Patents

Literature

55results about How to "Smooth ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

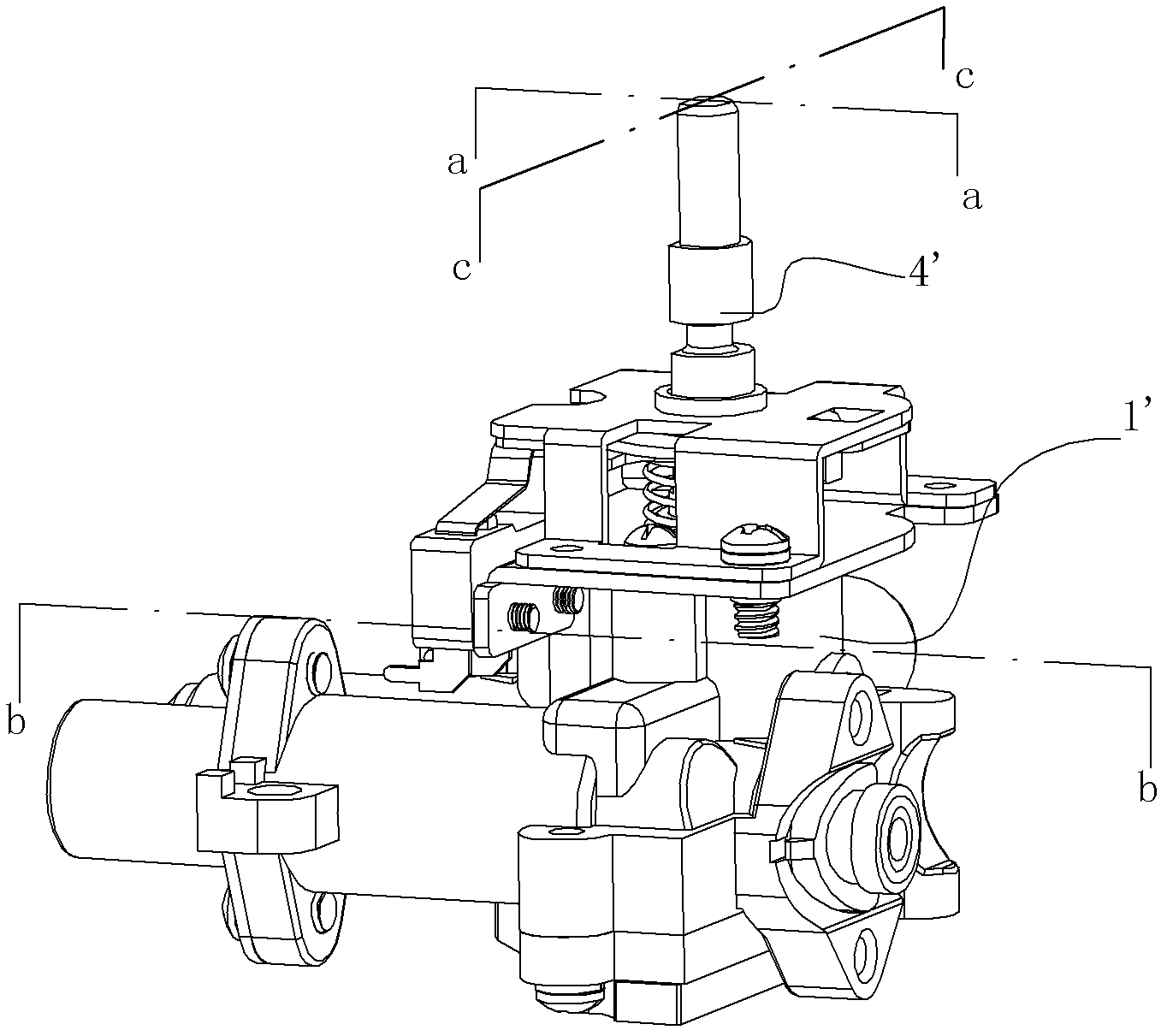

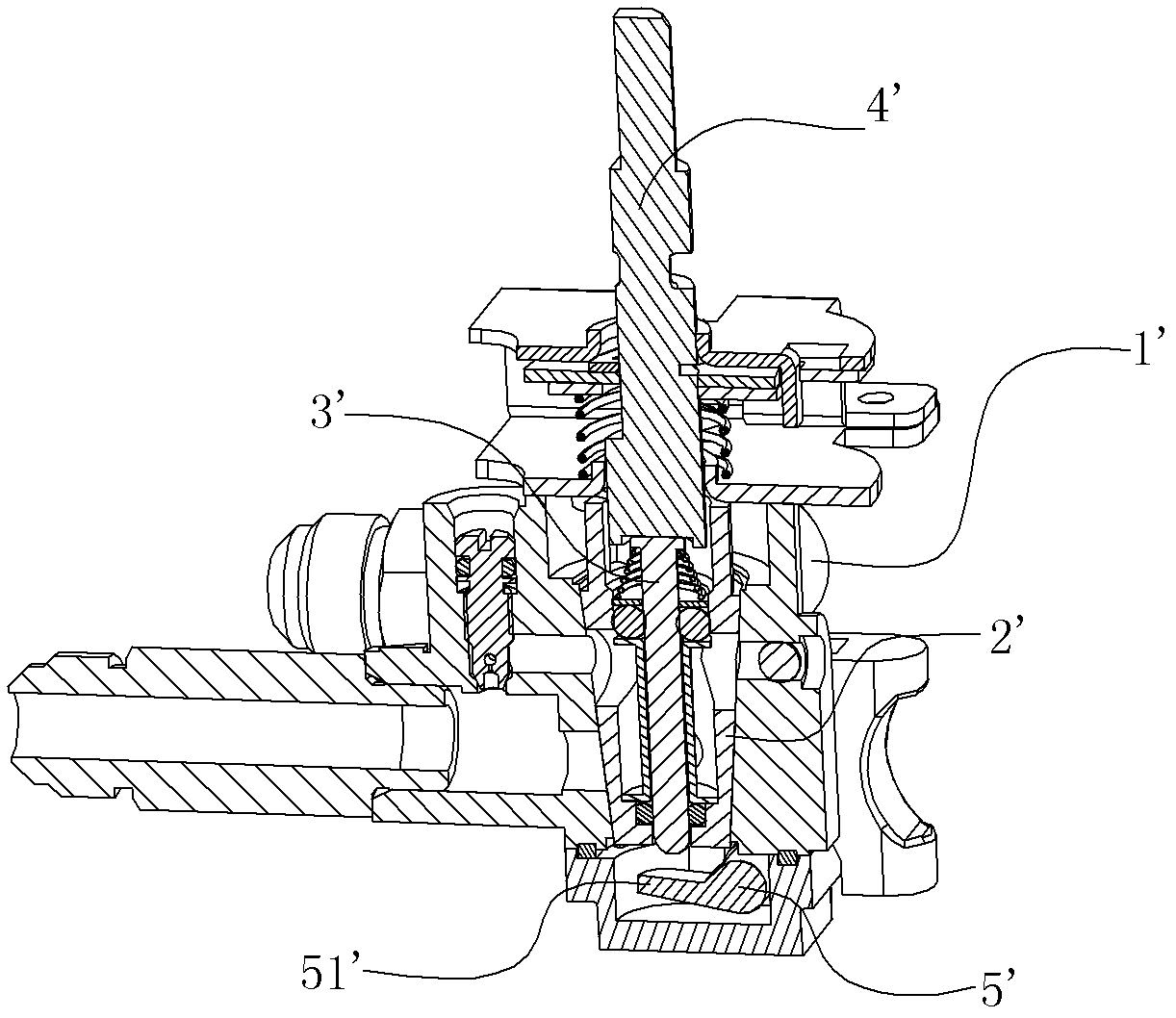

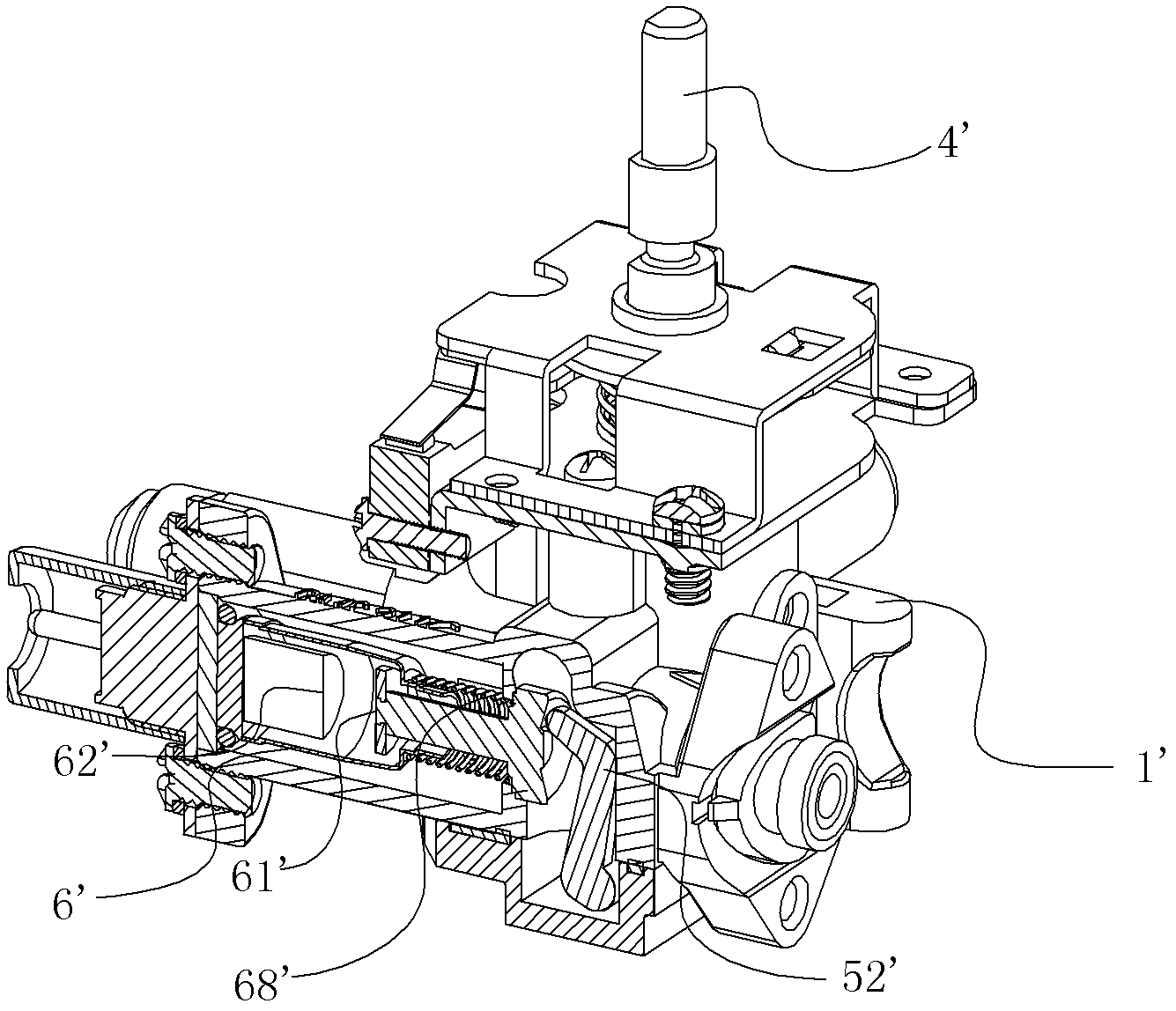

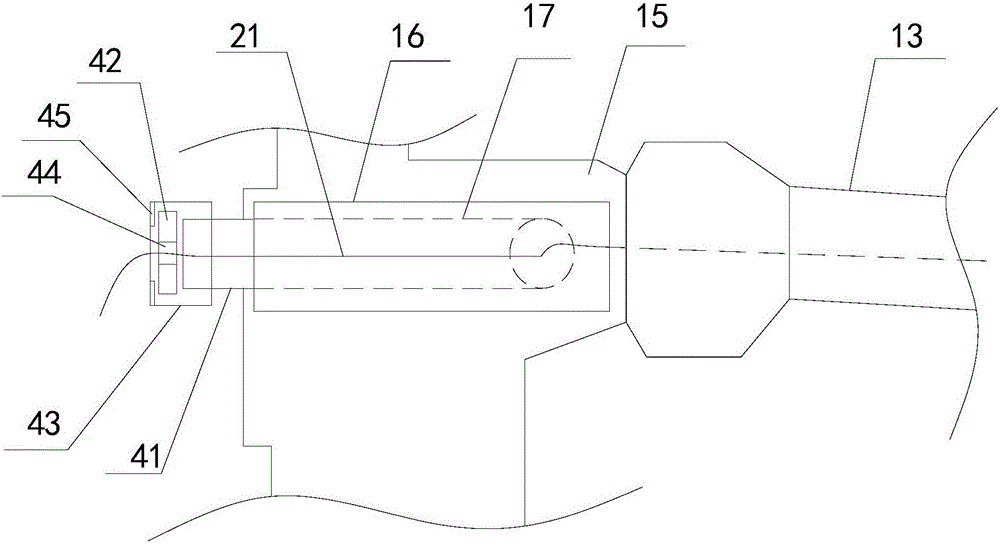

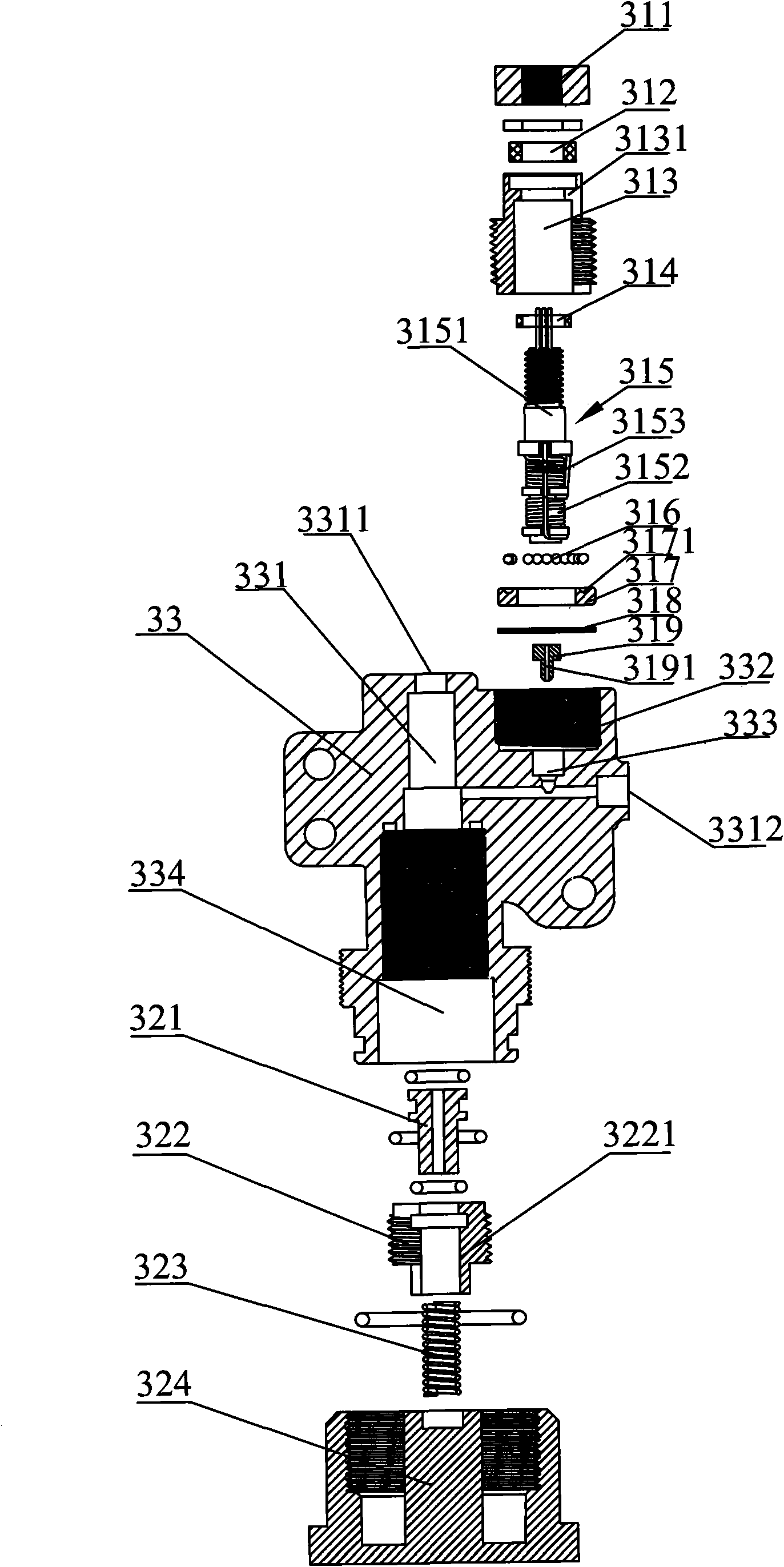

