Close-coupled scr post-processing packaging structure for light-duty diesel vehicles

A packaging structure, diesel vehicle technology, applied in mufflers, exhaust devices, engine components, etc., can solve the problems of low NOx catalytic conversion efficiency, limited layout space, etc., to achieve compact structure, less space occupation, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

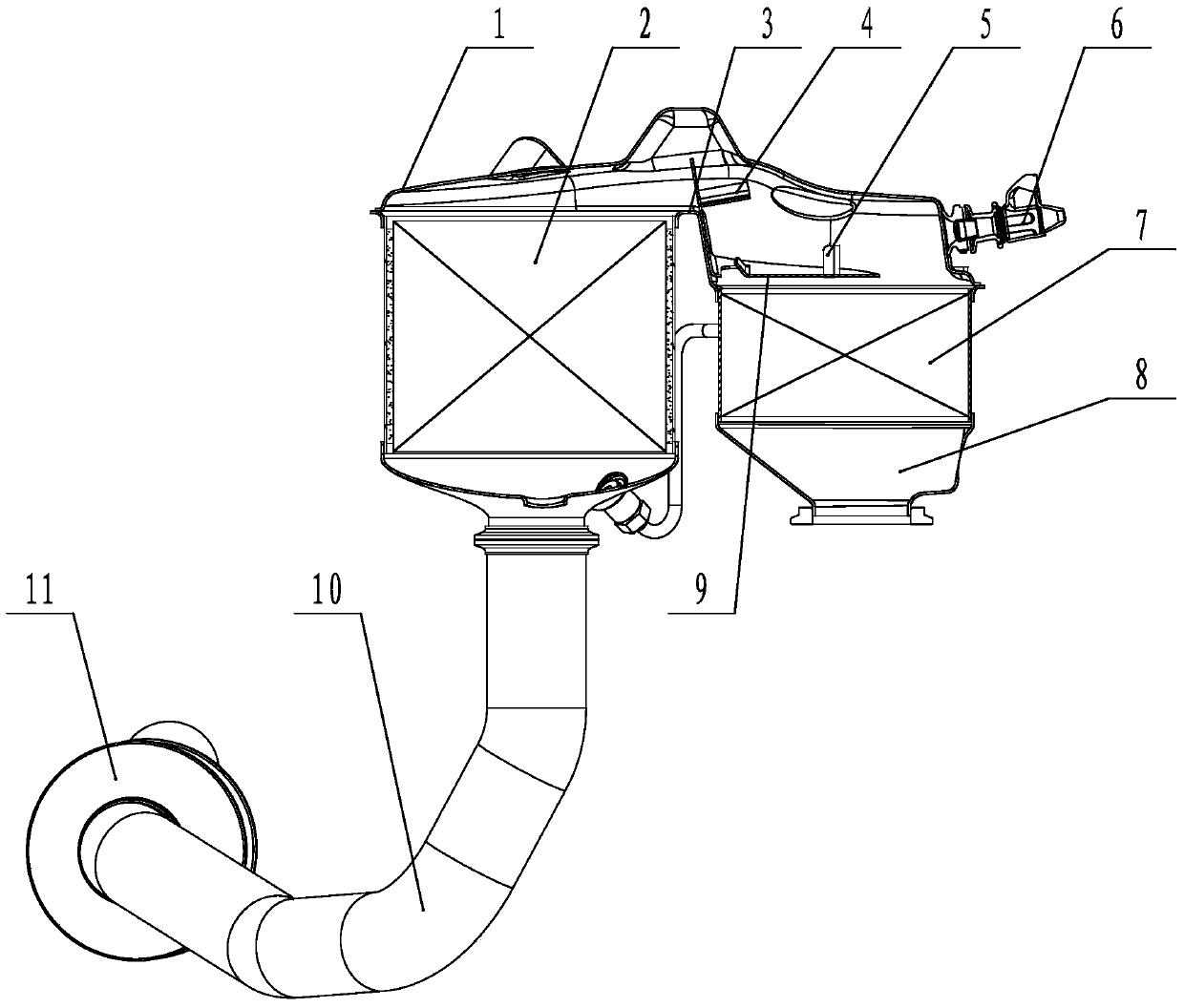

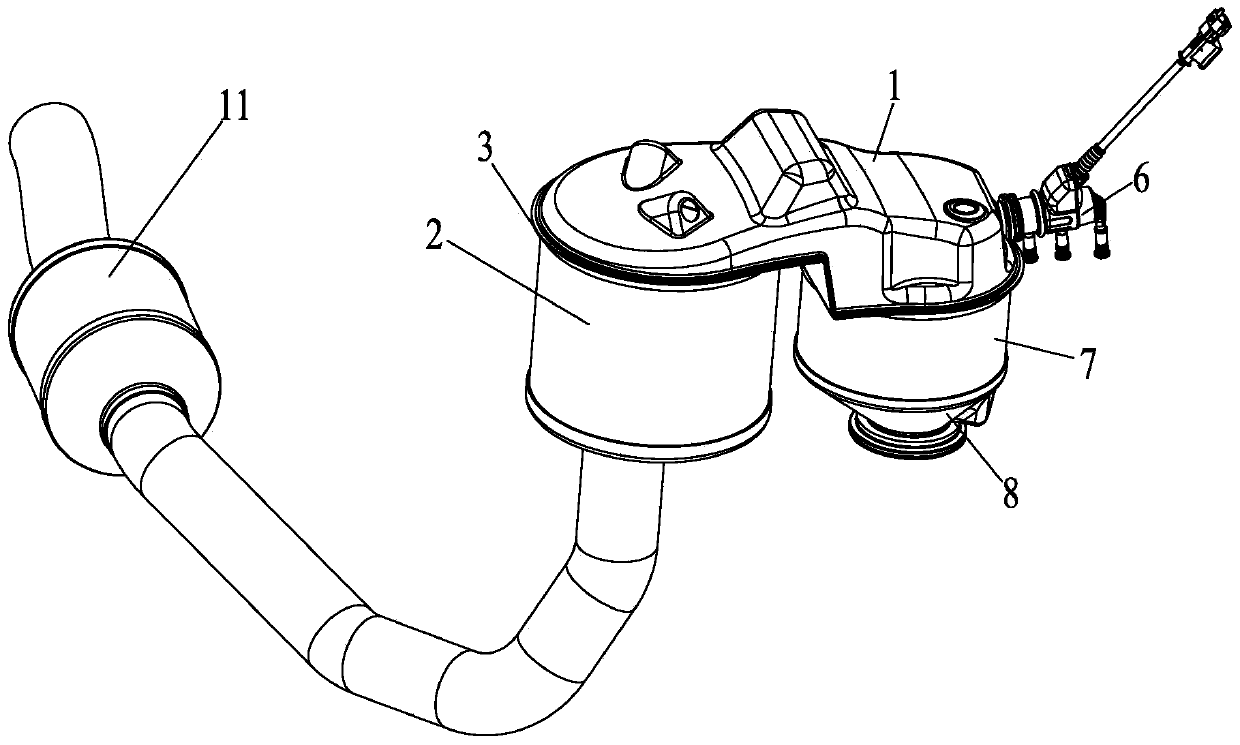

