Patents

Literature

80results about How to "Increase flow length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

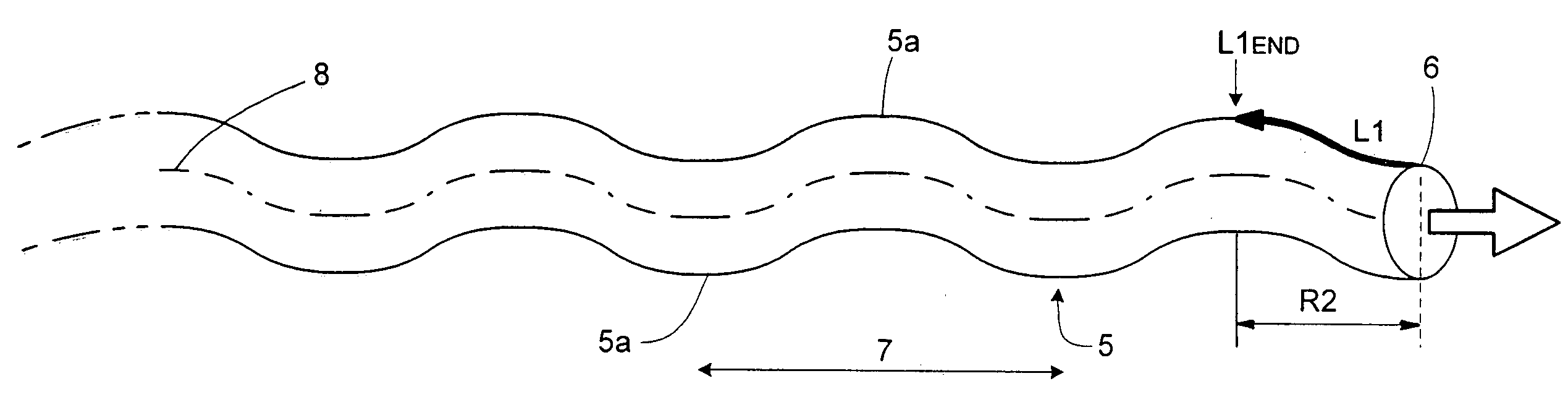

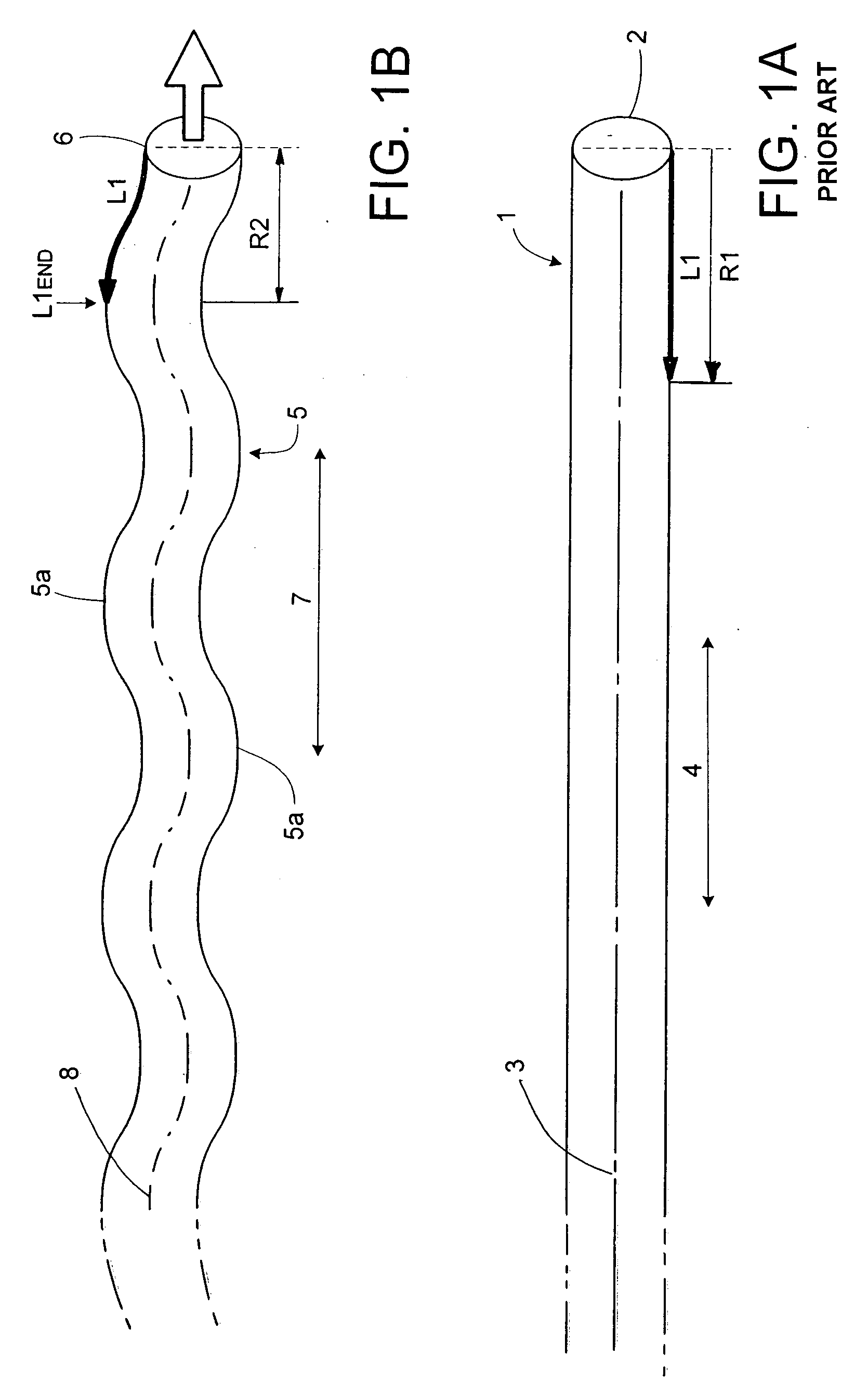

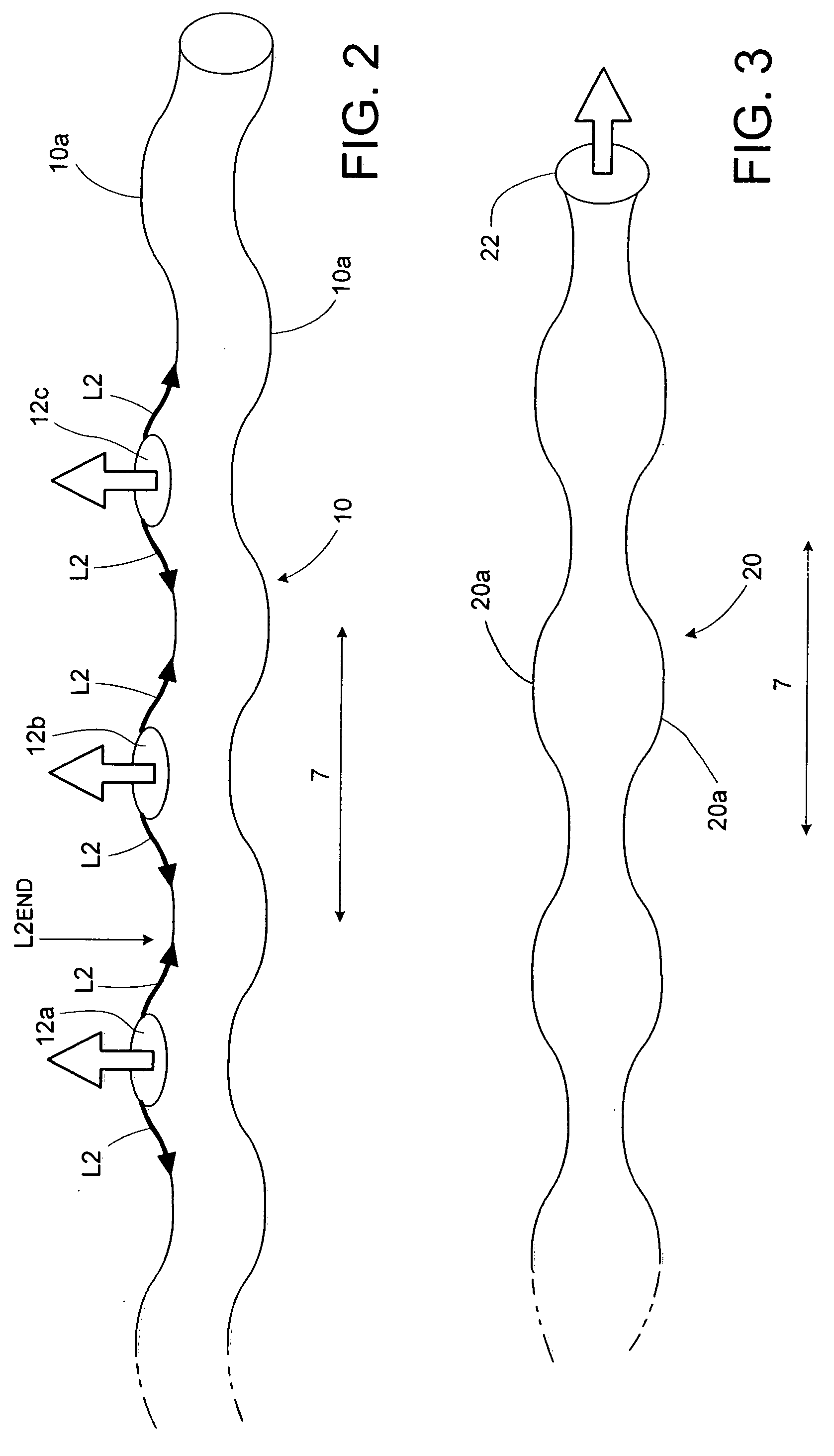

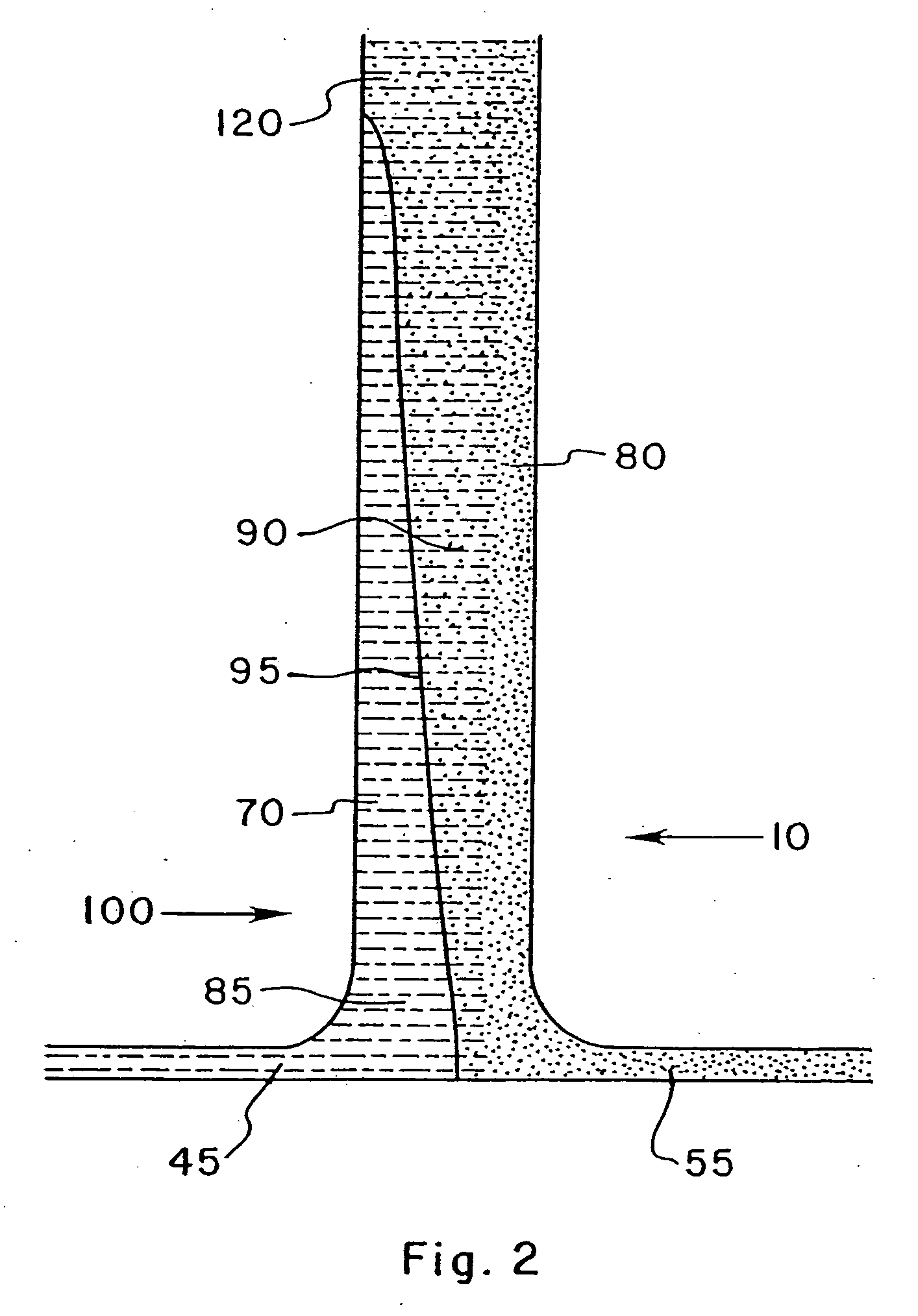

Intracranial catheter

InactiveUS20060253101A1Increase supplyImprove predictabilityCatheterPath lengthElectrical resistivity and conductivity

A catheter having an outer profile which is formed such that a path length along an outer surface of the catheter is greater than the corresponding length of the catheter, and to a method for determining the shape of a catheter, and wherein the elasticity and / or conductivity of the tissue into which the catheter is to be introduced is taken into account in order to determine the outer profile of the catheter.