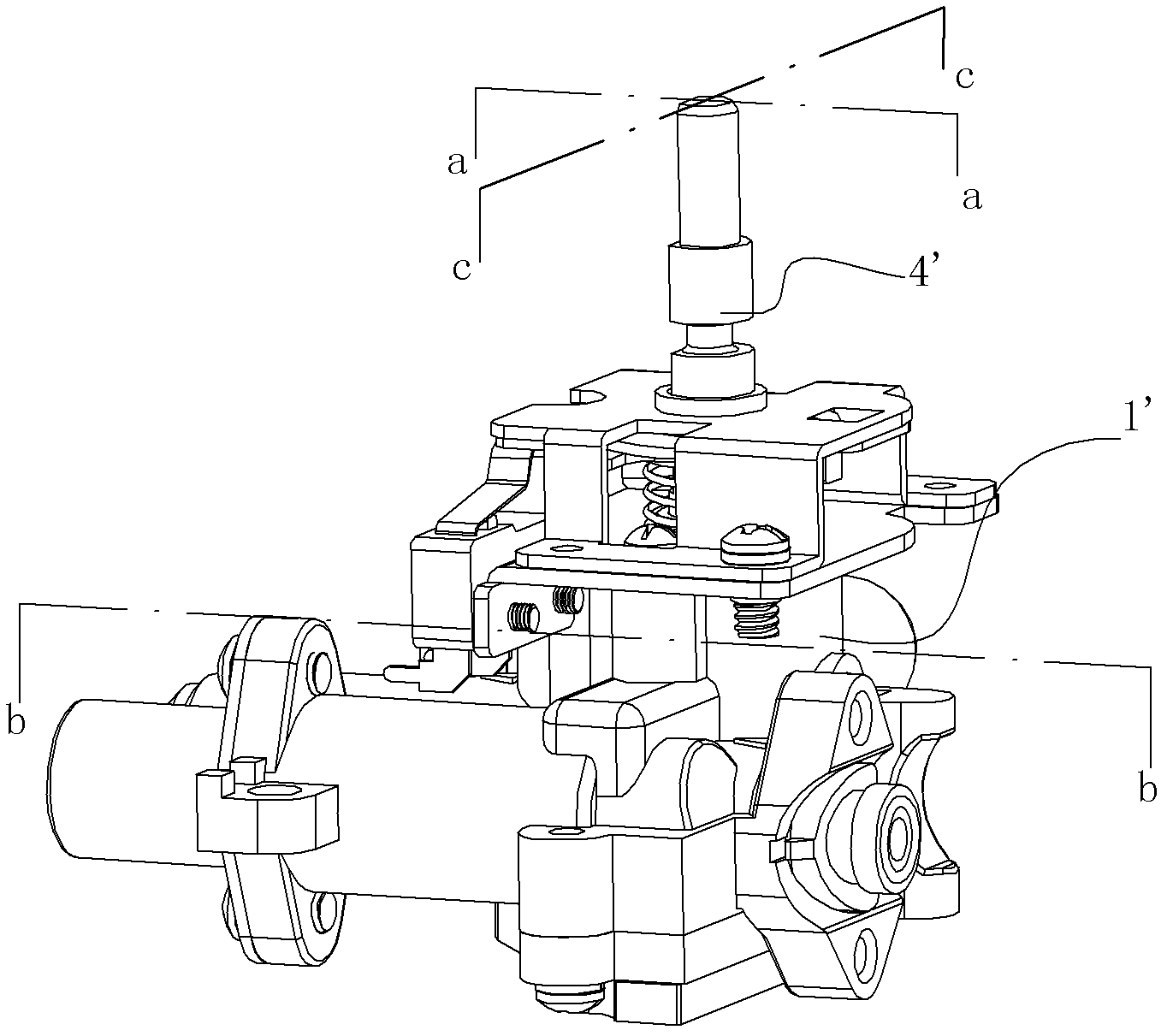

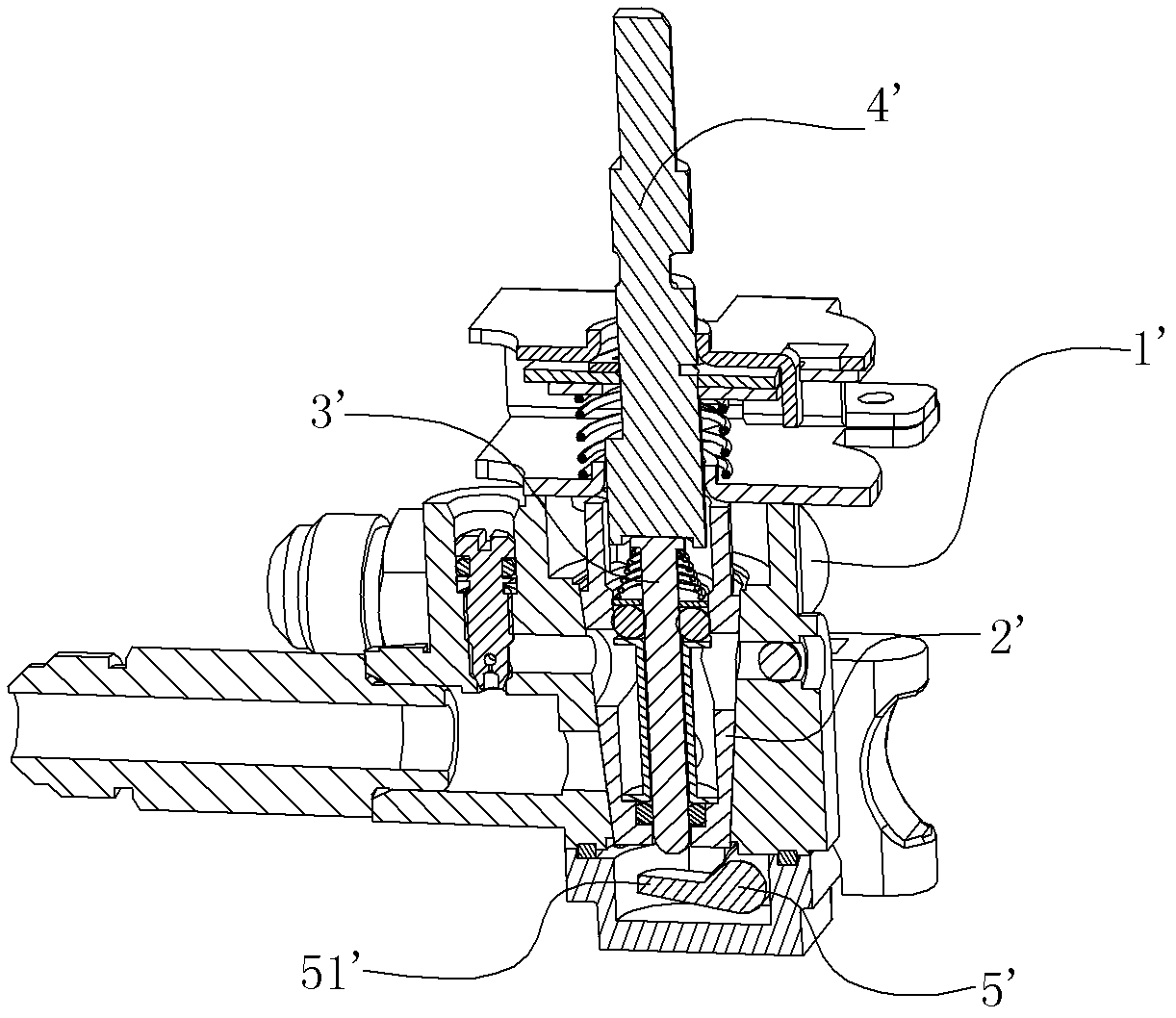

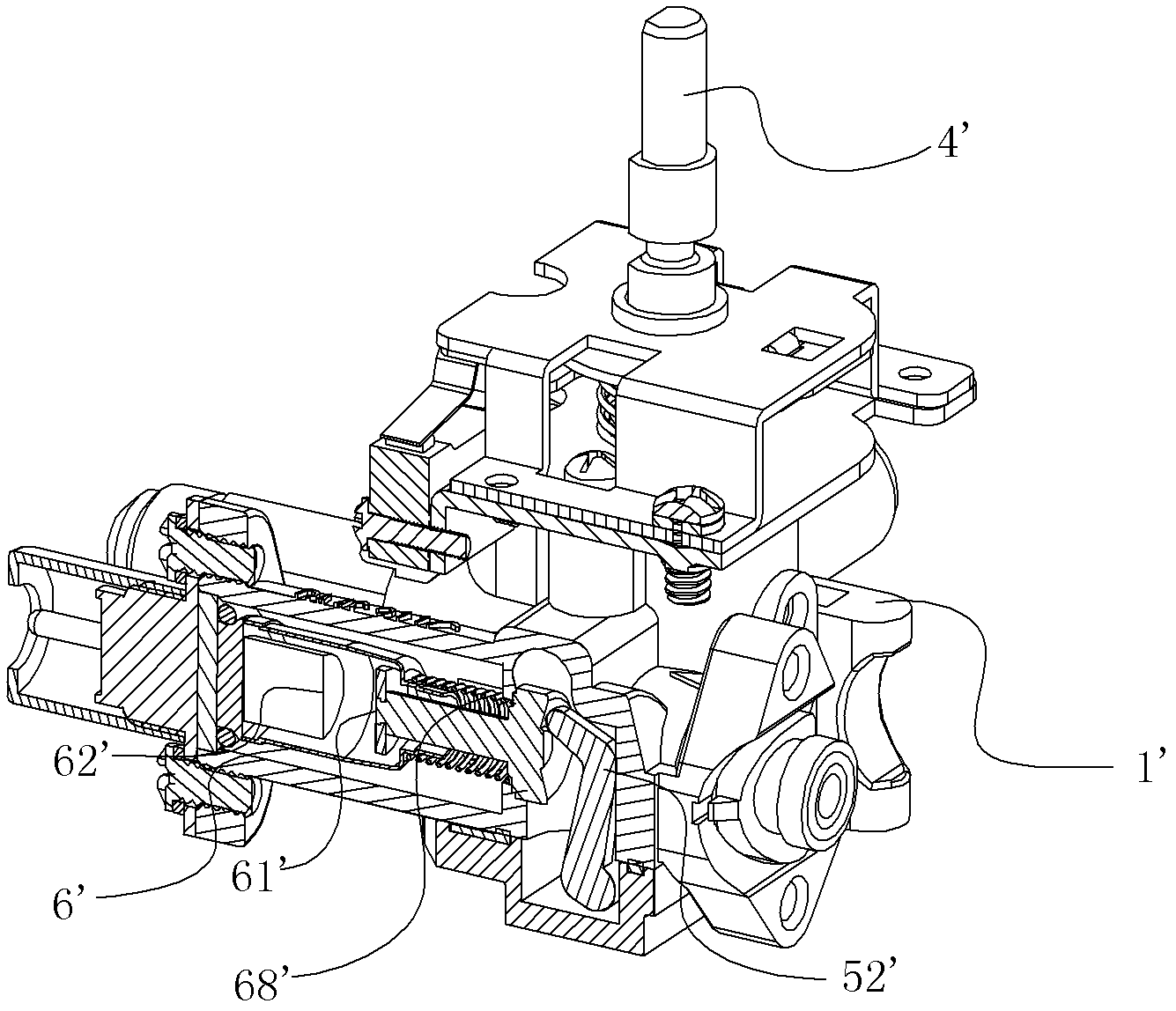

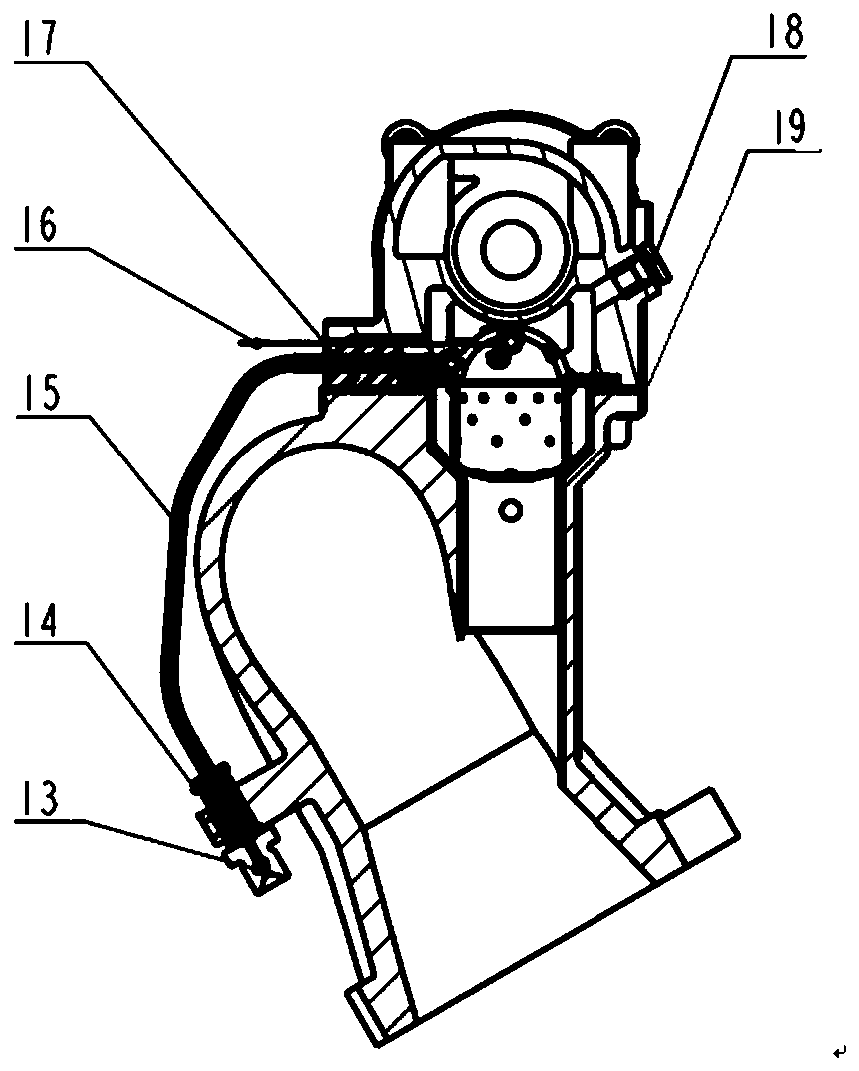

Valve body for gas stove

ActiveCN102588665ASmooth ignitionExtended service lifeOperating means/releasing devices for valvesEngineeringMechanical engineering

