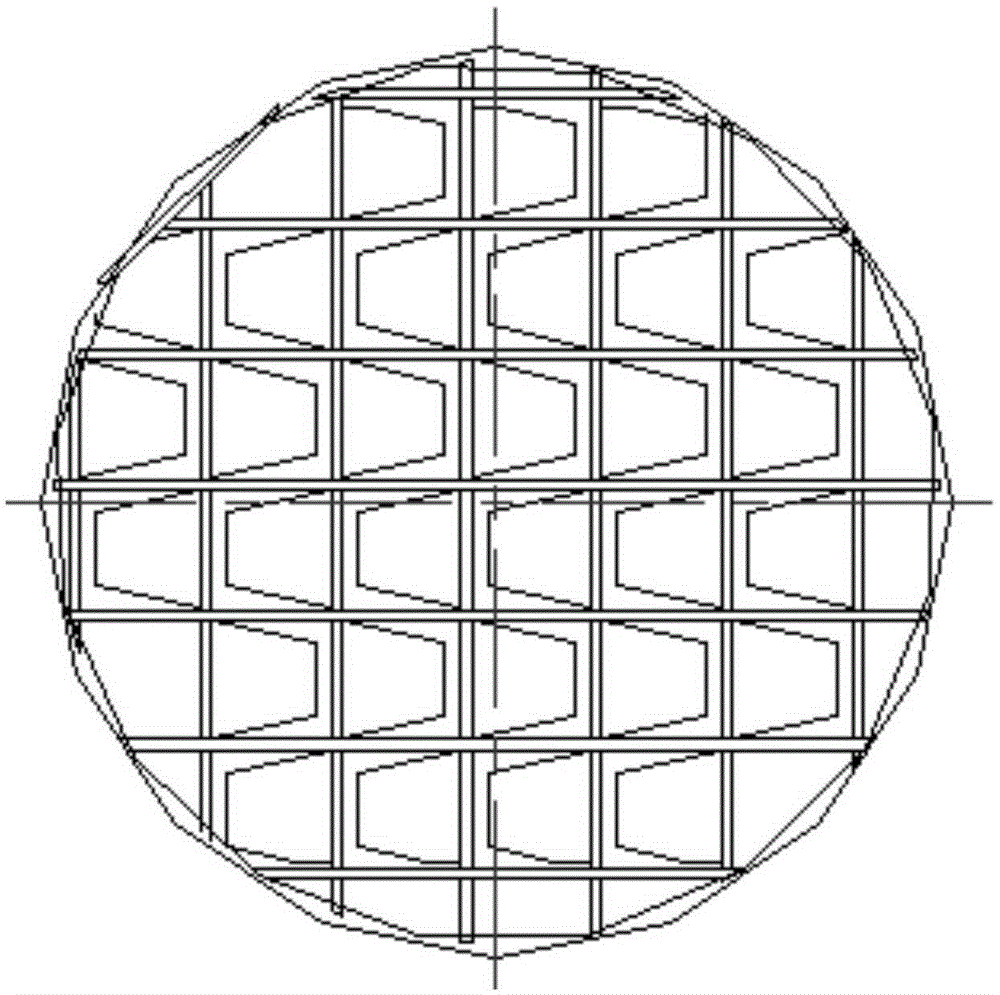

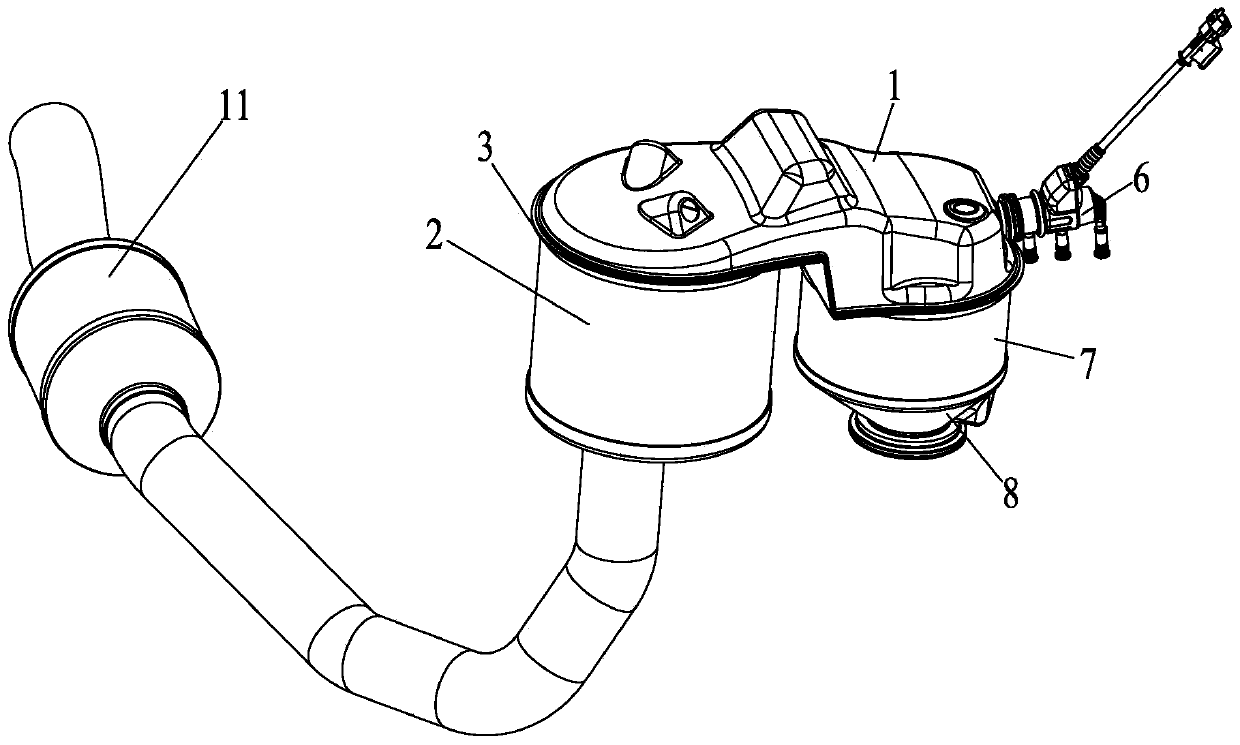

Gas-liquid stirring and mixing device of urea solution metering injection system

InactiveCN102116186ASolve the crystallization problemIngenious designExhaust apparatusDispersed particle separationEngineeringReducing agent

The invention relates to a gas-liquid stirring and mixing device of a urea solution metering injection system, comprising a metering valve, a compressed air inlet, a mixing cavity and an injection outlet, wherein the metering valve injects a reducing agent; the mixing cavity is used for gas-liquid stirring and mixing; the compressed air inlet is arranged on the side wall of the mixing cavity and tangent to the inner wall of the mixing cavity; and the injection outlet is arranged at the bottom of the mixing cavity. The invention has ingenious design, ensures good uniformity of a stirred and mixed suspension and can effectively solve the problems of deposition and crystallization inside the mixing cavity.