Owner:BRAINLAB

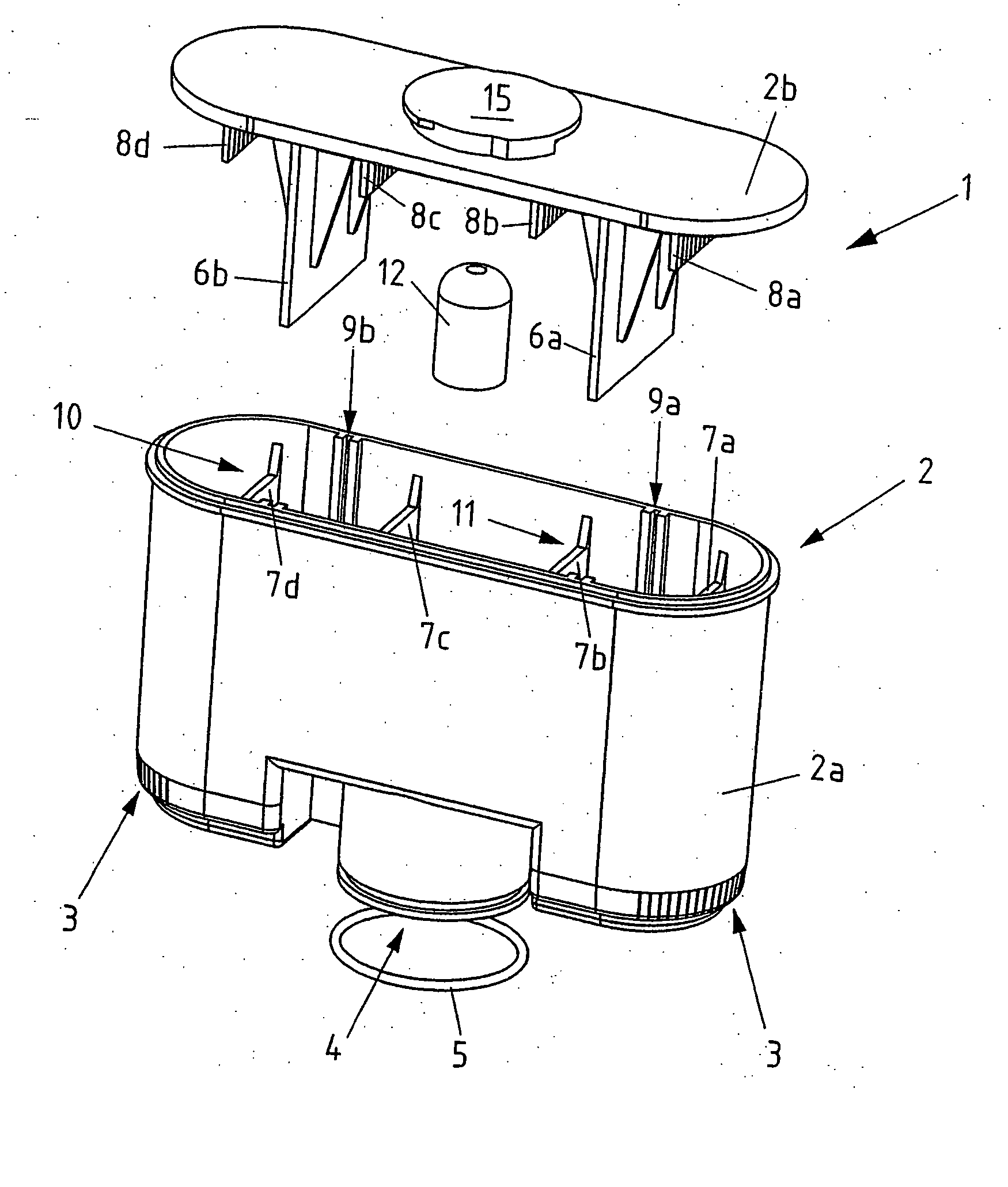

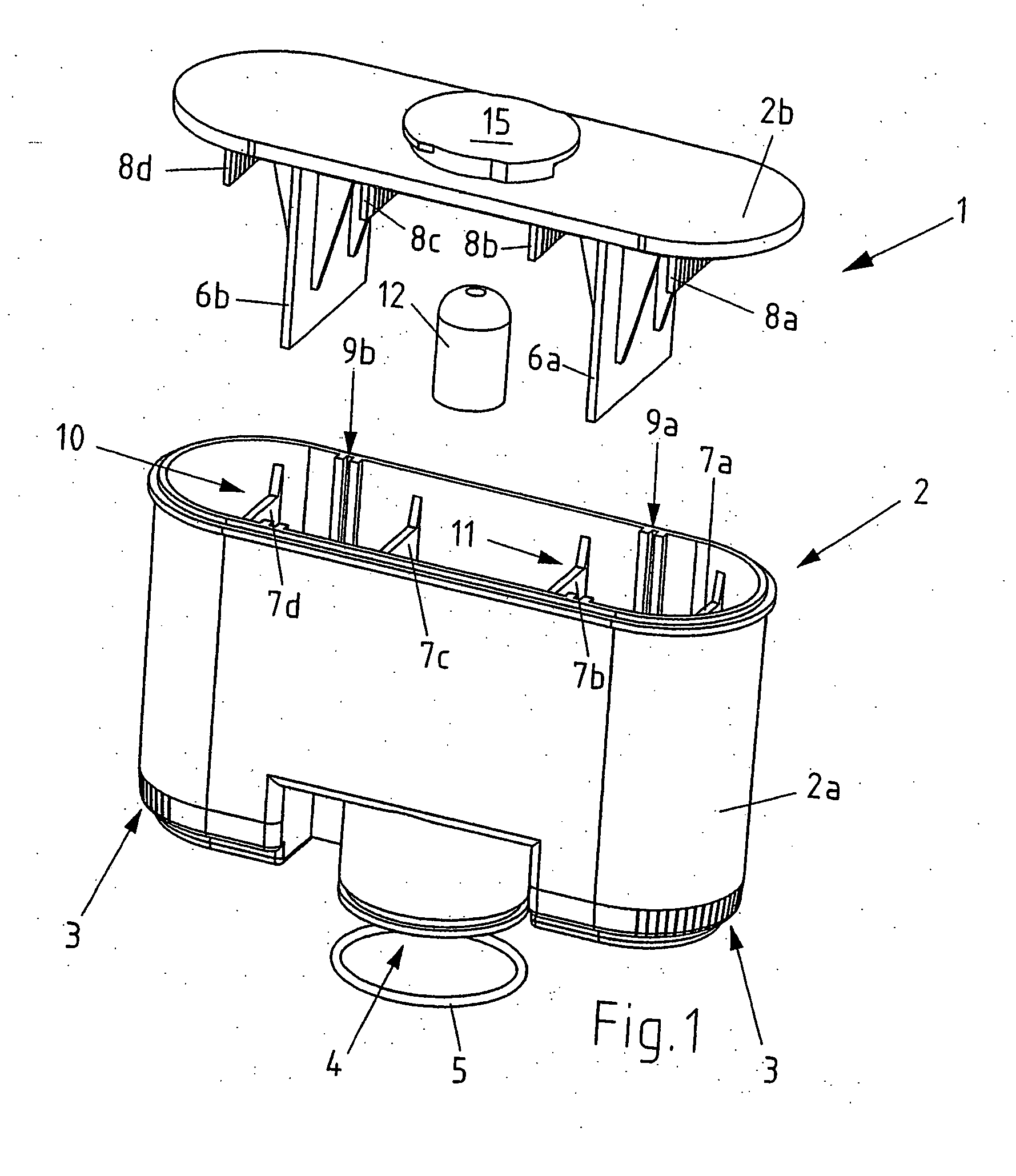

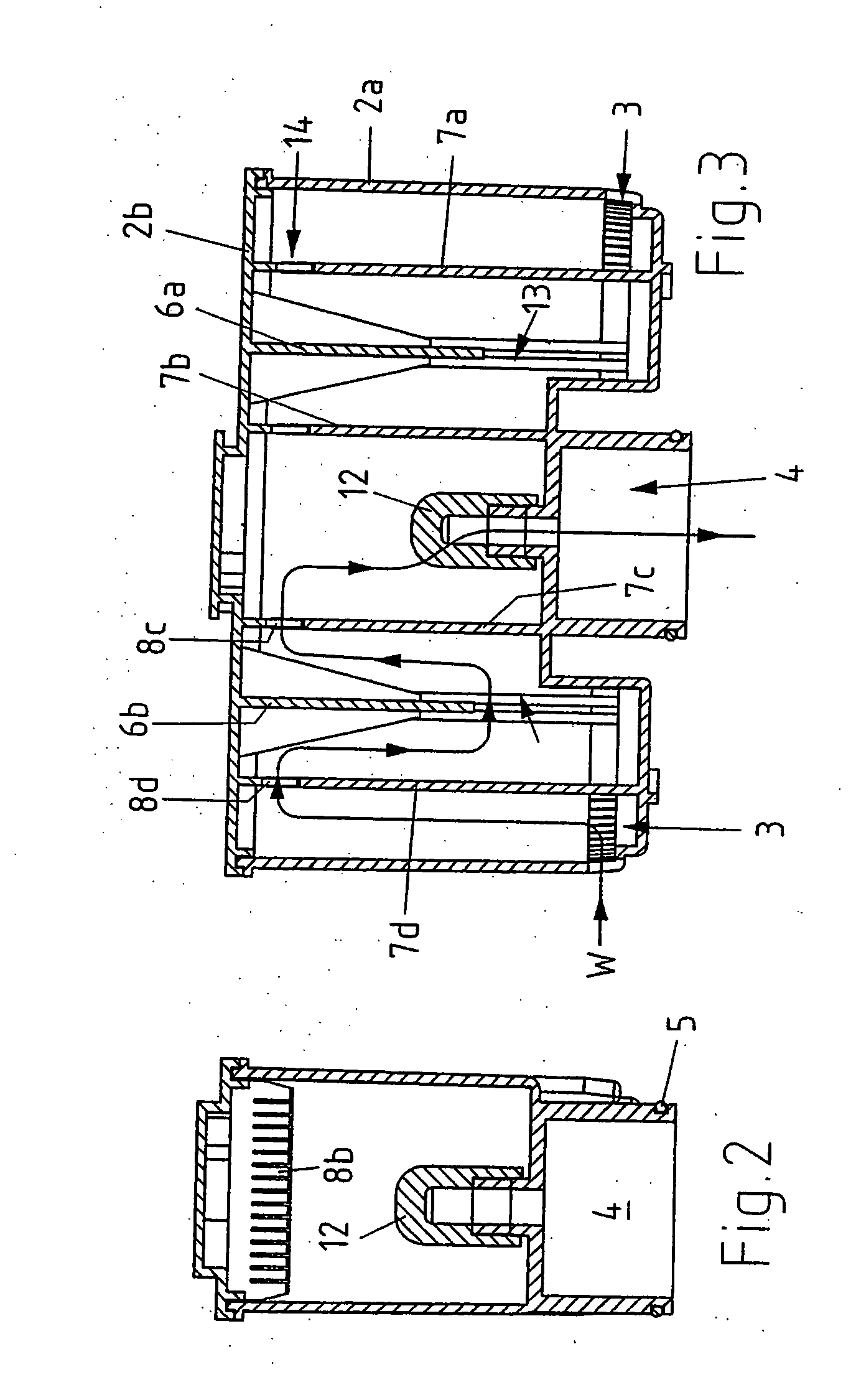

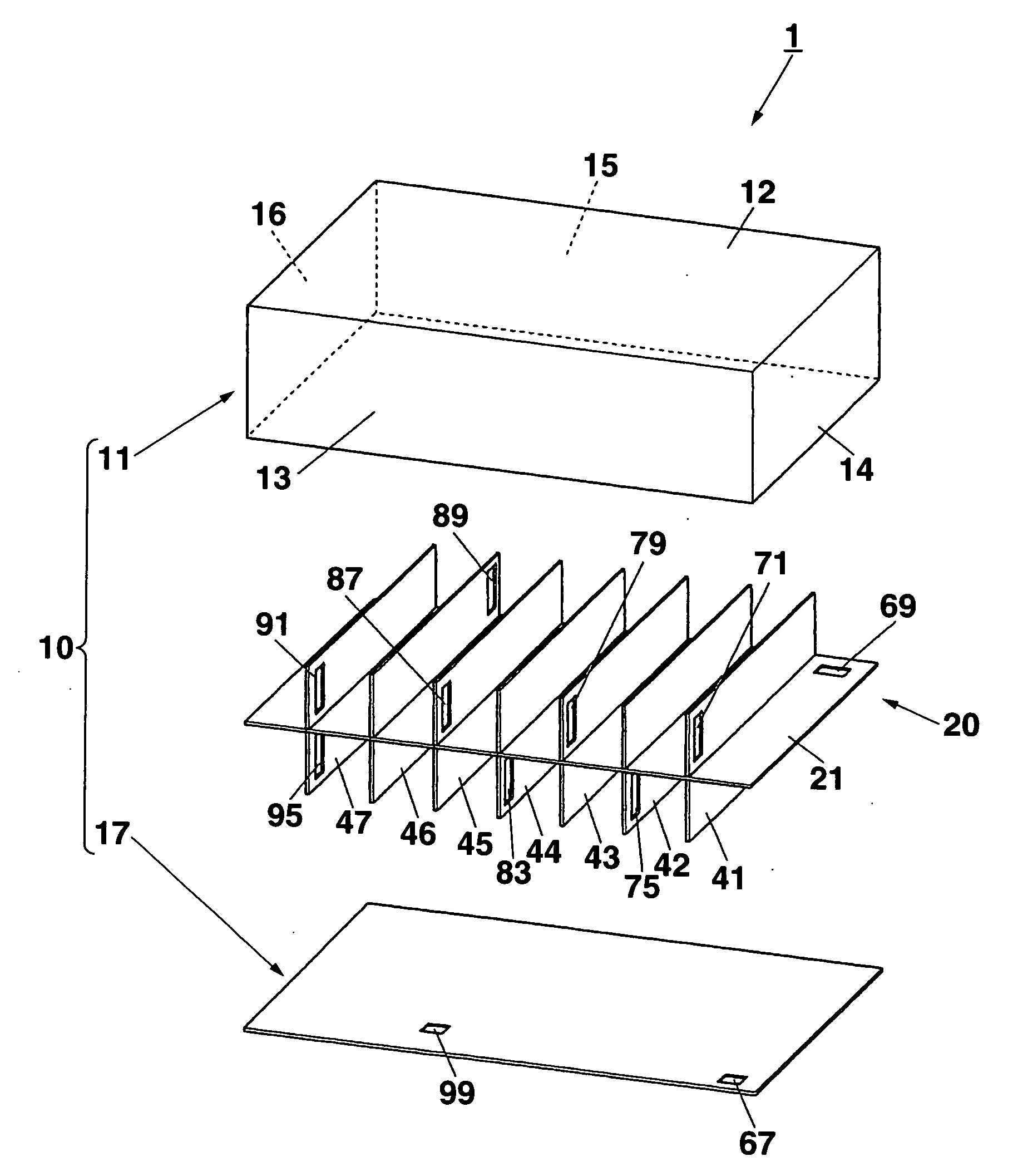

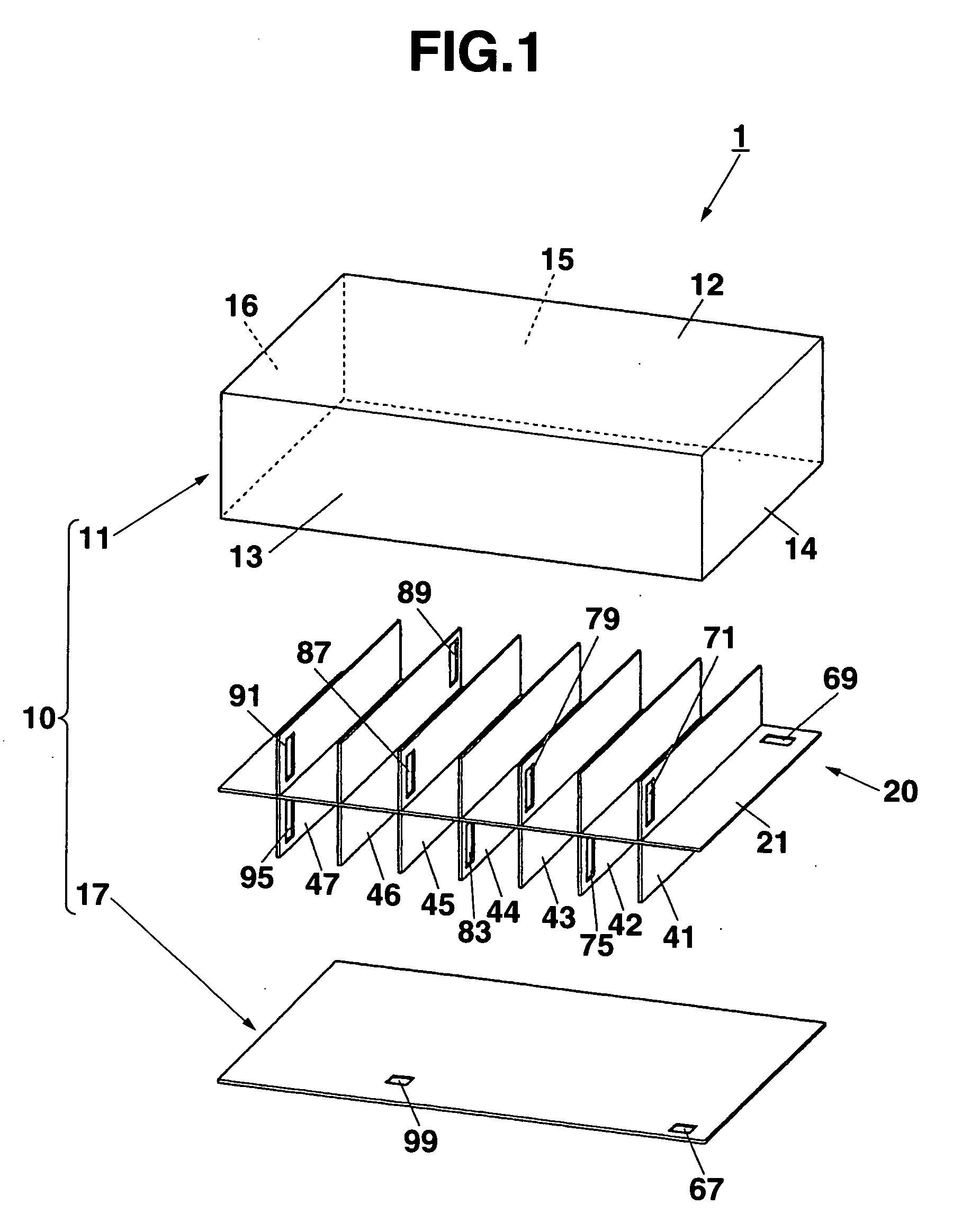

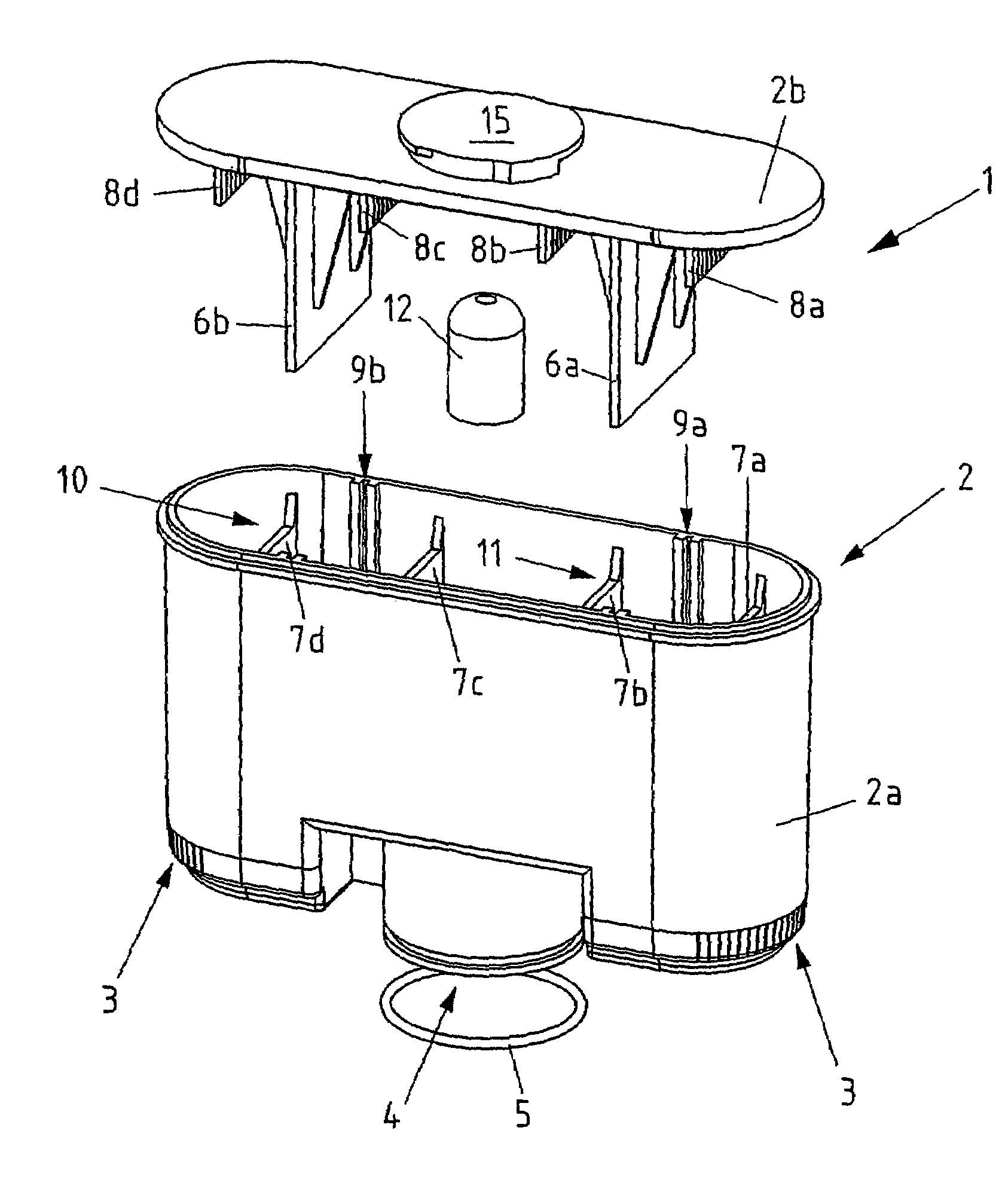

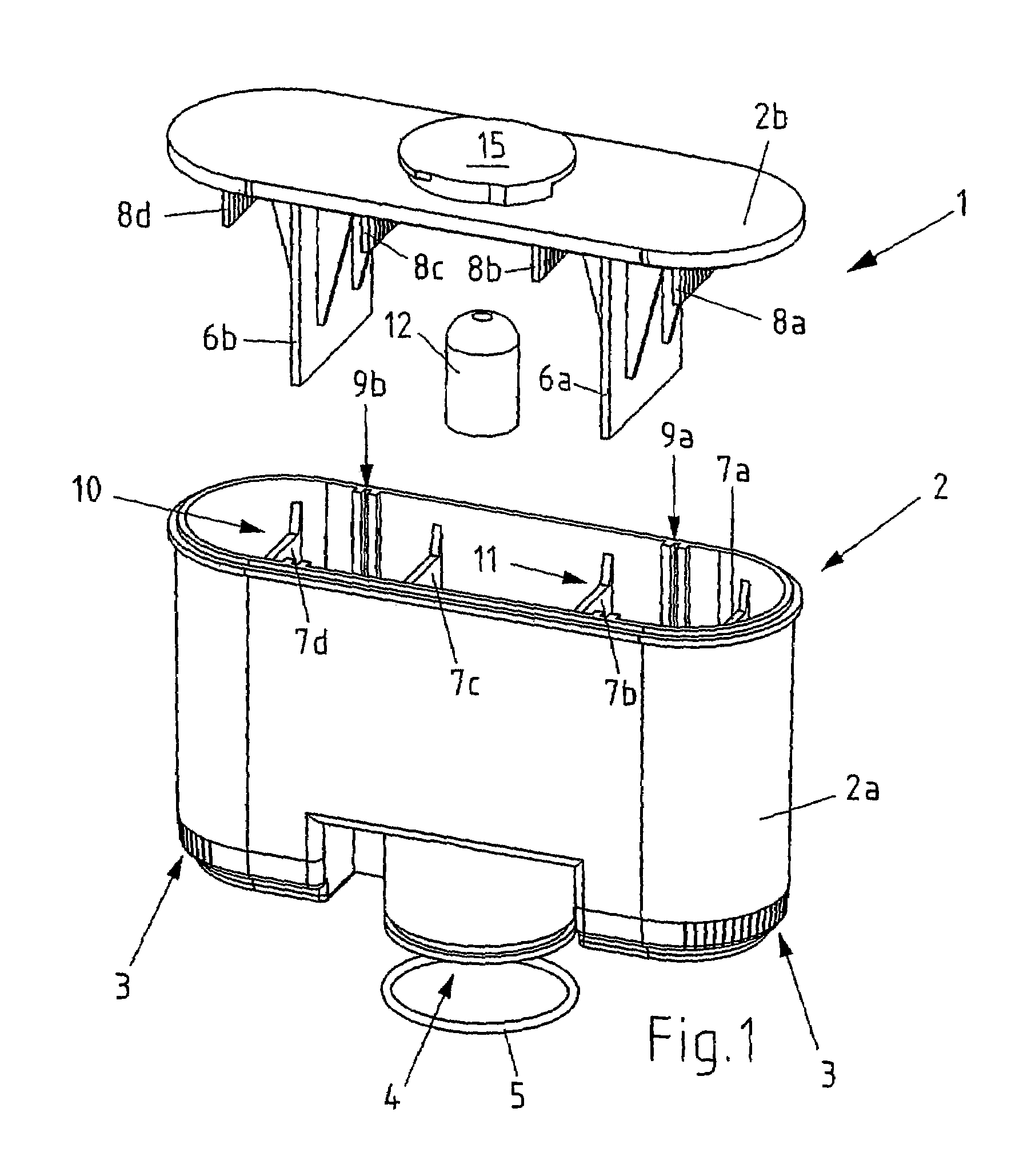

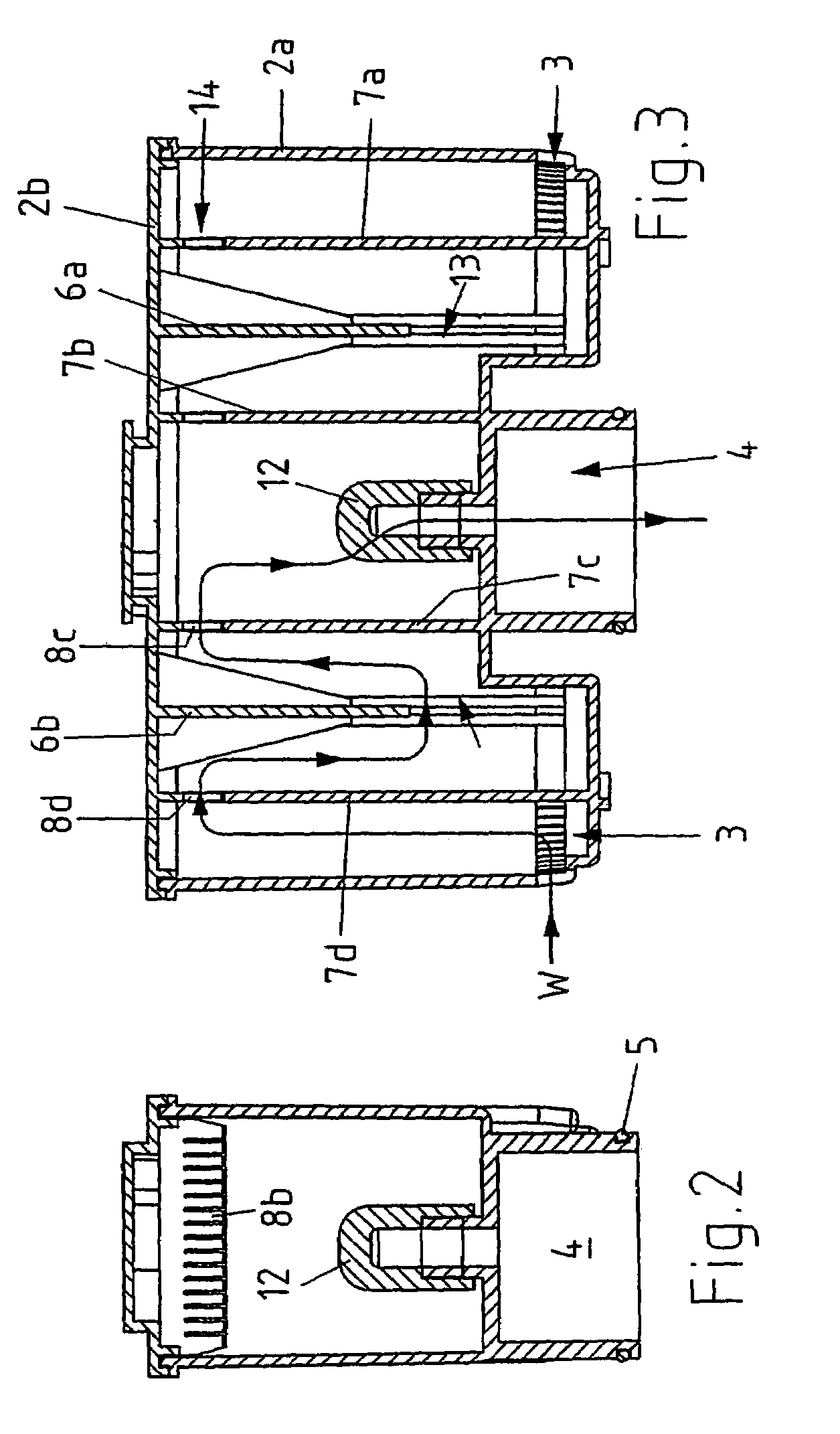

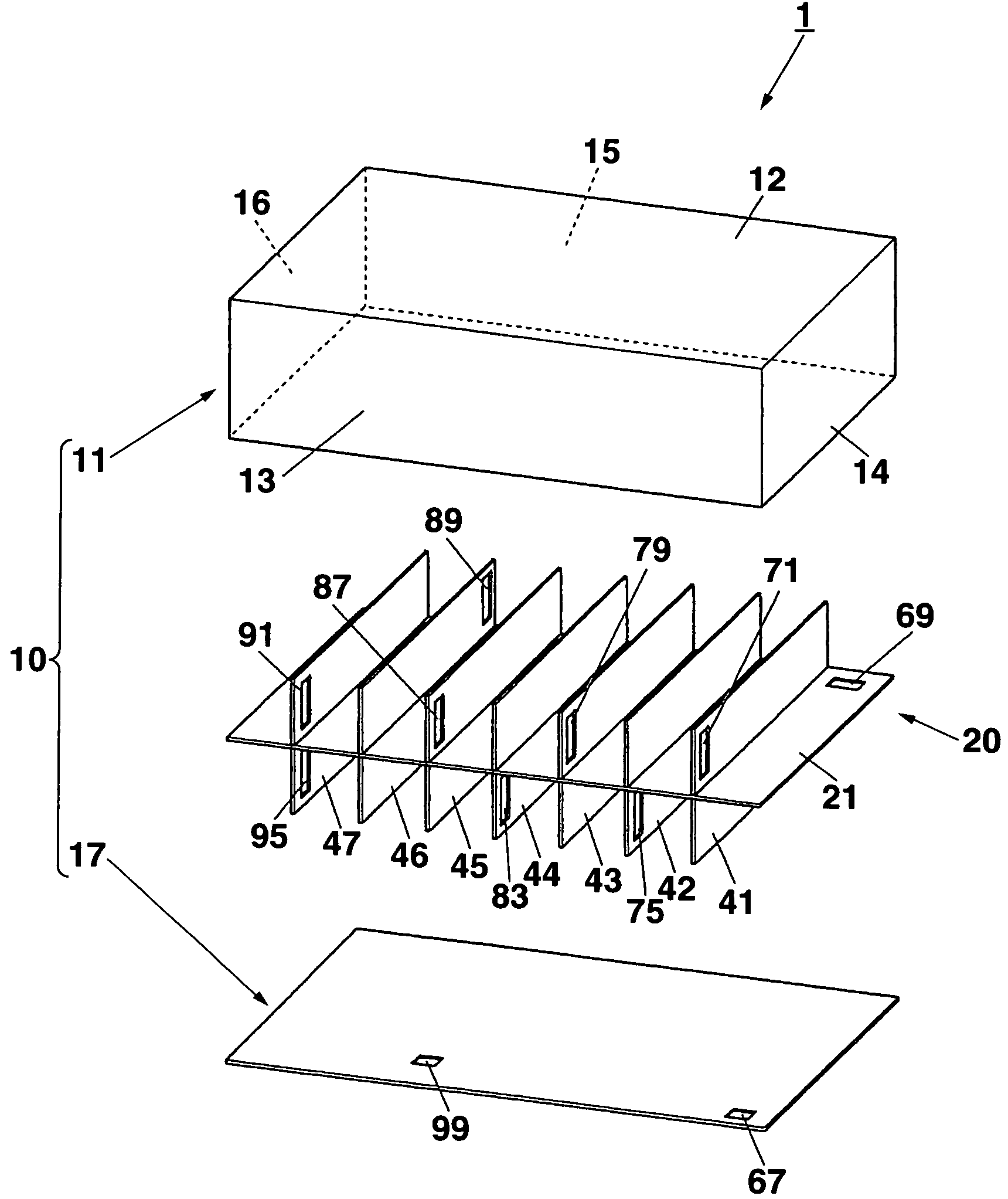

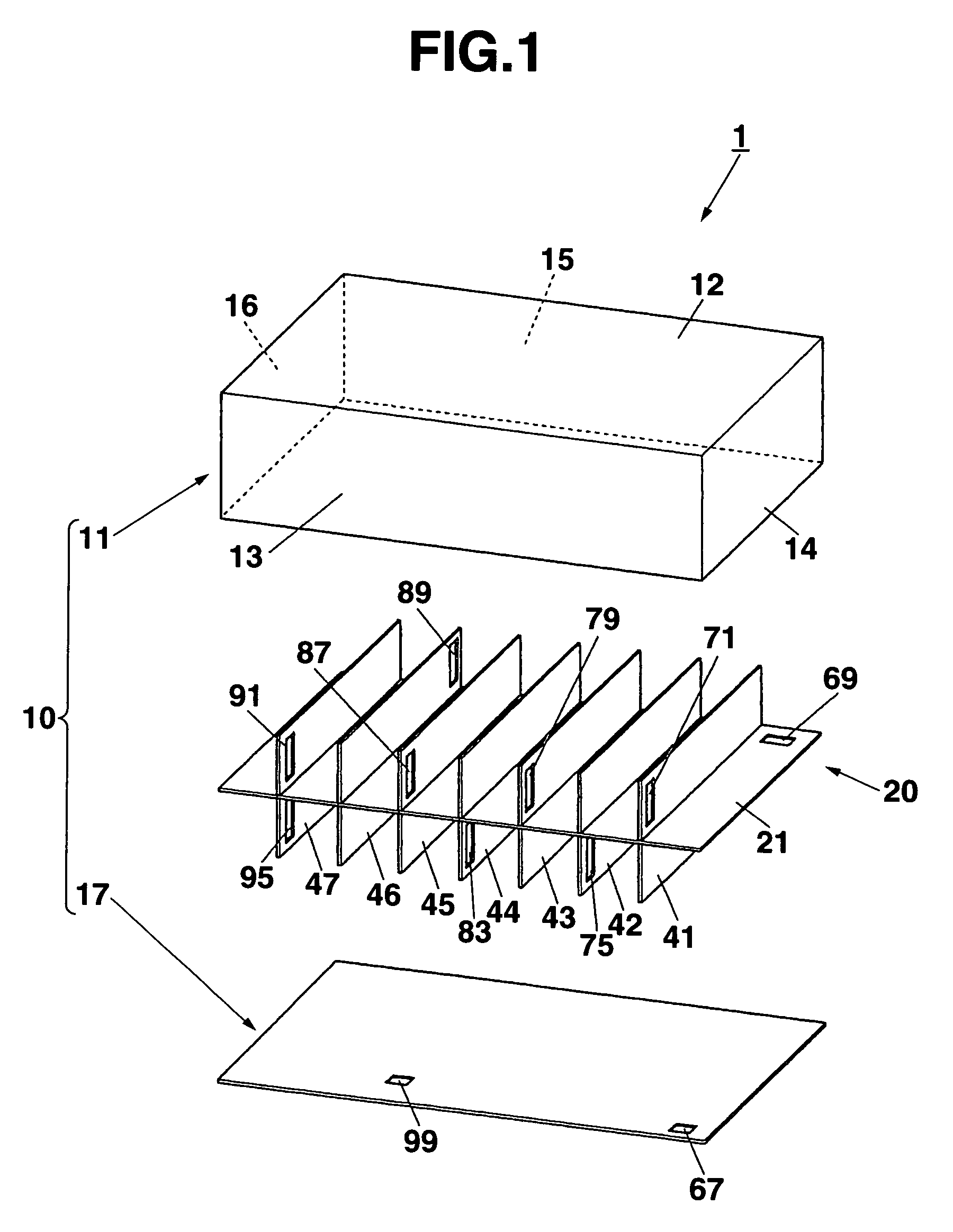

Filter cartridge for a water tank of a coffee machine

ActiveUS20050011824A1Avoid dangerInhibition formationTreatment involving filtrationWater/sewage treatment by ion-exchangeIon-exchange resinWaste management