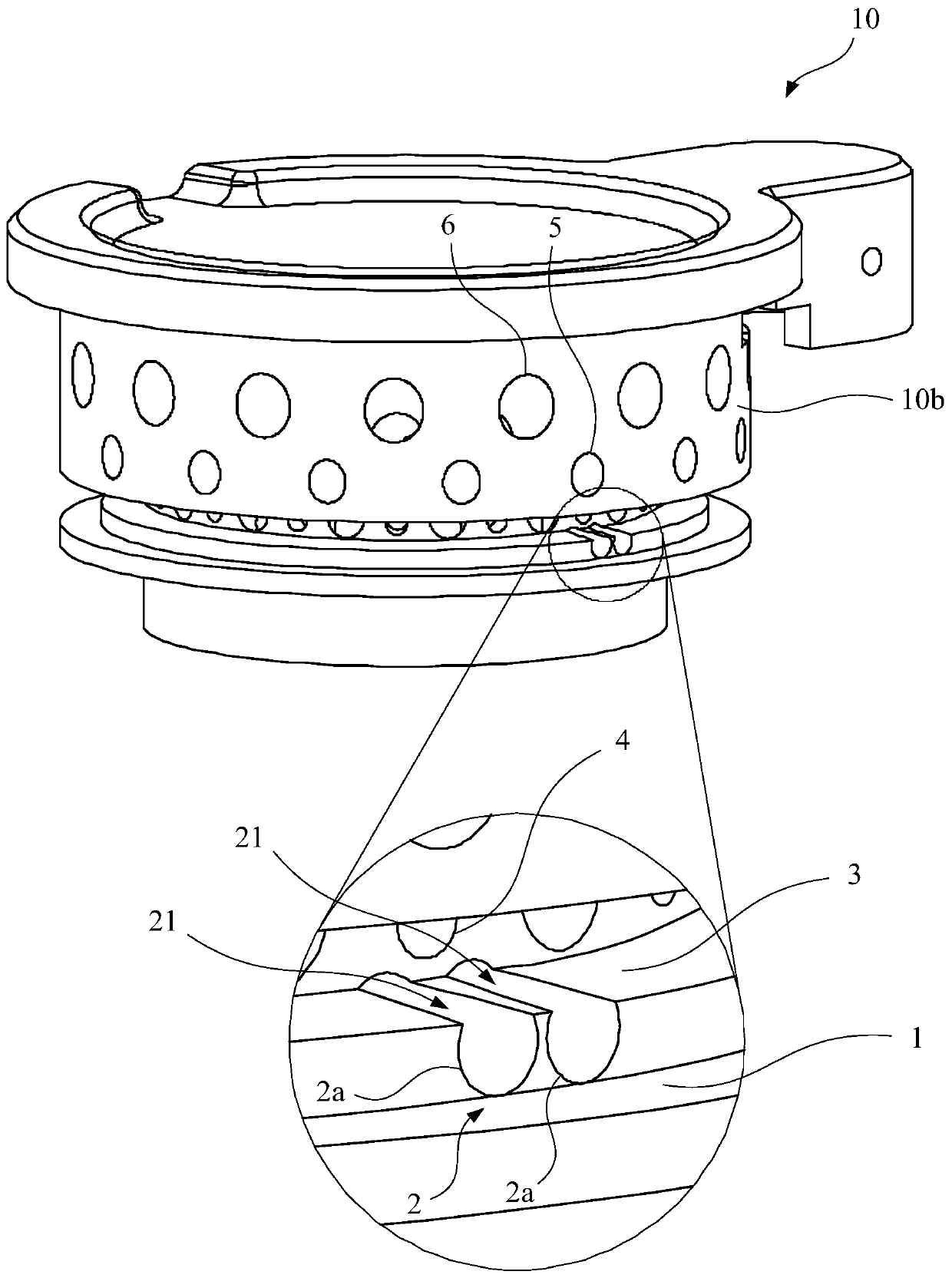

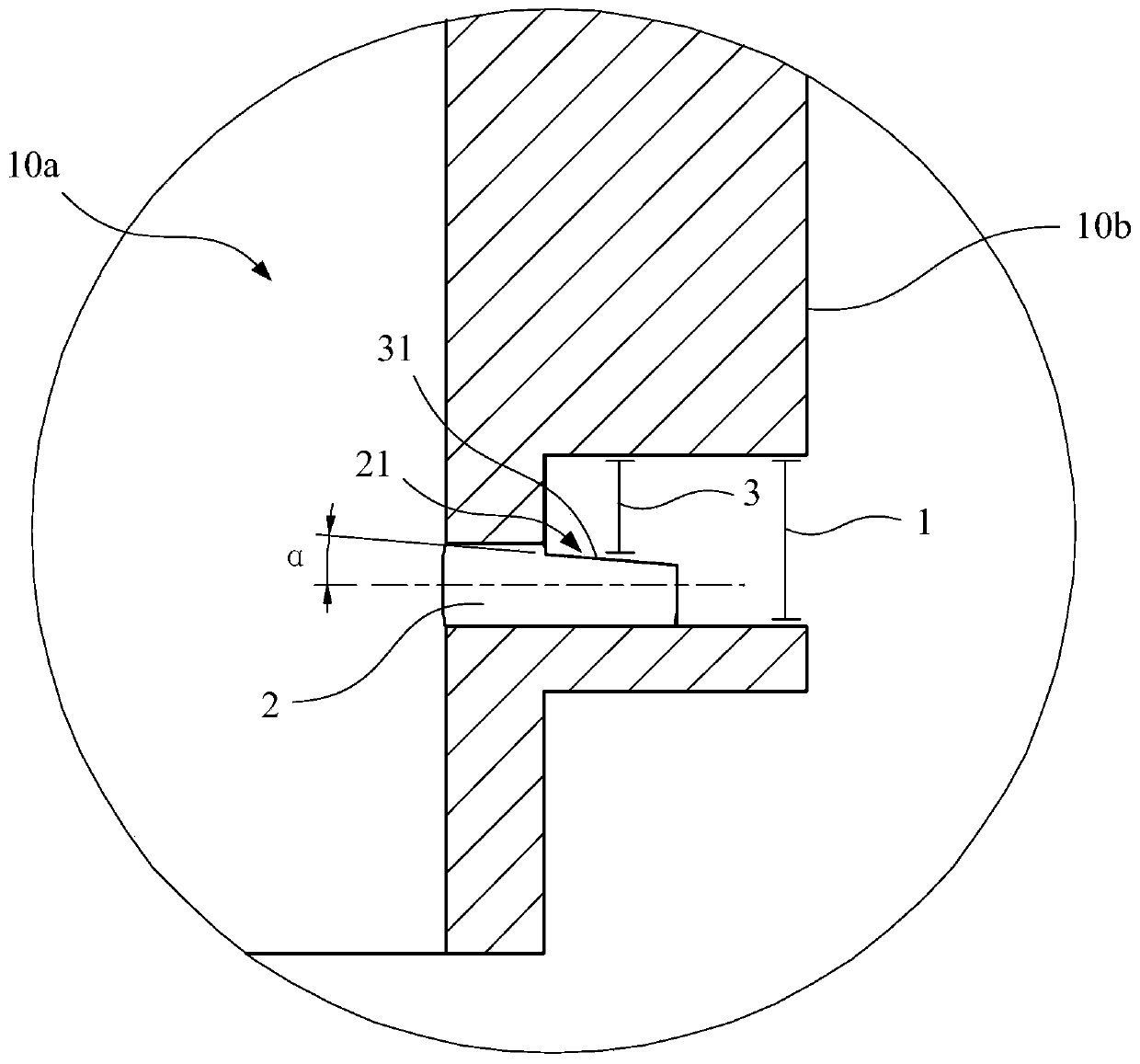

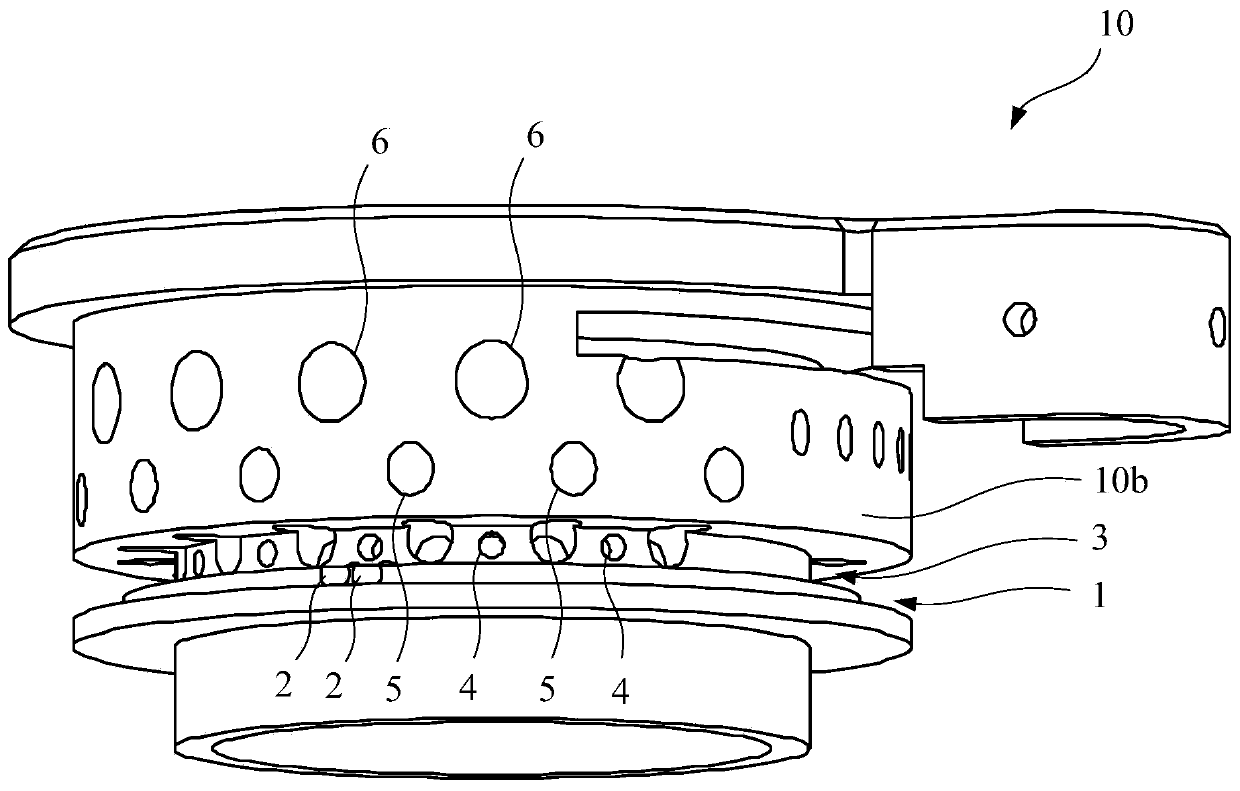

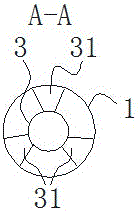

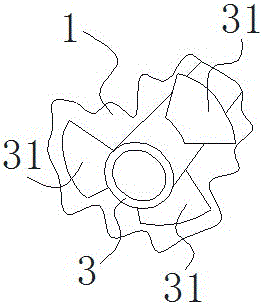

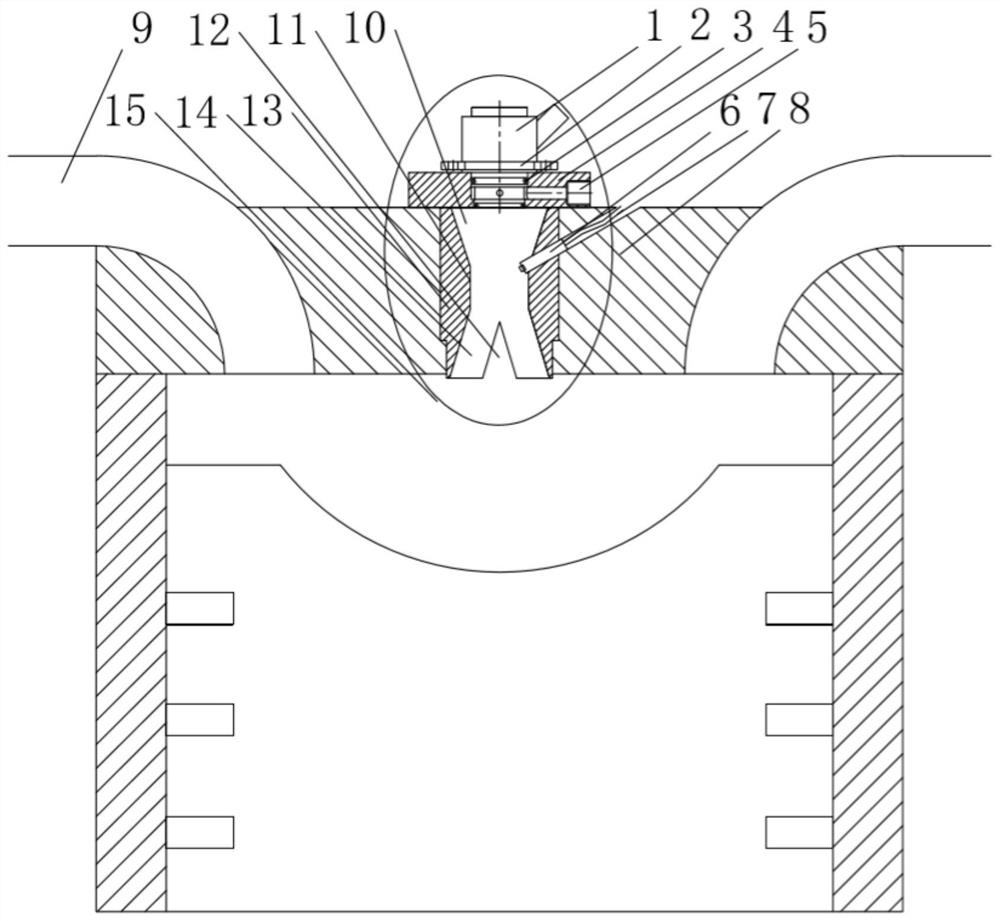

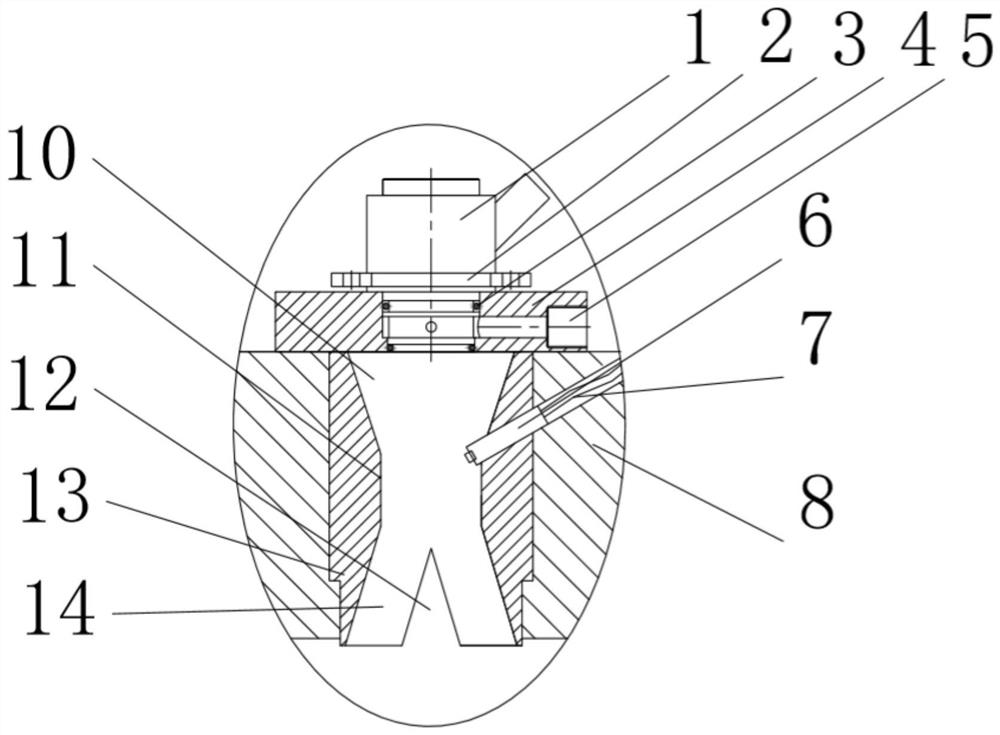

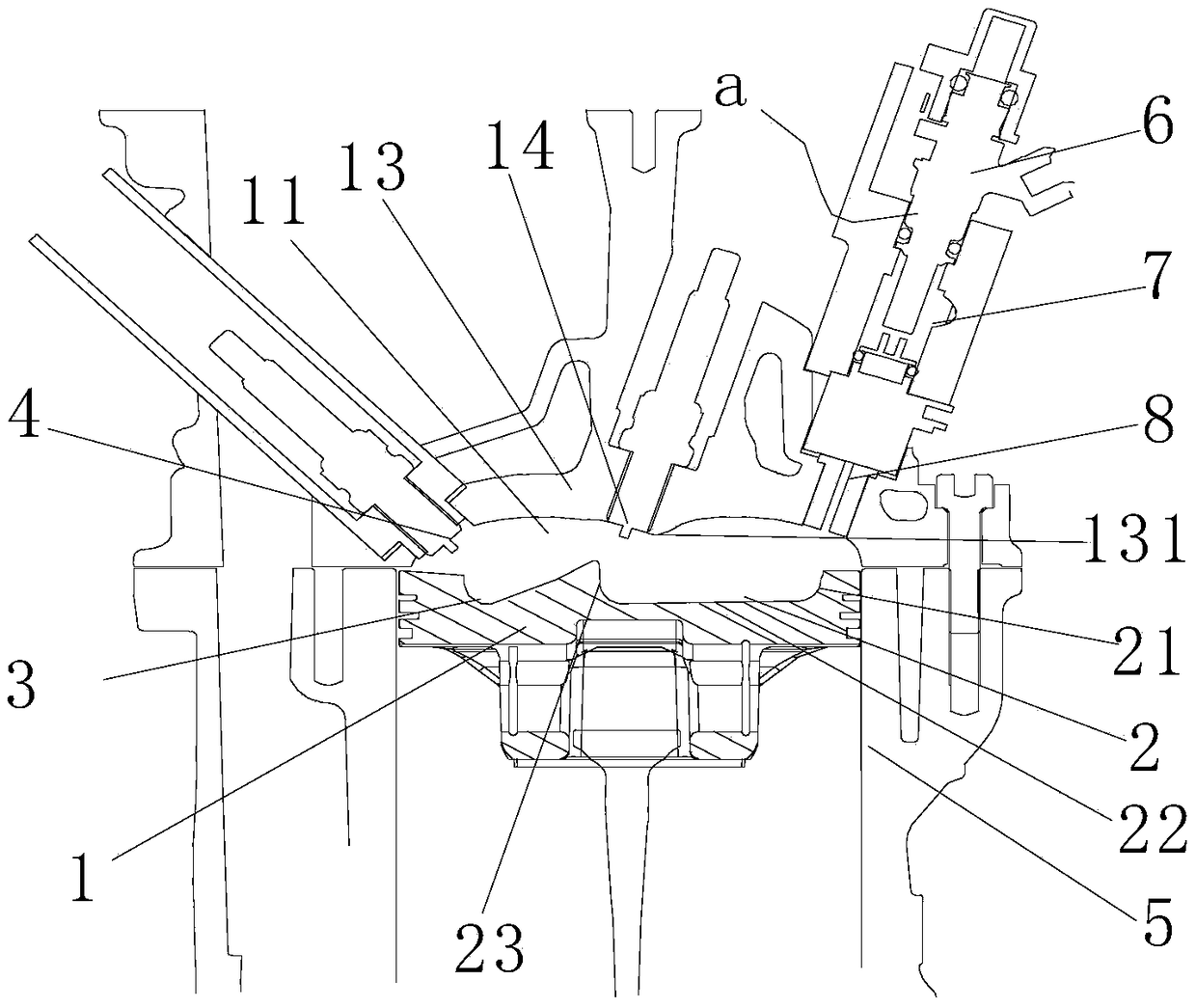

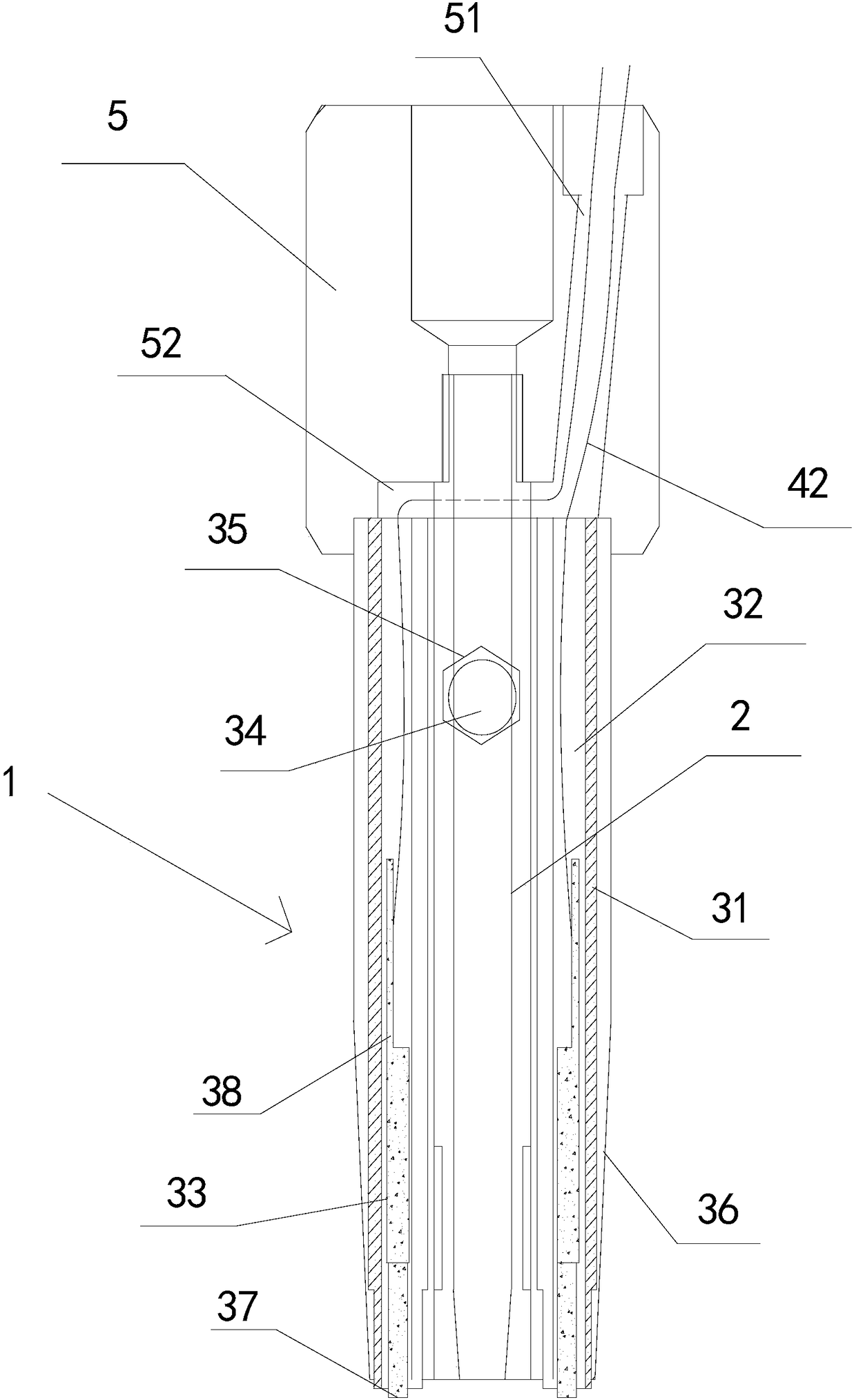

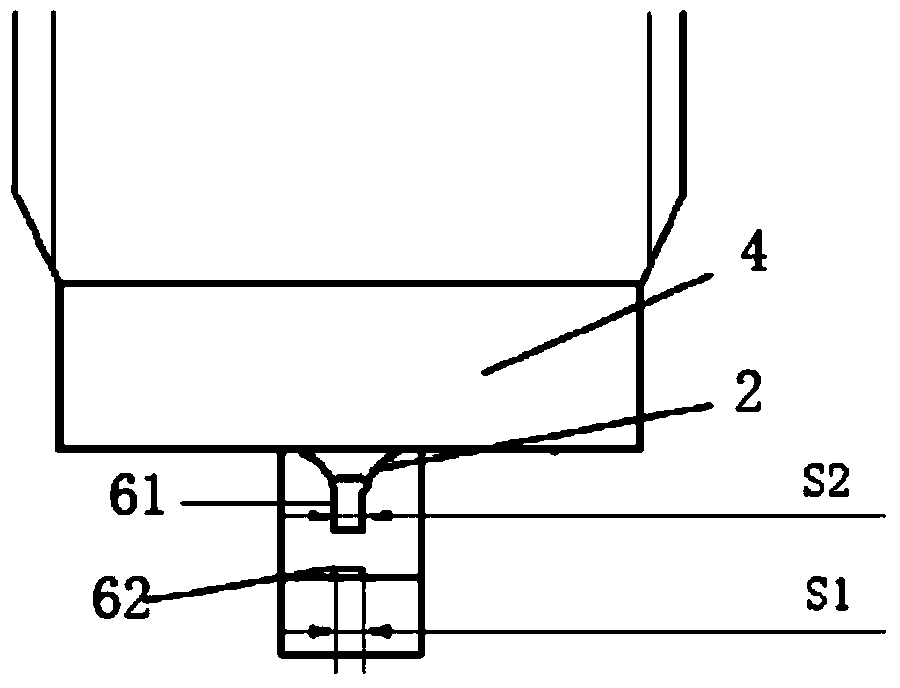

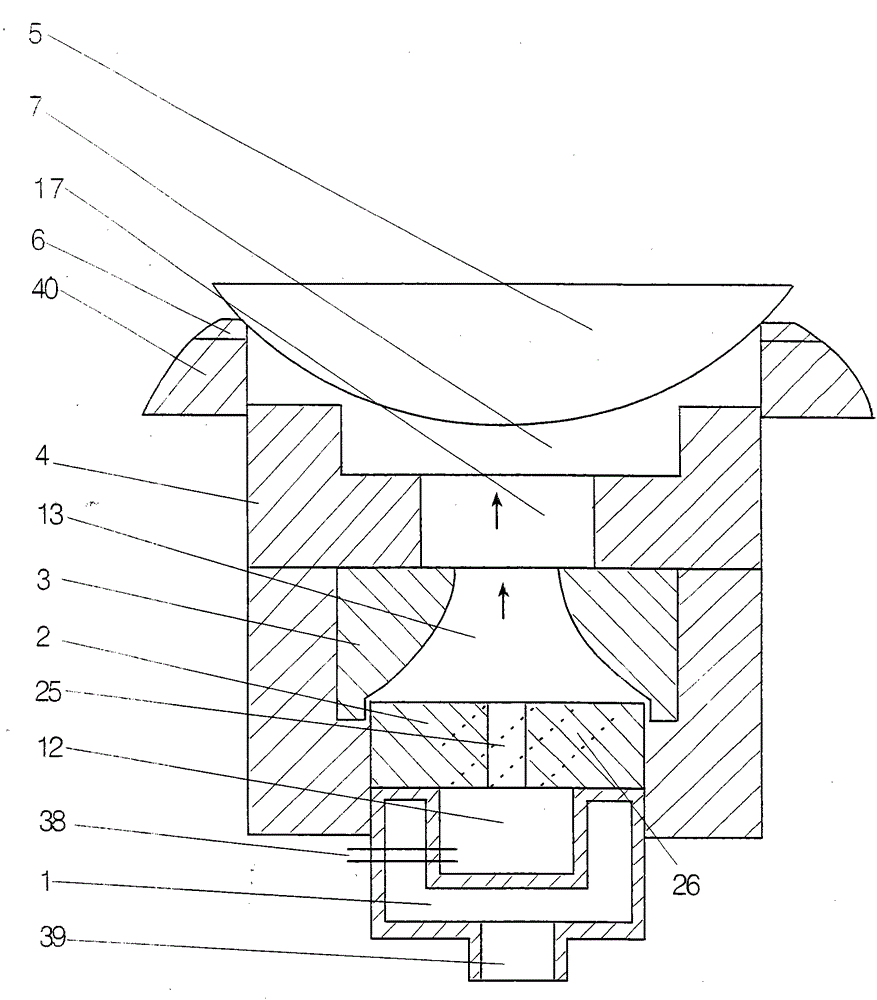

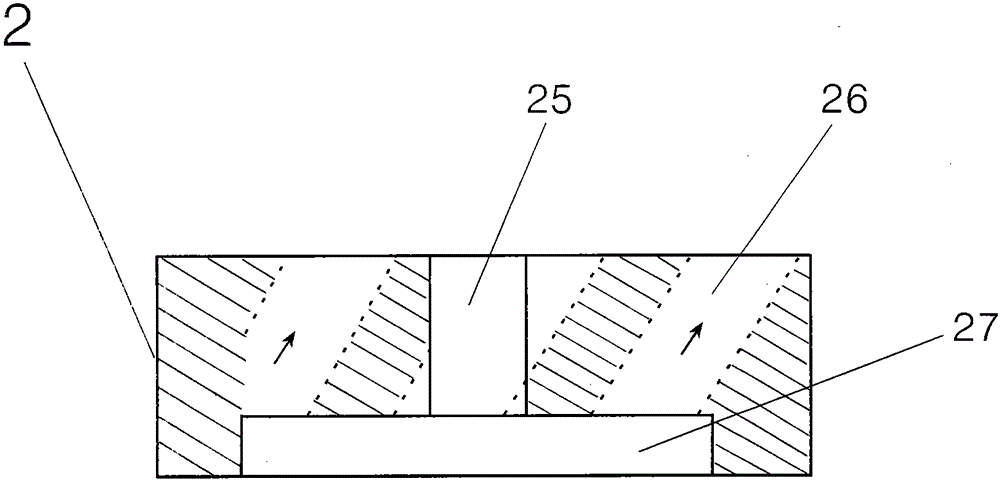

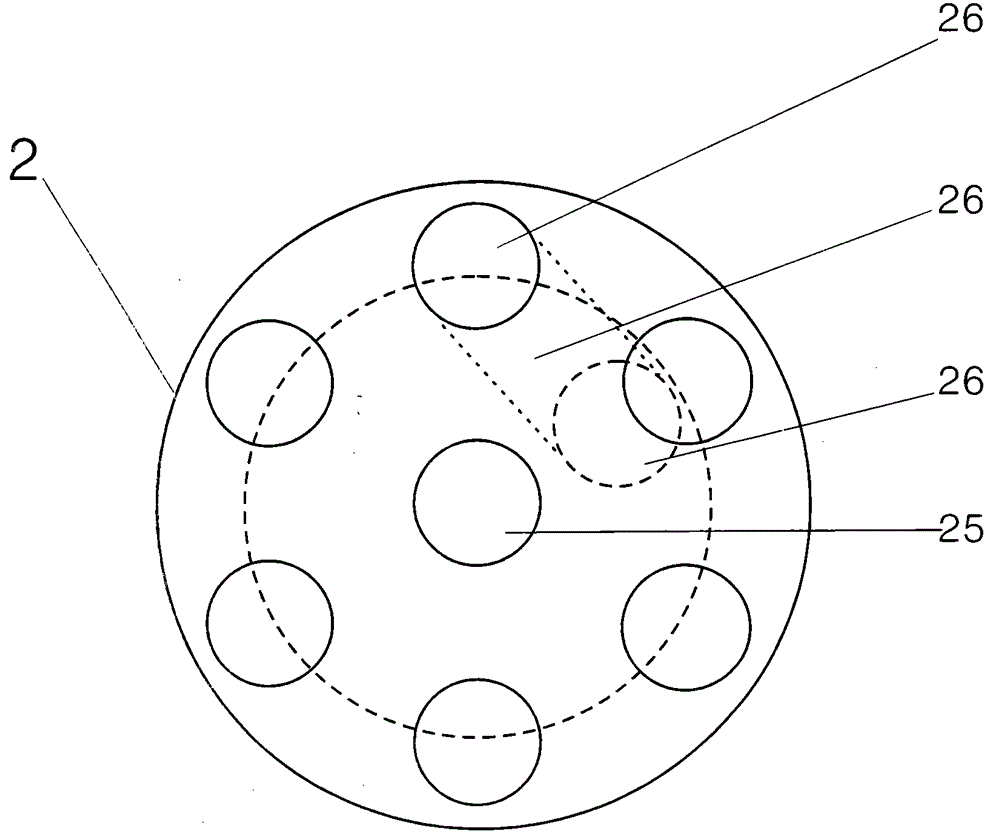

The present invention relates to a valve body for a gas stove, comprising a housing and a valve core, wherein inside the valve core there is provided a valve needle, above the valve needle there is provided a knob rod, the lower portion of the valve needle abuts against a boss at one end of a top rod, the other end of the top rod is provided with a push arm abutting against one end of an electromagnetic valve, a child lock on the valve body is unlocked in the process of pressing down the knob rod and a gas pipe is got through in a manner of rotation, the knob rod enables the actuation surfaces inside the valve body to mutually absorbed in the pressing-down process of the knob rod, the knob rod is pressed down to unlock the child lock using a stroke called as A, the knob is pressed down to enable the actuation surfaces inside the electromagnetic valve to mutually absorbed using a stroke called as B, and all the strokes of pressing down the knob rod are called as C (C>=A>=B). The valve body for a gas stove can ensure the absorption of the actuation surfaces inside the electromagnetic valve before unlocking the child lock, and also can ensure the smooth of the igniting, is provided with a function of buffer, can protect the top electromagnetic valve mechanism from being damaged by the action of an acting force, and enables the service life of the top electromagnetic valve mechanism to be prolonged.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