Owner:SUZHOU POWERGREEN EMISSION SOLUTION SYST

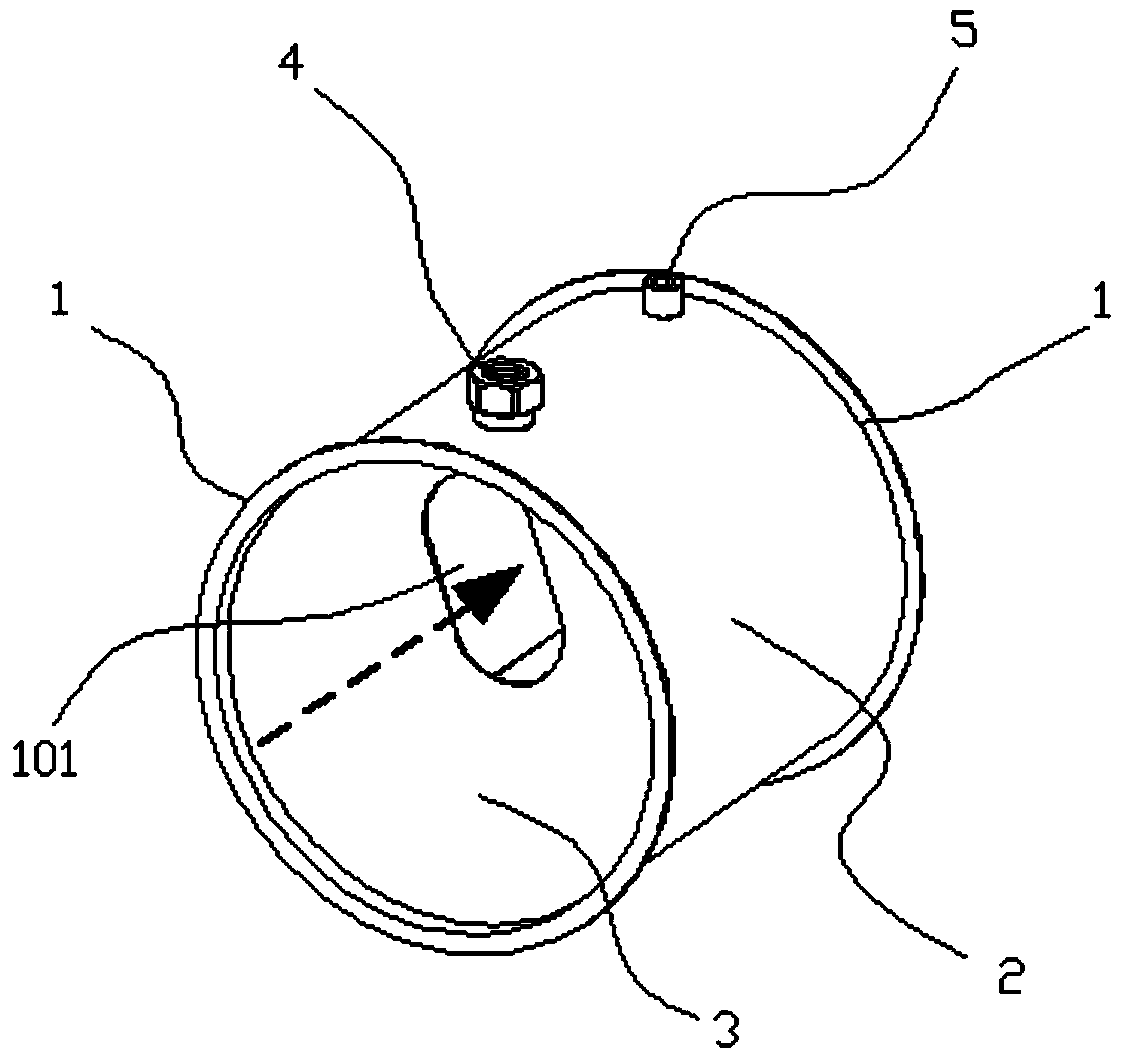

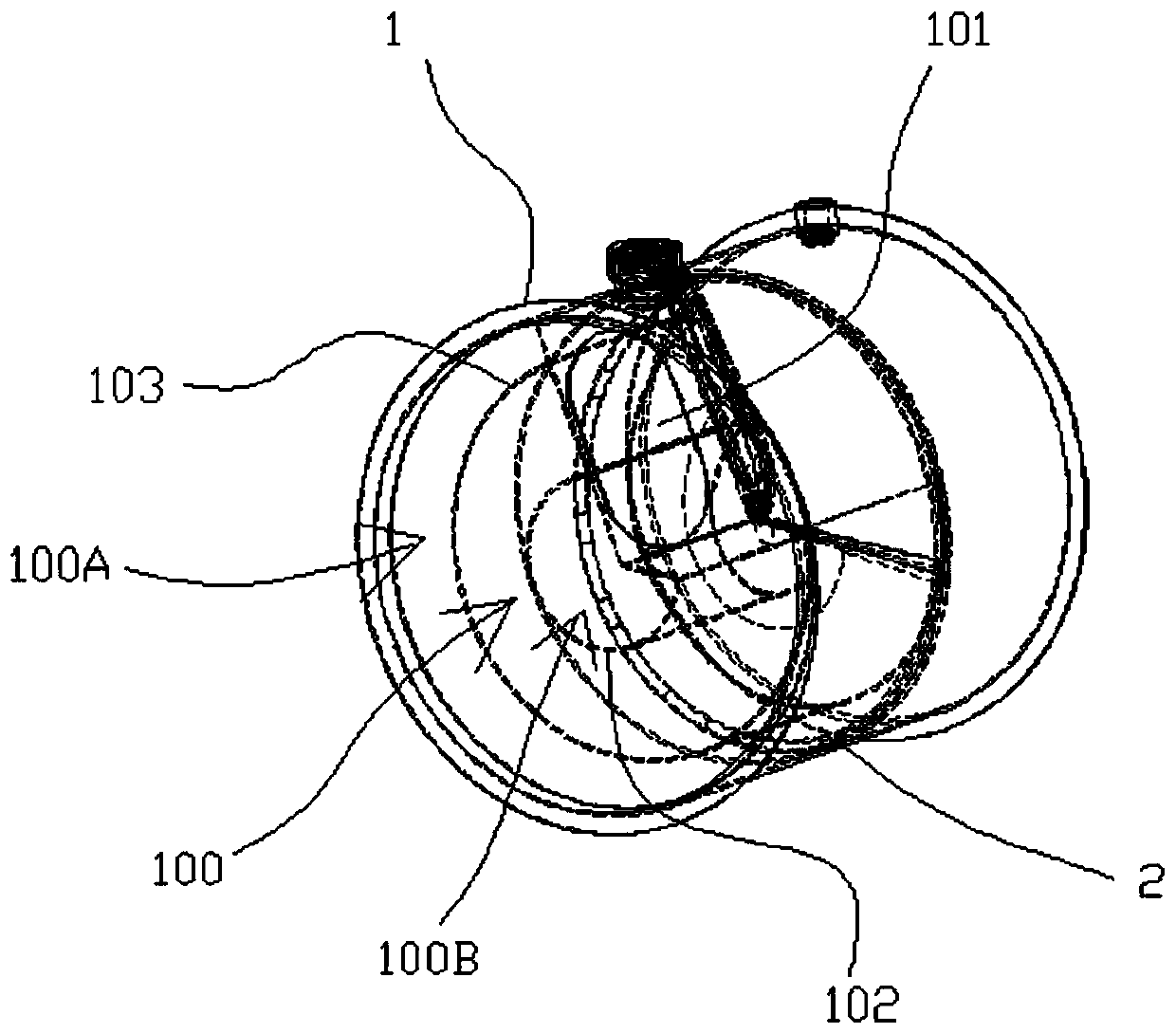

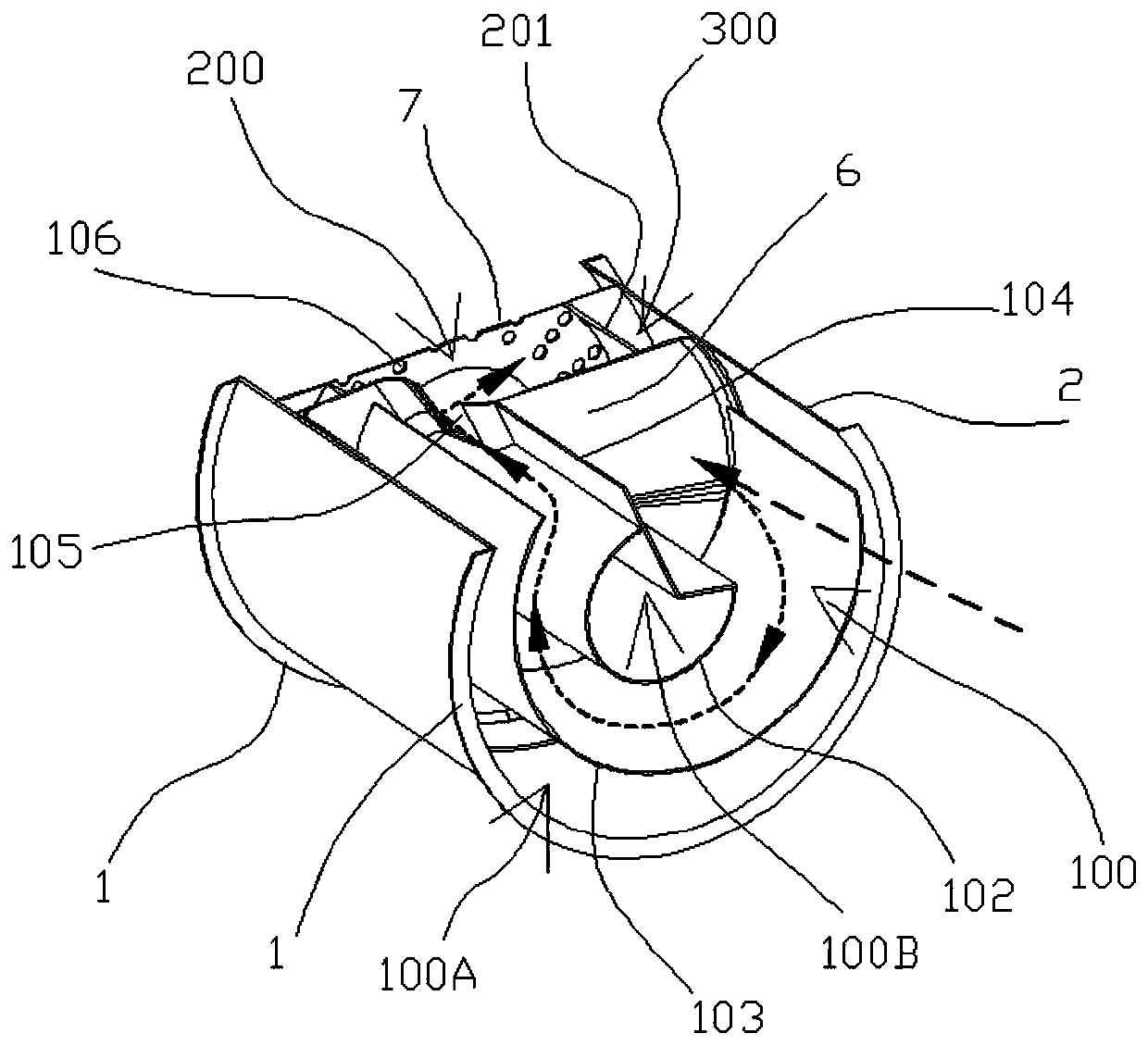

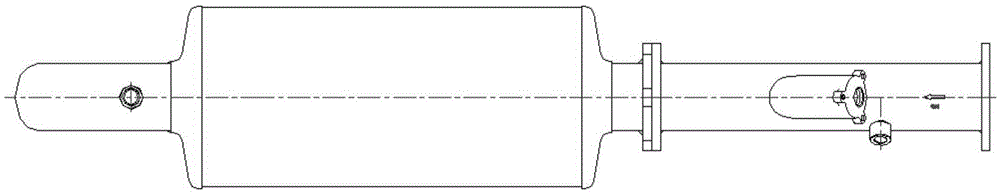

SCR urea mixer for diesel internal combustion engine aftertreatment system

ActiveCN110657007ASolve depositionSolve the crystallization problemInternal combustion piston enginesExhaust apparatusEngineeringInternal combustion engine

The invention discloses an SCR urea mixer for a diesel internal combustion engine aftertreatment system. The SCR urea mixer comprises a cylindrical shell and a urea nozzle, wherein a vortex mixing cavity is formed in the front end in the shell; an exhaust mixing cavity is formed in the rear end in the shell; the urea nozzle is arranged on the wall of the vortex mixing cavity; the vortex mixing cavity is arranged on the inner circumference of the cylindrical shell and is the gas flow mixing cavity with a spiral structure with convergent flow characteristics; air inlets are formed in the front end face and along the axial direction of the shell and the peripheral edge of the spiral structure; exhaust ports are formed in a connecting part connecting the vortex mixing cavity and the exhaust mixing cavity and along the peripheral direction of the central edge of the spiral structure; a circular hole is formed in the center of the rear end face of the exhaust mixing cavity; and a plurality of flow equalizing plate exhaust holes are uniformly formed in the radial periphery of the circular hole. According to the SCR urea mixer, urea liquid drops are transferred, crushed and atomized by utilizing exhaust hot tail gas flow, and is fully and uniformly mixed with the hot tail gas, so that the problems of urea deposition and crystallization are solved, and the gas flow uniformity and the ammonia gas uniformity of the mixer well meet the requirements of emission regulations.

Owner:SINOCAT ENVIRONMENTAL TECH

Riboflavine sodium phosphate composition injection and preparation method thereof

ActiveCN101601647ANo stimulationAvoid harmOrganic active ingredientsMetabolism disorderWater useSodium phosphates

The invention discloses a riboflavine sodium phosphate composition injection and a preparation method thereof. The riboflavine sodium phosphate composition injection comprises riboflavine sodium phosphate, citric acid, sodium hydroxide and sodium chloride. Each injection contains 5 to 15mg of riboflavine sodium phosphate, 2.1mg of citric acid, 2 to 4mg of sodium hydroxide and 0.6 to 0.8mg of sodium chloride. The preparation method comprises the following steps: adding water used for injection into the citric acid for stirring and dissolving; adjusting the pH to about 6.2 with sodium hydroxide; adding sodium chloride for stirring to dissolve the sodium chloride; adding the water used for injection and 1g of active carbon; adding riboflavine sodium phosphate while stirring; after the riboflavine sodium phosphate is completely dissolved, complementing the water for injection until the total amount is completely complemented; performing filtering, refluxing, filling, nitrogen charge, melting to seal, sterilizing at a high temperature; and after reducing the temperature, detecting with lamps, packing and checking, and obtaining the finished product. The riboflavine sodium phosphate composition injection does not crystallize, has good clarity and stability, and is helpful for improving the yield of the product, reducing the market rick of the product and is better applied to clinical treatment.