The filter cartridge for the water tank of a coffee machine comprises a housing having on both sides a plurality of slot-shaped openings constituting two inlets. For softening the water, the housing of the filter cartridge contains a ion exchange resin. The bottom of the housing comprises a central outlet. The interior of the housing is provided with a plurality of baffle members increasing the length of the flow path of the water between inlets and outlet. The housing comprises an upper portion and a lower portion, sealingly fixed to each other. The baffle members extend essentially in vertical direction and are alternately fixed to the upper and to the lower housing portion. Water passages are provided between the upper housing portion and the baffle members fixed to the lower housing portion, as well as between the lower housing portion and the baffle members fixed to the upper housing portion. The filter cartridge of the invention requires not much space, but offers high efficiency resulting from the long flowing path of the water through the ion exchange resin between inlets and outlet.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

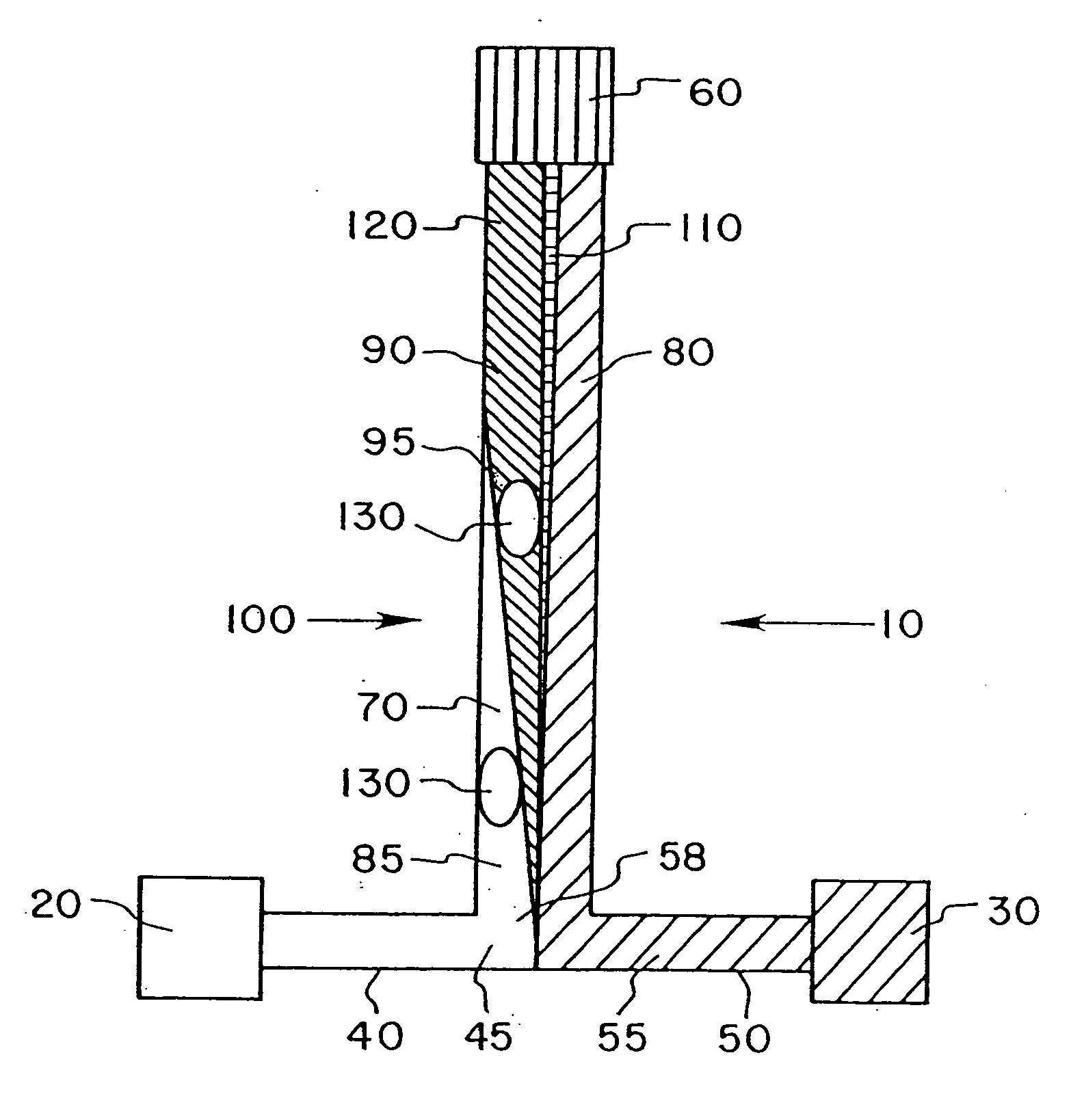

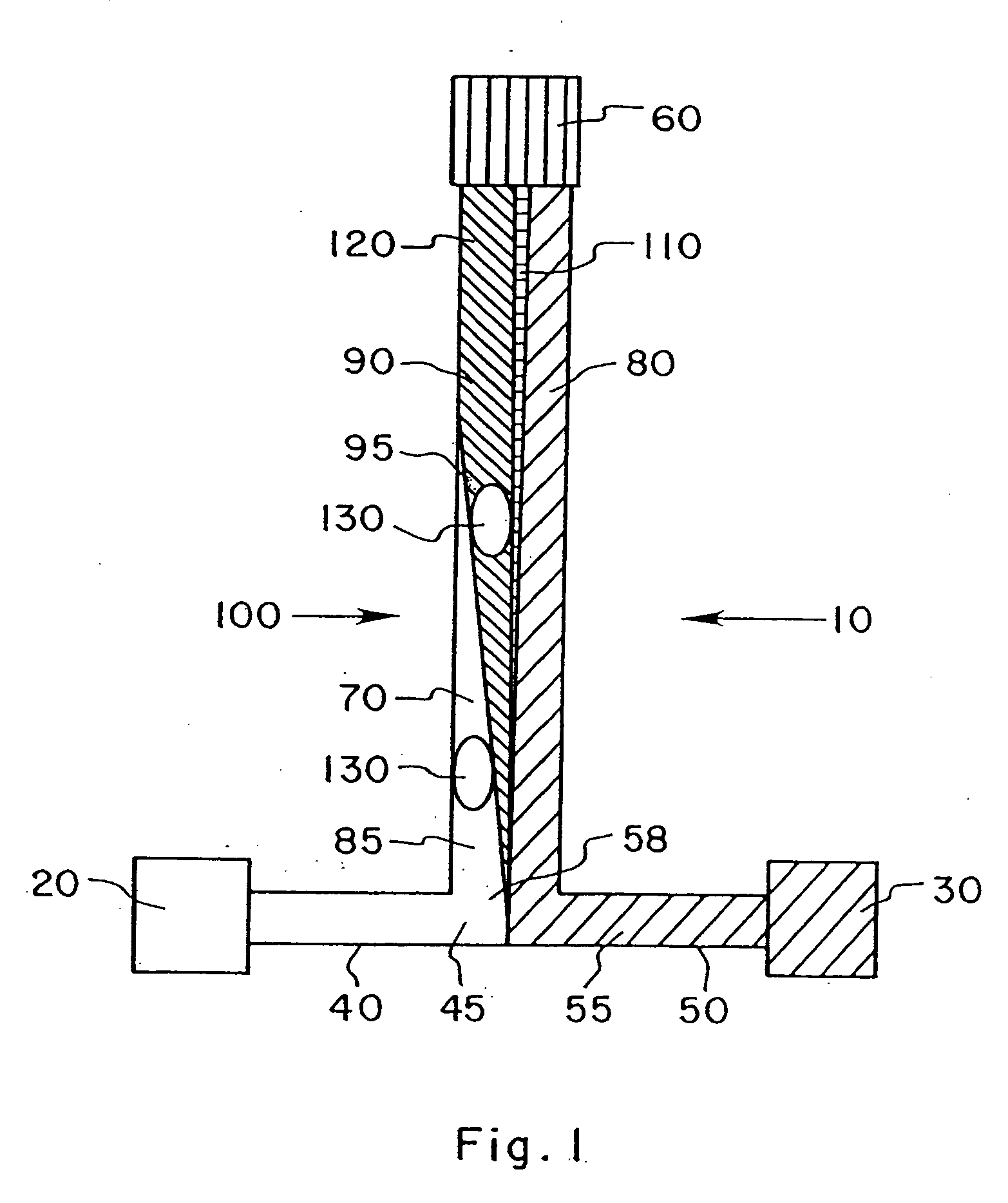

Microfabricated diffusion-based chemical sensor

InactiveUS20060073599A1Rapid mechanismIncrease flow lengthSolvent extractionDialysis systemsCell systemDiffusion

A channel-cell system is provided for detecting the presence and / or measuring the presence of analyte particles in a sample stream comprising: a) a laminar flow channel; b) two inlet means in fluid connection with said laminar flow channel for respectively conducting into said laminar flow channel (1) an indicator stream which may comprise an indicator substance which indicates the presence of said analyte particles by a detectable change in property when contacted with said analyte particles, and (2) said sample stream; c) wherein said laminar flow channel has a depth sufficiently small to allow laminar flow of said streams and a length sufficient to allow particles of said analyte to diffuse into said indicator stream to the substantial exclusion of said larger particles in said sample stream to form a detection area; and d) outlet means for conducting said streams out of said laminar flow channel to form a single mixed stream.

Owner:UNIV OF WASHINGTON

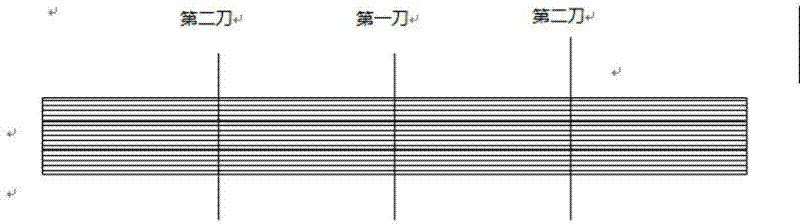

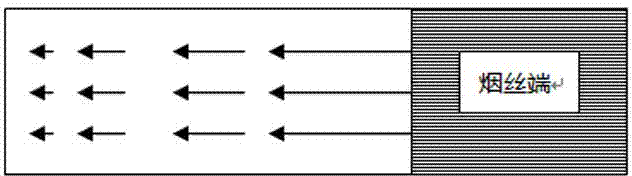

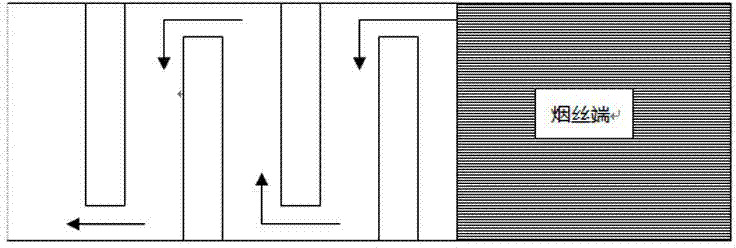

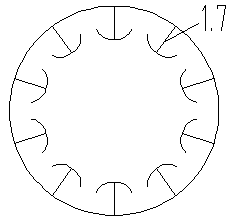

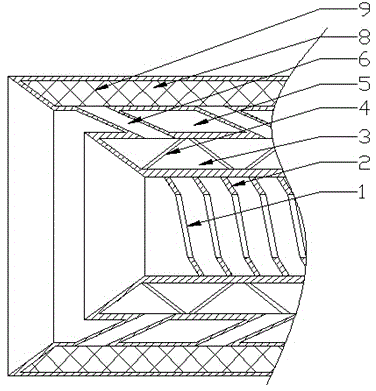

Composite solid filter rod and preparation method thereof

ActiveCN102499475ASimple processIncrease flow lengthTobacco smoke filtersPolymer sciencePolyvinyl chloride

The invention provides a composite solid type filter rod, belongs to the technical field of cigarette process, and particularly relates to a design and manufacturing method of a new material filter rod in a cigarette filter. The filter rod consists of one or a combination of more than one of medical grade PVC (polyvinyl chloride), medical grade PLA (poly lactic acid) and polycaprolactone serving as a raw material, and an auxiliary material glyceryl triacetate, wherein the weight ratio of the raw material to the auxiliary material is (1-9):1. According to the composite solid filter rod and the preparation method, the passing route of smoke in the filter can be effectively prolonged, and harmful ingredients in the smoke can be effectively filtered.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

