Method for flue gas purification and dust harmless treatment of refuse incineration power plant

A technology for harmless treatment and flue gas purification, which is applied in chemical instruments and methods, separation methods, and air quality improvement. The effect of dust treatment difficulty, reduction of activity and secondary pollution, and elimination of crystallization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

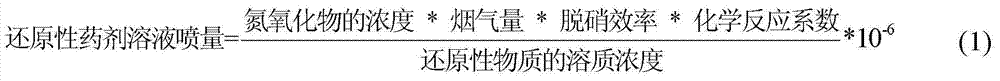

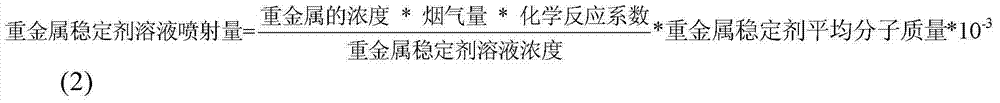

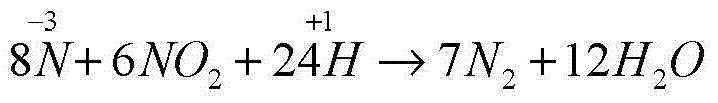

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 A power plant in Shanghai

[0067] Before the transformation of flue gas treatment, "SNCR+ wet desulfurization" was adopted. After adopting the present invention, spray the iron ammonium complex with a solute concentration of 12% in the temperature range of 900°C to 1000°C in the furnace, and spray sodium fumarate with a solute concentration of 15% in the temperature range of 100°C to 65°C Mixture with phosphate, solute mass ratio 1:4; spray mixture of calcium powder and magnesium powder (1:1~3), activated carbon powder. The content of flue gas pollutants and the leaching toxicity of heavy metals in flue gas dust are shown in Table 2 below.

[0068] Table 2 Flue gas pollutant emission concentration and dust heavy metal leaching concentration

[0069] serial number

[0070] Note: The extraction solution of dust samples is prepared according to HJ299-2007.

Embodiment 2

[0071] Example 2 A waste incineration power plant in the south

[0072] Before the transformation of flue gas treatment, "SCR+wet desulfurization" was adopted. After adopting the present invention, the iron-ammonia complex with a solute concentration of 17% was sprayed in the temperature range of the furnace from 900°C to 1000°C. The solute concentration sprayed in the temperature section is a mixture of sodium fumarate, phosphate, and triazine trisodium salt, the solute mass ratio is 1:0.5:1; the mixture of calcium powder and magnesium powder (1:2~4) ), activated carbon powder. The content of flue gas pollutants and the leaching toxicity of heavy metals in flue gas dust are shown in Table 3.

[0073] Table 3 Flue gas pollutant emission concentration and dust heavy metal leaching concentration

[0074] serial number

[0075] Note: The extraction solution of dust samples is prepared according to HJ299-2007.

Embodiment 3

[0076] Example 3 A waste incineration power plant in Northwest China

[0077] Before the transformation of flue gas treatment, "SCR+wet desulfurization" was adopted. After adopting the present invention, the iron-ammonia complex with a solute concentration of 17% was sprayed in the temperature range of the furnace from 900°C to 1000°C. The solute concentration sprayed in the temperature section is a mixture of sodium fumarate, phosphate, trisodium triazine, the solute mass ratio is 1:0.5:1.5; the mixture of calcium powder and magnesium powder (1:2~4) is sprayed , Activated carbon powder. The content of flue gas pollutants and the leaching toxicity of heavy metals in flue gas dust are shown in Table 4.

[0078] Table 4 Flue gas pollutant emission concentration and dust heavy metal leaching concentration

[0079] serial number

[0080] Note: The extraction solution of dust samples is prepared according to HJ299-2007.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com