Groove-type solar heat collector adopting wind-driven rotating manner and provided with wave-shaped heat collection pipe

A trough-type solar energy and heat-collecting tube technology, which is applied to solar heat collectors, solar heat collectors using working fluids, and solar thermal energy, can solve the problem of reduced efficiency of trough-type solar heat collectors and uneven heating of heat-conducting working fluid , Heat collector tubes are unevenly heated, etc., to achieve the effect of simple structure, prolonging the residence time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

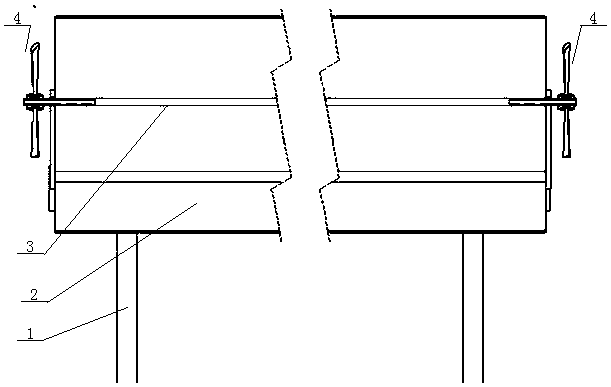

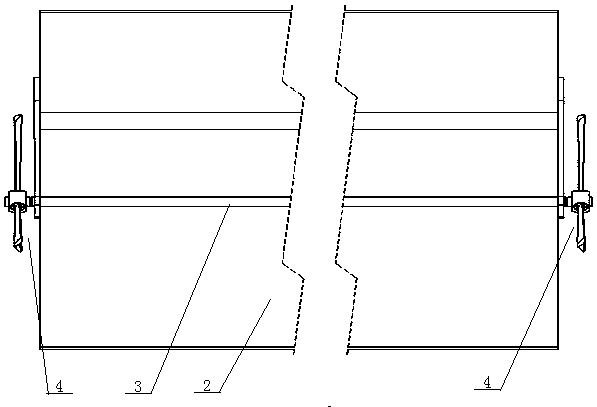

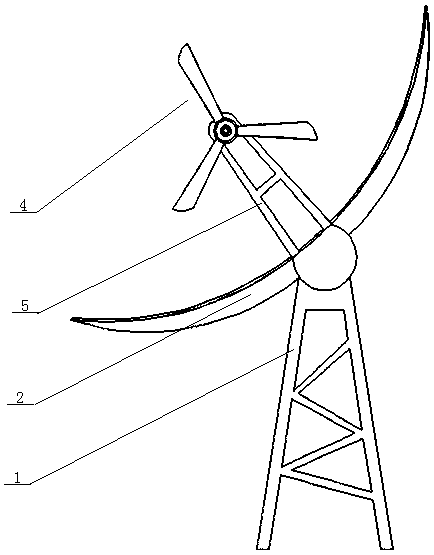

[0021] refer to Figure 1-Figure 8 , the present embodiment is a kind of wind-driven rotating corrugated heat collecting tube trough solar collector, which includes a support frame 1, a trough lens 2 and a tube support frame 5, and the trough lens 2 is fixedly connected to the top of the support frame 1, The tube support frame 5 is placed on the top of the support frame 1 and the two ends of the trough lens 2, the lower end of the tube support frame 5 is fixedly connected with the support frame 1, and the upper end is located above the trough lens 2, and also includes the heat collecting tube part 3 and the rotating part 4. The heat collecting tube part 3 is placed above the trough lens 2, mounted on the tube supporting frame 5 and hinged, the two ends of the heat collecting tube part 3 protrude out of the tube supporting frame 5 respectively, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com