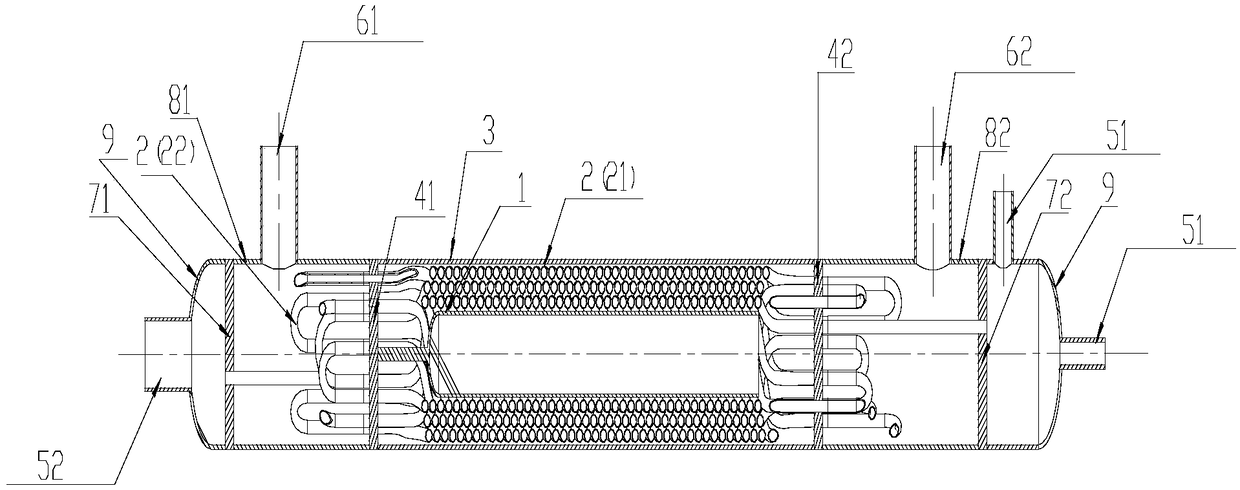

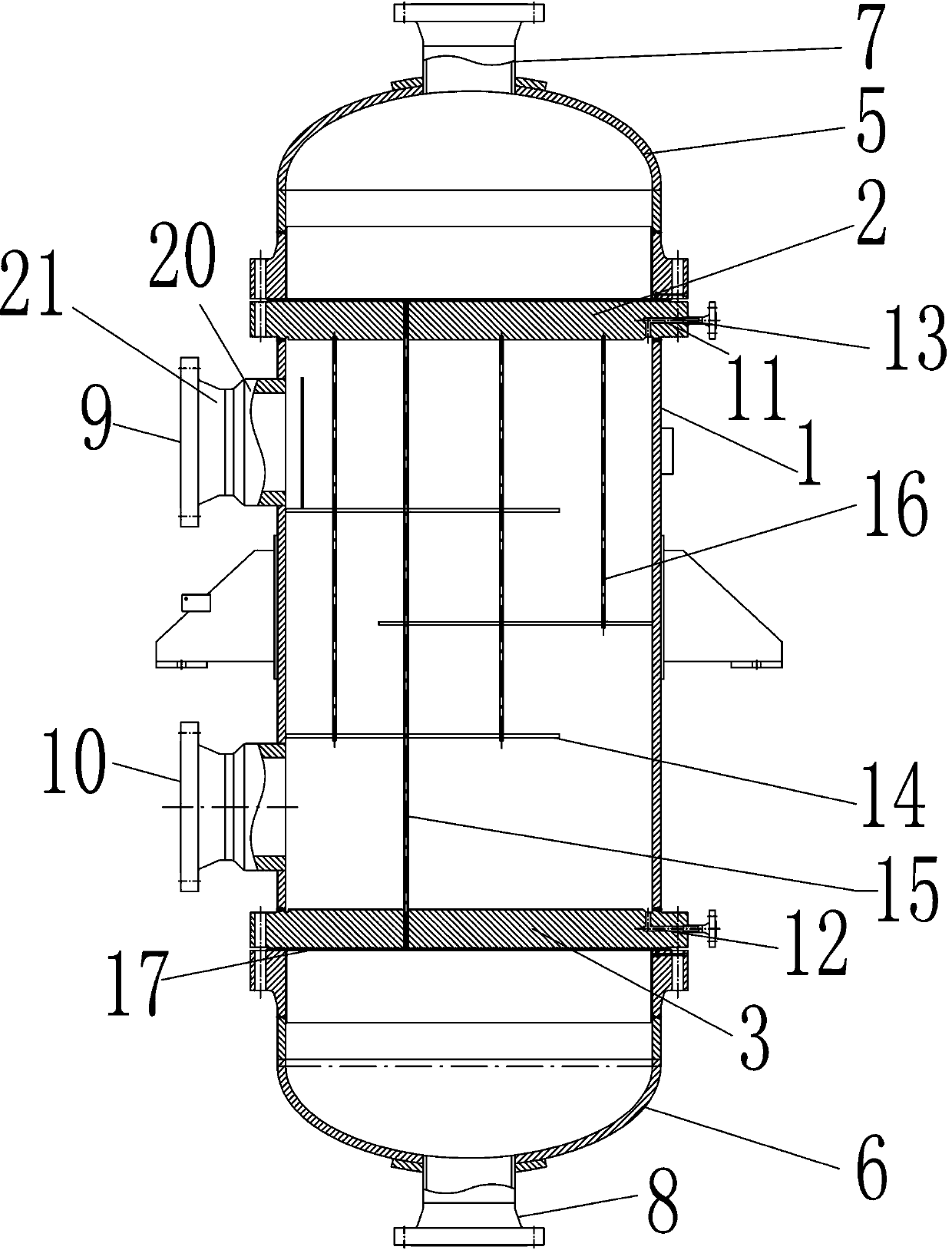

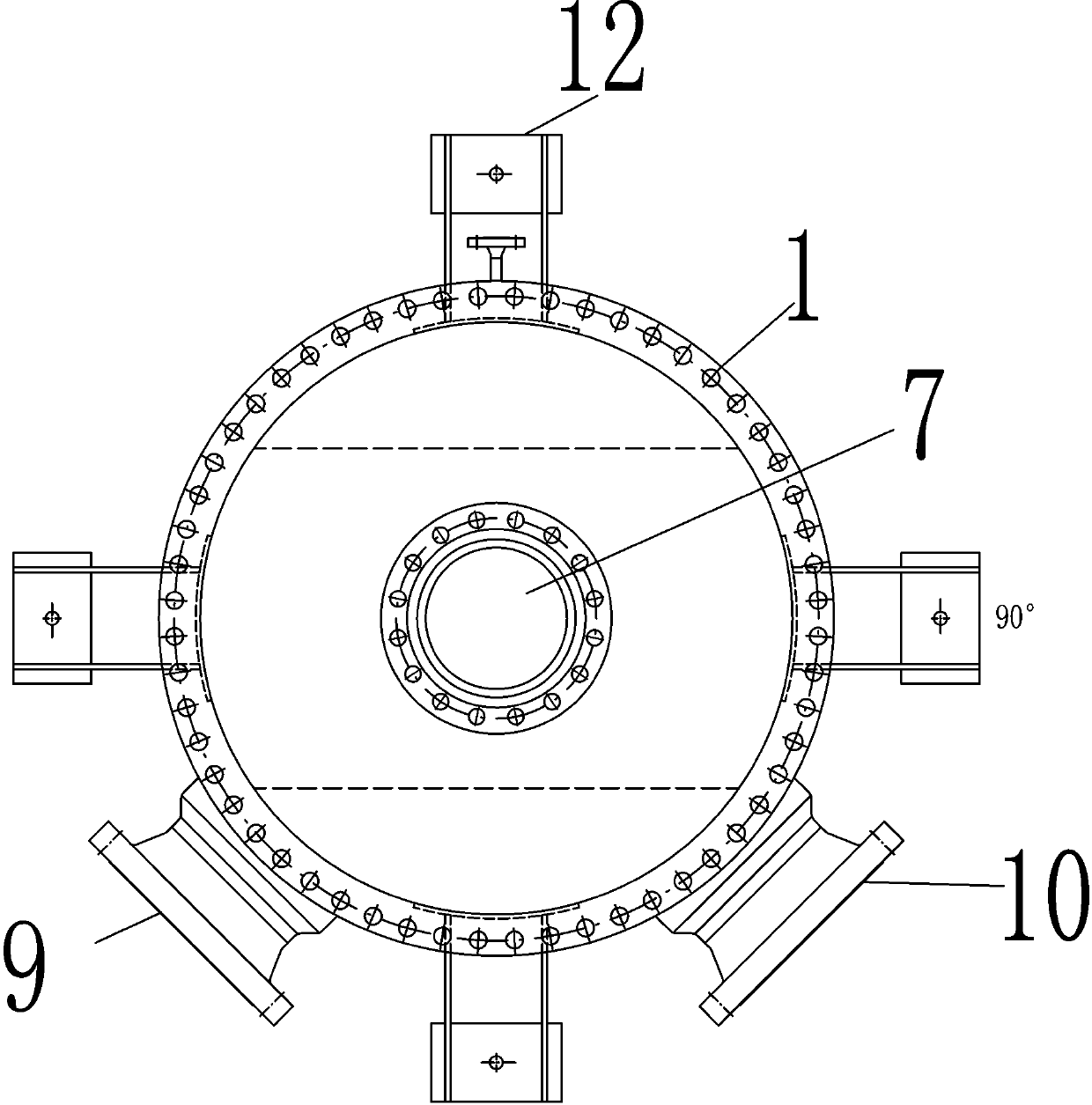

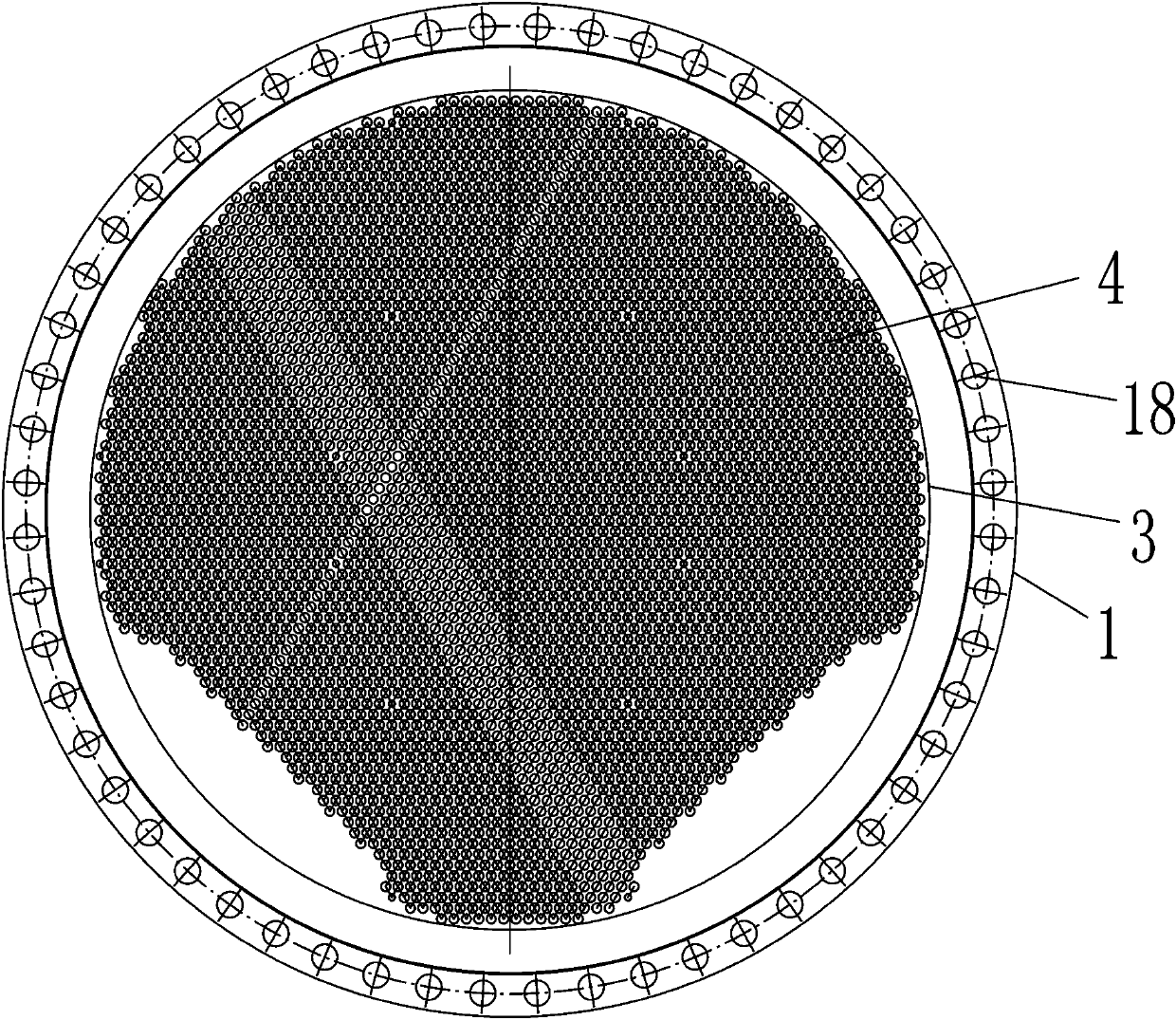

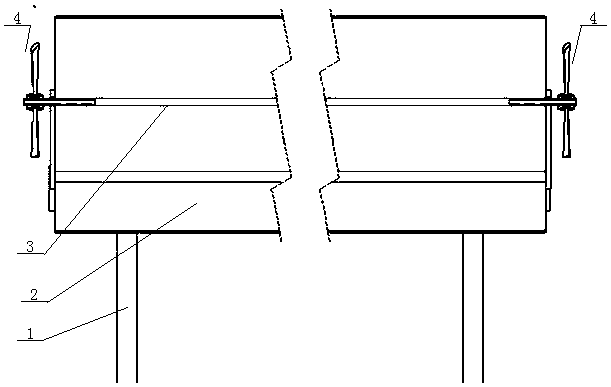

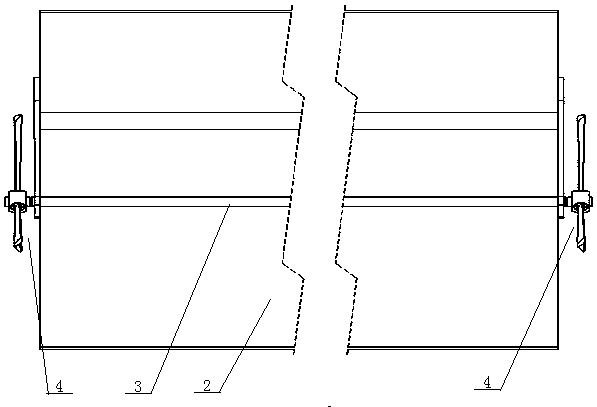

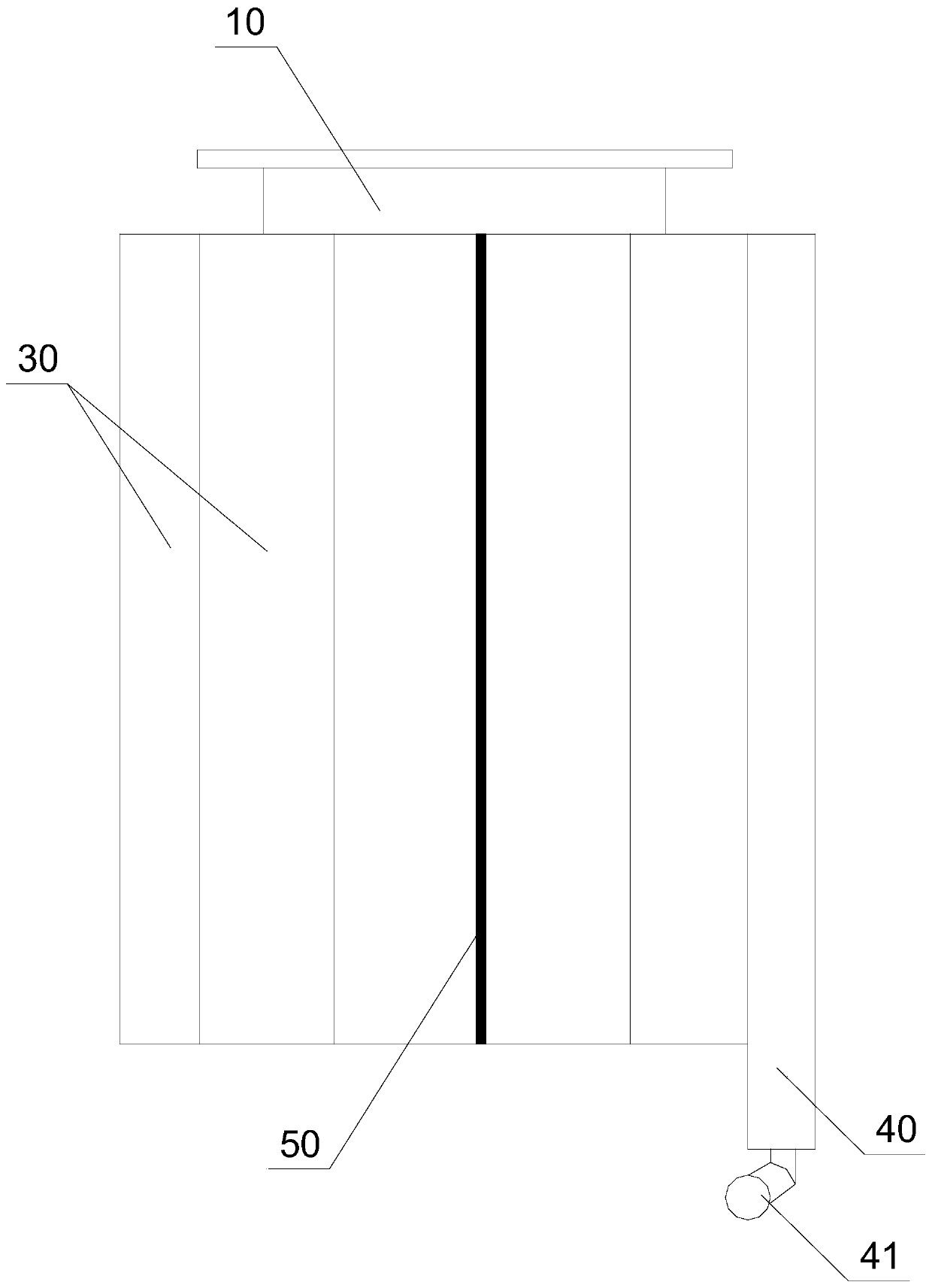

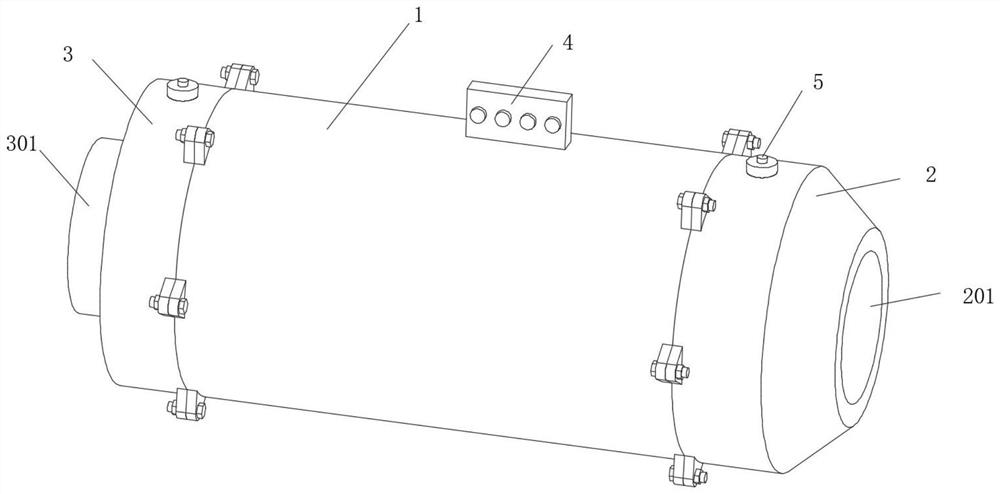

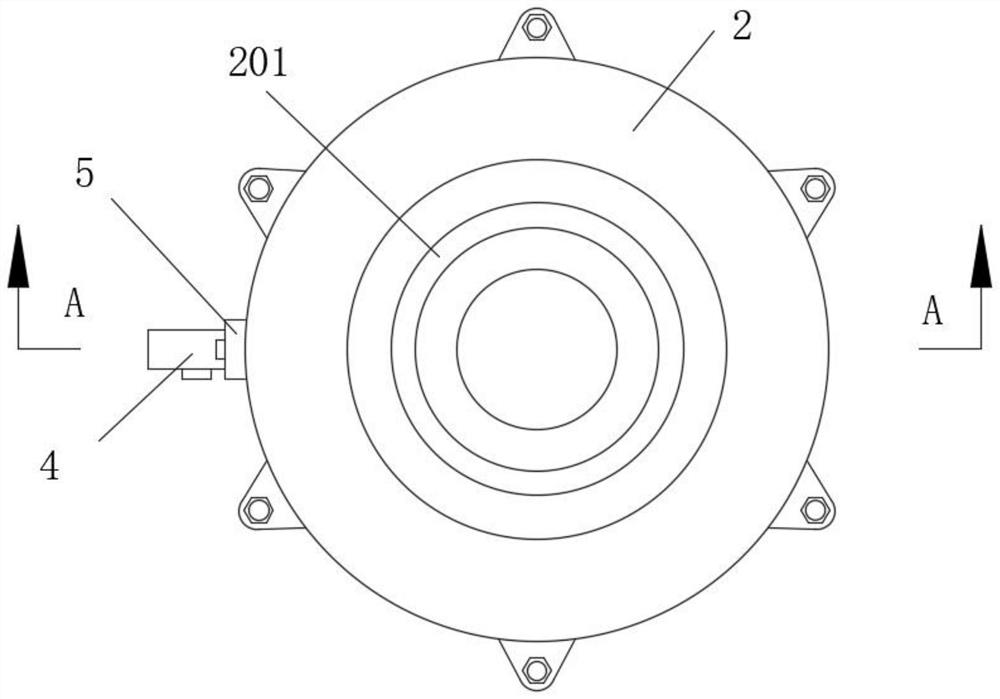

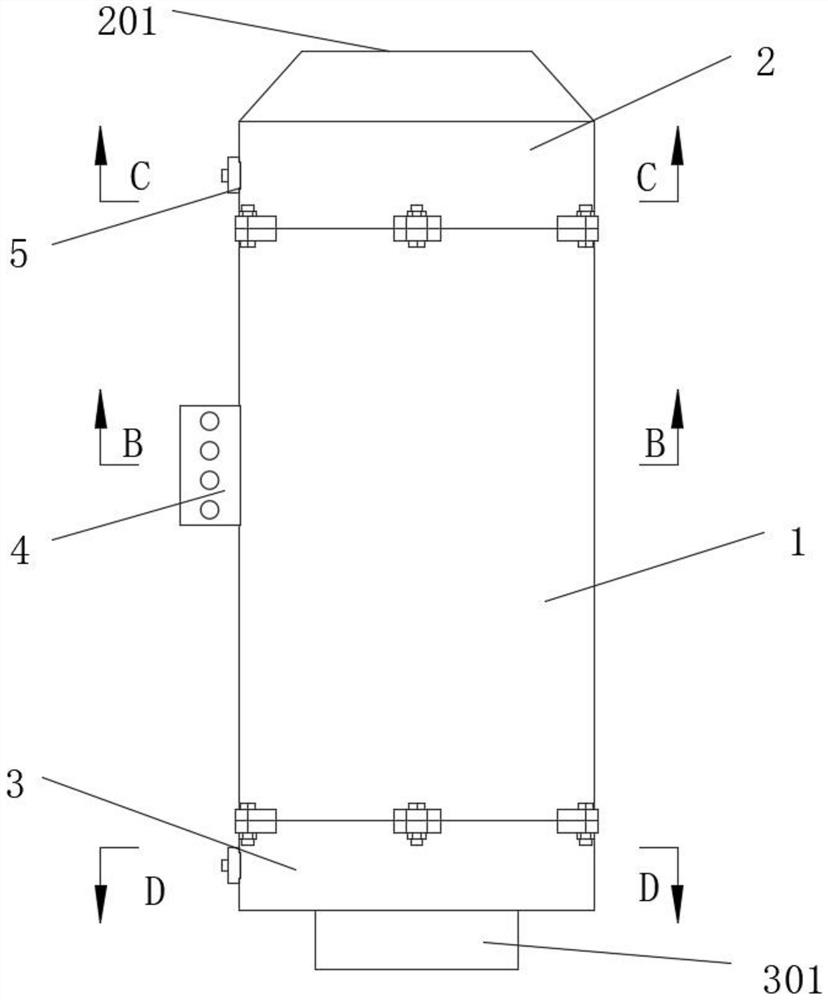

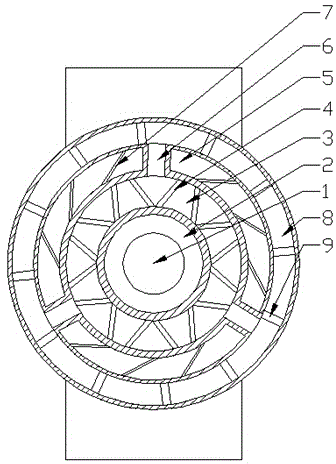

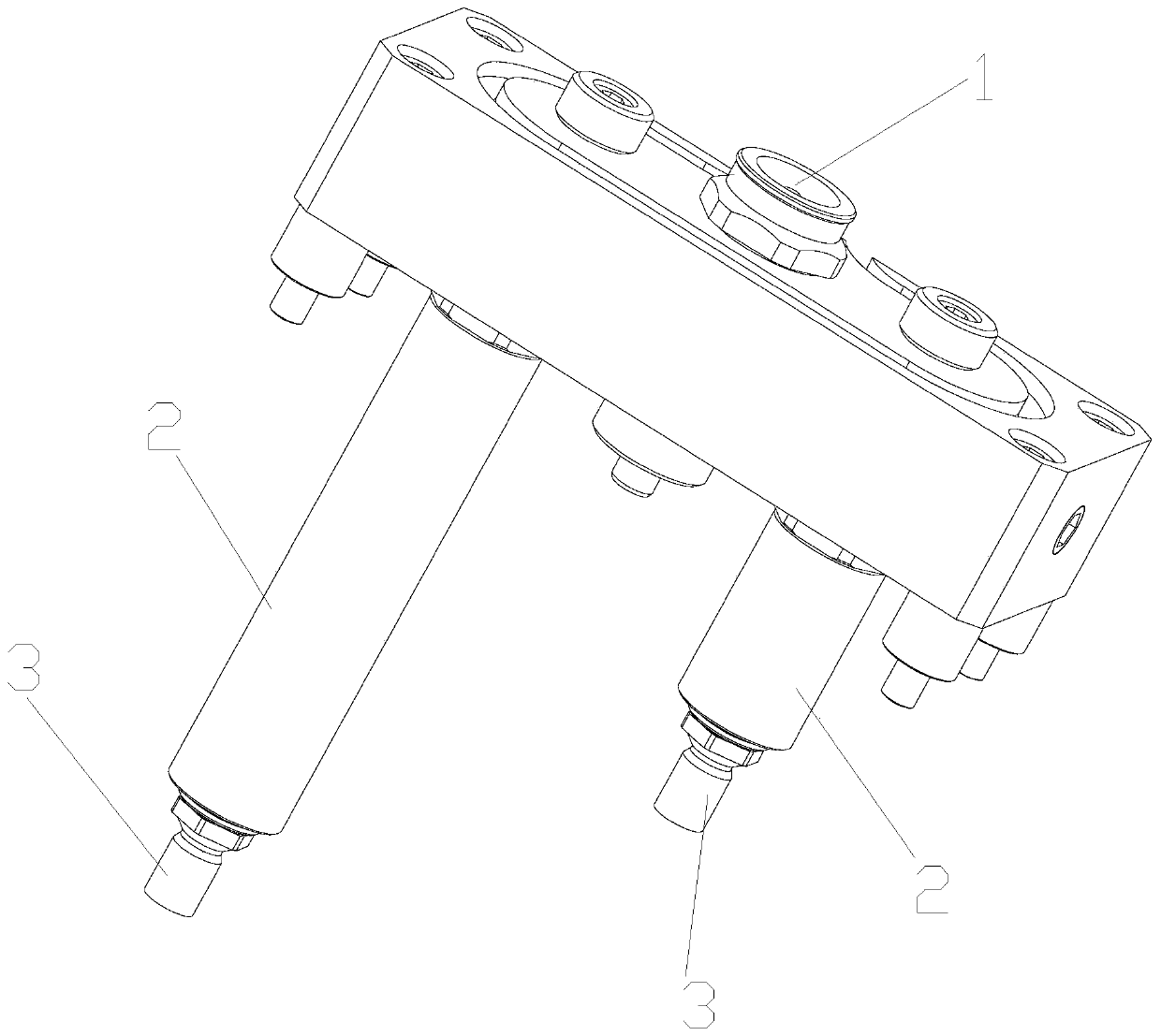

Tubular reactor

PendingCN108465454AIncrease flow lengthExtended stayChemical/physical/physico-chemical stationary reactorsReaction rateEngineering

The invention provides a tubular reactor. The reactor comprises a reaction tube (2) capable of containing reaction fluid which passes through and reacts in the tube, the reaction tube (2) comprises aplurality of spiral tubes (21), the spiral tubes (21) spirally wind, or the spiral tubes (21) are arranged in a spiral array, and the spiral tubes (21) are sequentially connected in series to form reaction tubes. According to the reactor, the residence time of the reaction fluid is greatly increased, the problems in the prior art that a pipeline needs to be processed too long and cannot be easilyachieved in the industry when the reaction rate is low are solved, the floor space is effectively reduced, the reactor is well achieved, the heat exchange effect is improved, the flow length of the fluid is increased, the reaction residence time is ensured, and the reactor is suitable for reactions with large residence time.

Owner:SHANDONG HIMILE CHEM TECH +1

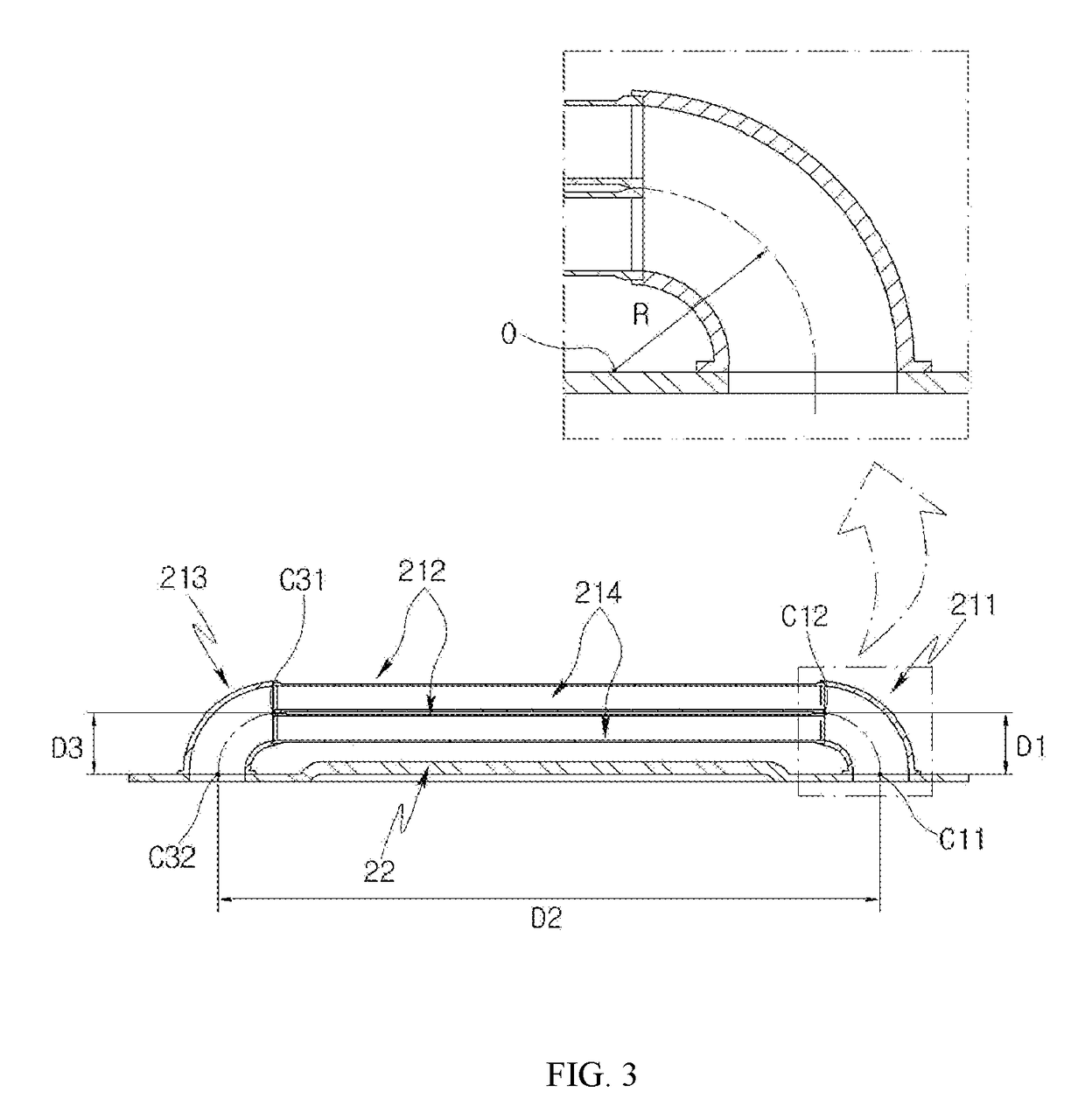

Reactor

InactiveUS20070071653A1Improve rigidityIncrease flow lengthExhaust apparatusChemical/physical/physico-chemical microreactorsBackplaneEngineering

Owner:CASIO COMPUTER CO LTD

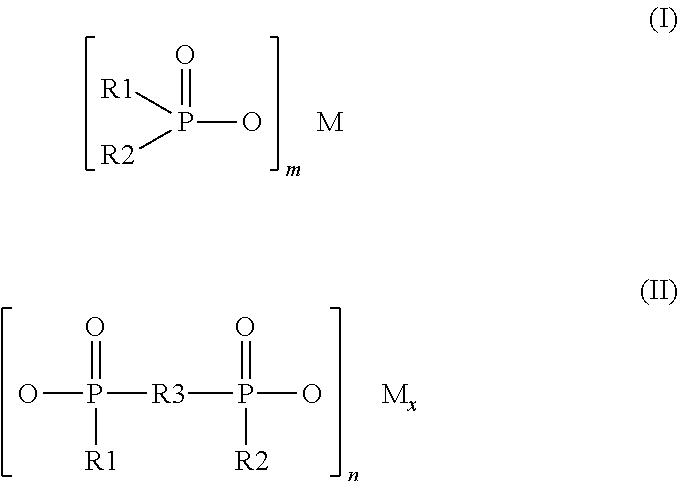

Partially aromatic moulding compositions and their uses

ActiveUS8324297B2Reliable weldingEasy to processPigmenting treatmentNon-fibrous pulp additionPolyamideFire retardant

Polyamide molding composition, in particular for use for components of electronic and / or electrical components, having the following composition:(A) 30-100% by weight of a partially aromatic, partially crystalline copolyamide made up of100% by weight of diacid fraction composed of:72.0-98.3% by weight of terephthalic acid (TPA) and / or naphthalenedicarboxylic acid;28.0-1.7% by weight of isophthalic acid (IPA)and 100% by weight of diamine fraction composed of:51.0-80.0% by weight of 1,6-hexanediamine (HMDA);20.0-49.0% by weight of aliphatic, unbranched C9-C12-diamine;(B) 0-70% by weight of fillers and reinforcing materials;(C) 0-25% by weight of flame retardants;(D) 0-5% by weight of additives;where the components (A)-(D) add up to 100% by weight.

Owner:EMS PATENT AG

Environmental protection type polyvinyl chloride composition

ActiveCN101555336AExcellent color retentionExcellent long-term thermal stabilityChemistryStabilizing Agents

The invention discloses an environmental protection type polyvinyl chloride composition which comprises the following components according to the weight percentage: 70.3-89.4 of polyvinyl chloride, 1-3 of stabilizing agent, 1-3 of plasticizing agent, 0.4-2.0 of lubricating agent, 1-3 of modifying agent I, 3-7 of modifying agent II, 3-8 of modifying agent III, 1-3 of paint and 0.2-0.7 of assistant. Aims at overcoming the defects existing in the prior art, the invention provides the injection grade environmental protection type polyvinyl chloride composition which has good fluidity and physical property and satisfies the requirements for environmental protection and health.