Owner:江西制药有限责任公司

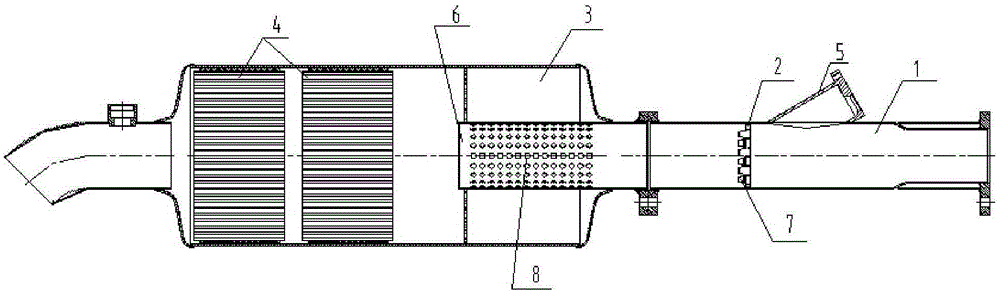

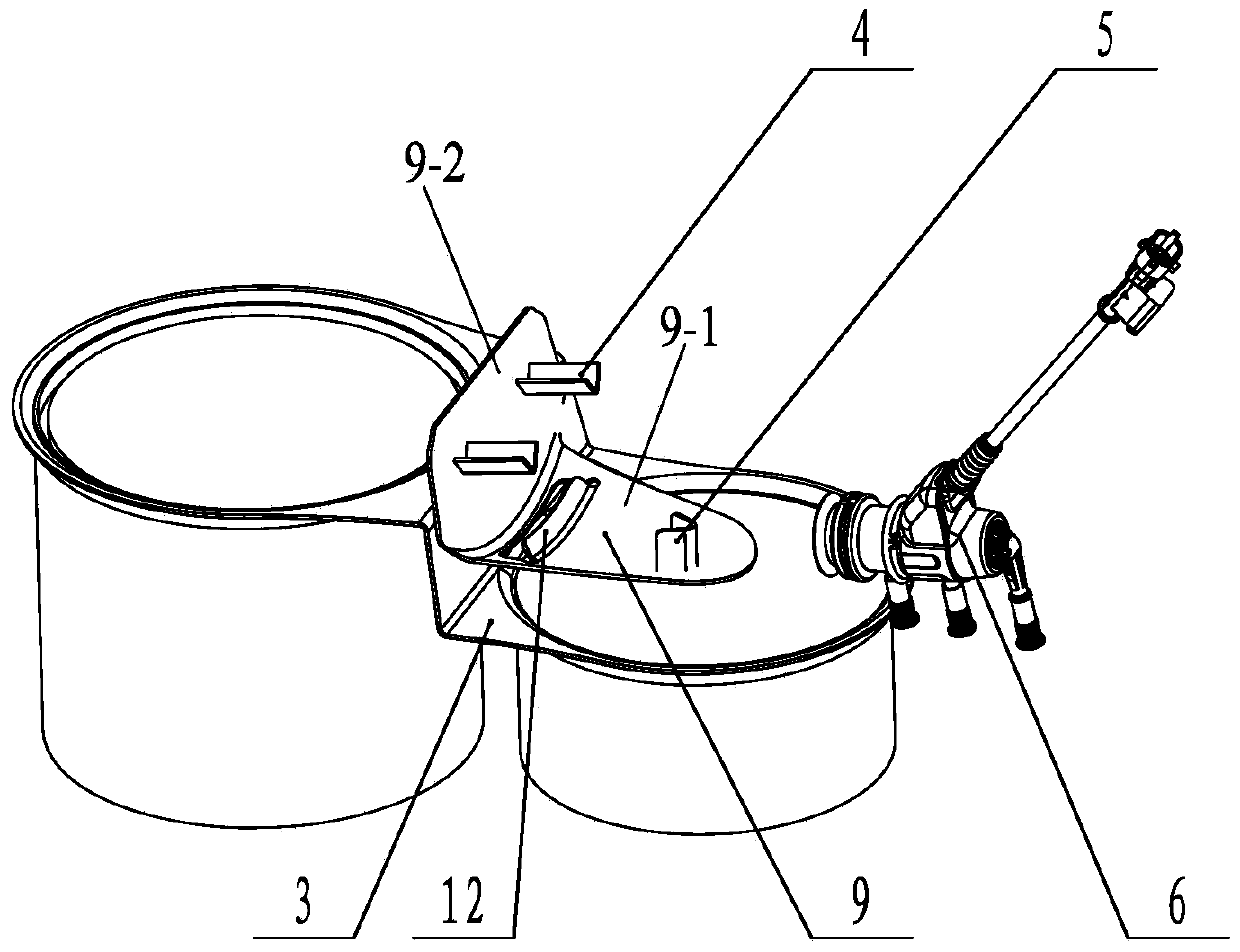

Tightly-coupled selective catalytic reduction (SCR) aftertreatment packaging structure of light diesel vehicle

ActiveCN105587386AReduced risk of crystallizationReasonable mixed structureExhaust apparatusSilencing apparatusParticulatesPulp and paper industry

The invention belongs to the technical field of automobile exhaust aftertreatment and relates to a tightly-coupled selective catalytic reduction (SCR) aftertreatment packaging structure of a light diesel vehicle. The tightly-coupled SCR aftertreatment packaging structure comprises a particulate trap and a diesel oil oxidation catalyst. The particulate trap is connected with the diesel oil oxidation catalyst through a lower clamshell-shaped shell; the upper end of the lower clamshell-shaped shell is connected with an upper clamshell-shaped shell in a tightly coupled mode to form an enclosed cavity; a flow guide plate is fixedly connected to the vertical folded surface of the lower clamshell-shaped shell and comprises a horizontal plate and a vertical plate which are connected into a whole; the vertical plate extends towards the inside of the enclosed cavity; a flow guide groove is formed in the root position of the horizontal plate; a second flow guide block is disposed at the outer end of the horizontal plate; a first flow guide block is mounted on the vertical plate; a urea spray nozzle is installed on the upper clamshell-shaped shell; and the center line of the urea spray nozzle and the second flow guide block intersect. By means of the structural design, full mixing of urea liquid drops with air flow can be facilitated, and the urea pyrolysis and hydrolysis environment temperature is guaranteed.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

SCR after-treatment packaging structure for diesel engine

ActiveCN105257377AImprove conversion efficiencyLow costExhaust apparatusSilencing apparatusAfter treatmentEngineering

The invention discloses an SCR after-treatment packaging structure for a diesel engine. The SCR after-treatment packaging structure for the diesel engine comprises an injection connecting pipe, a mixer, a silencer and a urea injector installation seat. The mixer is arranged in the injection connecting pipe. The urea injector installation seat is arranged on the injection connecting pipe. The silencer is installed at the end, with the mixer, of the injection connecting pipe. The mixer, the silencer and the like are integrally designed and the installation position of the mixer is located at an intersection of the center line of the urea injector installation seat and the injection connecting pipe. In the direction of the center line of the injection connecting pipe, multiple blades of the mixer are distributed on the left side and the right side, the angle of each blade is 60 degrees, and the blades are welded into the injection connecting pipe. By the adoption of the SCR after-treatment packaging structure for the diesel engine, the problem that a urea aqueous solution is crystallized in a vent pipe of a selective catalytic reduction (SCR) after-treatment system can be solved.