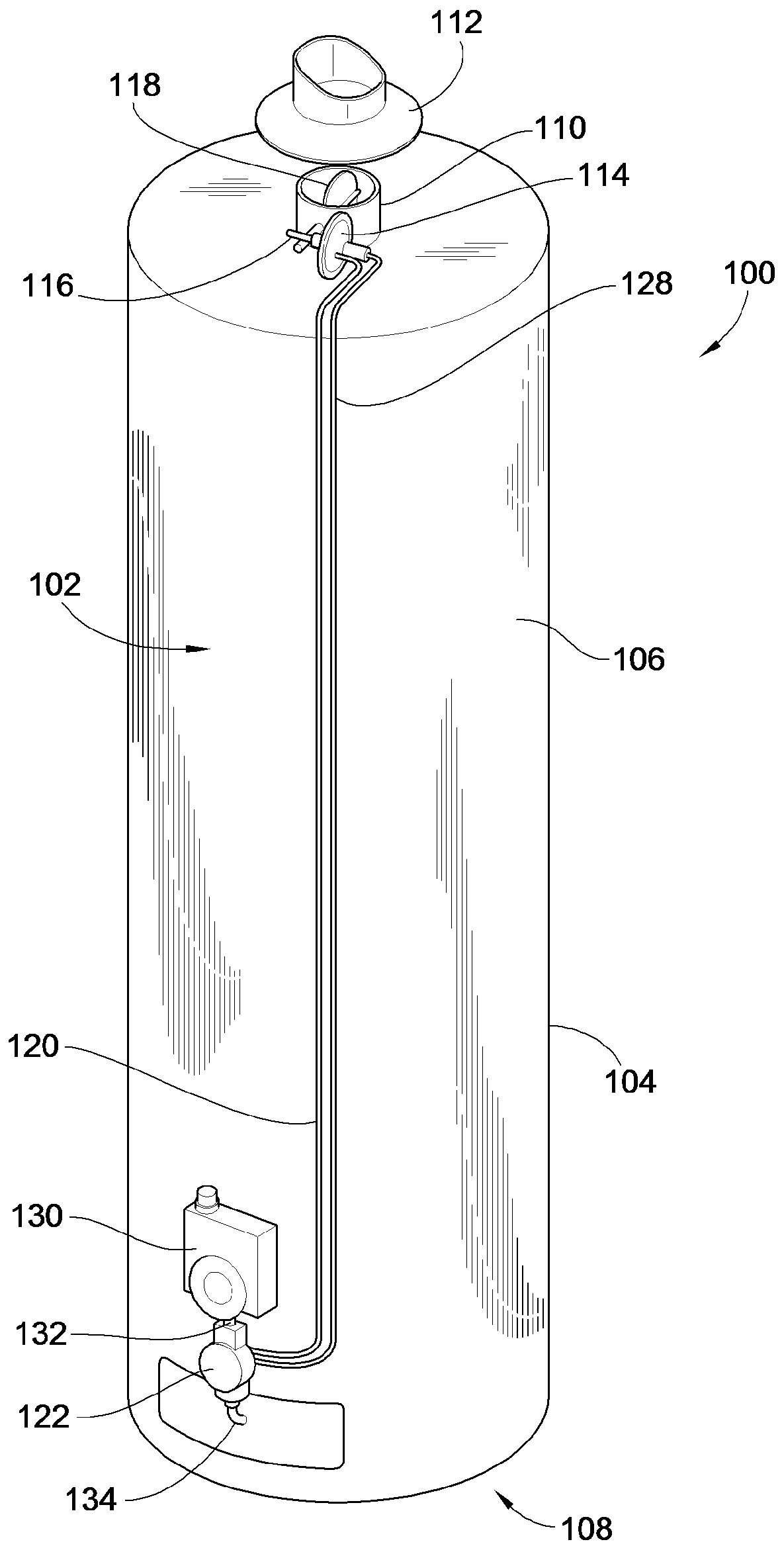

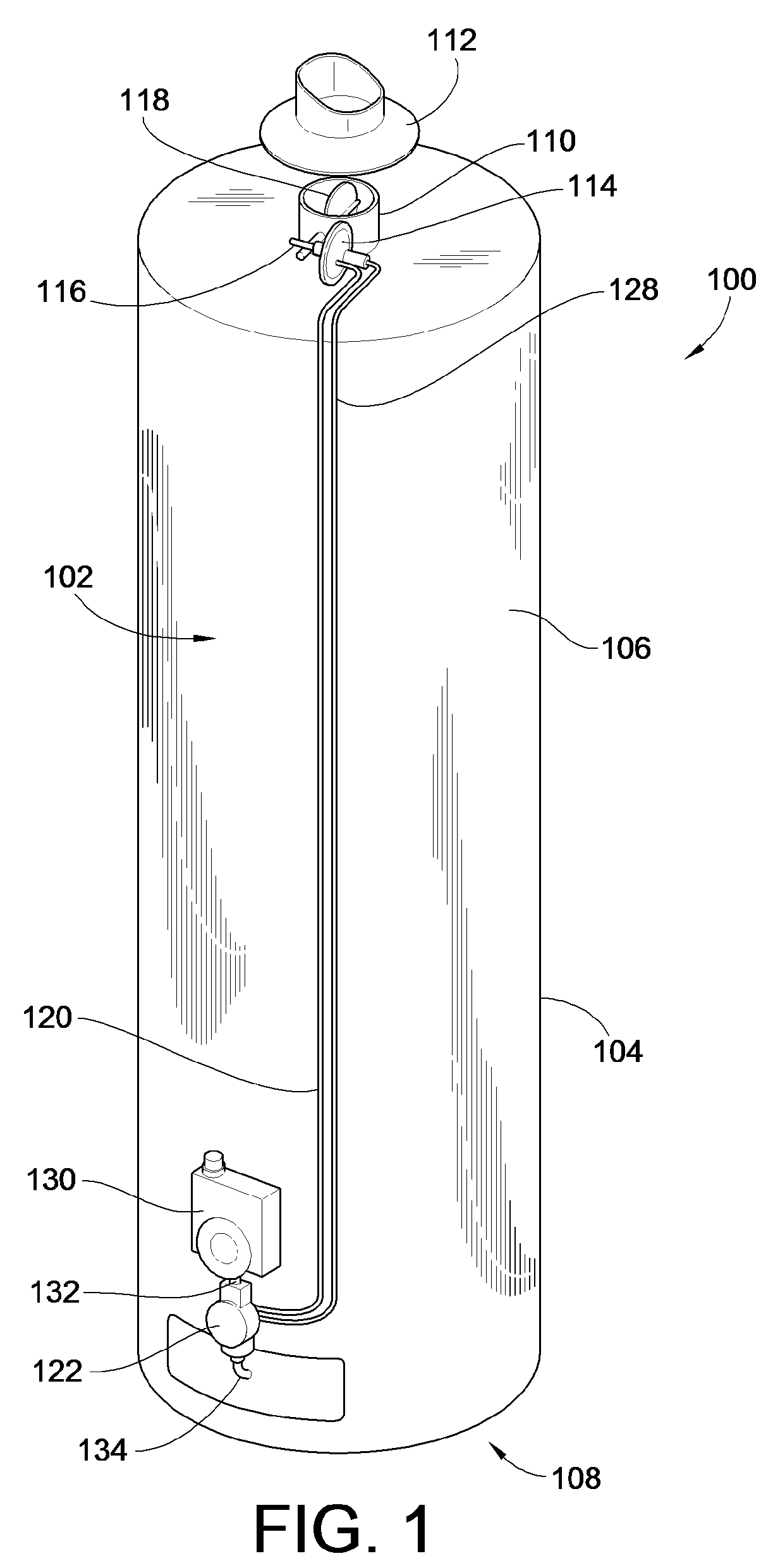

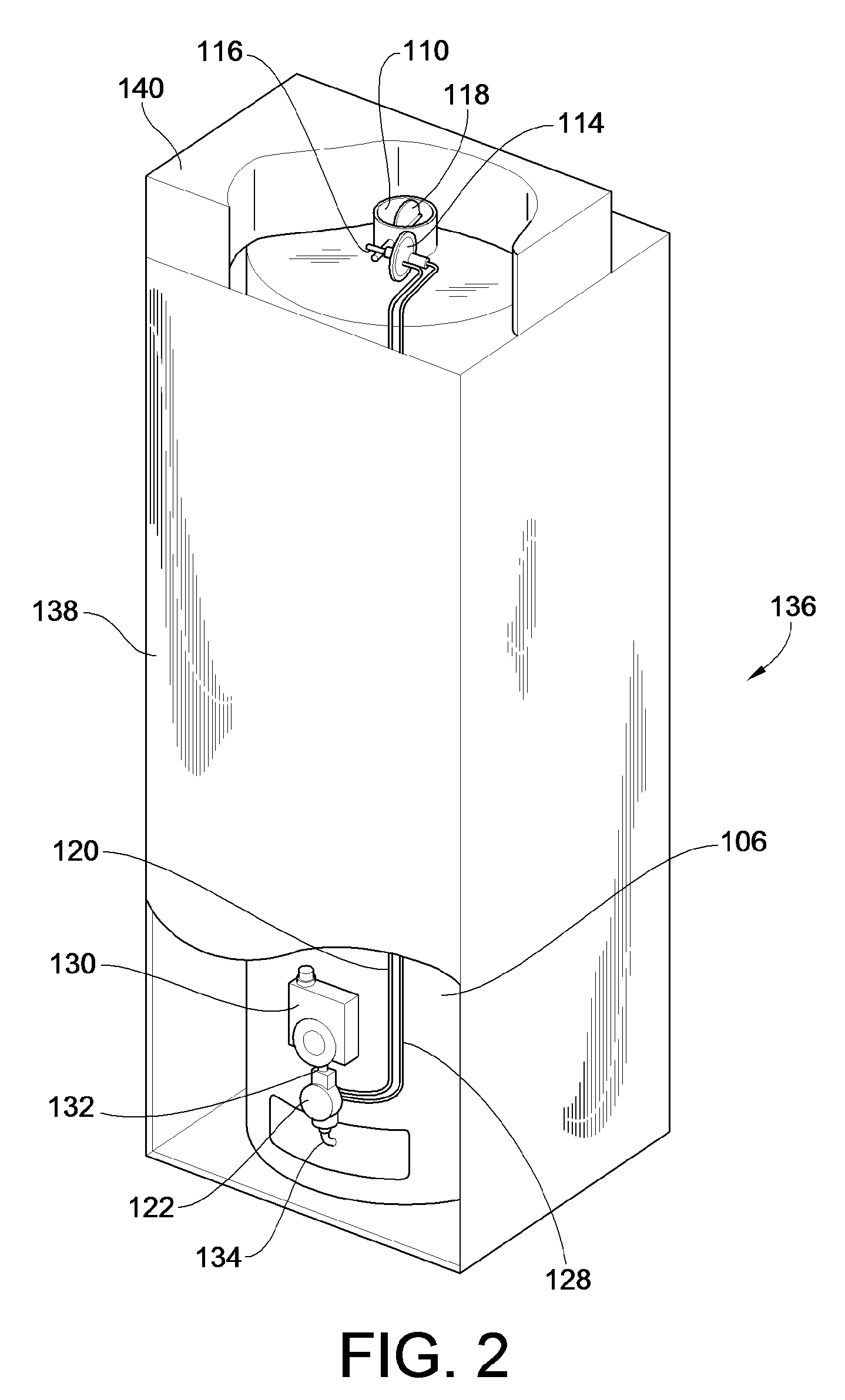

Micro-Pilot For Gas Appliance

InactiveUS20100015559A1Save energyReducing greenhouse gas emissionMechanical apparatusIncandescent ignitionCombustorFuel gas