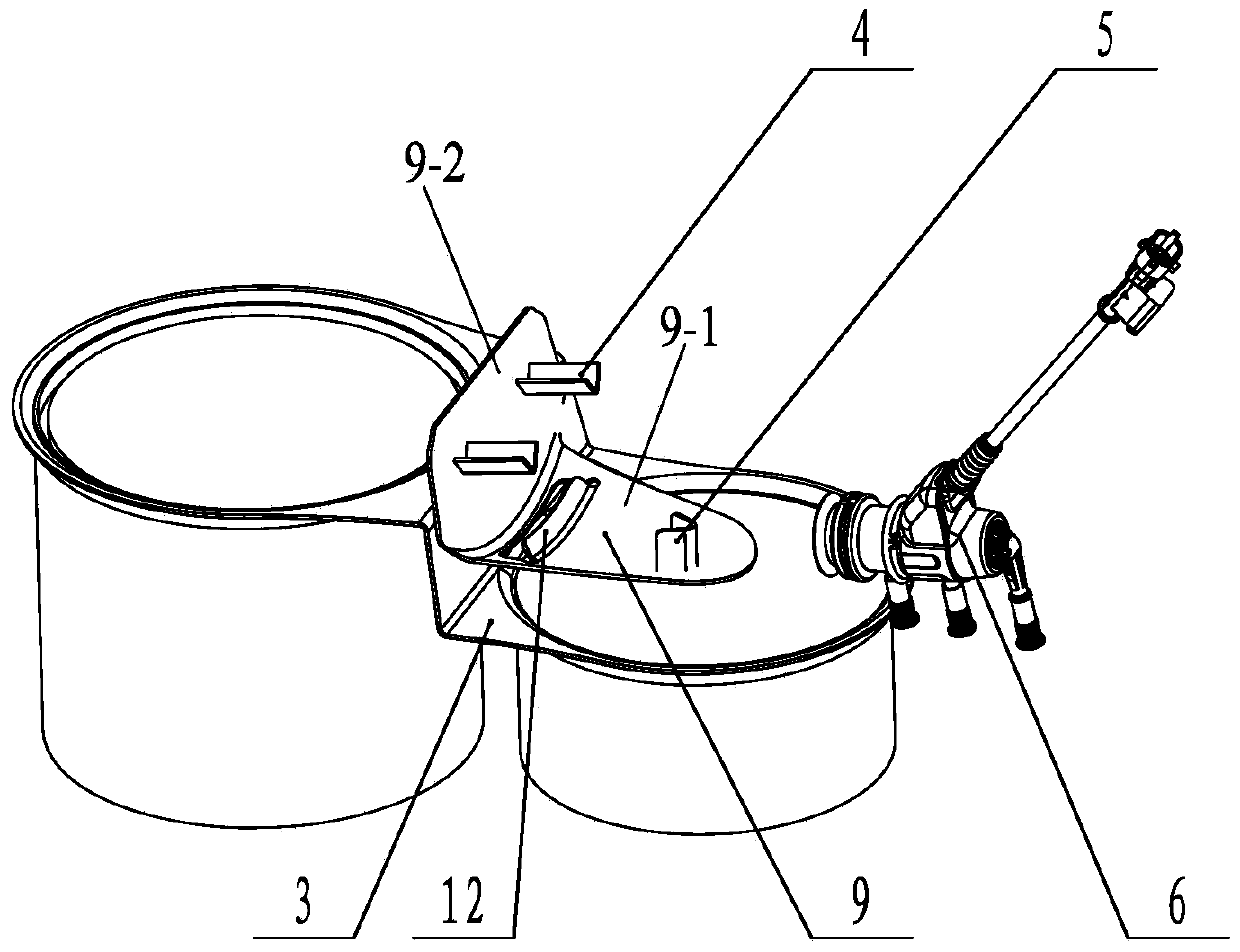

[0012] Figure 1~3 , including upper clam shell 1, particle trap 2, lower clam shell 3, first diversion block 4, second diversion block 5, urea nozzle 6, diesel oxidation catalyst 7, air intake end cover 8, guide Flow plate 9, connecting pipe 10, selective catalytic reduction device 11, diversion tank 12, etc.

[0013] like Figure 1~3 As shown, the present invention is a light-duty diesel vehicle close-coupled SCR after-treatment packaging structure, including a particle trap 2, a diesel oxidation catalyst 7, and the particle trap 2 and the diesel oxidation catalyst 7 pass through The lower clam shells 3 are connected, and the upper ends of the lower clam shells 3 are tightly coupled to the upper clam shell 1 to form a closed cavity. Connected horizontal plate 9-1, vertical plate 9-2, the vertical plate 9-2 extends towards the closed cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com