Aqueous urea solution decomposing mixing device

A technology of urea aqueous solution and mixing device, which is applied in the direction of silencer, exhaust device, exhaust treatment, etc., and can solve the problems of not easy to form crystals on the inner wall of the end cover, low cost of parts and assembly, cost of parts and assembly Advanced problems, to achieve the effect of reducing crystallization risk, low assembly cost, and low component cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

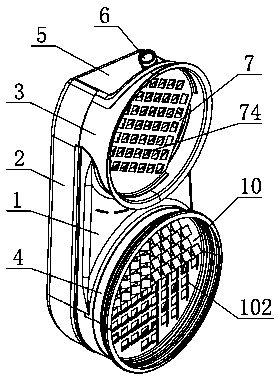

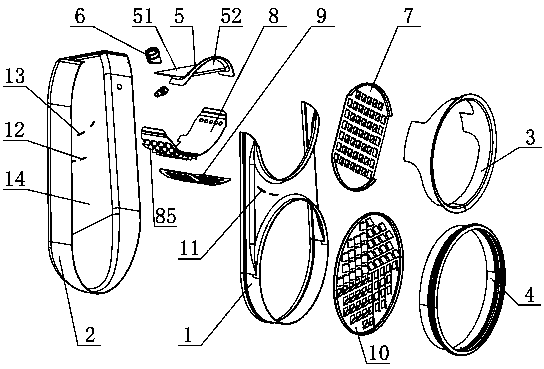

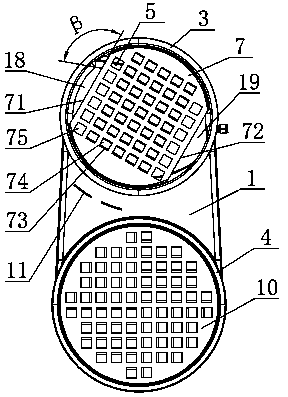

[0045] Such as figure 1 As shown, the front shell 1 of the present invention is fixed on the rear shell 2, and the top of the rear shell 2 is fixedly provided with a top cover 5, and the front shell 1, the rear shell 2, and the top cover 5 are surrounded by an internal cavity 14; The cover 5 is provided with a nozzle seat 6, and the urea nozzle extends into the inner cavity 14 through the nozzle seat 6 (not shown in the figure); an air intake cylinder 3 is installed between the top cover 5 and the upper part of the front shell 1, and the air intake cylinder The air inlet channel of 3 is embedded with a deflector 7, the deflector 7 is provided with a guide vane 74, the lower part of the front shell 1 is equipped with an outlet tube 4, and the outlet channel of the outlet tube 4 is embedded with a swirl plate 10, The swirl plate 10 has swir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com