Owner:广东顺威赛特工程塑料开发有限公司

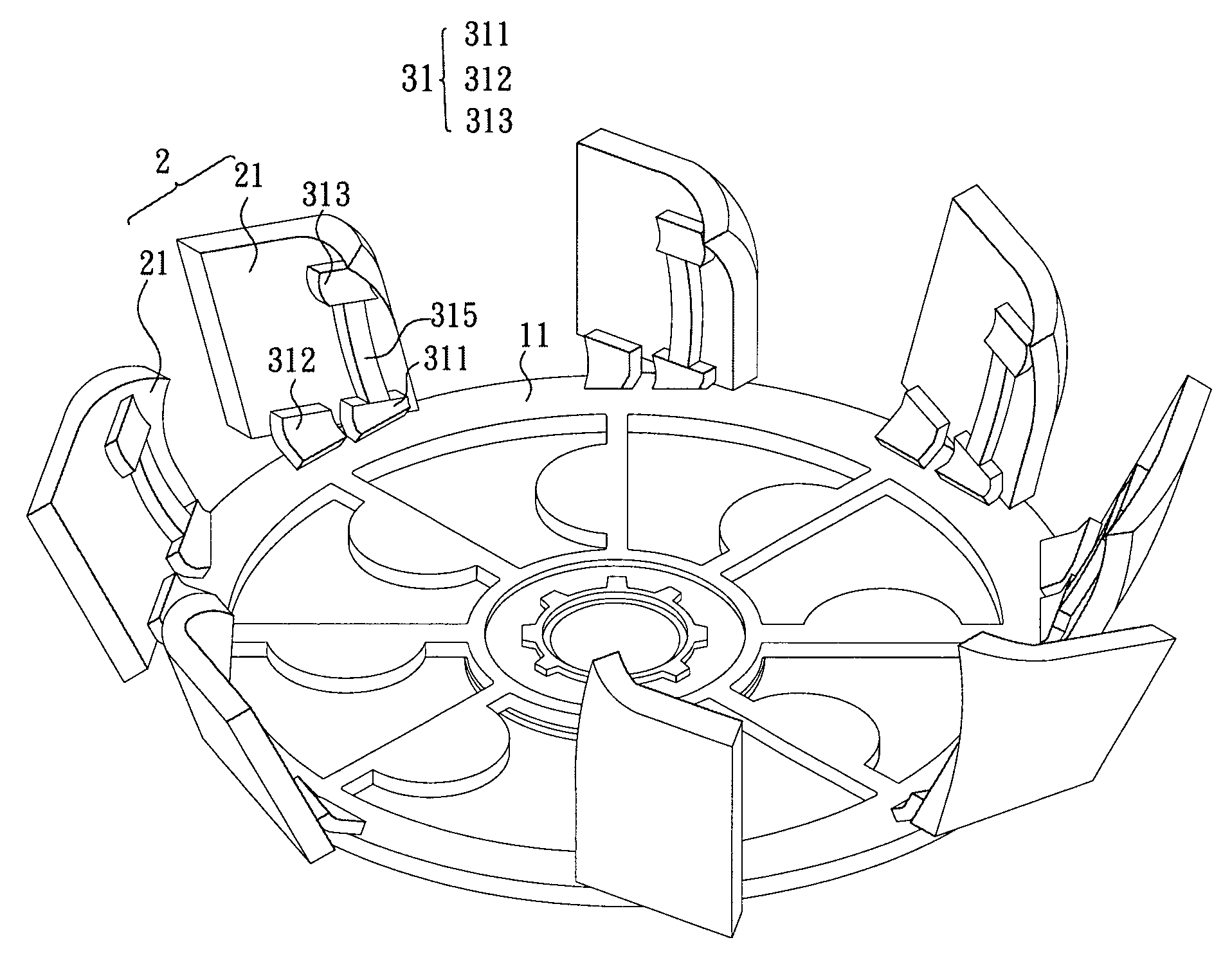

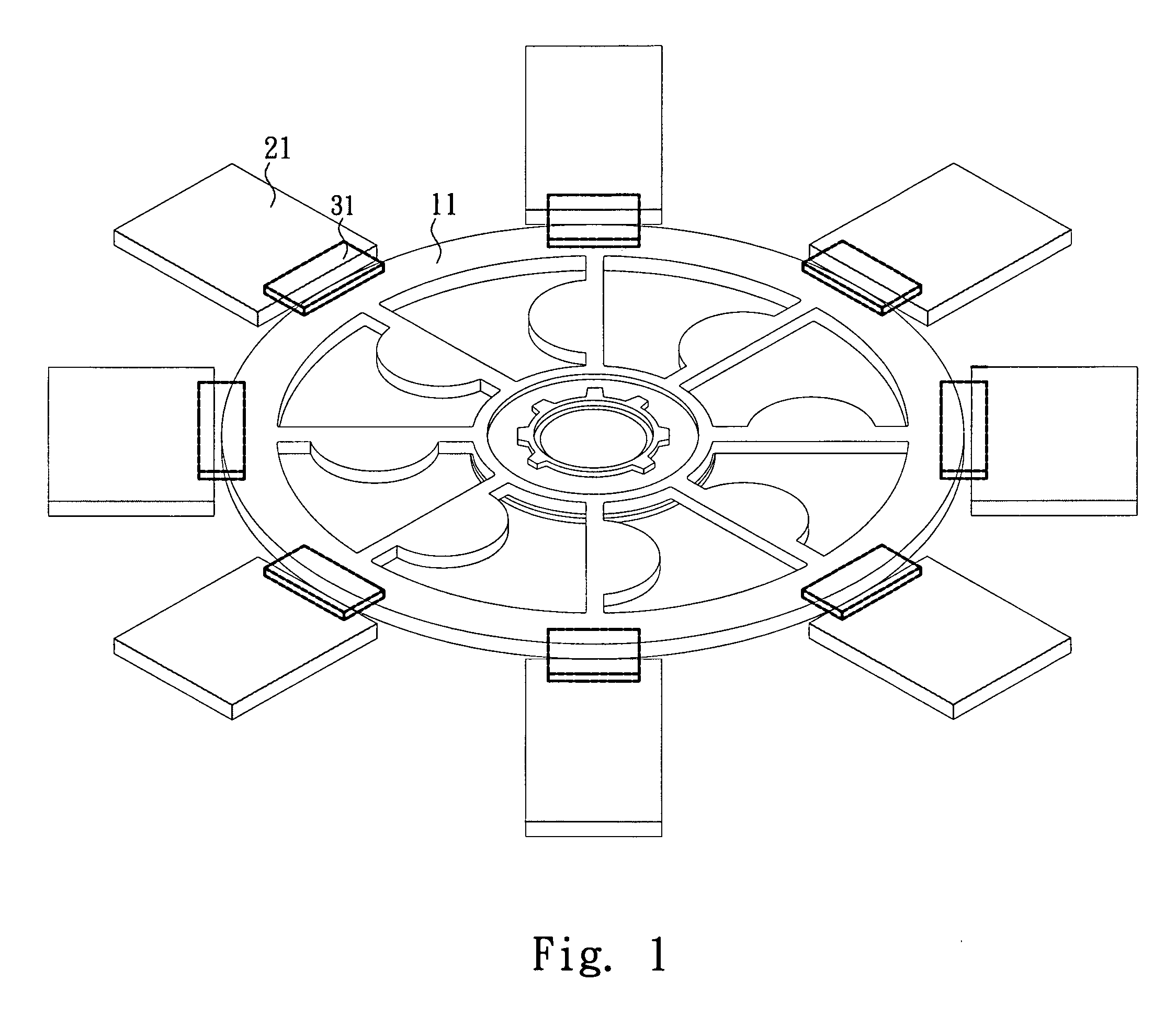

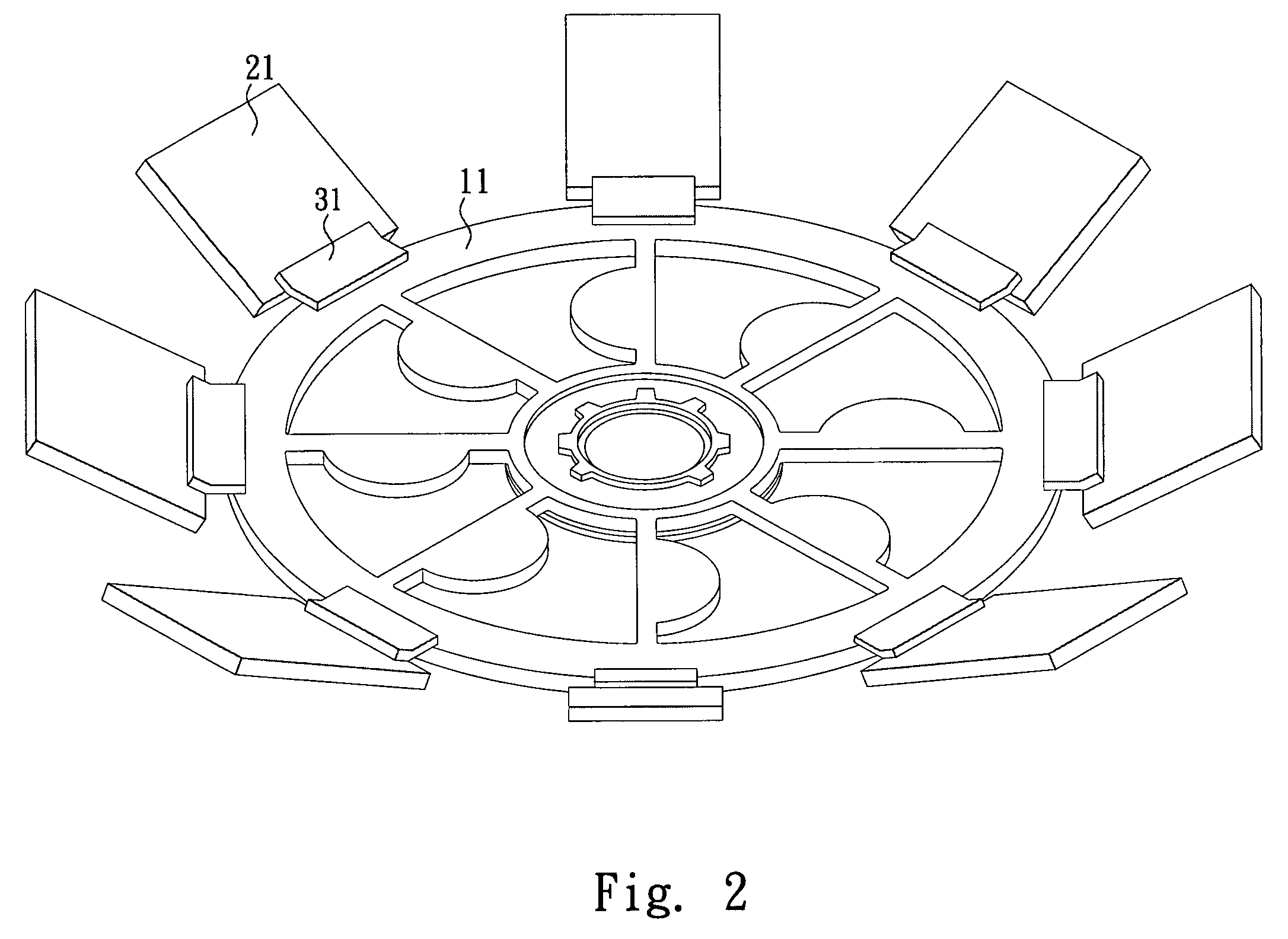

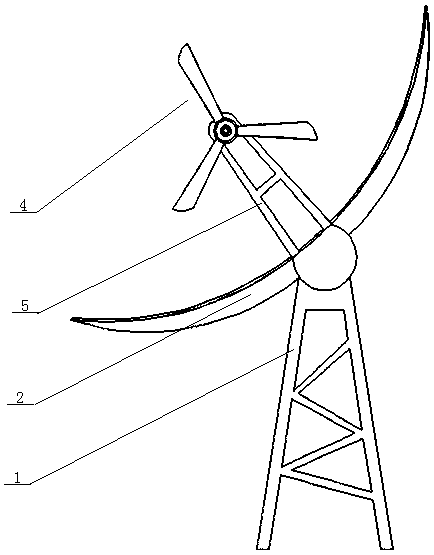

Self-assembly micro blade

InactiveUS20090185909A1Increase air flow rateEasy to controlPropellersPump componentsEngineeringActuator

The present invention relates to a self-assembly micro blade applied to a micro fan. The micro fan combines at least a self-assembly micro blade and a motor using an actuator as the main body of the micro fan. The self-assembly micro blade includes at least a movable part of a microstructure, at least an elastic joint provided between an outer ring of the micro fan and the movable part. The elastic joint is composed of a polyimide film, which is heated to contract and generate surface tension by using a reflow process so as to lift up the movable part of the microstructure; moreover, the movable part is bent in a curved form through the elastic link exhibits a multi-layer shape by serially connecting at least two movable parts so as to complete the self assembly of the micro blade, thereby increasing air flow rate and improving air flow length.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Filter cartridge for a water tank of a coffee machine

ActiveUS7294266B2Improve efficiencySmall sizeTreatment involving filtrationWater/sewage treatment by ion-exchangeIon-exchange resinWaste management

Owner:KONINK PHILIPS ELECTRONICS NV

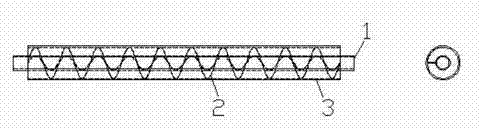

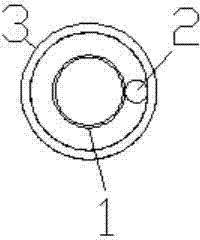

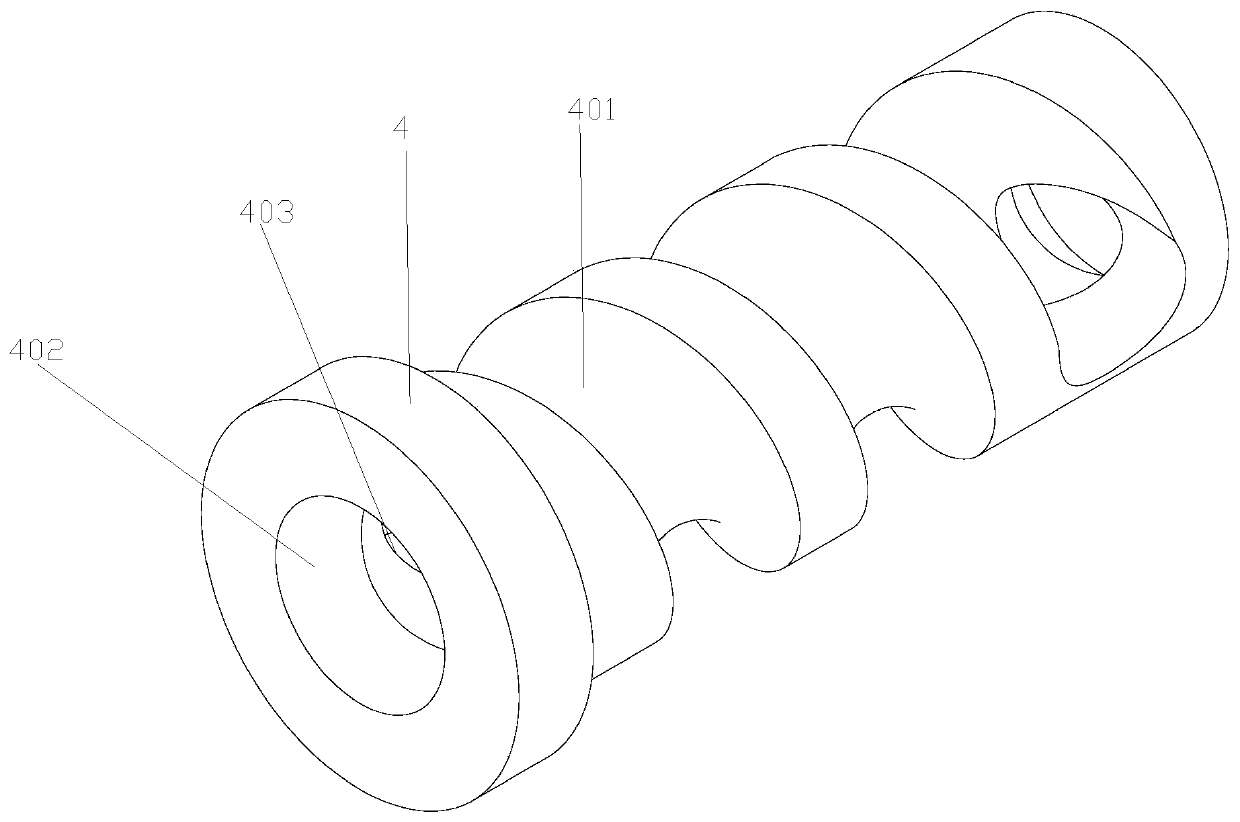

Line-up type full-contact heat exchange tube

InactiveCN104848712AIncrease flow lengthIncrease contact areaStationary tubular conduit assembliesHeat transfer modificationElectrical conductorContact time

The invention discloses a line-up type full-contact heat exchange tube and relates to the technical field of liquid and gas heat exchange, in particular to heat energy exchange and recovery. The line-up type full-contact heat exchange tube comprises an internal tube, a spiral guiding extend-range ferrule and an external tube; both the internal tube and the spiral guiding extend-range ferrule are arranged inside the external tube and are coaxial to the same; the spiral guiding extend-range ferrule sleeves the internal tube from the outer wall and is arranged inside the external tube, and a spiral guiding channel is formed between the internal tube and the external tube. The spiral guiding extend-range channel is formed between the spiral guiding extend-range ferrule and the internal and external tubes, flow length of materials in the channel is effectively increased, contact area and contact time of refined materials and a heat exchange conductor are increased, and uniformity in heat exchange is improved; the internal tube is arranged inside the spiral guiding extend-range channel, the materials inside and outside the material channel are subjected to heat exchange simultaneously, and utilization upon generation is achieved; the line-up type full-contact heat exchange tube is more complete in heat exchange, high in heat exchange efficiency, more compact in structure, good in shaping, flexible to use, wide in applicability and especially suitable for energy-saving recovery of instant heat exchange.

Owner:陈永秋

Aqueous urea solution decomposing mixing device

PendingCN110821615AReduce hindranceReduce lossesInternal combustion piston enginesExhaust apparatusVertical planeEngineering

The invention discloses an aqueous urea solution decomposing mixing device. A spoiler and a pore plate are arranged between a front shell and a rear shell. The spoiler and the pore plate divide an inner cavity into an upper spraying cavity, a middle flow guide cavity and a lower rotational flow cavity. A top cover is arranged at the top of the rear shell. An inclined plane is arranged in the spraying cavity, and an included angle is formed between the vertical plane and the inclined plane. A flow guide plate is provided with a flow guide vane. The spoiler is provided with a turbulent flow vane. A rotational flow plate is provided with a rotational flow vane outwards through a third vane hole. The inner cavity of the aqueous urea solution decomposing mixing device is divided into the spraying cavity, the flow guide cavity and the rotational flow cavity only through the spoiler and the pore plate. Little blocking occurs in an airflow channel, the airflow channel is smoother, mixed airflow passes through few turning points in the airflow channel, energy loss is small, and the airflow pressure drop is low. The top cover is provided with an inclined lower plane, and the spraying cavityforms a cavity which is asymmetric along the vertical plane. A nozzle seat is located in a low position of the lower plane, and thus the urea spraying line is toward the direction directly facing thedirection of the turbulent flow vane of the spoiler.

Owner:无锡亿利环保科技有限公司

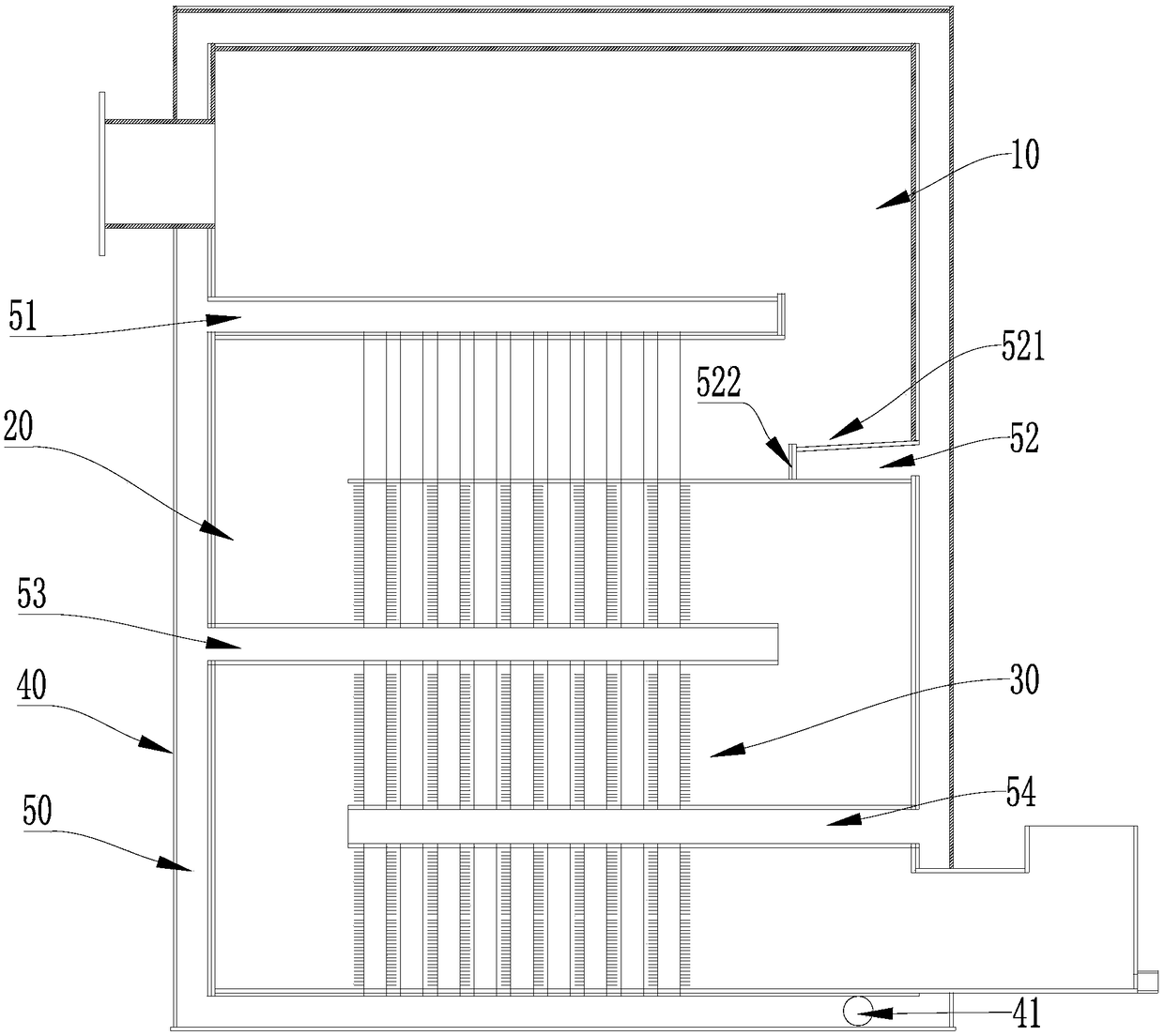

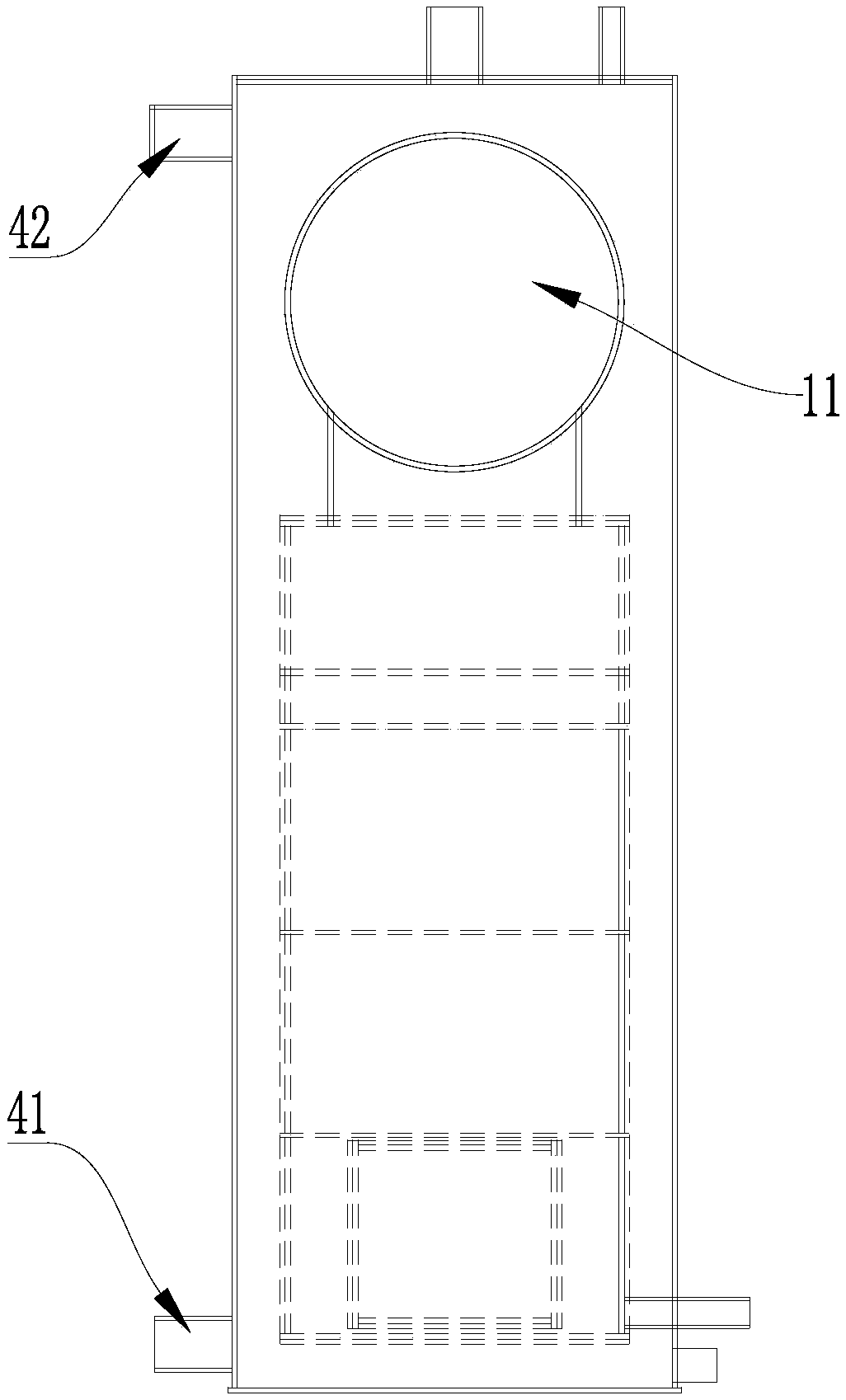

Condensation boiler

PendingCN108826688AIncrease flow lengthImprove thermal efficiencyAir heatersSustainable buildingsCombustion chamberCombustor

The invention provides a condensation boiler, and belongs to the technical field of boilers. The condensation boiler comprises a combustion chamber, a smoke cooling chamber communicating with the combustion chamber, and a cooling pipe set fixed into the smoke cooling chamber. At least one smoke baffle plate for forming a continuous smoke channel with at least one level of turning structure throughdivision is fixed in the smoke cooling chamber, the combustion chamber is provided with a combustor connector communicating with a combustor, and the smoke cooling chamber is provided with a smoke outlet communicating with a smoke outlet pipeline. A communication port of the combustion chamber and the smoke cooling chamber is an inlet of the continuous smoke channel, a smoke outlet is an outlet of the continuous smoke channel, and the cooling pipe set communicates with a cooling water supply assembly of the boiler. According to the provided condensation boiler, effective cooling of smoke in the smoke cooling chamber is achieved, water steam in the smoke is cooled and condensed, low-temperature emission of smoke is guaranteed, the heat efficiency of the boiler is high, and additional heatexchanger arrangement is not needed. The structure is simple, and the equipment cost is low.