Owner:ANHUI QUANCHAI ENGINE

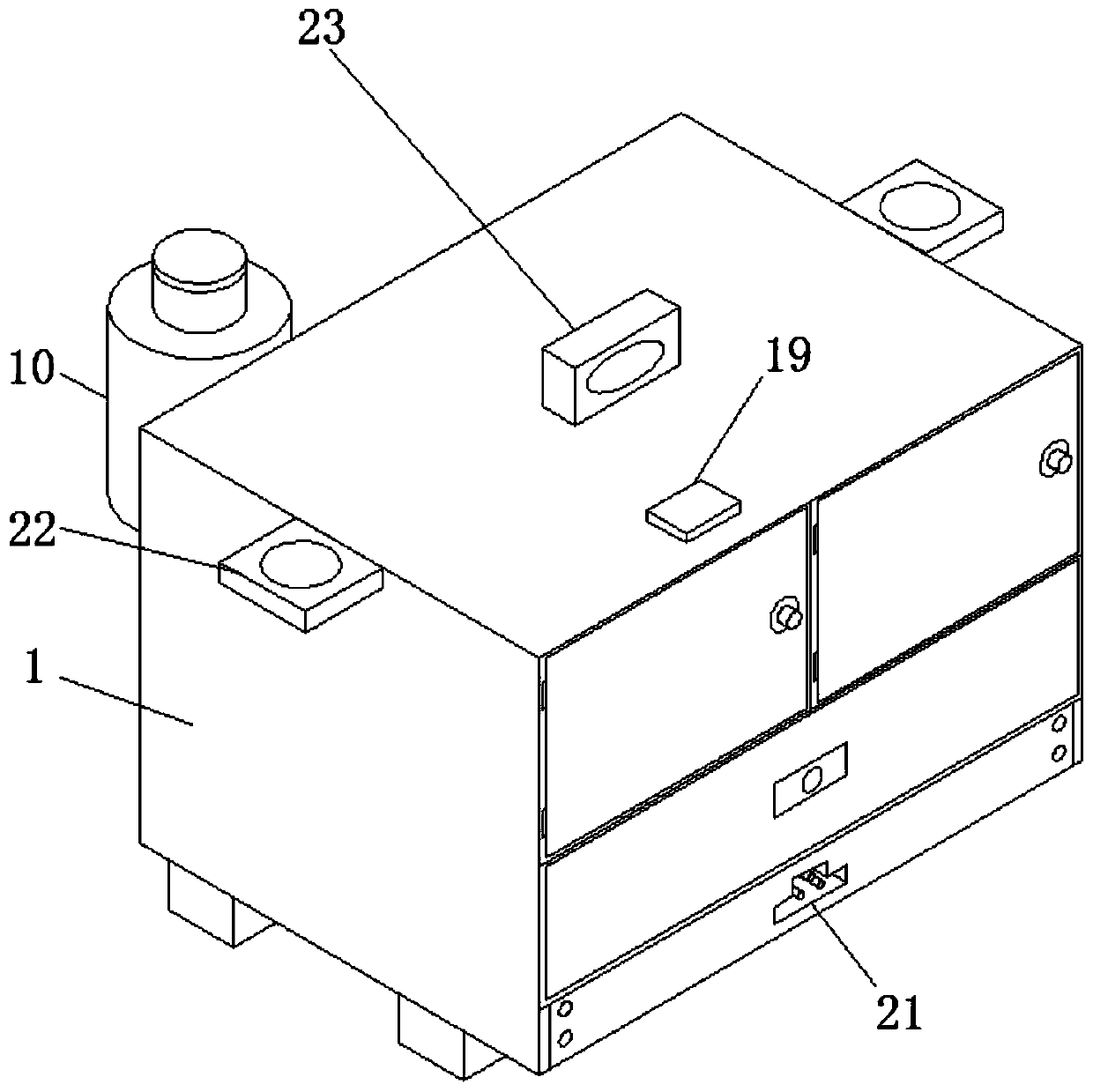

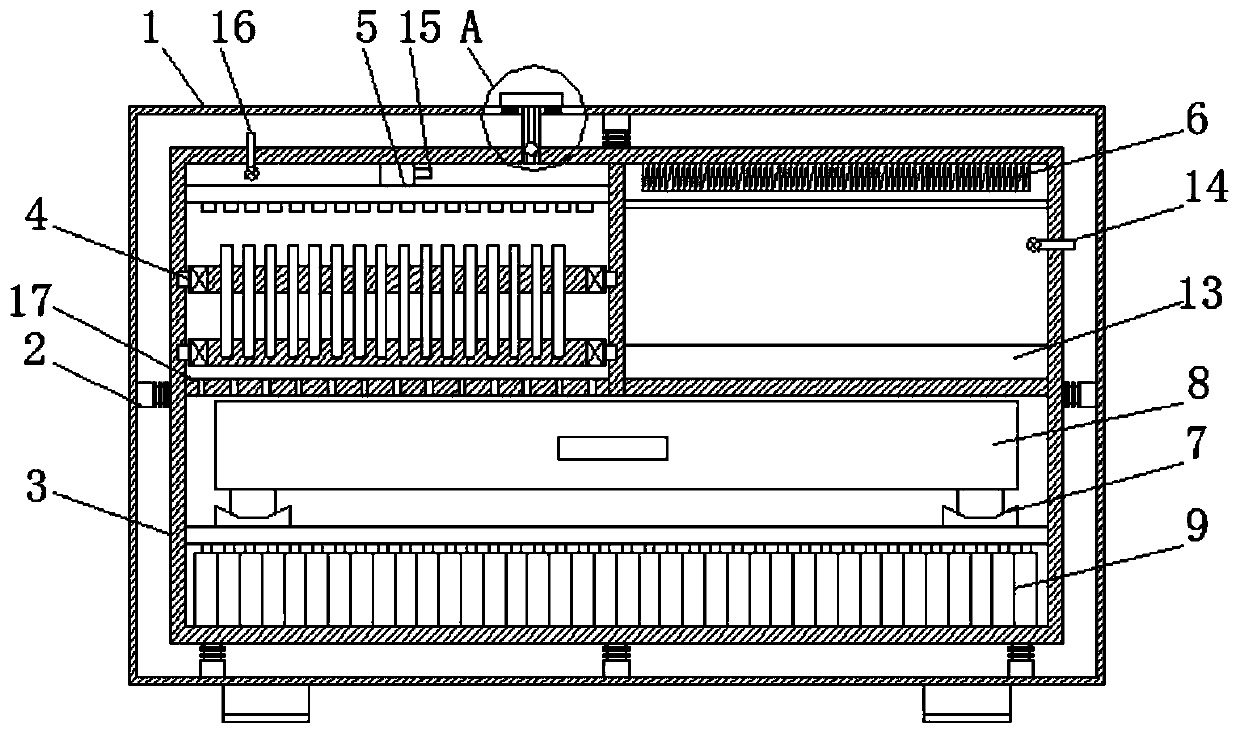

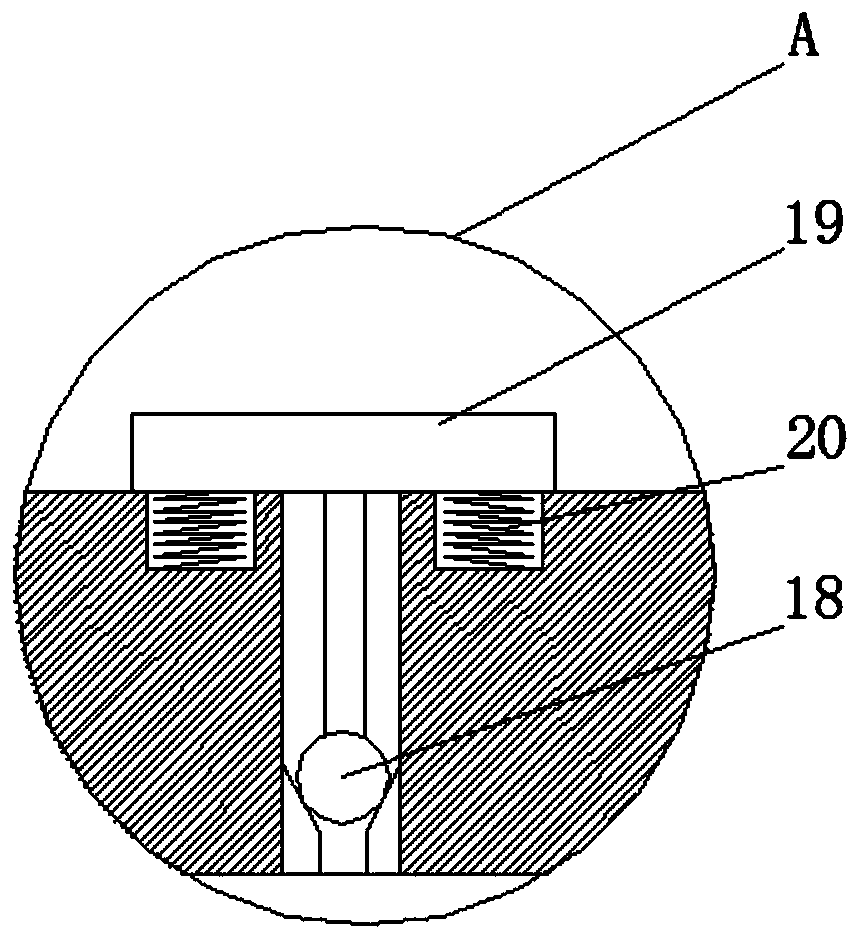

Vehicle-mounted medical sample storage box

PendingCN110002112AEasy to storeSolve the crystallization problemShock-sensitive articlesContainers to prevent mechanical damageEngineeringBottle

The invention discloses a vehicle-mounted medical sample storage box. The vehicle-mounted medical sample storage box comprises a storage box body, an inner box body is fixedly connected into the storage box body through a damping telescopic rod, a blood sample storage cavity, a mannitol adjusting cavity, a limb placing cavity and a lithium battery cavity are sequentially formed in the inner box body from top to bottom, a sliding groove is formed in the blood sample storage cavity, and a blood sample storage device is arranged in the sliding groove in a sliding connection manner. According to the vehicle-mounted medical sample storage box, through cooperation of a liquid nitrogen bottle 10, an electromagnetic valve 15 and a second thermistor 16, the vehicle-mounted medical sample storage box can carry out low-temperature storage on a blood sample in the blood sample storage cavity in the storage process of the blood sample, when the temperature is higher than the set temperature, a circuit is conducted, the electromagnetic valve 15 is started, liquid nitrogen gas enters the blood sample storage cavity through a temperature adjusting pipe 5, the inner temperature is adjusted, and theblood sample storage is greatly facilitated.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