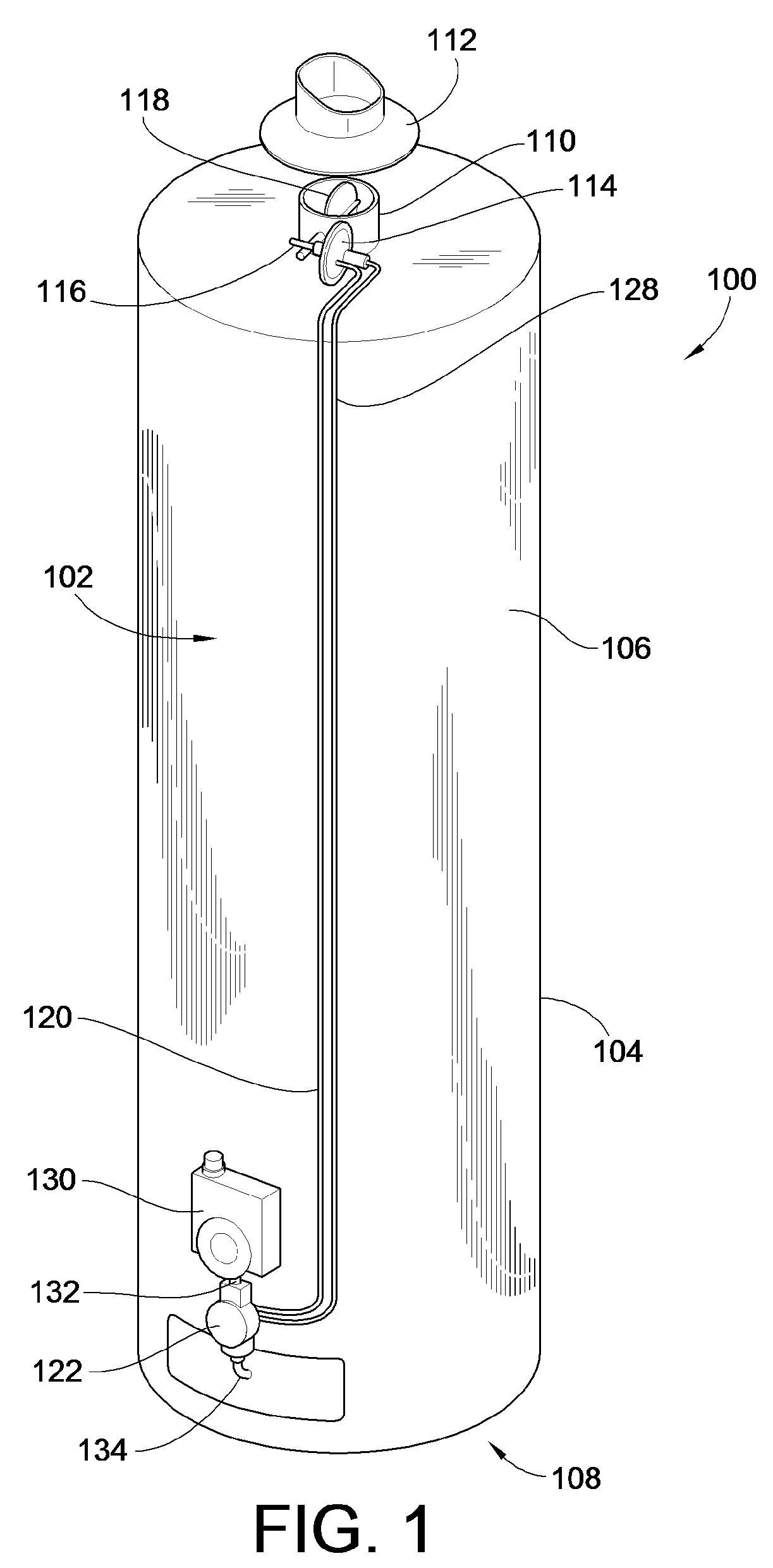

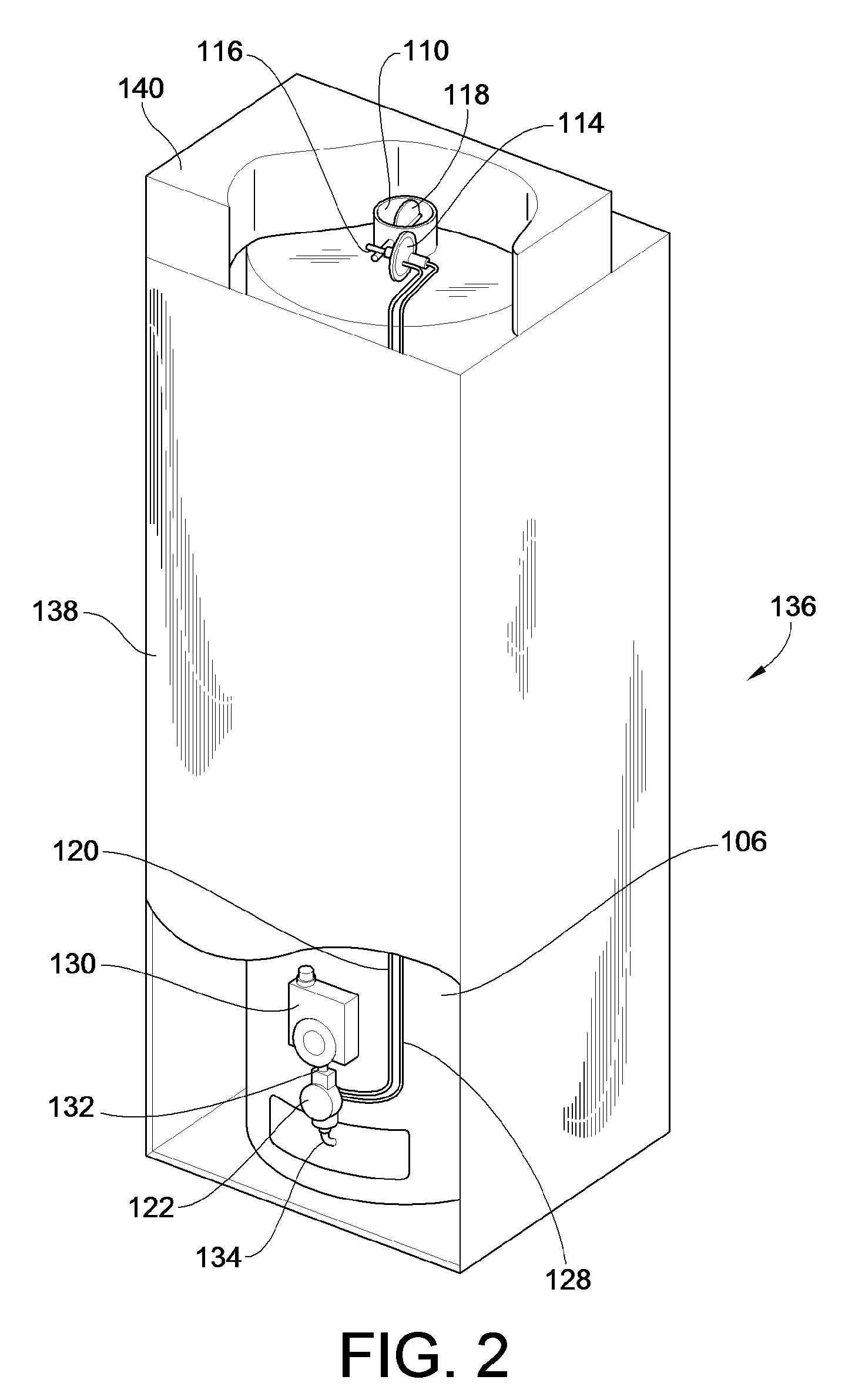

A micro pilot for a gas hot water heater is provided. The micro pilot provides a flame that is substantially smaller than a typical pilot in a hot water heater during standby operation of the burner. Just prior to allowing gas to flow to the burner upon a call for heat, a pilot flame of sufficient size to ensure ignition of the burner is provided. In one embodiment this larger pilot flame is produced by providing an additional amount of bleed gas to the pilot to increase flame size. In another embodiment, bleed gas is provided to a separate booster pilot, which is ignited by the micro pilot. The flame from the booster pilot is then used to ignite the main burner. This design allows for the micro pilot to be positioned closer to the flame trap of a flammable vapor resistant hot water heater to ensure smooth ignition of any such vapor.

Owner:INVENSYS CONTROLS AUSTRALIA

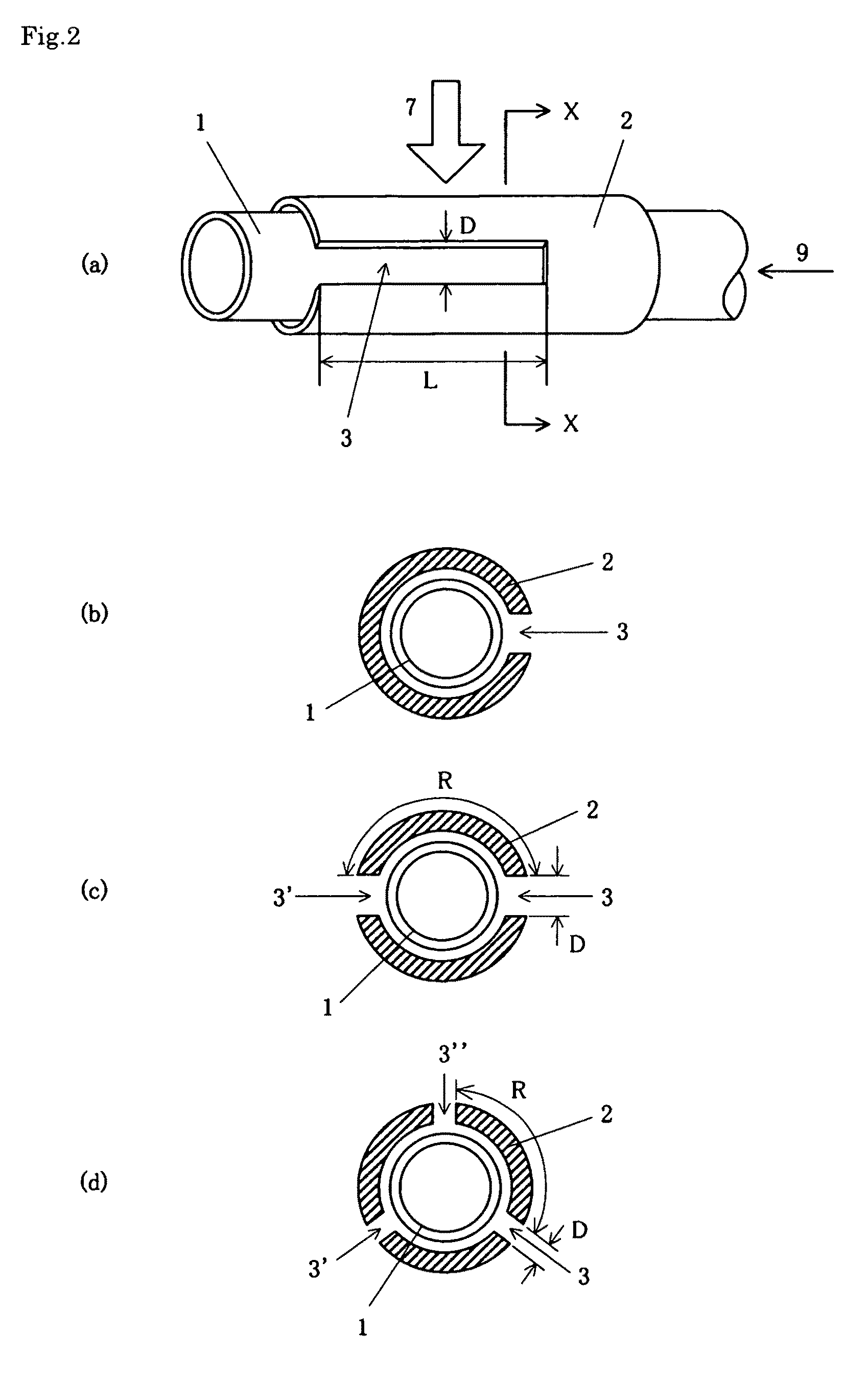

Plasma generator and method of generating plasma using the same

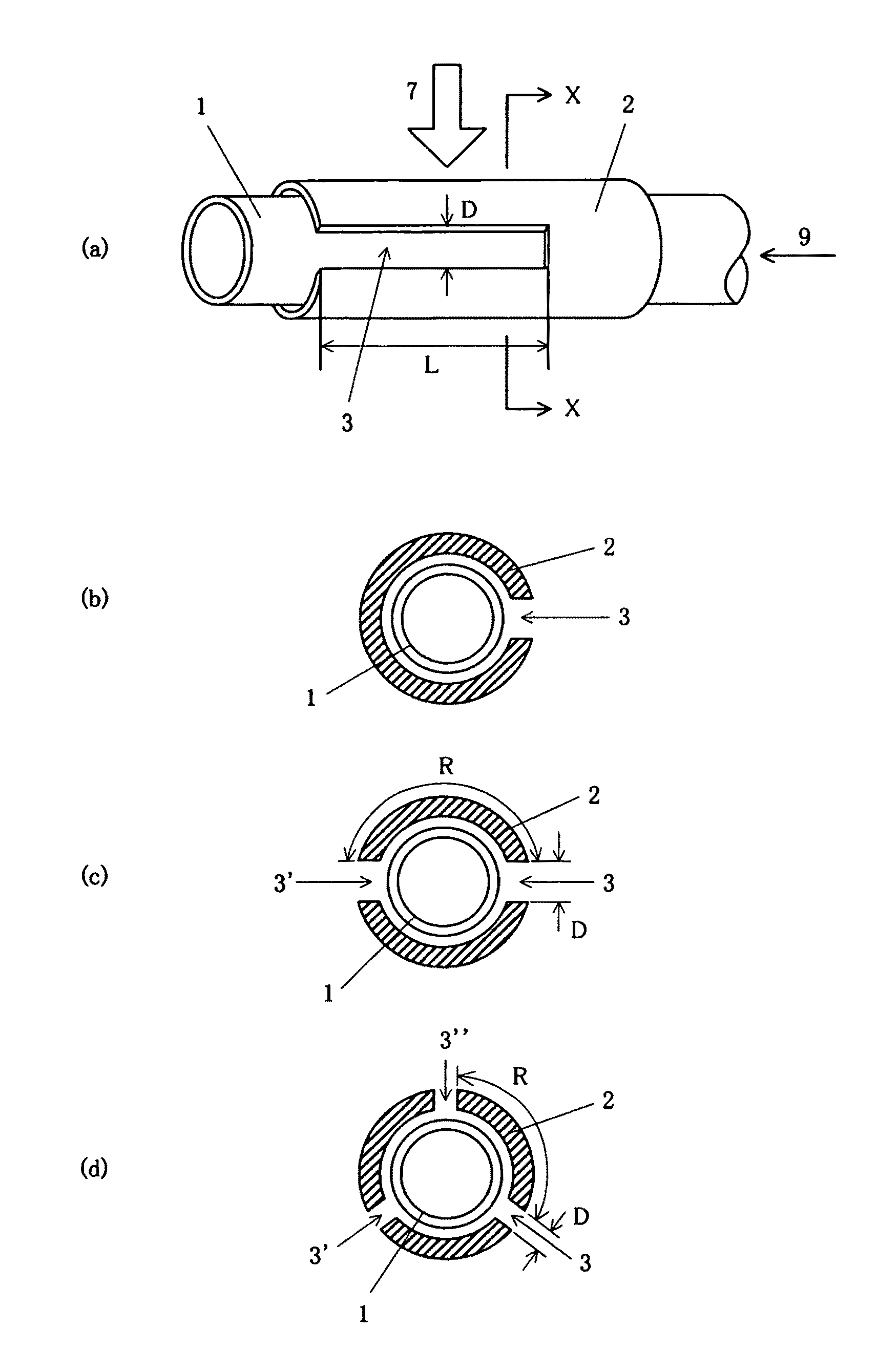

InactiveUS8216433B2Avoid changes in impedanceWeaken energyElectric discharge tubesGas-gas reaction processesMicrowavePlasma generator

A plasma generator in which the variation of the impedance in the cavity before and after plasma is ignited is less and hardly affected by the shape of the cavity, and the ignitability of the plasma is improved and a method of generating plasma using the plasma generator are provided. The plasma generator comprises a nonconductive gas flow pipe (1) for introducing a gas (9) for generating plasma and discharging it into the atmosphere and a conductive antenna pipe (2) surrounding the gas flow pipe. A microwave (7) is applied to the antenna pipe to change the gas in the gas flow pipe into plasma. The plasma generator is characterized in that a slit (3) with a predetermined length is formed in the antenna pipe (2) along the axial direction of the gas flow pipe. Preferably, the plasma generator is characterized in that the length of the slit is an integral multiple of the half-wave length of the applied microwave.