Owner:LANGFANG JINHUA BOILER

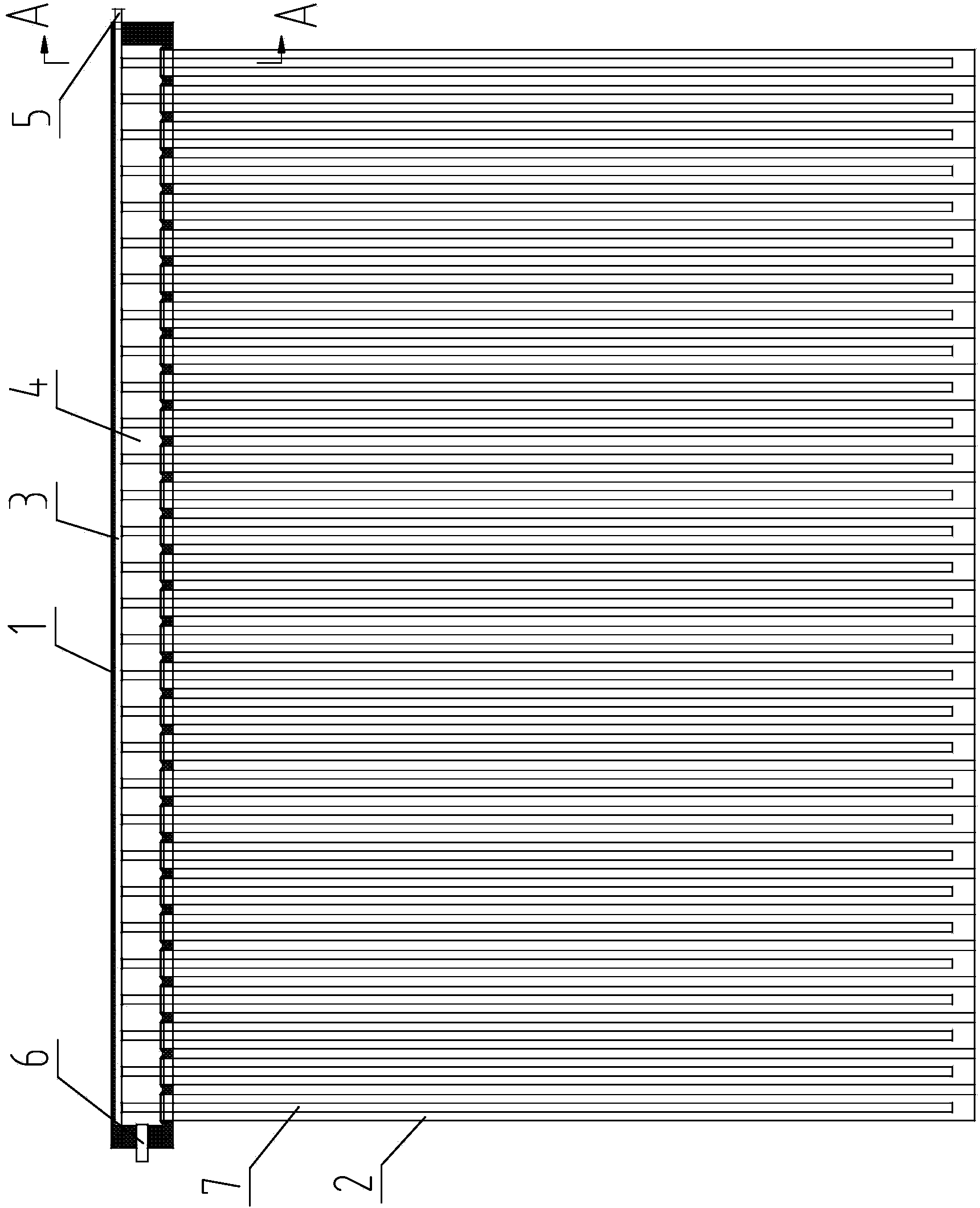

Solar air heating collector

InactiveCN104006550AIncrease flow lengthPrevent convective exchangeSolar heating energySolar heat devicesCold airEngineering

The invention discloses a solar air heating collector which comprises an air header and vacuum tubes perpendicular to the axis of the air header. Each vacuum tube is a blind tube with open end and the other closed end, cold air flowing channels and hot air flowing channels parallelly arranged and spaced are arranged in the air header, air inlet tubes communicated with the cold air flowing channels and air outlet tubes communicated with the hot air flowing channels are arranged on the air header, the open ends of the vacuum tubes are in sealed connection with the outer wall of the air header and then is communicated with the hot air flowing channels, a cold air guide tubes with two open ends are arranged in each vacuum tube, one end of each cold air guide tube is close to the closed end of the corresponding vacuum tube, the other end of each cold air guide tube is communicated with the corresponding cold air flowing channel. By arranging the cold air guide tubes in the common vacuum tubes and utilizing the vacuum tubes to absorb solar radiation energy and collect heat, hot air is discharged through exchange with cold air pressed by a fan, so that cold air can obtain much heat and accordingly can be heated, the solar energy heat is fully utilized, the heat collecting effect is improved, energy is saved, and the using cost is reduced.

Owner:CHANGZHOU SUNLIGHT SOLAR ENERGY

Method for producing non-foamed molded body

Owner:SHINSEI KAGAKU INDS

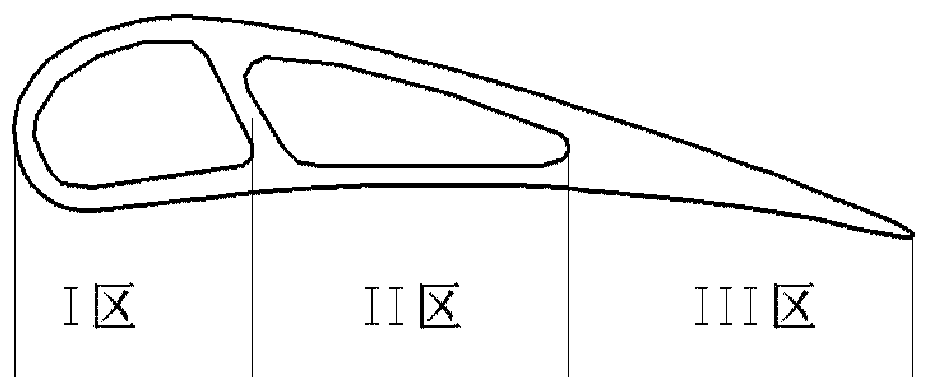

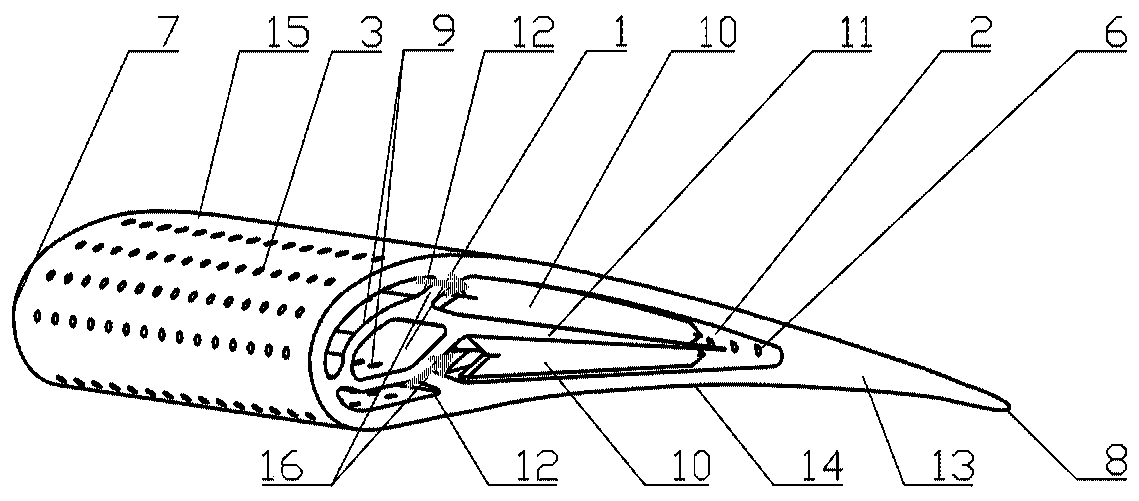

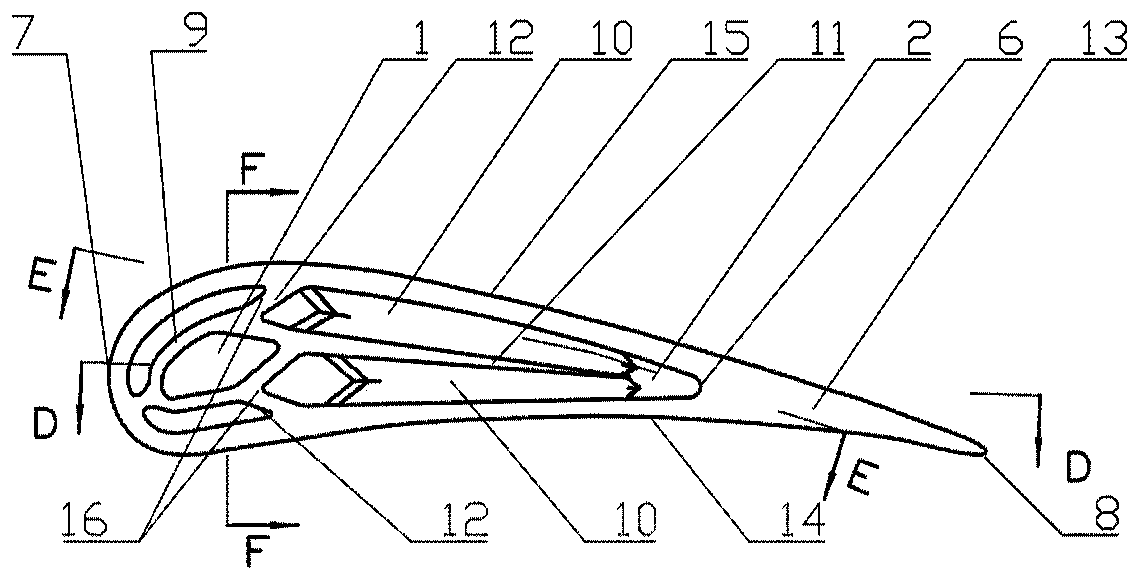

Turbine blade cooling structure adapted to integrated printing and molding and engine

PendingCN111425261AAdapt to printing processing methodsMeet actual internal cooling needsBlade accessoriesMachines/enginesSuction forceTurbine blade

The invention discloses a turbine blade cooling structure adapted to integrated printing and molding and an engine. The turbine blade cooling structure adapted to integrated printing and molding includes a leading edge, a trailing edge, a pressure surface and a suction surface of a turbine blade; the blade is defined to be a first cooling zone, a second cooling zone and a third cooling zone in sequence from the leading edge to the trailing edge; the first cooling zone includes air film holes and a closed impingement cooling plate; the air film holes are arranged on the front edge of the firstcooling zone; the impingement cooling plate is arranged inside the first cooling zone, and the impingement cooling plate is provided with impingement cooling holes; the second cooling zone includes two sets of inclined matrix ribs and matrix rib support plates; and the third cooling zone includes seam splitting grooves. The invention adopts a cooling structure combined with three cooling zones, which not only improves the cooling effect, but also meets the requirements of integrated printing and molding.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

High-temperature carburetor

InactiveCN107830755AImprove work efficiencySimple structureHeat exchanger casingsStationary tubular conduit assembliesCarburetorHigh intensity

The invention discloses a high-temperature carburetor. Pipe holes are vertically formed in a first pipe plate and a second pipe plate; a first channel shell ring and a second channel shell ring are fixedly mounted at the top and the bottom of a cylinder through flanges; a raw material side inlet is mounted at the top of the first channel shell ring; a raw material side outlet is mounted at the bottom of the second channel shell ring; a product side inlet and a product side outlet are mounted on the left side wall of the cylinder in sequence from top to bottom; an emptying port and a removing port are respectively formed in the top and the bottom of the right side wall of the cylinder; a heat exchange pipe is arranged in the cylinder; a pull rod is vertically arranged on the lower end surface of the right side of the first pipe plate; and a baffle plate is transversely welded on the inner wall of the cylinder. The high-temperature carburetor is simple in structure, excellent in overalltightness, high in working efficiency, high in strength, suitable for work in various environments, high in applicability and suitable for large-scale popularization.

Owner:浙江明一化工机械有限公司

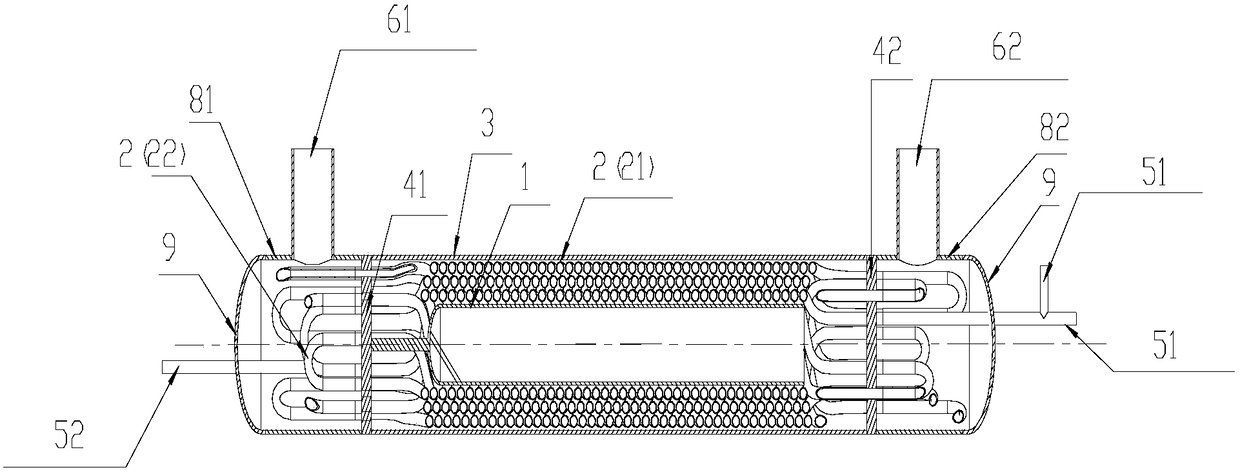

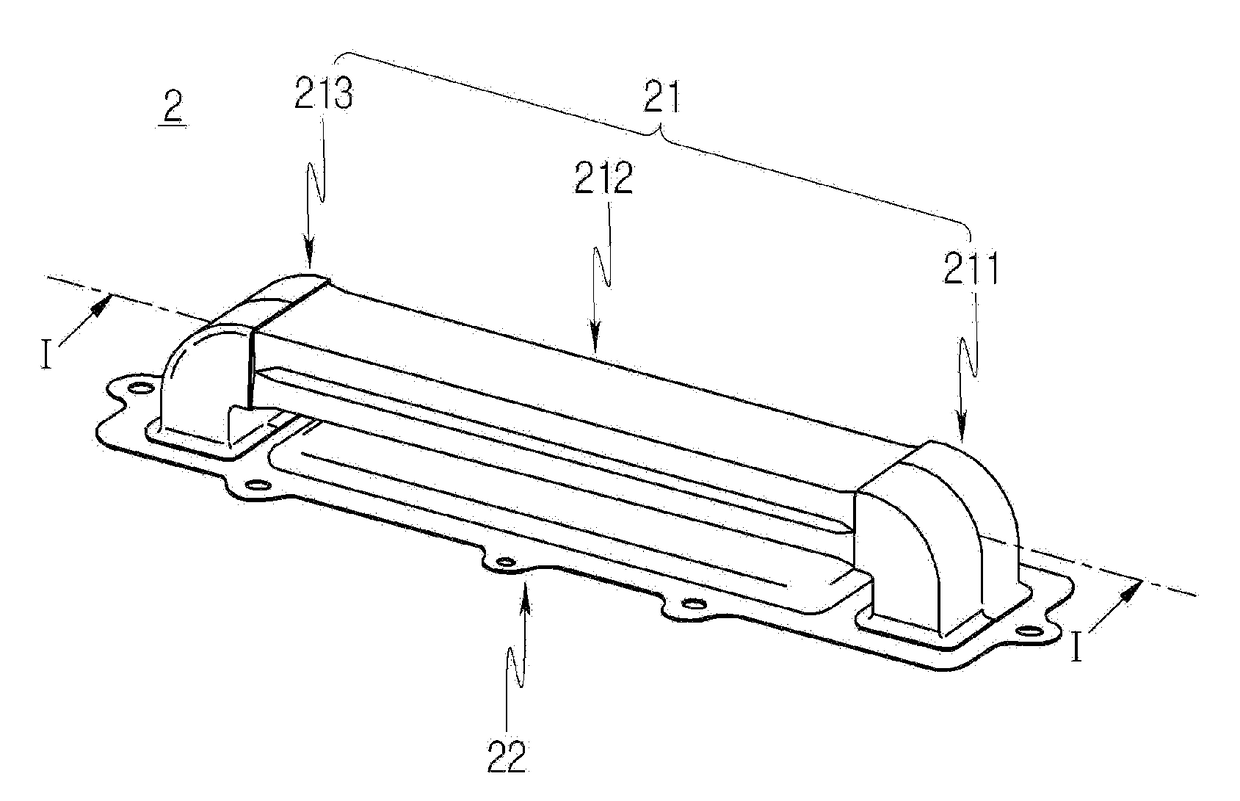

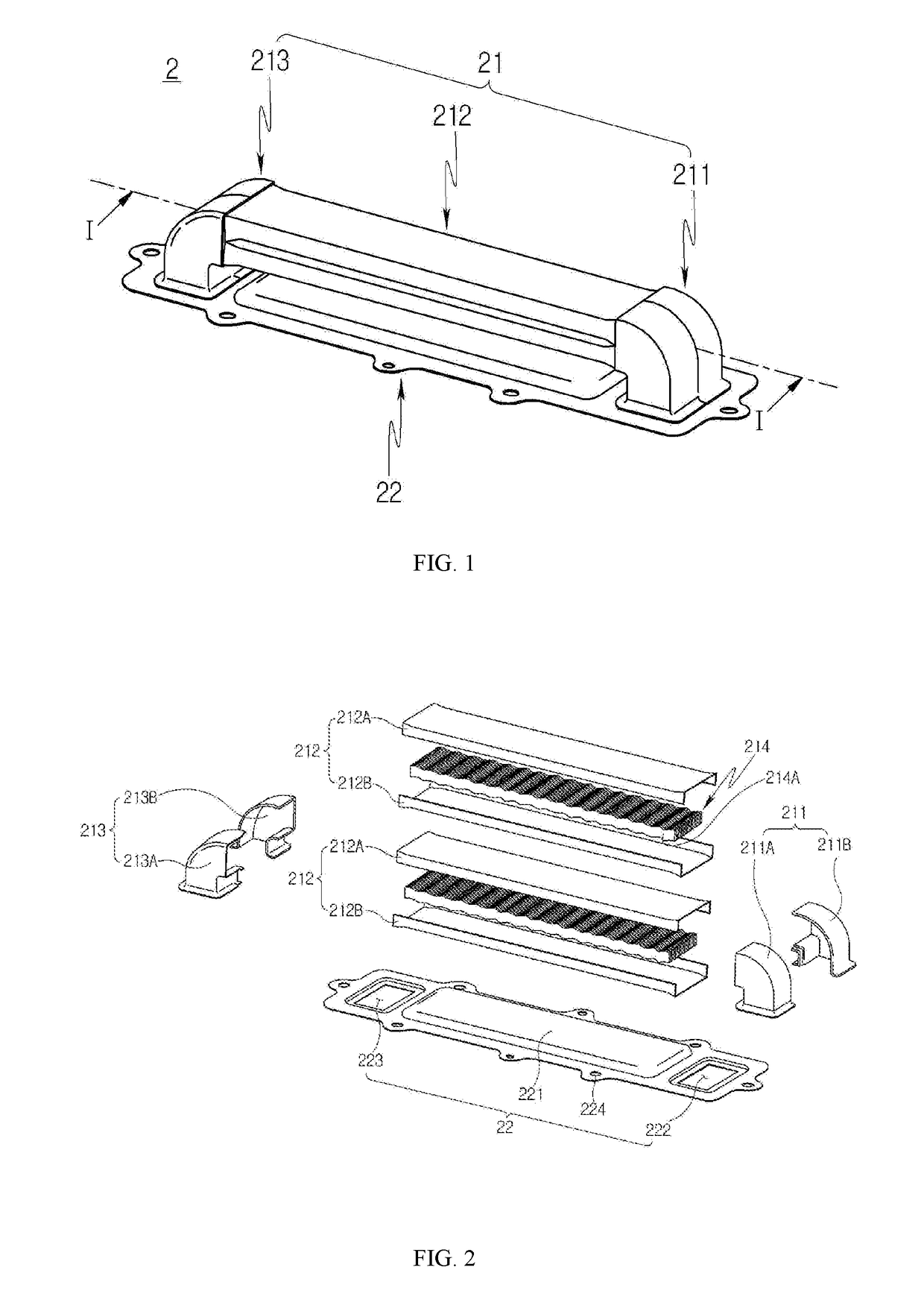

Exhaust gas cooler

ActiveUS20180238276A1Increase flow lengthLower overall pressure dropRecuperative heat exchangersExhaust gas recirculationHeat sinkExhaust gas

Disclosed herein is an exhaust gas cooler. The exhaust gas cooler may include a heat exchange pipe received in cooling water of an engine, and through which exhaust gas of the engine passes to exchange heat with the cooling water, and a plate configured to mount the heat exchange pipe to the engine. The heat exchange pipe may include a first pipe unit communicating with an inlet hole for exhaust gas and changing a flow direction of exhaust gas drawn from the inlet hole, a second pipe unit communicating with the first pipe unit, and a third pipe unit communicating with an exhaust gas return hole and the second pipe and changing a flow direction of exhaust gas to guide the exhaust gas to the return hole. A heat dissipation fin may be provided in an internal passage of the second pipe unit.

Owner:HANON SYST

Reactor

InactiveUS7572417B2Improve rigidityIncrease flow lengthExhaust apparatusRegenerative fuel cellsEngineeringMechanical engineering

Owner:CASIO COMPUTER CO LTD

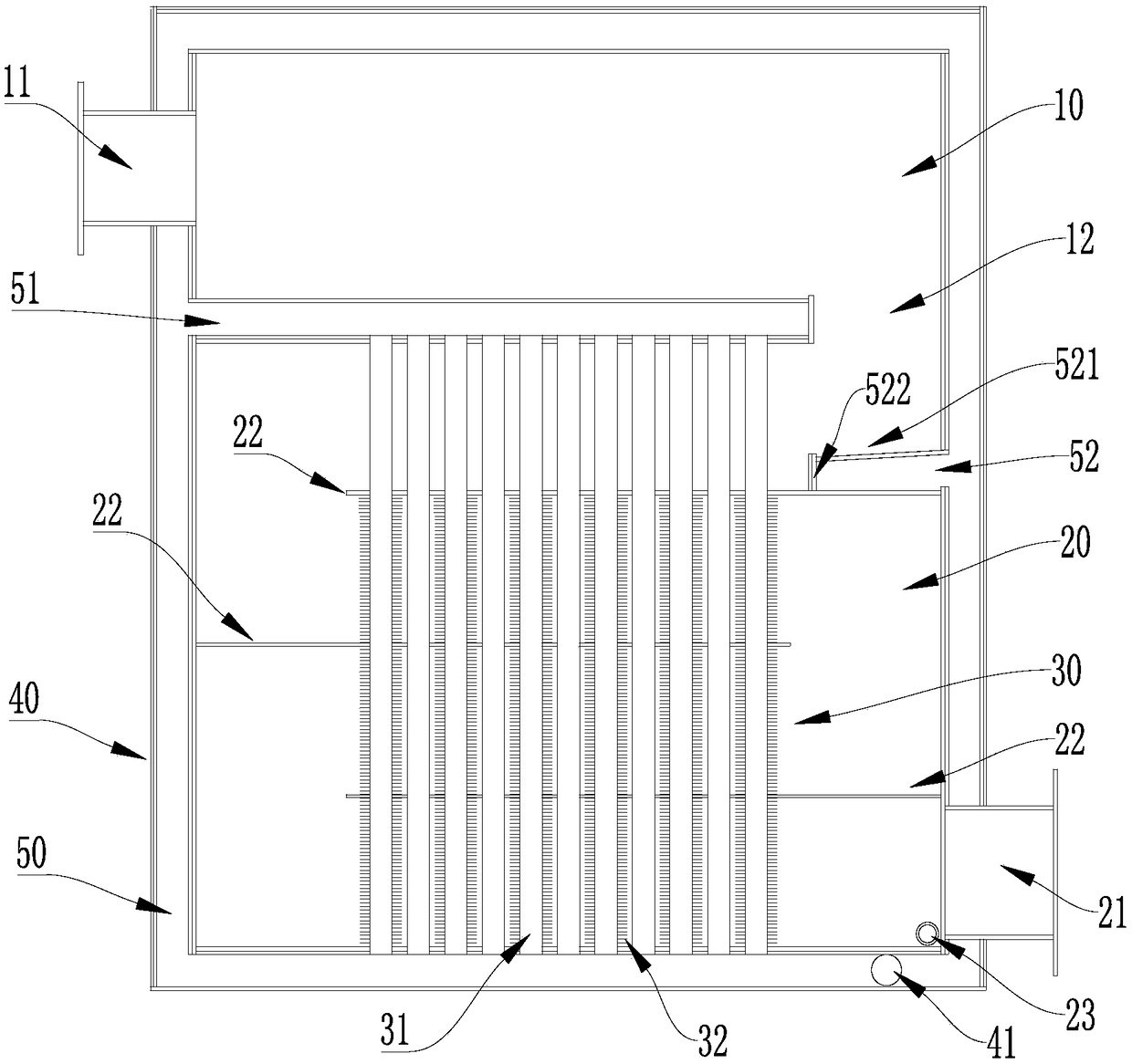

Sedimentation tank for paint spraying wastewater treatment

ActiveCN105060563ATo achieve the purpose of primary treatment of wastewaterIncrease flow lengthMultistage water/sewage treatmentTreatment pondPrecipitation

The invention discloses a sedimentation tank for paint spraying wastewater treatment. The sedimentation tank comprises a first stage treatment tank, a second stage treatment tank and a third stage treatment tank, wherein the first stage treatment tank is used for receiving paint spraying wastewater flowing from an external paint spraying process; wastewater discharged from the third stage treatment tank flows to an external follow-up wastewater treatment process; the first stage treatment tank, the second stage treatment tank and the third stage treatment tank are sequentially arranged in the wastewater treatment direction; a water inlet passage and a water outlet passage are arranged on the side wall of each treatment tank; the bottoms of the water inlet passages of the treatment tanks are higher than those of the water outlet passages of the treatment tanks; the water inlet passage of the latter stage treatment tank is positioned below the water outlet passage of the former stage treatment tank to form a step; the cross section area of the water inlet passage of the latter stage treatment tank is larger than the cross section area of the water outlet passage of the former stage treatment tank; the water inlet passage of the latter stage treatment tank is used for collecting wastewater discharged from the water outlet passage of the former stage treatment tank. According to the sedimentation tank, solid-state waste residue blocks can be separated from paint spraying wastewater in lower cost, the purpose of primary wastewater treatment is achieved, the equipment is simple, and the popularization and the application are facilitated.