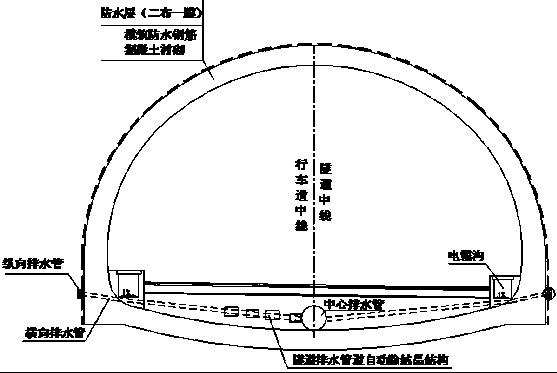

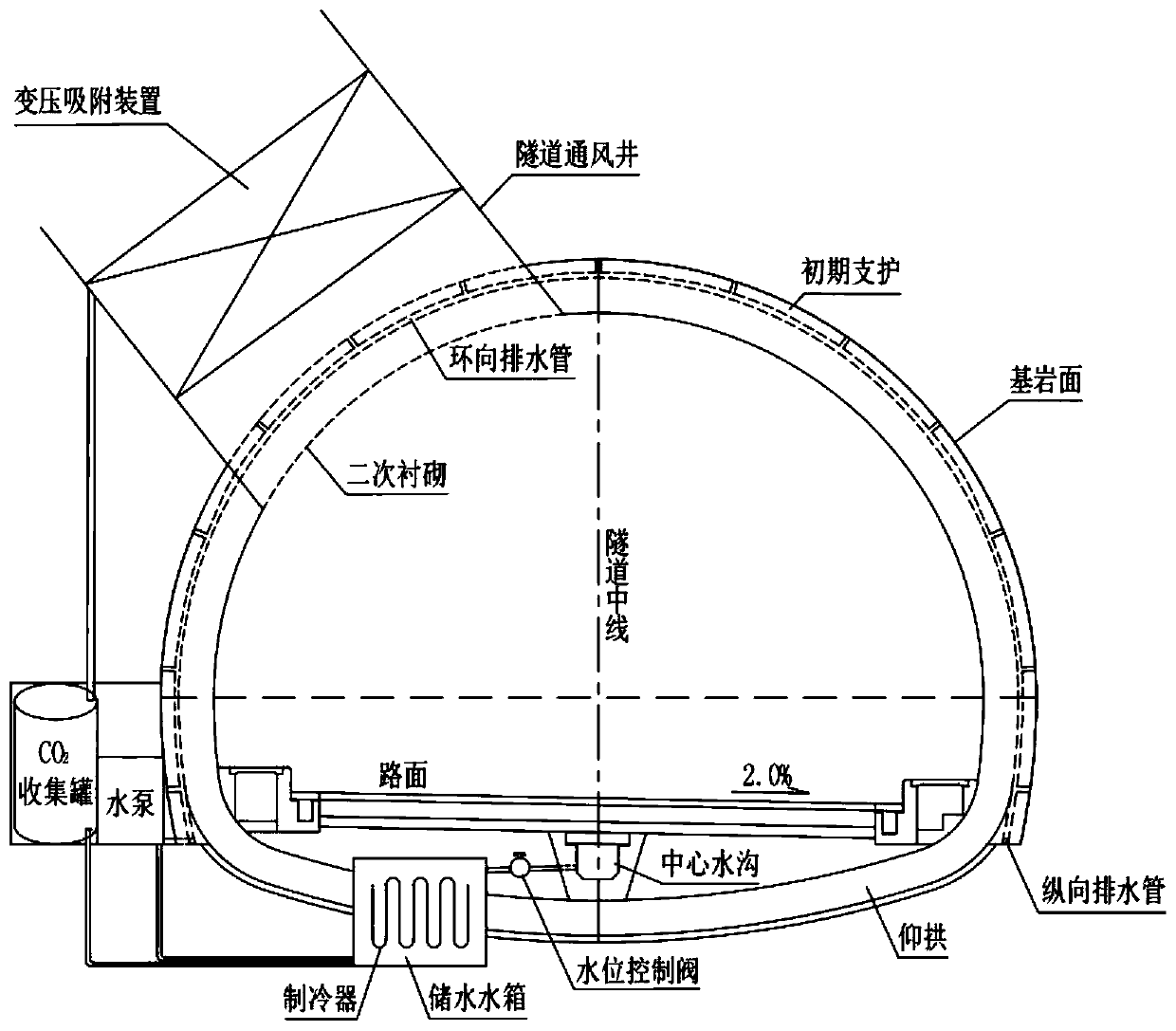

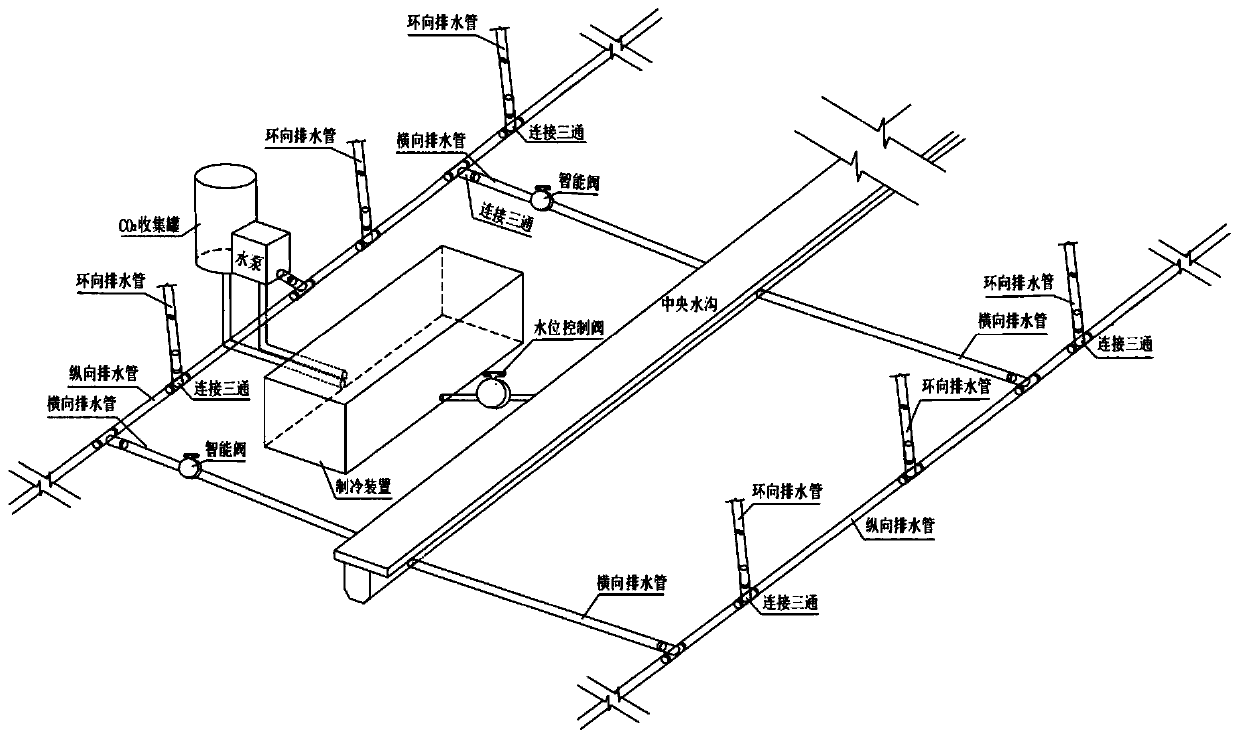

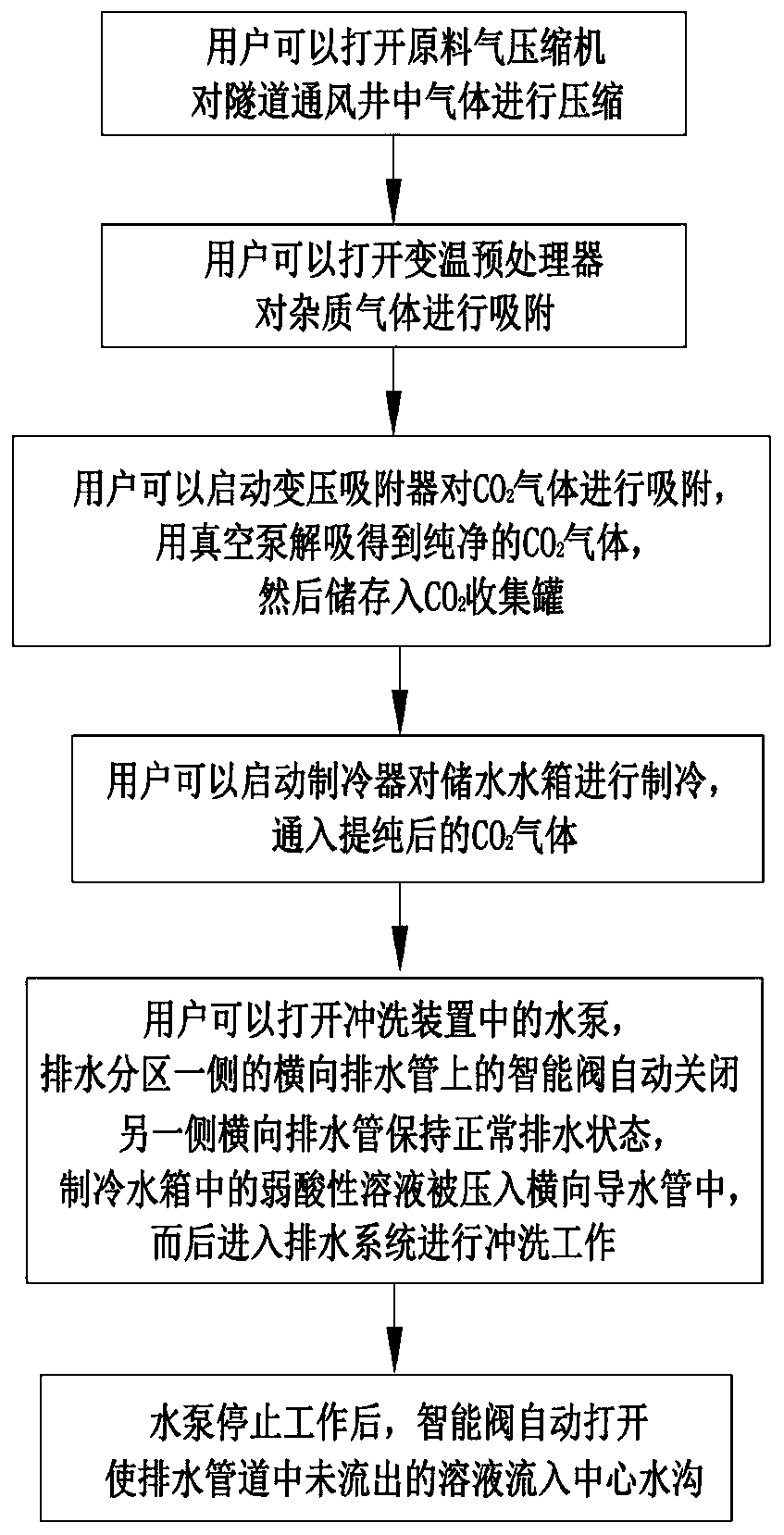

Green system and method for removing grown-up karst tunnel draining pipeline crystals

ActiveCN111589805ASolve the crystallization problemEfficient use ofDomestic cooling apparatusCarbon compoundsKarst tunnelWaste gas

The invention relates to a green system and method for removing grown-up karst tunnel draining pipeline crystals and belongs to the technical field of tunnel engineering. The system comprises a CO2 purifying device composed of a pressure swing adsorption device (PSA device) and a CO2 collecting tank, and a refrigerating device composed of a water storage water tank and a refrigerator. The bottom of the water storage water tank is connected with a water pump and the CO2 collecting tank, and the upper portion of the water storage water tank is connected with a center ditch through a water levelcontrol valve. The water pump is connected with a longitudinal water draining pipe on one side of the interior of a water draining zone through a connecting three-way joint, a transverse water draining pipe on the side of the interior of the water draining zone is connected with an intelligent valve, and a transverse water draining pipe on the other side of the water draining zone keeps the normalwater draining state. By means of the green system and method for removing grown-up karst tunnel draining pipeline crystals, the crystal problem of a water draining system can be solved greenly, in addition, CO2 waste gas in a tunnel and tunnel drained water can be effectively utilized, self marketing of CO2 gas in the karst tunnel is achieved, and a new application direction is also provided forautomobile tail gas treatment and karst tunnel water resource utilization.

Owner:CHONGQING UNIV

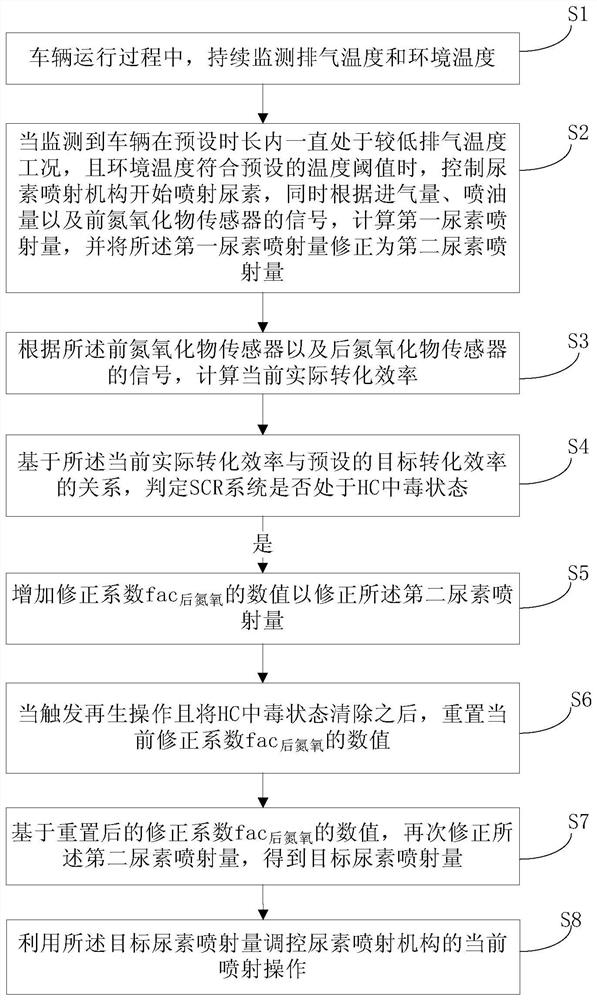

Urea injection control method for SCR (selective catalytic reduction) system

ActiveCN113653552ASolve efficiency problemsSolve the crystallization problemInternal combustion piston enginesExhaust apparatusControl engineeringProcess engineering

The invention discloses a urea injection control method for an SCR (Selective Catalytic Reduction) system. The urea injection control method has the conception that after a urea injection mechanism of the SCR system is started by a vehicle, if the current actual conversion efficiency is lower than the set target conversion efficiency, correction coefficient fac post-nitrogen oxygen is increased until regeneration operation is triggered, and the nitrogen and oxygen after the correction coefficient fac are forcibly reset; for example, the correction coefficient fac post-nitrogen oxygen can be reset initial value can be reset to an initial value 1 or other correction factors are adopted to correct the correction coefficient fac post-nitrogen oxygen, so that the fac post-nitrogen oxygen is set to be other set values, and the current urea injection amount is regulated and controlled in time; and therefore, the urea injection amount can be synchronously recovered to be a normal injection value after the efficiency of the SCR system is recovered to be normal through regeneration, and the problems of reduction of the reefficiency and crystallization of the SCR system caused by excessive injection of urea can be solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

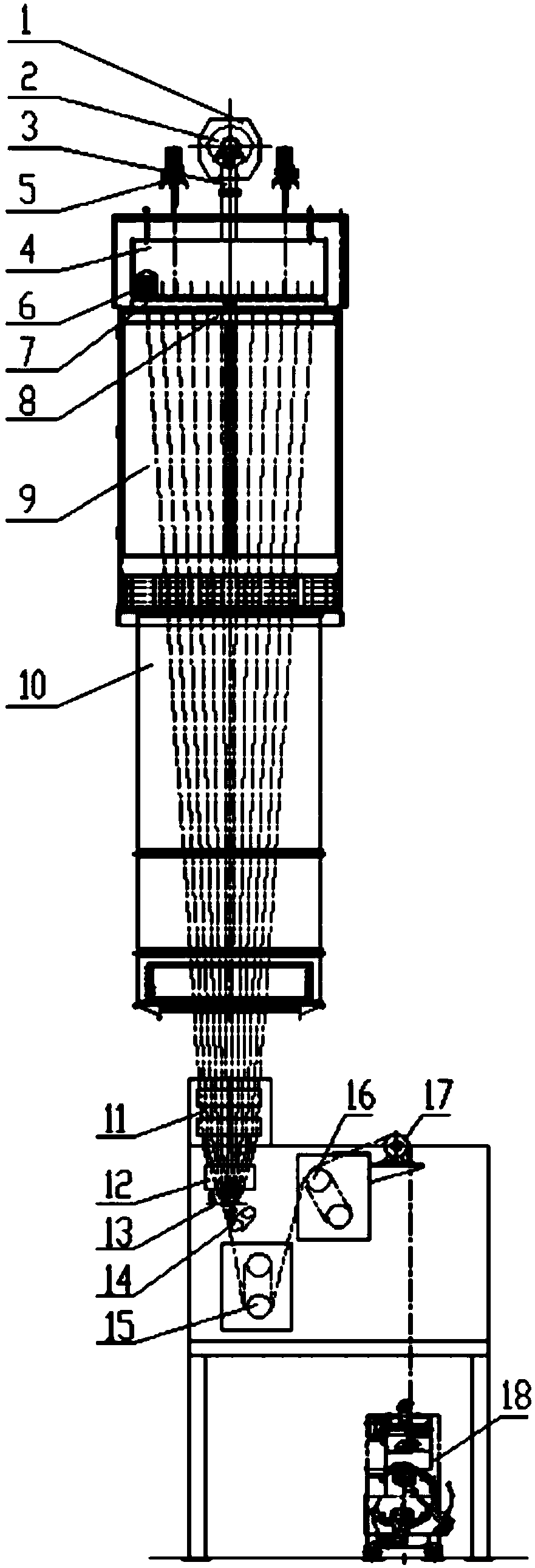

FDY filament spinning-pulling machine

ActiveCN108642585AImprove the problem of spinning end breakageSolve the crystallization problemArtificial thread manufacturing machinesSpinning head liquid feederHigh pressure waterHigh pressure

The invention discloses an FDY filament spinning-pulling machine, which comprises, successively arranged according to manufacturing process, an extruder, a melt mass pipe network, a measuring pump, aspinning device, a cooling device, a corridor part, an oil feeding device, a wire guiding-stretching device and a winding device. The cooling device includes a retarded cooler part, a monomer suctionpart and a side blowing cooling part, wherein the retarded cooler part is communicated between the spinning device and the side blowing cooling part, and is arranged at an output end of the spinning device; the retarded cooler part includes a delayed cooling wind chamber and a retarded heater, and the retarded heater part heats the delayed cooling wind chamber; the monomer suction part is communicated with an inlet end of the side blowing cooling part; the output end of the side blowing cooling part is communicated with the corridor part. By setting up the monomer suction device and jetting the suction monomer with high pressure water, the problem in prior devices that monomer crystal adheres to a spinneret plate and the air outlet of the side blowing cooling part can be solved, which cancause deterioration of spinning condition and increase broken ends. Then production cycle can be shortened and spinning quality can be improved.

