Composite solid filter rod and preparation method thereof

A composite filter rod and filter rod technology, applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problems of reducing the amount of tar and not increasing the travel of mainstream smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A composite solid filter rod, which is composed of medical grade PLA as a raw material and auxiliary materials, namely plasticizer triacetin,

[0029] a. Material selection: Screen medical-grade material pla with transparent or translucent color and melting point ≥100°C;

[0030] b. Quantitative feeding, mix according to the ratio of pla and auxiliary materials 1:0.5, weigh the mixed materials with a total weight ≥ 10kg and place them in the feeding device of the injection molding machine;

[0031] c. Weigh the mixed material in step b and use the feeding device to send it to the heating device of the injection molding machine;

[0032] d. The model airway aperture is 1mm;

[0033] e. Heat treatment at a temperature of 100-300°C for 0.5-1 hour;

[0034] f. Perform pressure injection molding of the melted fluid obtained in step d at a mold pressure of 20 MPa;

[0035] g. After the mold cools for 90 seconds, open the mold and pick up the parts;

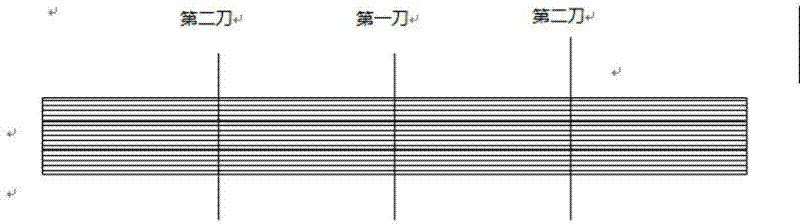

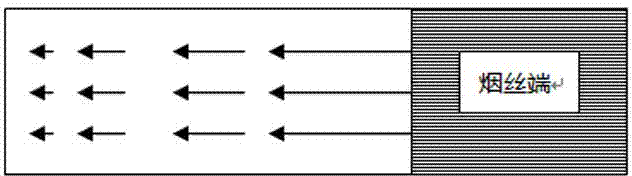

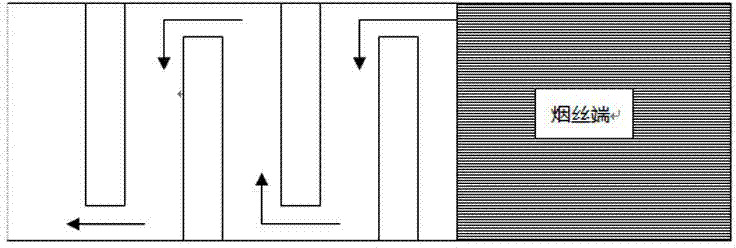

[0036] h. Divide the ...

Embodiment 2

[0039] A composite solid filter rod, which is composed of polycaprolactone as a raw material and glycerol triacetate as an auxiliary material,

[0040] a. Material selection: Screen polycaprolactone, a medical-grade material whose color is transparent or translucent, and whose melting point is ≥100°C;

[0041] b. Quantitative feeding, according to the ratio of polycaprolactone and plasticizer 1.5:0.2, weigh the total weight ≥ 10kg and place it in the feeding device of the injection molding machine;

[0042] c. Weigh the mixed material in step b and use the feeding device to send it to the heating device of the injection molding machine;

[0043] d. The model airway aperture is 1.5mm;

[0044] e. Heat treatment at a temperature of 100-300°C for 1 hour;

[0045] f, the melted fluid obtained in step e is subjected to pressure injection molding at a mold pressure of 25 MPa;

[0046] g. After the mold is cooled for 90 seconds, the mold is opened and the parts are taken;

[0047...

Embodiment 3

[0050] A composite solid filter rod, which is composed of medical grade pvc as a raw material and glycerol triacetate as an auxiliary material,

[0051] a. Material selection: Screen medical-grade materials whose color is transparent or translucent, and whose melting point is ≥100°C;

[0052] b. Quantitative feeding, according to the ratio of PVC and plasticizer 2:0.5, weigh the total weight ≥ 10kg and place it in the feeding device of the injection molding machine;

[0053] c. Weigh the mixed material in step b and use the feeding device to send it to the heating device of the injection molding machine;

[0054] d. The model airway aperture is 2.2mm;

[0055] e. Heat treatment at a temperature of 170°C for 0.5 hours;

[0056] f. Perform pressure injection molding of the melted fluid obtained in step d at a mold pressure of 20 MPa;

[0057] g. After the mold is cooled for 90 seconds, the mold is opened and the parts are taken;

[0058] h. Divide the cooled injection parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com