Owner:FUJIAN YINGHAO CULTURAL & CREATIVE CO LTD

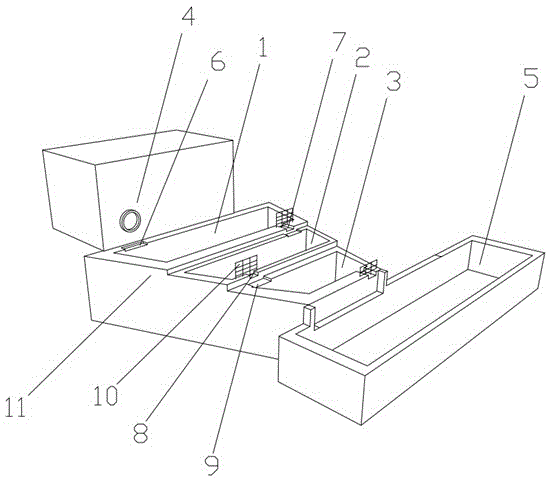

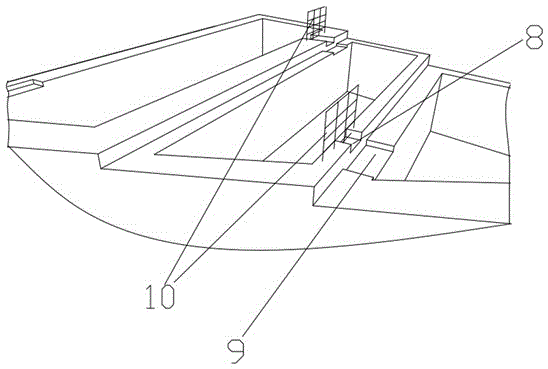

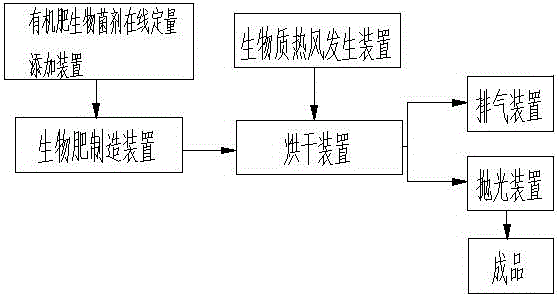

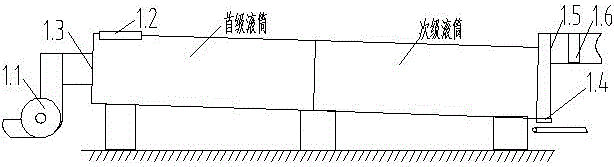

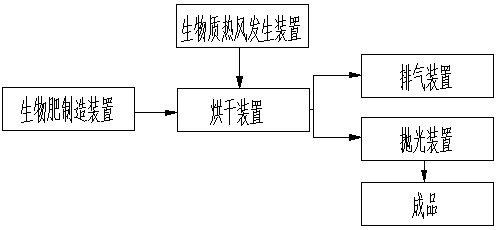

Novel organic bio-fertilizer production system

InactiveCN106083239ASmooth feedingAdd evenlyBio-organic fraction processingManure dryingPulp and paper industryBiomass

The invention discloses a novel organic bio-fertilizer production system. The novel organic bio-fertilizer production system comprises an organic fertilizer bio-inoculant online quantitative addition device, a bio-fertilizer preparation device, a biomass energy hot air generation device, a drying device, an exhaust device and a polishing device. The organic fertilizer bio-inoculant online quantitative addition device is connected with the bio-fertilizer preparation device through a conveying belt, the bio-fertilizer preparation device and the biomass energy hot air generation device are connected with a feeding port and an air inlet of the drying device respectively, and the tail end of the drying device is connected with the polishing device and the exhaust device. The novel organic bio-fertilizer production system aims at achieving the technical purposes of continuously producing organic bio-fertilizer, quantitatively adding bio-inoculant online and achieving higher environmental friendliness, energy saving performance and efficiency; according to the novel organic bio-fertilizer production system, biomass energy is utilized for producing bio-fertilizer, so that the production cost of an enterprise is lower, and higher environmental friendliness is achieved.

Owner:SICHUAN KAIERFENG AGRI TECH CO LTD

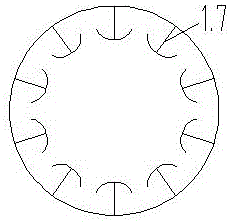

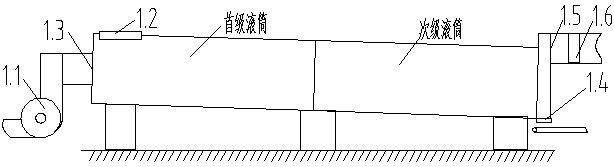

Organic biological fertilizer production system

InactiveCN107759265ASmooth circulationEasy to dryManure dryingDrying gas arrangementsCombustion chamberTechnical object

The invention discloses an organic biological fertilizer production system, which comprises a biological fertilizer production device, a biomass energy source hot air generation device, a drying device, an exhaust device and a polishing device, wherein the biological fertilizer production device and the biomass energy source hot air generation device are connected with a feed inlet and an air inlet of the drying device respectively; the tail end of the drying device is connected with the polishing device and the exhaust device; the biomass energy source hot air generation device comprises a biomass gas generation furnace, a filter and a combustion chamber which are sequentially connected; and a pipeline between the filter and the combustion chamber is connected with an air blower. The technical object of the invention is to provide the organic biological fertilizer production system which is more environment-friendly and energy-saving and higher in efficiency, and the organic biological fertilizer production system uses biomass energy sources to produce a biological fertilizer, so that the production cost of enterprises is lower and a better environmental protection effect is achieved.

Owner:SICHUAN KAIERFENG AGRI TECH CO LTD

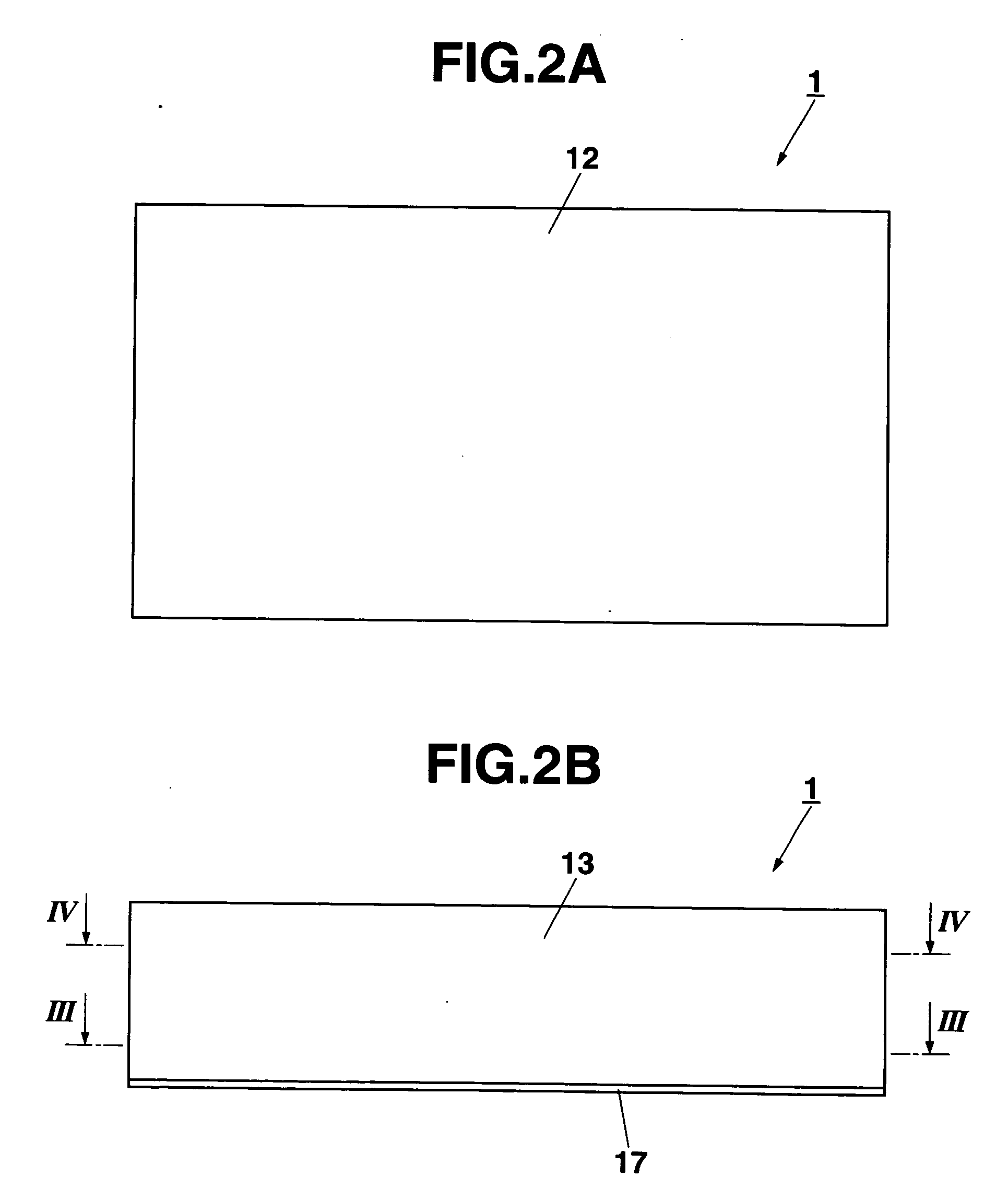

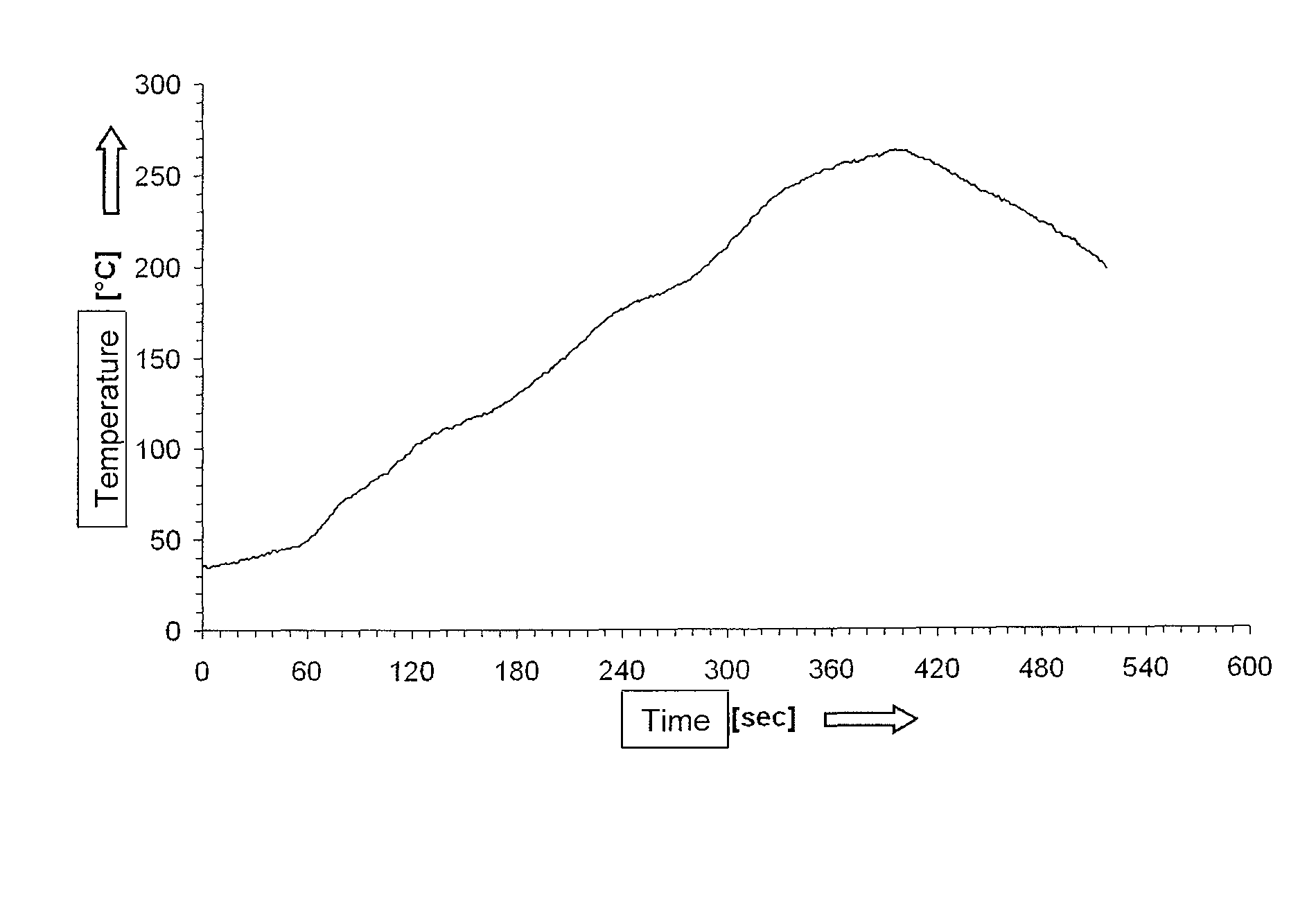

Method for producing non-foamed molded body and non-foamed molded body

Provided are a process for efficiently producing a non-foamed molded body by impregnating an amorphous thermoplastic resin with 0.3 to 3.0% by mass of carbon dioxide and / or 0.05 to 1.0% by mass of nitrogen and then supplying the amorphous thermoplastic resin thus obtained which is impregnated with carbon dioxide and / or nitrogen to an uppermost stream part of a cylinder in an injection molding machine and molding it and a non-foamed molded body produced thereby.

Owner:SHINSEI KAGAKU INDS

Groove-type solar heat collector adopting wind-driven rotating manner and provided with wave-shaped heat collection pipe

InactiveCN107062645AIncrease flow lengthExtended staySolar heating energyHeat transfer optimizationPipe supportWind force

The invention discloses a groove-type solar heat collector adopting a wind-driven rotating manner and provided with a wave-shaped heat collection pipe. The groove-type solar heat collector comprises a support frame, a groove-type lens and pipe support frames, wherein the groove-type lens is fixedly connected to the support frame, the pipe support frames are arranged on the support frame and at the two ends of the groove-type lens, the lower ends of the pipe support frames are fixedly connected with the support frame; and the upper ends of the pipe support frames are located above the groove-type lens. The groove-type solar heat collector is characterized by further comprising a heat collection pipe component and a rotation component, wherein the heat collection pipe component is arranged above the groove-type lens, and is installed on the pipe support frames in a penetrating manner and hinged; the two ends of the heat collection pipe component stretch out of the pipe support frames separately; and the rotation component is arranged at the outer sides of the pipe support frames, and is connected to the end head of the heat collection pipe component in a sleeving manner and fixedly connected. During use, a heat exchange working medium in the wave-shaped heat collection pipe of the heat collection pipe component flows along the wave-shaped heat collection pipe; and a wind wheel group used as the rotation component rotates to drive the heat collection pipe component to rotate and adjusts the windward side of a blade in real time under the effect of an environmental wind force, thereby stabilizing a rotation speed of the wave-shaped heat collection pipe.

Owner:NORTHEAST DIANLI UNIVERSITY

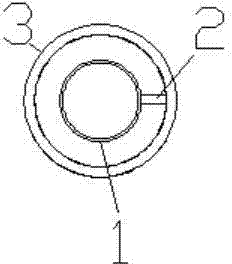

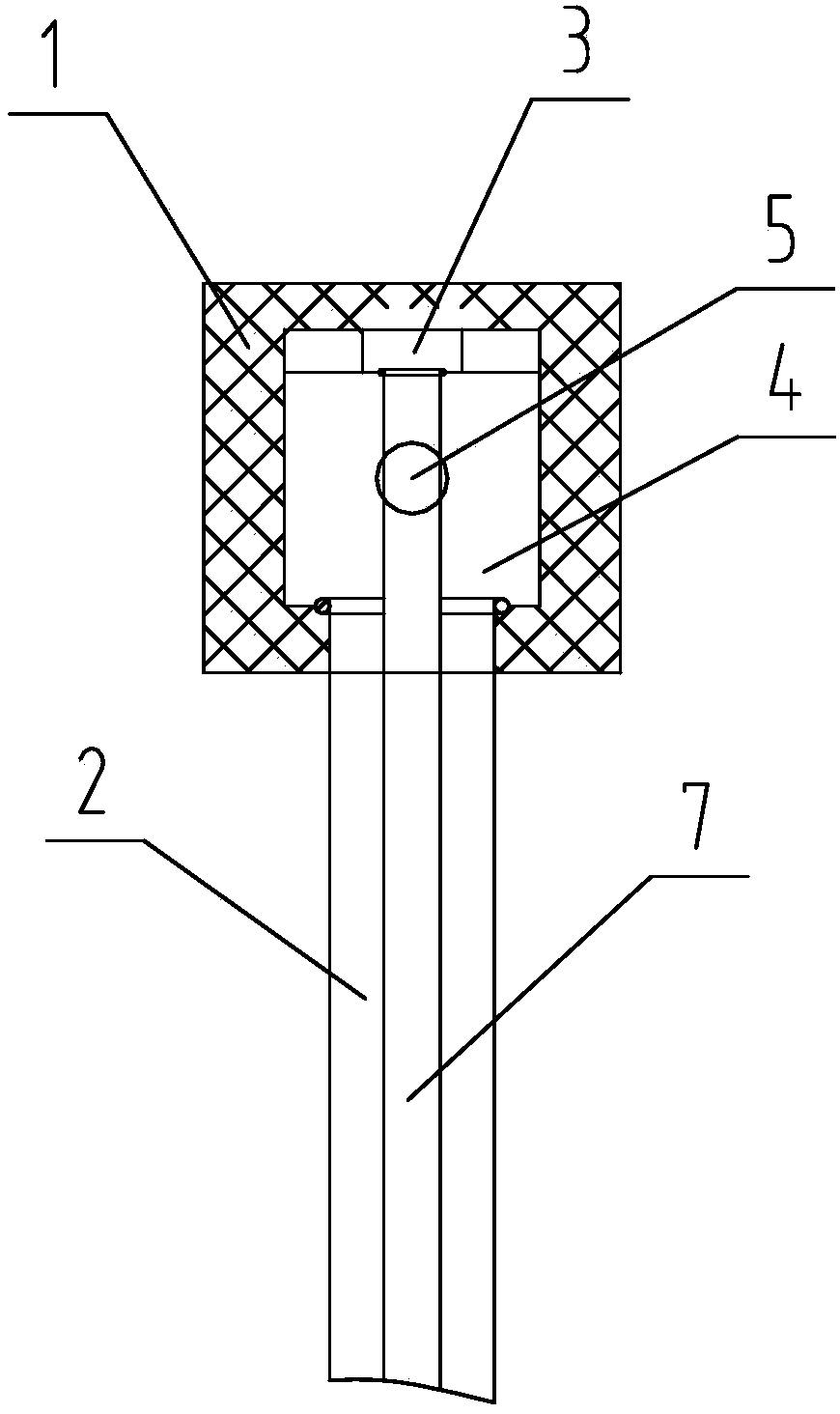

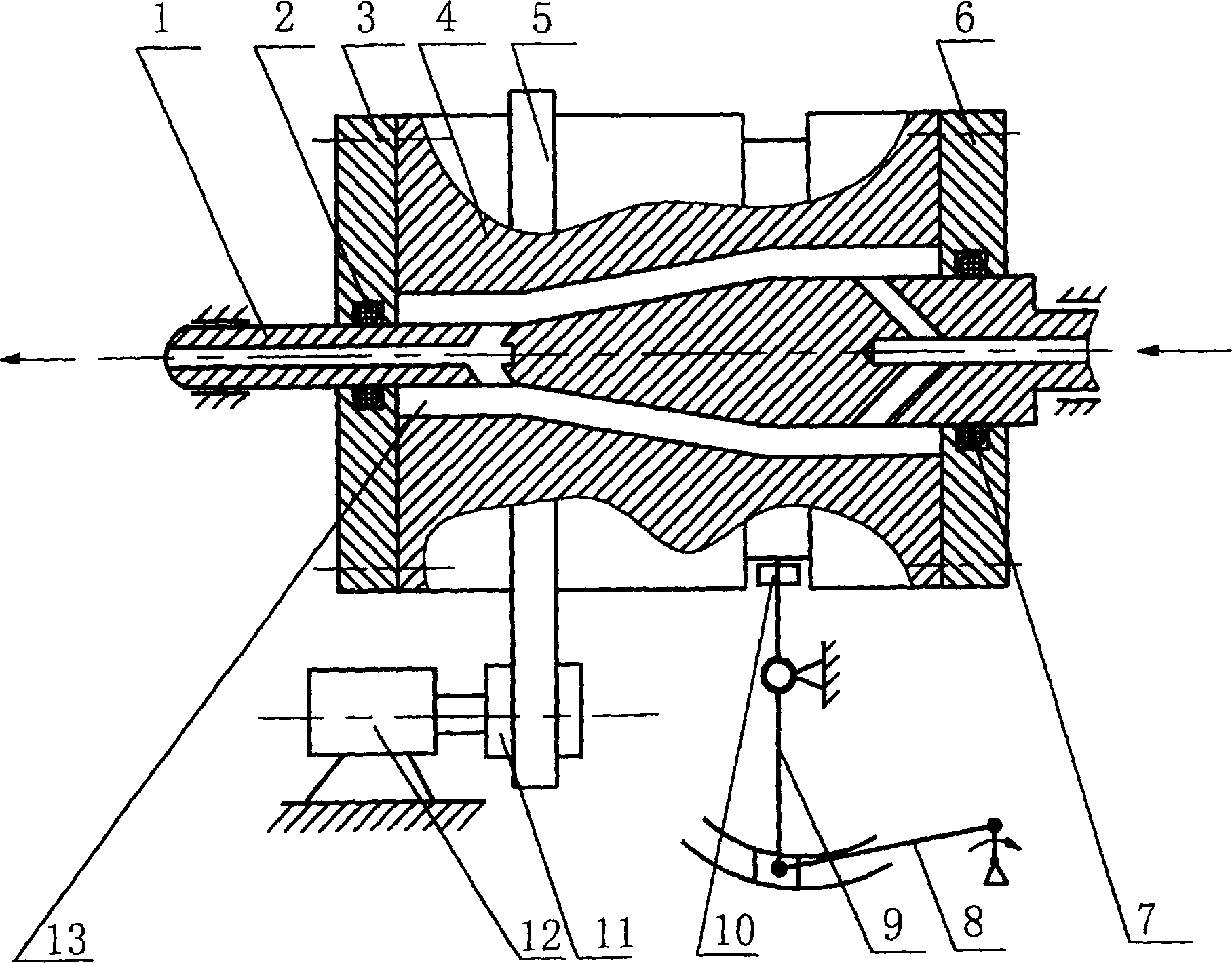

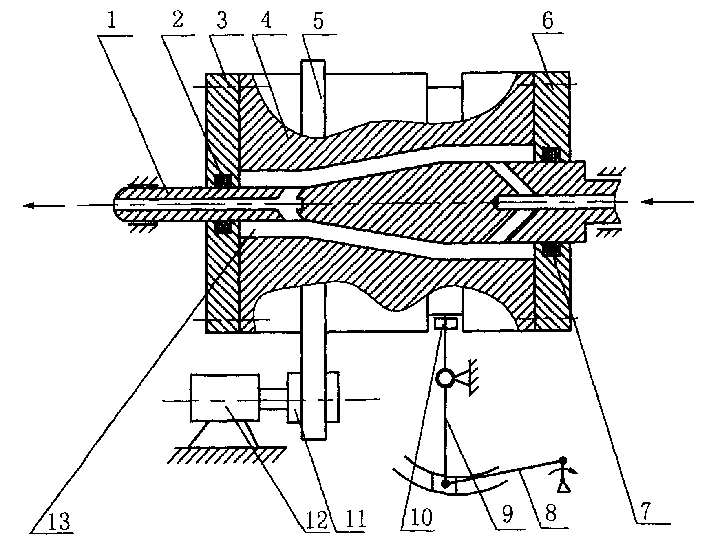

Auxiliary formation device of polymer product

InactiveCN1190306CAvoid Bad DefectsLow viscosityJigging conveyorsBiological activationBiomedical engineering

The present invention relates to an auxiliary forming device of polymer product, in particular. Its structure is as follows: said auxiliary forming device is formed from forming cavity, inlet and outlet, the described forming cavity comprises of a closed hollow cavity formed from valve body, jacket cover-mounted on the valve obdy and left end cover and right end cover of said jacket, and said value body has a melt channel communicated with the forming cavity, its outlet end is connected with die sprue bush and its inlet is connected with the outlet of extrusion activation injector, and the between of left end cover, right end cover and valve body is sealed with sealing ring, and the said jacket is respectively connected with rotating device and vibrating device.