Owner:BEIJING CHONGLEE MACHINERY ENG

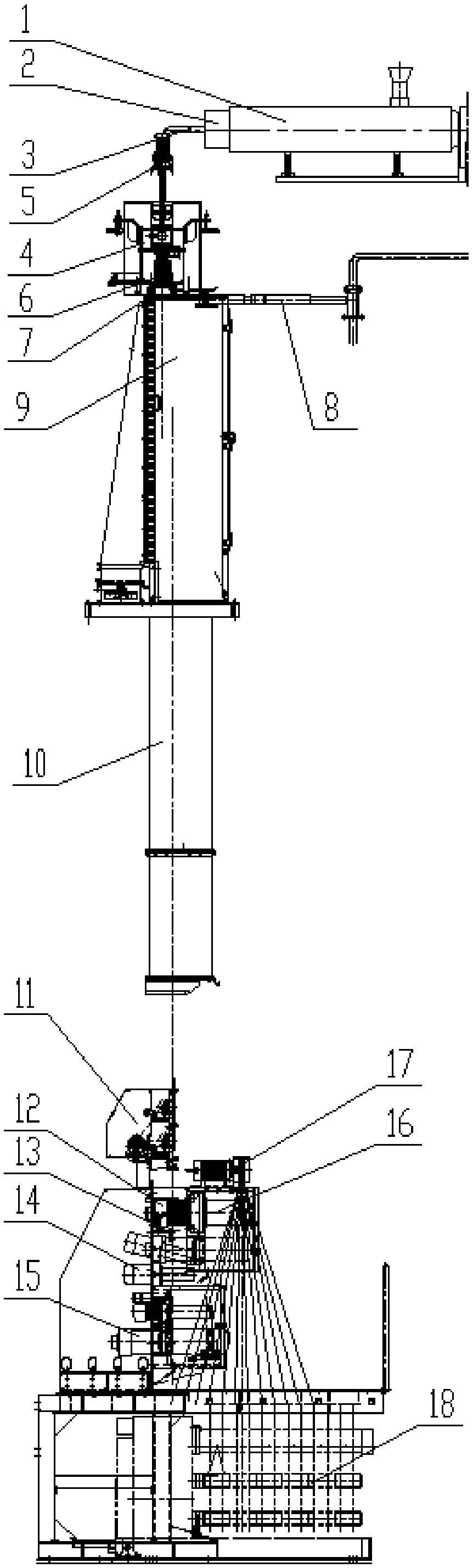

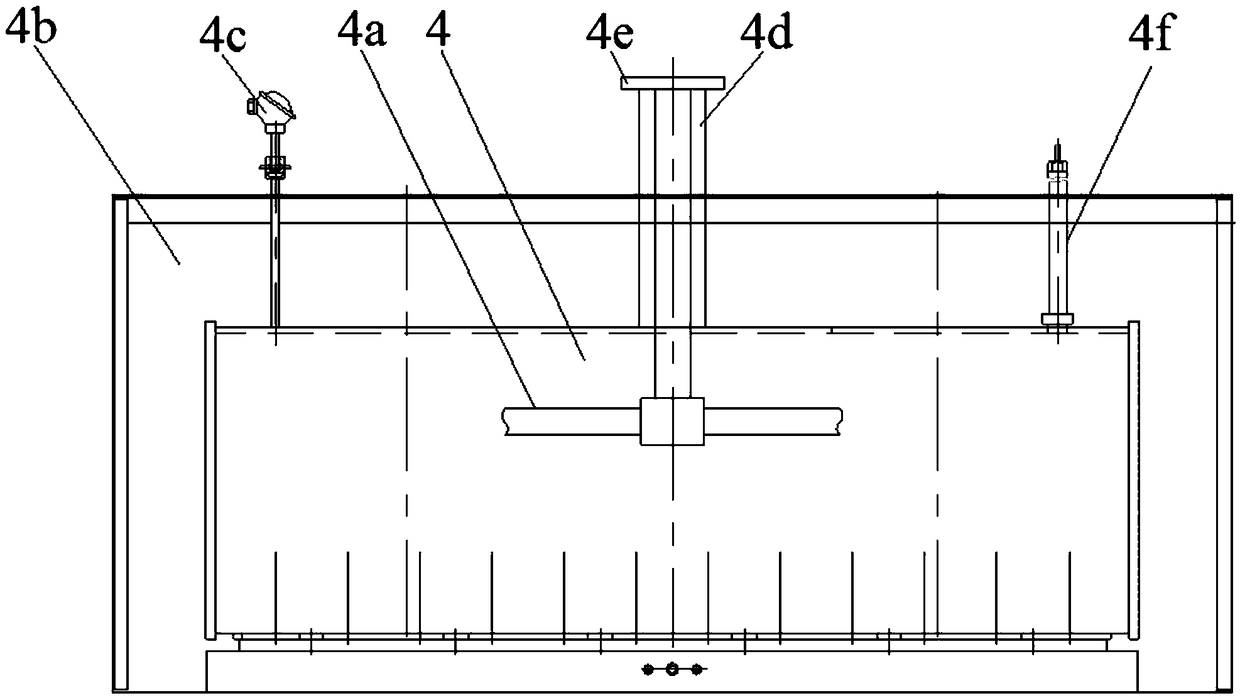

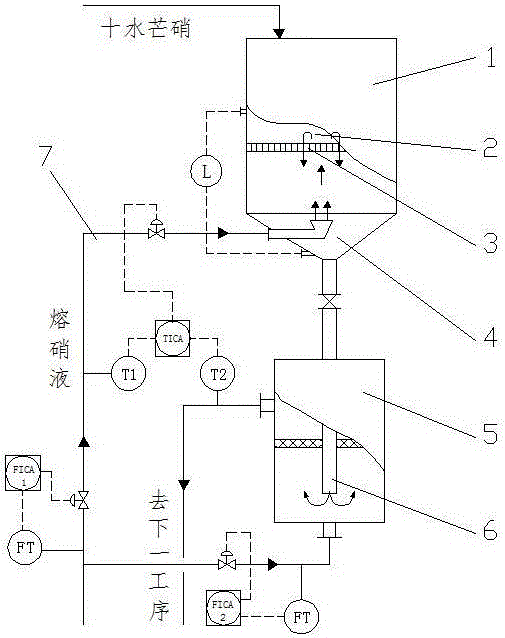

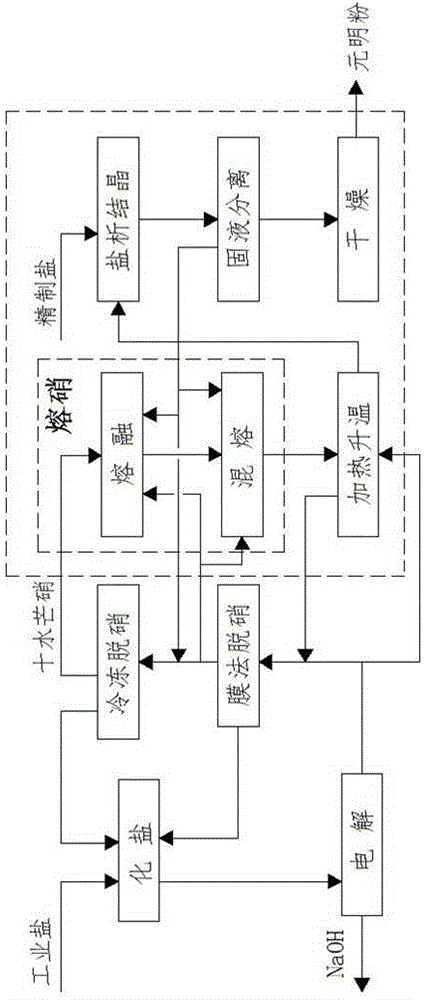

Method for preparing anhydrous sodium sulphate from mirabilite hydrate in chlor-alkali production and related nitre melting equipment

ActiveCN106745093AAchieve transferPrecise control of product qualityElectrolysis componentsAlkali metal sulfite/sulfate dehydrationMelting tankGrating

The invention provides a method for preparing anhydrous sodium sulphate from mirabilite hydrate in chlor-alkali production and related nitre melting equipment. According to the method, the target of producing the anhydrous sodium sulphate from the mirabilite hydrate is achieved through the steps of nitre melting liquid introduction, reasonable nitre melting, heating and warming, salting-out crystallization and solid-liquid separation. The adopted nitre melting equipment comprises a nitre melting tank and a mixing melter, wherein an inner cavity of the nitre melting tank is divided into a solid-phase area and a melting area by a grating; the mixing melter communicates with the lower part of the melting area; and one path of the nitre melting liquid enters the melting area to melt the mirabilite hydrate, and the other path enters the mixing melter to be mixed and melted with nitrate slurry settled from the melting area. The process is creatively fused with a whole chlor-alkali system, a new production process is created for co-production of caustic soda of chlor-alkali enterprises, refined salt and anhydrous sodium sulphate and large-scale use of underground cheap high-SO4<2-> brine. Compared with a currently running mirabilite hydrate technology, the method has the characteristics of continuous efficient and stable operation, environment protection, energy conservation and production of high-quality anhydrous sodium sulphate.

Owner:朱发彬

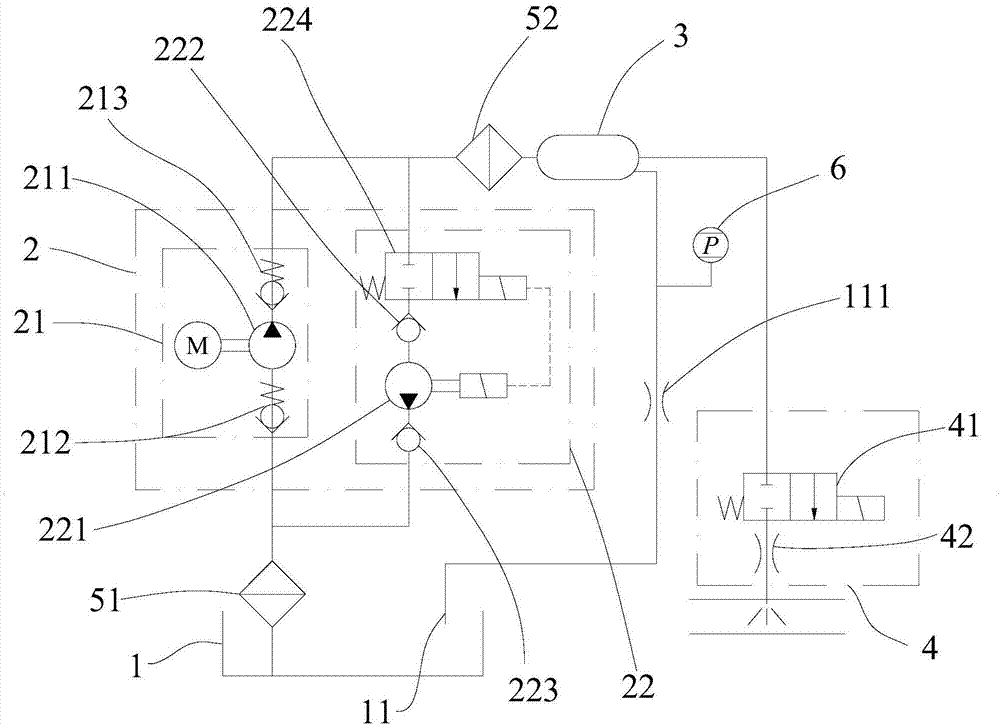

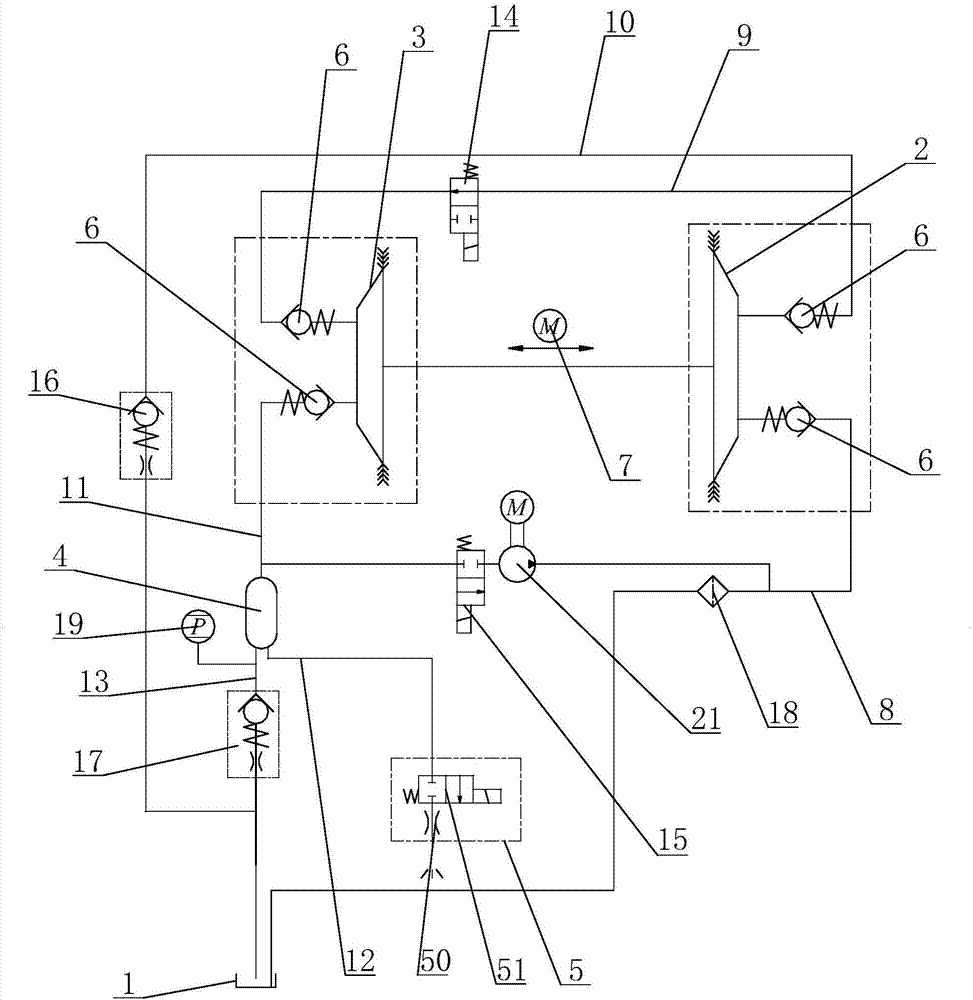

Urea solution supply system

ActiveCN107476860AImprove efficiencyEfficient use ofExhaust apparatusSilencing apparatusDiaphragm pumpEngineering

The invention discloses a urea solution supply system. The urea solution supply system comprises a urea box, a first diaphragm pump, a second diaphragm pump, an energy storage device and a nozzle module which are connected through pipelines, wherein the first diaphragm pump communicates with the urea box through a liquid inlet pipeline; the liquid outlet end of the liquid inlet pipeline is divided into two pipelines, one pipeline is connected with the liquid inlet end of the second diaphragm pump through a connecting pipeline, and the other pipeline communicates with the urea box through a backflow pipeline; the second diaphragm pump is connected with the liquid inlet end of the energy storage device through a first liquid outlet pipeline, the liquid outlet end of the energy storage device is divided into two pipelines, one pipeline is connected with the nozzle module, and the other pipeline communicates with the urea box through a third liquid outlet pipeline; and a reversing valve is mounted on the connecting pipeline, a primary backflow module is mounted on the backflow pipeline, and a second backflow module is mounted on the third liquid outlet pipeline. The urea solution supply system not only can prevent urea from crystallizing and blocking the pipelines, but also is stable in running and low in noise and improves jet precision.

Owner:HUST WUXI RES INST +1

Fondaparinux sodium composition injection and preparation method thereof

InactiveCN106727289AEffective pH adjustmentHigh clarityOrganic active ingredientsInorganic non-active ingredientsSodium hydroxideChemistry

The invention relates to a Fondaparinux sodium composition injection and a preparation method thereof. The injection is prepared from raw materials as follows: 5-10 parts by mass of Fondaparinux sodium, 6-12 parts by mass of sodium chloride, 2.6-3 parts by mass of a buffer solution and 3-6 parts by volume of water for injection, wherein the buffer solution is a mixture of citric acid, sodium hydroxide and hydrochloric acid, and a mass ratio of citric acid, sodium hydroxide and hydrochloric acid is (2.4-2.6):1:(1.3-1.9); the raw materials are subjected to orderly feeding, stirring, filtering, reflowing, filling, nitrogen charge, fused sealing, high-temperature sterilization, light inspection after cooling, packaging and checking, and the Fondaparinux sodium composition injection is obtained. The Fondaparinux sodium composition injection prepared with the method cannot produce crystals, is good in clarity, greatly improves the stability and is better applied to clinical treatment.

Owner:ABA CHEM SHANGHAI

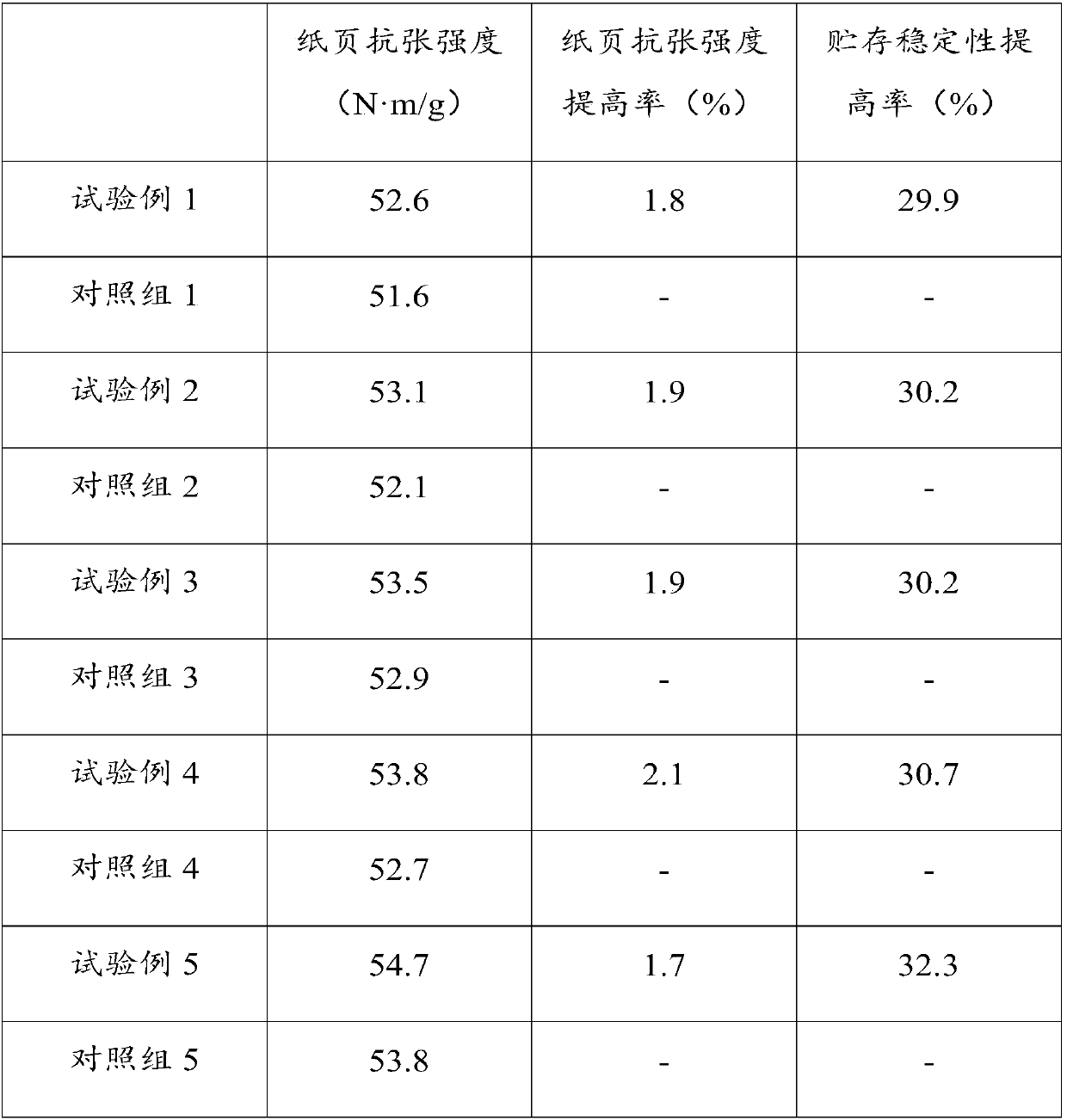

A kind of starch glue for paper sheet surface sizing and processing method thereof

ActiveCN106868940BReduce the number of broken headsImprove adhesionWater-repelling agents additionAdhesiveAlpha-amylase

The invention relates to paper sheet surface sizing starch glue and a processing method thereof and belongs to the field of starch glue. The processing method comprises the steps of mixing starch and water, then adding starch compound enzyme and heating and boiling to obtain a starch glue initial product; deactivating enzyme in the starch glue initial product, adding starch glue enhancer and mixing to obtain the paper sheet surface sizing starch glue. The starch complex enzyme is prepared from alpha-amylase, beta-amylase, glycerinum and salt, and the weight ratio of the alpha-amylase to the beta-amylase to the glycerinum to the salt is (50 to 65):(5 to 10):(10 to 20):(2 to 5). The starch glue enhancer is prepared from hydroxypropyl methyl cellulose, sodium carboxymethyl cellulose, liquid caustic soda and penetrant, and the weight ratio of the hydroxypropyl methyl cellulose to the sodium carboxymethyl cellulose to the liquid caustic soda to the penetrant is (30 to 40):(20 to 30):(2 to 4):(0.5 to 1). The processing method has a simple technology and low production cost and greatly reduces wastewater treatment load in a production process. In addition, the starch glue has good quality, can solve the problems of starch glue colloidal particle solution crystallization and poor storage viscosity stability and meets a requirement of common printing paper.

Owner:WUHAN SUNHY BIOLOGICAL

Urea supply injection system with two-stage injection function

PendingCN113482750AAchieving Dual Injection FunctionLow costInternal combustion piston enginesExhaust apparatusControl engineeringProcess engineering

The invention discloses a urea supply injection device with a two-stage injection function. The urea supply injection device aims to realize quantitative injection and metering of two paths of urea nozzles. According to the the technical scheme, the urea supply injection device with the two-stage injection function is characterized in that two paths of urea injection can achieve respective accurate metering and output through unique structural design, the post-treatment double-path urea injection demand of the China VII vehicle emission standards is met, high-pressure air is adopted for assisting urea injection, the high-pressure air is introduced into two mixing cavities through pipeline design to be mixed with urea, and the total urea injection amount is controlled by controlling the rotating speed of a motor of a urea pressure building mechanism and combining with a pressure sensor, the urea injection amount of the second path is the difference value between the total urea injection amount and the urea injection amount of the first path, so that the urea injection amount of the second path is indirectly and accurately controlled in real time, the high-pressure gas can purge the mixing cavities and the nozzles, and urea crystallization in the injection device and at the nozzles can be effectively prevented.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