Owner:JILIN UNIV

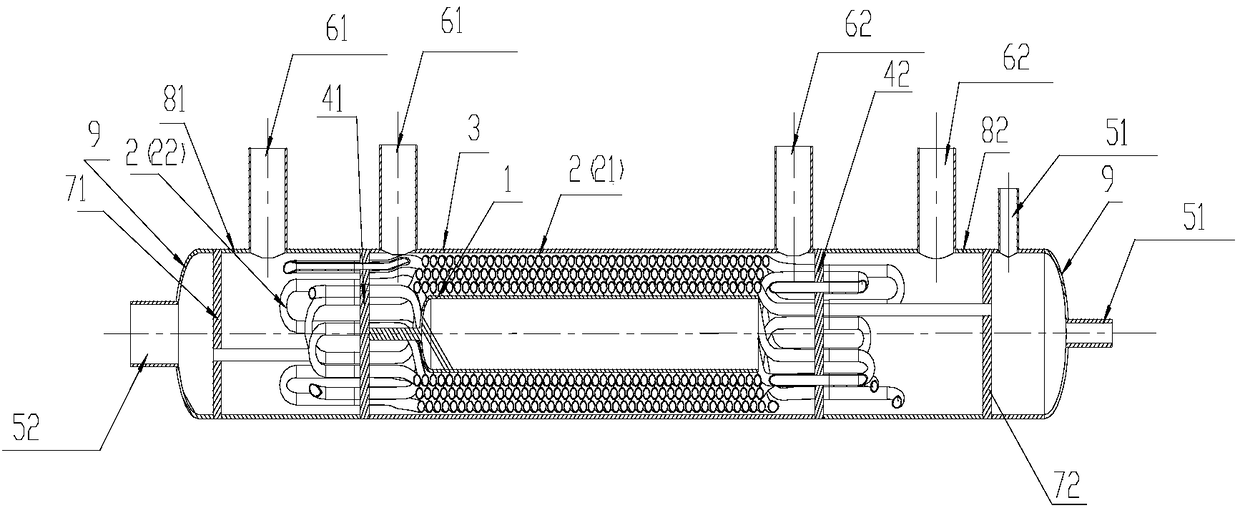

Heat exchanger

PendingCN110132041ASmooth ignitionSufficient heat exchangeIndirect heat exchangersCombustion technology mitigationCombustion chamberPlate heat exchanger

The invention relates to a heat exchanger comprising a combustion chamber, a high-temperature smoke delivery pipe, multiple jacketed pipes and a condensation smoke discharge pipe. The high-temperaturesmoke delivery pipe, the multiple jacketed pipes and the condensation smoke discharge pipe are arranged in the circumferential direction of the combustion chamber. The combustion chamber communicateswith the high-temperature smoke delivery pipe. The multiple jacketed pipes sequentially communicate. Each jacketed pipe comprises an inner pipe, an outer pipe arranged outside the inner pipe in a sleeving manner, and an end cover. The high-temperature smoke delivery pipe communicates with one jacketed pipe, and the condensation smoke discharge pipe communicates with another jacketed pipe. By means of the heat exchanger, the heat exchange efficiency can be improved, the ignition success rate can be ensured, the structure is reasonably distributed, the device space occupation rate is decreased,and the device economy is improved.

Owner:周清桂

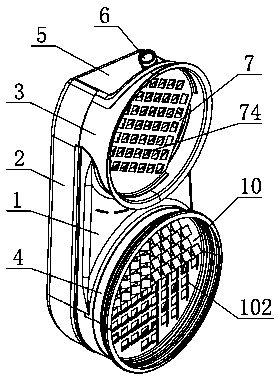

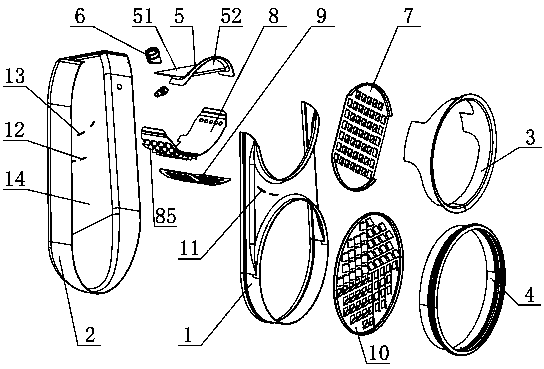

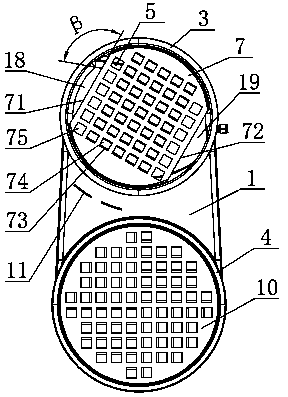

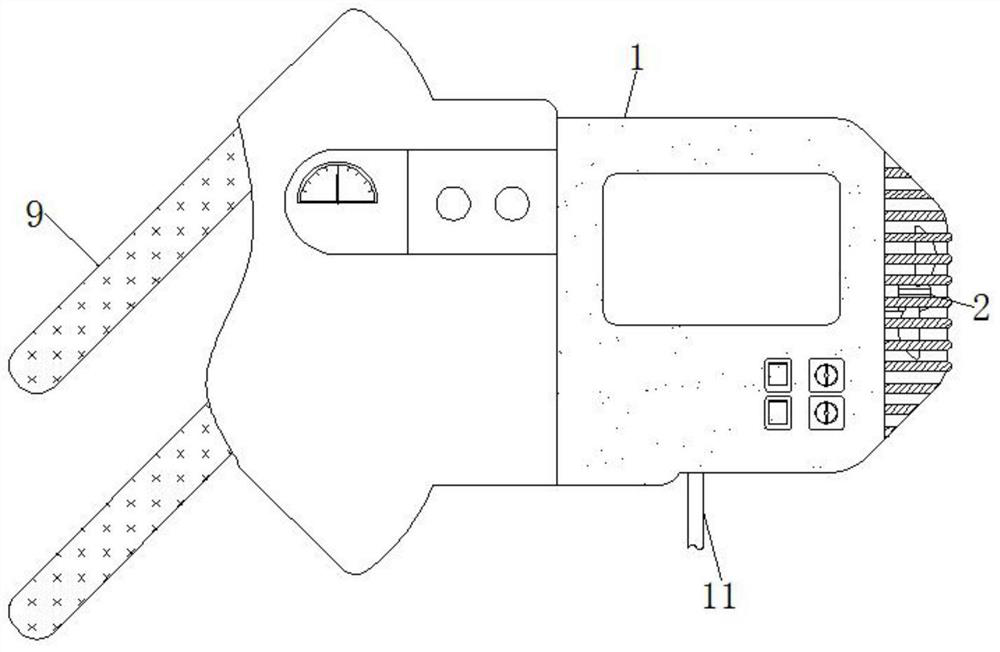

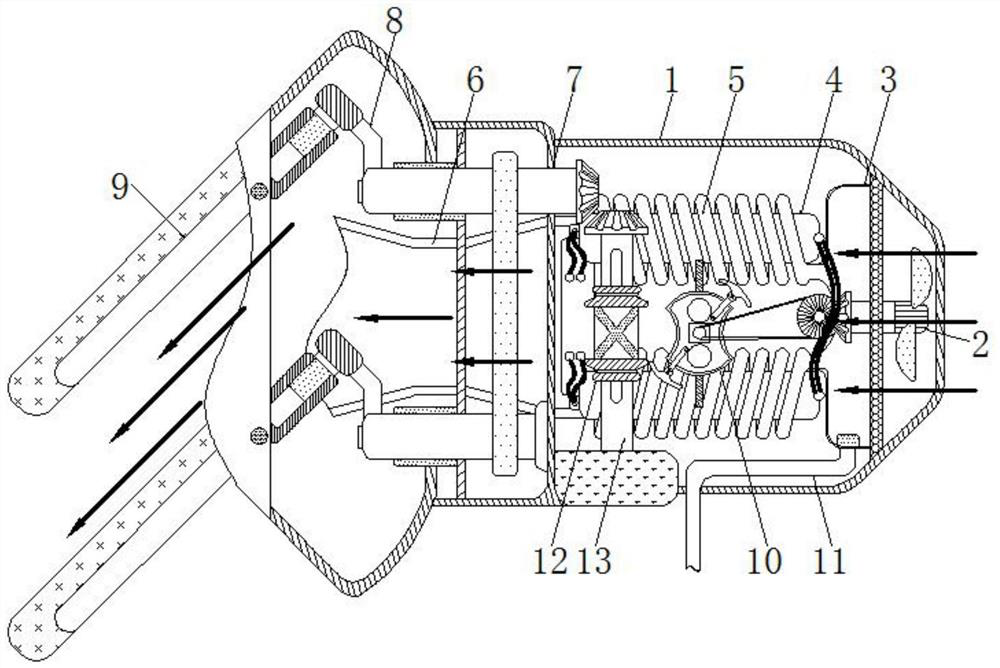

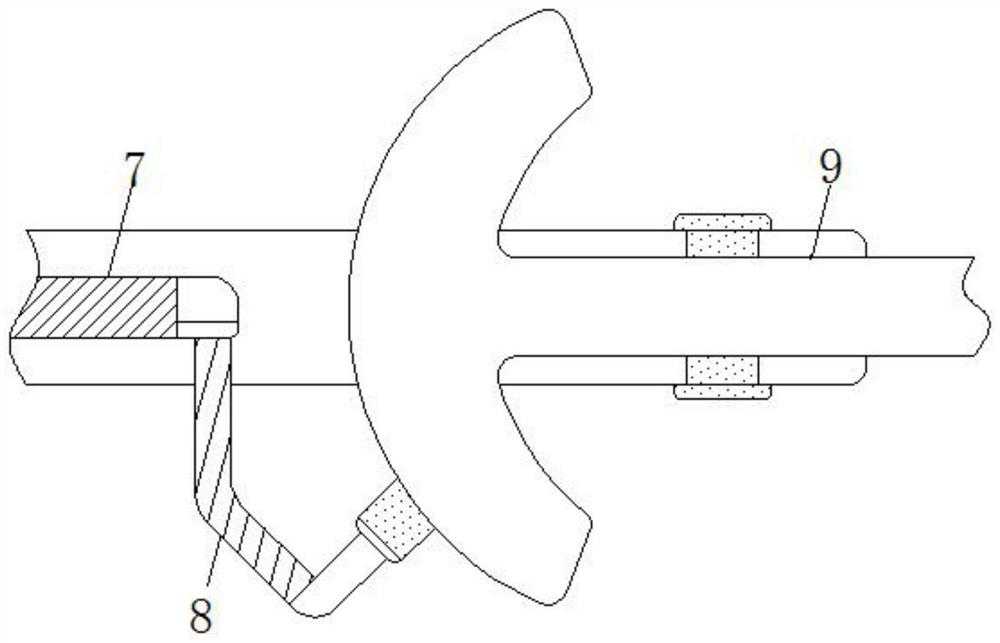

Intelligent air sterilizer for hospital operating room

InactiveCN112303802BIncrease flow lengthImprove disinfection and sterilization effectMechanical apparatusLighting and heating apparatusAir compressionOperating theatres

Owner:郭洪彬

Efficient industrial waste gas treatment method

PendingCN113058372AIncrease flow rateGuaranteed stable workGas treatmentDispersed particle separationCooling effectEnvironmental engineering

The invention relates to the technical field of environmental protection, and discloses an efficient industrial waste gas treatment method.The efficient industrial waste gas treatment method comprises a shell, a gas inlet head is fixedly installed on one side of the shell, a gas outlet head is fixedly installed on the other side of the shell, the inner wall of the shell is movably sleeved with a first titanium cylinder, and a third titanium cylinder is fixedly installed in the middle of the shell; a second titanium cylinder is movably installed in the position, between the first titanium cylinder and the third titanium cylinder, in the shell, and lamp tubes are annularly, evenly and movably installed in the positions, between the adjacent titanium cylinders, in the shell. The shell is designed to be cylindrical, and the cylindrical titanium cylinders and lamp tubes are arranged in the shell uniformly in a movable manner, a metal net containing TiO2 sol is replaced by the metal cylinders, a net-shaped structure is not adopted, and the titanium cylinders in the shell are designed into structures with different lengths, so that the cooling effect on the lamp tubes is improved, the wind resistance of gas circulation is reduced, and the purification efficiency is improved.

Owner:龚才荣

High-efficiency superheater

The invention relates to a high-efficiency superheater which is arranged in a superheating flue and comprises a first-stage heating flue and a second-stage heating flue sleeving outside the first-stage heating flue, wherein the first-stage heating flue comprises a flue gas channel A; heat exchange fins A are arranged in the flue gas channel A; an annular heating chamber A is formed in the outer wall of the flue gas channel A; the second-stage heating channel comprises an annular heating chamber B; an annular flue gas channel B is arranged between the inner wall of the annular heating chamber B and the outer wall of the annular heating chamber A; the annular heating chamber B and the annular heating chamber A are communicated through a plurality of connecting pipes; a conical groove is formed in one side, toward the superheating flue, of the superheater; the axis of the conical groove is coaxial with the flue gas channel A; the bottom surface edge of the conical groove is positioned in the outer wall surface of the annular heating chamber B. A dividing wall type heat exchanger with an annular structure replaces an original dividing wall type heat exchanger with an array pipeline structure, so the flowing resistance of high-temperature flue gas flowing in the superheater is reduced.

Owner:临沂恩科开发建设有限公司

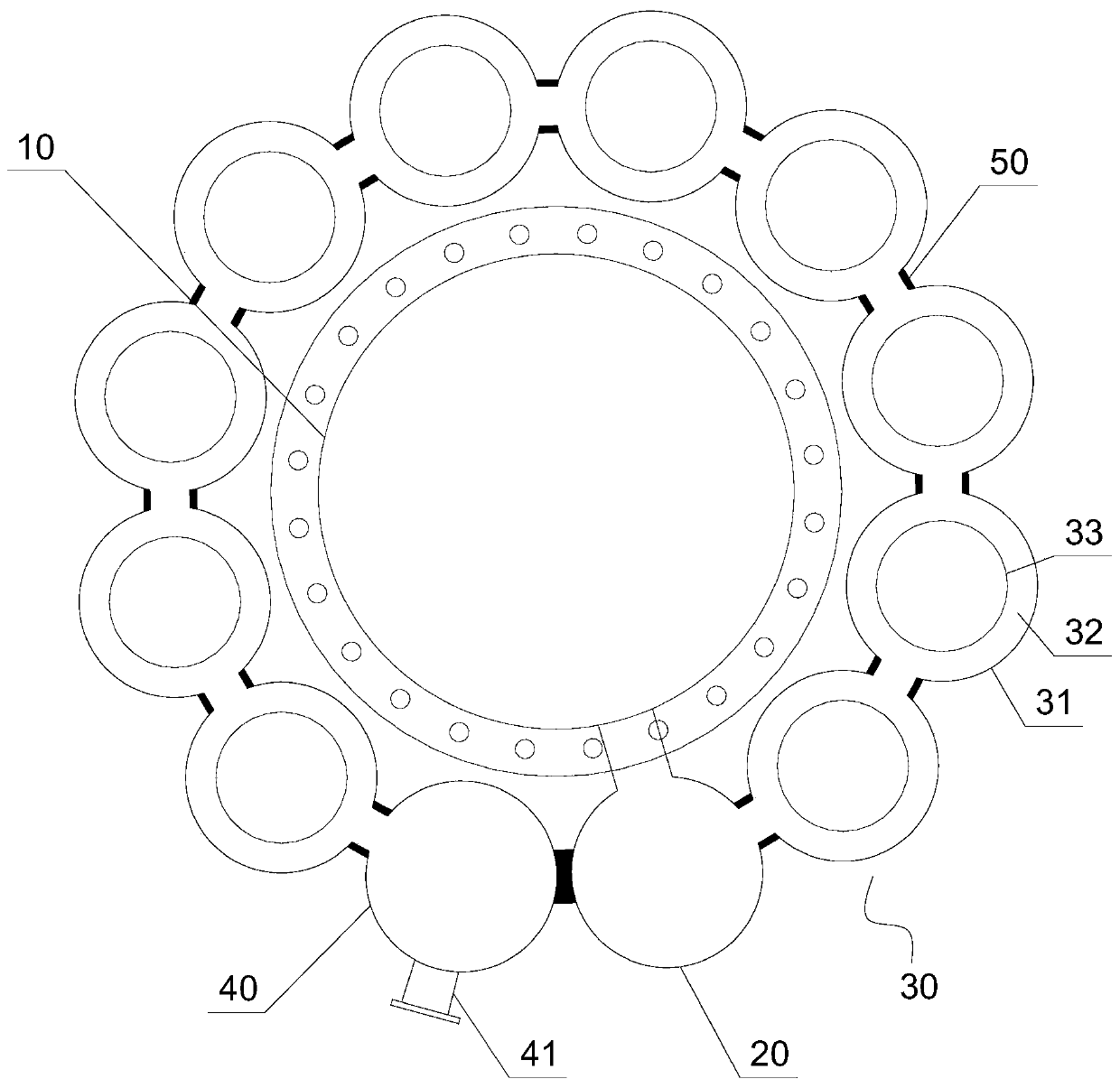

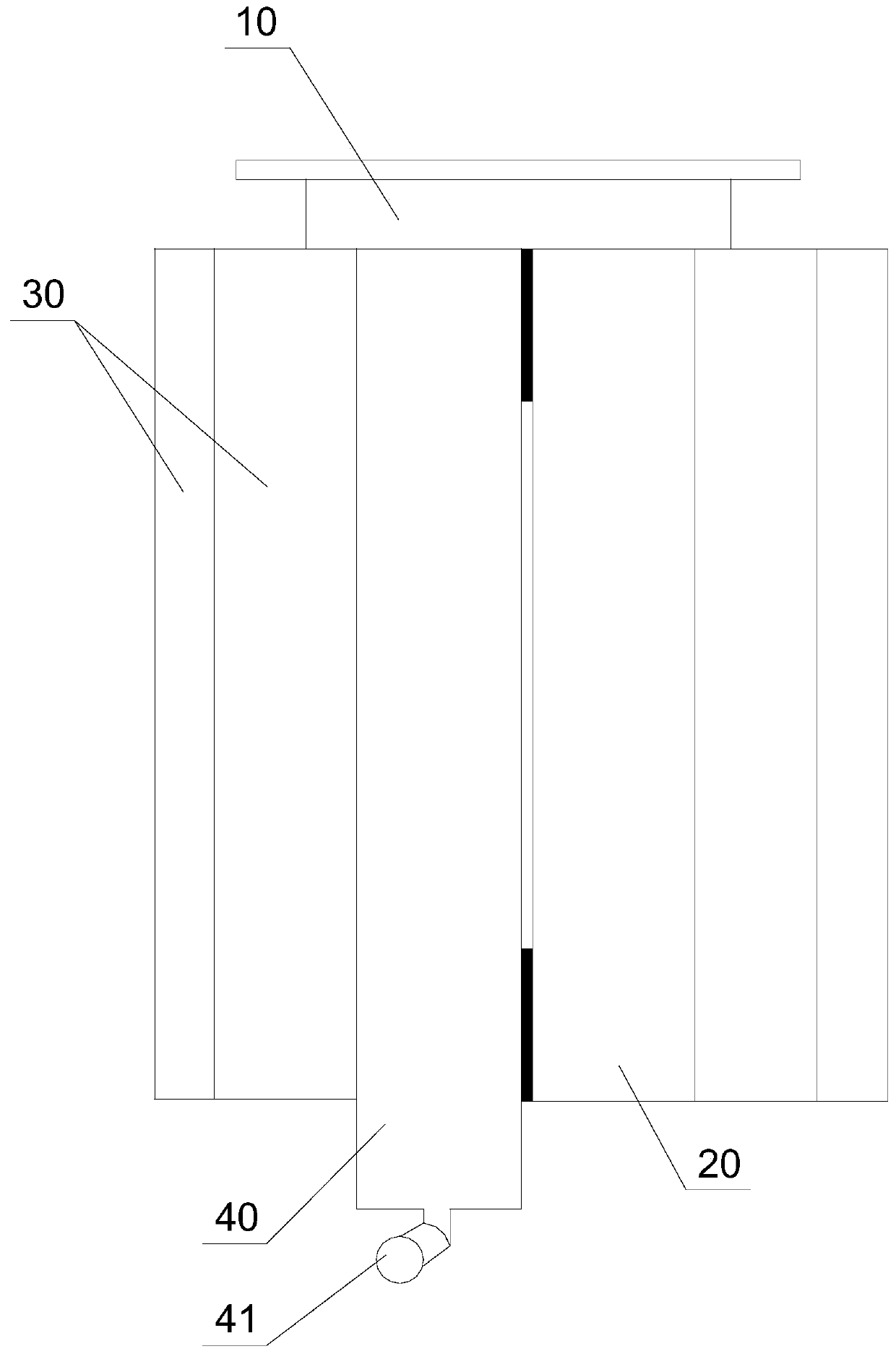

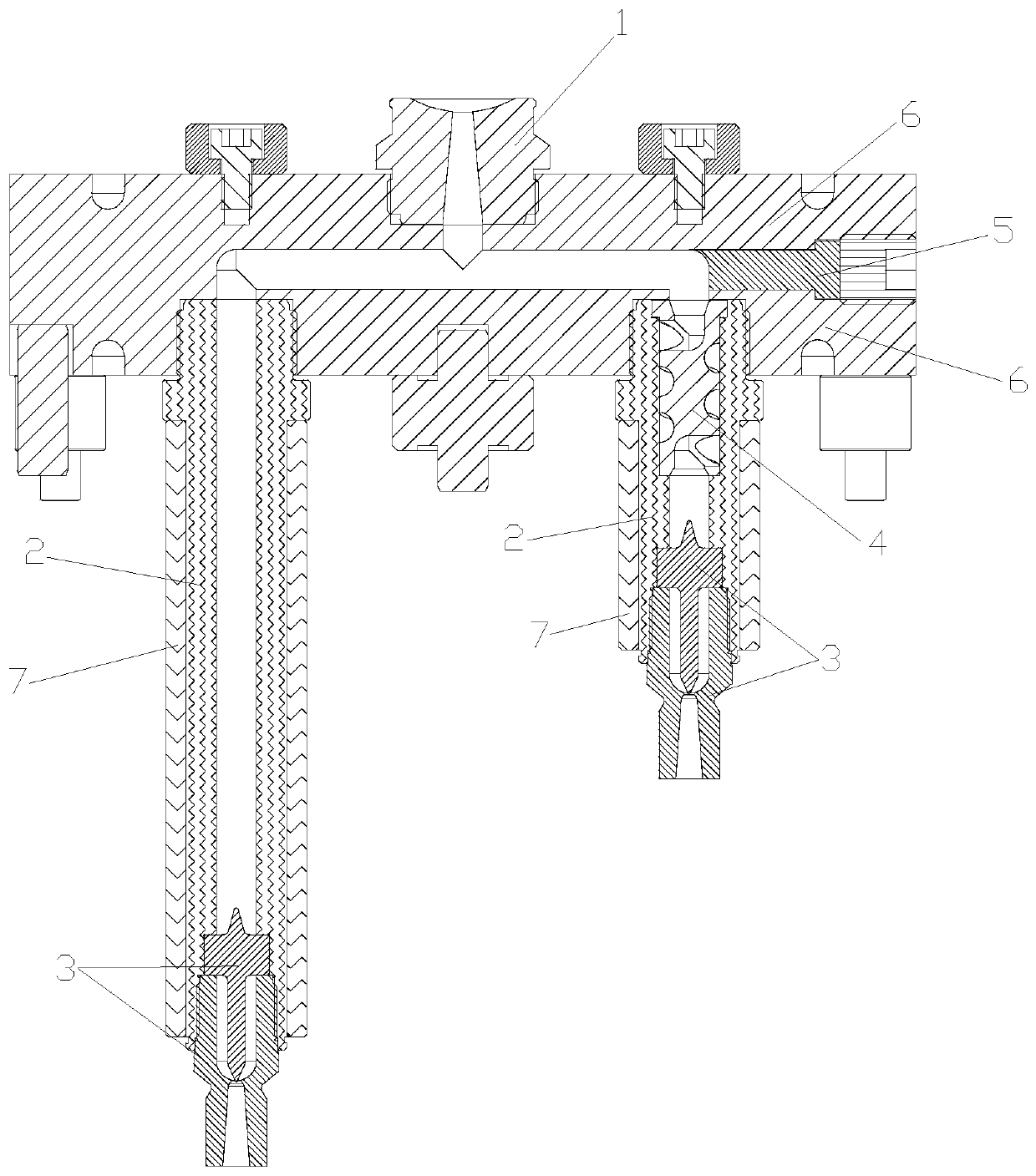

Hot runner flow and flow length adjusting insert and hot runner system

The invention discloses a hot runner flow and flow length adjusting insert and a hot runner system. The hot runner flow and flow length adjusting insert comprise a columnar base body. Material holes are correspondingly formed in the two ends of the base body. A spiral slideway is arranged on the outer side wall of the base body. The slideway is communicated with the material holes. After the insert is mounted in a runner cylinder with the relatively short length, due to the fact that the spiral slideway is arranged on the base body, the straight-line-shaped flow path in an original runner cylinder is changed into a spiral curve flow path, the flow length of a plastic raw material in the short runner cylinder is increased, the flow length difference of the two plastic raw materials in a long runner cylinder and the short runner cylinder is shortened, the discharging is more uniform, the gap between the hot runner point and the point is shortened, and the closer balance is achieved.

Owner:绍兴市思德龙热流道有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com