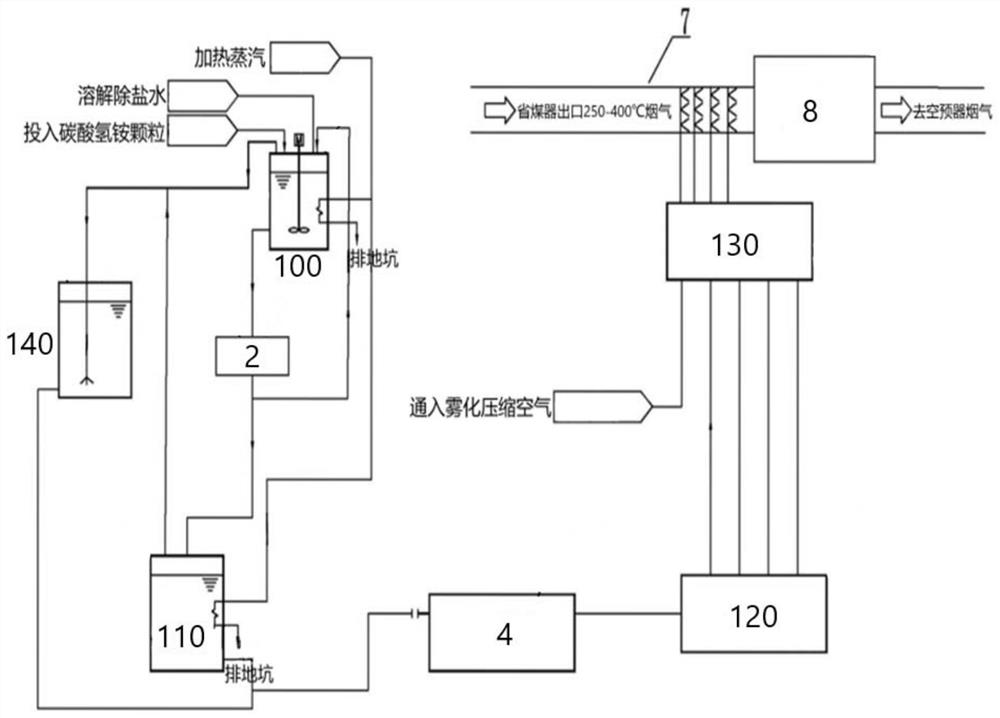

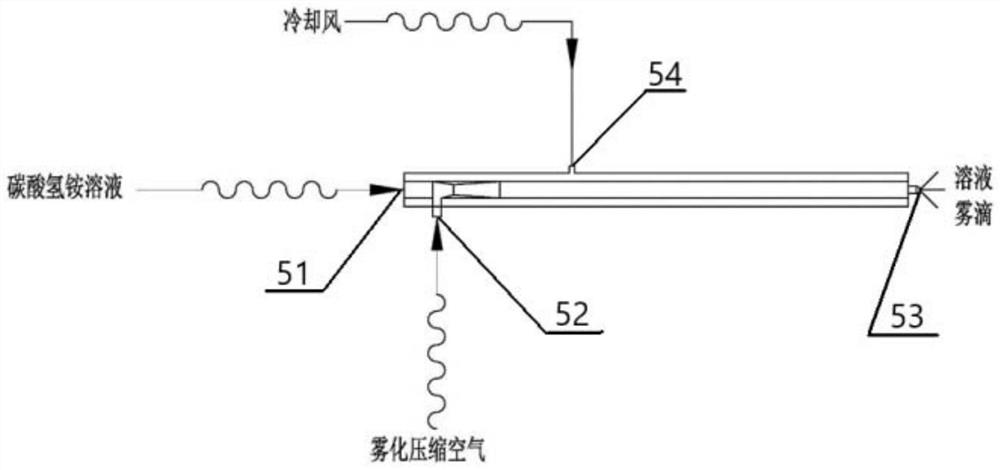

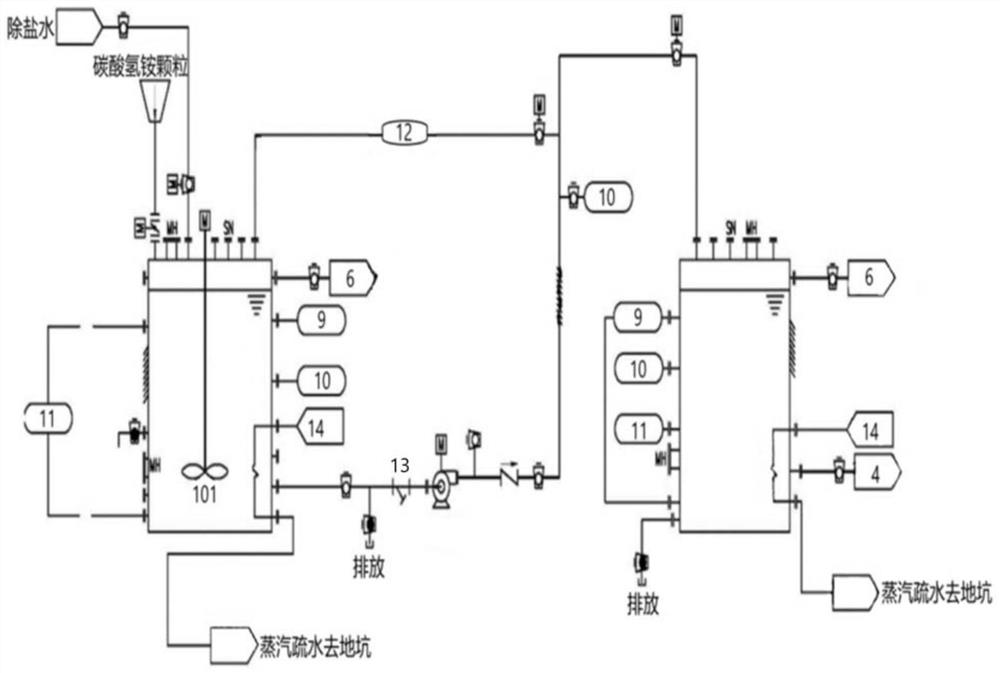

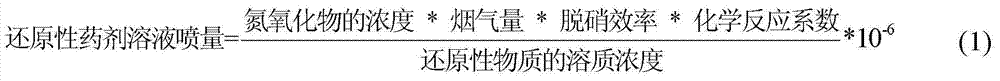

Ammonium bicarbonate direct injection denitration reduction system and method

PendingCN113877420AReduce productionAvoid problems caused by escapesGas treatmentDispersed particle separationFlue gasPhysical chemistry

The invention provides an ammonium bicarbonate direct injection denitration reduction system and method. An ammonia preparation system is simple. The preparation conditions of a thermal power plant under different loads at present can be met. On-demand distribution of ammonia at different positions of an inlet flue is realized. The operation and maintenance cost is low. The problems that the system is easily blocked and a safety risk exists when a ammonium bicarbonate solution is stored are solved. The system comprises an ammonium bicarbonate dissolving device, an ammonium bicarbonate solution storage device, a metering distribution module, an injection device and an SCR denitration reactor which are connected in sequence. The injection device comprises a plurality of parallel injectors, a nozzle is arranged at the output end of each injector, an ammonium bicarbonate solution inlet is formed in the input end of each injector, a communicated atomized compressed air inlet is formed in one side of each ammonium bicarbonate solution inlet, and the injectors are arranged in an inlet flue of the SCR denitration reactor in the flue gas direction. The metering distribution module is connected with the ammonium bicarbonate solution inlets of the injectors.

Owner:XIAN THERMAL POWER RES INST CO LTD

Method for preparing mixed rare earth carbonate by using mixed precipitant in sulphuric acid system

InactiveCN107760867AReduce outputReduce the temperatureProcess efficiency improvementAmmonium sulfateChemistry

The invention discloses a method for preparing mixed rare earth carbonate by using a mixed precipitant in a sulphuric acid system. The method comprises the following steps: with continuous stirring, mixing ammonium bicarbonate and industrial-grade ammonia water in the molar ratio of 5.6:4.4-10:1, and adding water at 15-30 DEG C to enable the concentration of the mixed precipitant to be 3 to 7 mol / L; placing the mixed precipitant and a seed crystal into a reaction tank, wherein the seed crystal is the mixed rare earth carbonate which is produced by taking mixed sulphuric acid rare earth solution as a raw material; with continuous stirring, controlling the temperature of the solution in the reaction tank to be 20-50 DEG C, and slowly adding the mixed sulphuric acid rare earth solution into the reaction tank, wherein the adding time is 2 to 6 hours, and the using amount enables the pH of the solution equal to be 6.5-7; after the ending of precipitating, aging for 0.5-2 hours at the temperature of 30-50 DEG C with stirring; filtering and washing a precipitant to obtain the mixed rare earth carbonate and ammonium sulphate-containing precipitation wastewater. According to the method, theoutput quantity of the precipitation wastewater can be reduced.

Owner:CHINA NORTHERN RARE EARTH (GROUP) HIGH TECH CO LTD

Application of tri(hydroxymethyl)aminomethane hydrochloride solution in medicine for treating hyperuricemia

PendingCN112007021AGood water solubilityEasy dischargeOrganic active ingredientsSkeletal disorderDiseaseSide effect

The invention discloses application of a salt formed by combining tri(hydroxymethyl)aminomethane and acid radicals or an aqueous solution of the salt to preparing of a medicine for treating hyperuricemia, gout, acute and chronic arthritis, urinary calculus diseases and related diseases. The treatment action mechanism is as follows: tri(hydroxymethyl)aminomethane and uric acid are combined throughhydrogen bonds to generate a uric acid-tri(hydroxymethyl)aminomethane conjugate, uric acid crystallization is prevented, and uric acid crystals (calculi) are dissolved; meanwhile, the combination of uric acid with macromolecular substances such as blood fat and blood sugar is reduced, and the influence of uric acid on blood fat and blood sugar is reduced. Compared with existing three action mechanisms of 1, intake reduction, 2, endogenous synthesis inhibition and 3, kidney excretion promotion for treating hyperuricemia, the action mechanism of the invention can be called as a fourth action mechanism. The invention can also be referred to as a fourth treatment method for hyperuricemia. And the problems of uric acid crystallization and influence of uric acid on blood fat and blood sugar aresolved in a targeted manner. The action mechanism is clear; the curative effect is good; and the side effect is small.

Owner:BEIJING CHANGSHENG PHARM TECH CO LTD

Hydrogenation reaction ammonium salt crystallization prevention device

InactiveCN104826565AReduce loadSimple methodChemical/physical/physico-chemical processesHydrogenation reactionThree stage

A hydrogenation reaction ammonium salt crystallization prevention device specifically includes a reaction furnace, a refining reactor, heat exchangers, a new hydrogen inlet, a raw oil inlet, water injection points and a water injection line, and is characterized in that: the four heat exchangers are in series connection, the reaction furnace and the refining reactor are in series connection, three stages of water injection points are arranged in front of the heat exchangers, and are in series connection, and according to the demand, the water injection points are intermittently used, the water injection points are replaced by E-2101A / B outlet for water injection, device circulating volume can be restored to normal, and the system pressure drop is decreased significantly. By adjusting of the water injection point temperature between ammonium salt crystallization point and water dew point temperature adjusting of the water injection flow of water injection points 1 and 2 according to the flow, the heat exchange effect can achieve the best state, and solid ammonium salt crystallization can be eliminated. The hydrogenation reaction ammonium salt crystallization prevention device solves the problem of low temperature part ammonium salt crystallization in the reaction system, improves the heat exchange efficiency, reduces the load of a heating furnace, and increases the output of the product.

Owner:SHANDONG SHENGXING CHEM

Close-coupled scr post-processing packaging structure for light-duty diesel vehicles

ActiveCN105587386BReduced risk of crystallizationReasonable mixed structureExhaust apparatusSilencing apparatusParticulatesHydrolysis

The invention belongs to the technical field of automobile exhaust aftertreatment and relates to a tightly-coupled selective catalytic reduction (SCR) aftertreatment packaging structure of a light diesel vehicle. The tightly-coupled SCR aftertreatment packaging structure comprises a particulate trap and a diesel oil oxidation catalyst. The particulate trap is connected with the diesel oil oxidation catalyst through a lower clamshell-shaped shell; the upper end of the lower clamshell-shaped shell is connected with an upper clamshell-shaped shell in a tightly coupled mode to form an enclosed cavity; a flow guide plate is fixedly connected to the vertical folded surface of the lower clamshell-shaped shell and comprises a horizontal plate and a vertical plate which are connected into a whole; the vertical plate extends towards the inside of the enclosed cavity; a flow guide groove is formed in the root position of the horizontal plate; a second flow guide block is disposed at the outer end of the horizontal plate; a first flow guide block is mounted on the vertical plate; a urea spray nozzle is installed on the upper clamshell-shaped shell; and the center line of the urea spray nozzle and the second flow guide block intersect. By means of the structural design, full mixing of urea liquid drops with air flow can be facilitated, and the urea pyrolysis and hydrolysis environment temperature is guaranteed.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

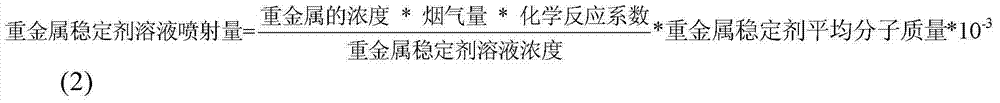

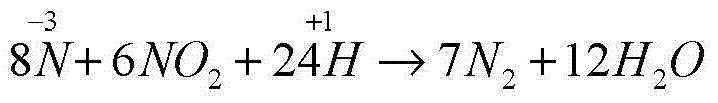

Method for flue gas purification and dust harmless treatment of refuse incineration power plant

ActiveCN104258714AEmission reductionReduce processing difficultyDispersed particle separationAir quality improvementPhosphatePotassium

The invention discloses a method for flue gas purification and dust harmless treatment of a refuse incineration power plant. The method comprises the following steps: spraying a reducing agent solution to a hearth of a refuse incineration furnace in a temperature range of 900-1,000DEG C; spraying pollutant treatment agents including heavy metal treatment agents and adsorbing agents to a flue in a temperature range of 100-65DEG C, wherein the reducing agent solution is iron ammonia complex, hypophosphite or phosphite, and the heavy metal treatment agents comprise alkyl sodium dithiocarbamate / sylvite, dithio-thiazole, phosphate and polymer thereof and 1,3,5-triazine-2,4,6-trithiol trisodium salt. According to the method disclosed by the invention, the reducing agent solution such as the iron ammonia complex, the hypophosphite and the like is adopted for reducing nitric oxide; the heavy metal treatment agents such as the phosphite, magvac sodium, magvac potassium, trithiol trisodium salts and the like are adopted for purifying and stably treating heavy metals; finally, the adsorbing agents are used to perform a neutralization reaction with sulfur oxide and chloride, so that the stable synchronous treatment of flue gas purification and the heavy metals is realized.

Owner:宝武集团环境资源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com