Owner:UNIVERSITY OF THE RYUKYUS

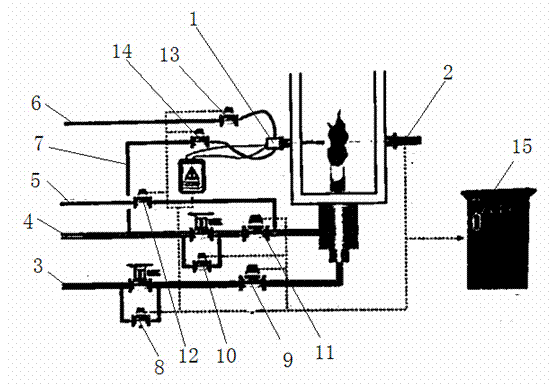

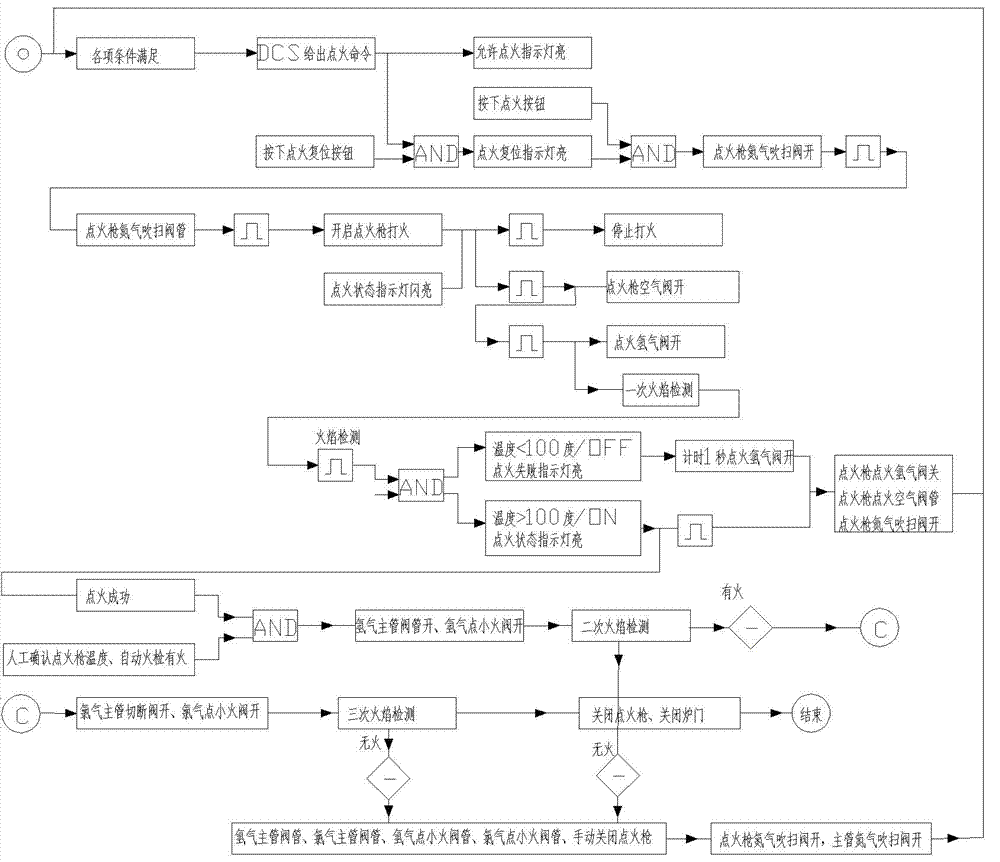

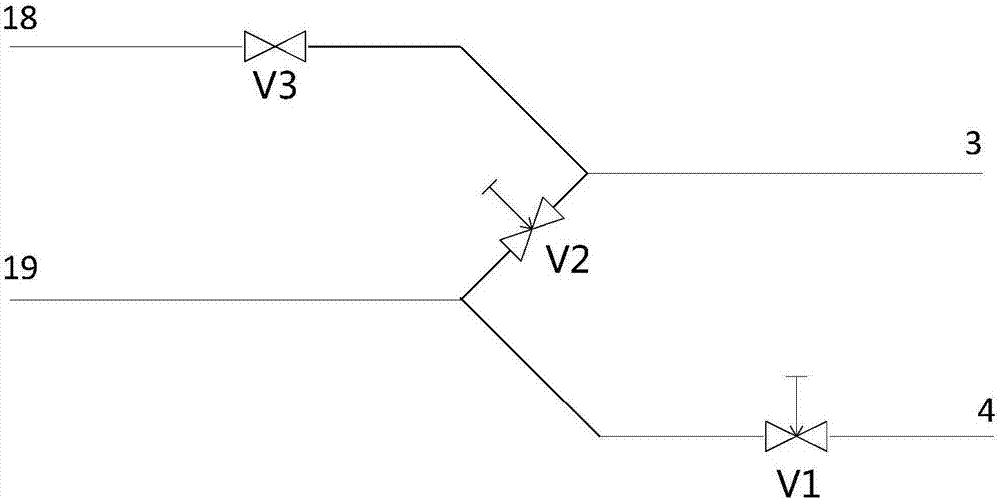

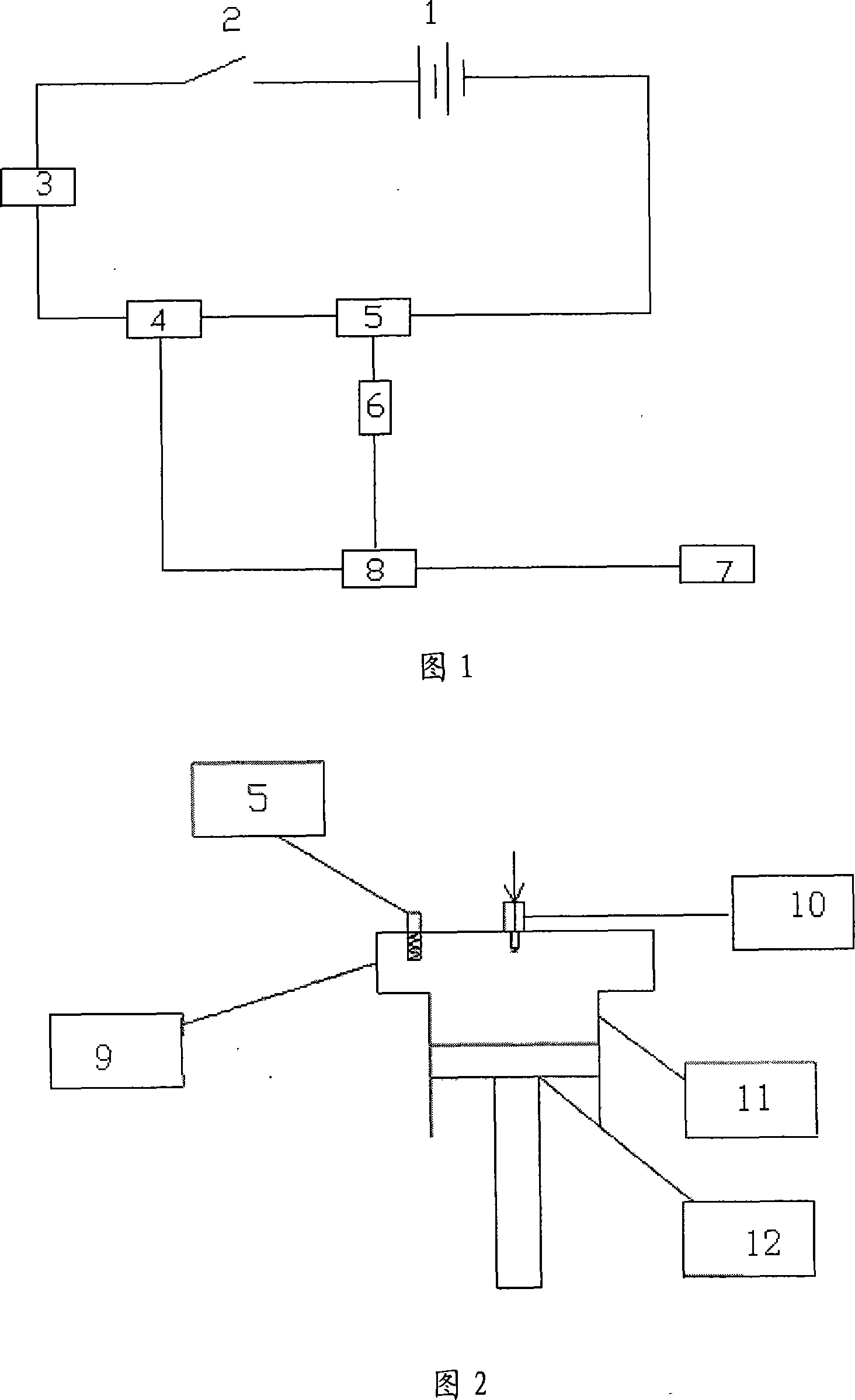

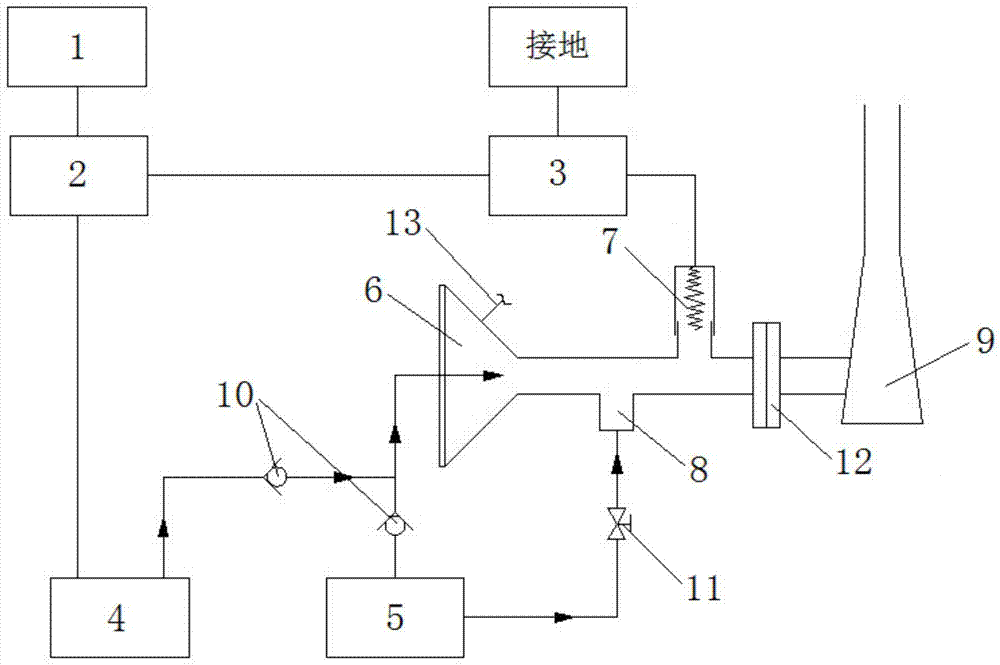

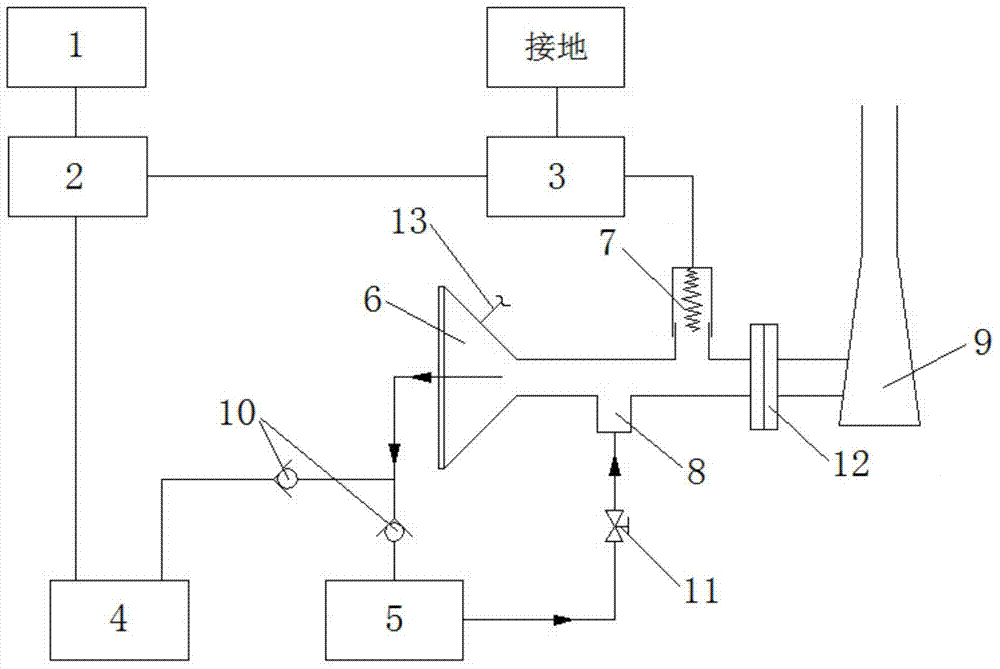

Automatic ignition system of chlorine hydride synthesis furnace and control method of automatic ignition system

ActiveCN104501206ACompact structureOperational securityChlorine/hydrogen-chloridePilot flame ignitersNitrogenEngineering

The invention relates to an automatic ignition system of a chlorine hydride synthesis furnace and a control method of the automatic ignition system. The automatic ignition system comprises an ignition gun, a flame monitor, a chlorine inlet pipeline, a hydrogen inlet pipeline and a nitrogen inlet pipeline, wherein the ignition gun and the flame monitor are arranged on the side edges of the opening of the chlorine hydride synthesis furnace; the chlorine inlet pipeline, the hydrogen inlet pipeline and the nitrogen pipeline are simultaneously and parallelly connected in series with the bottom of the opening of the chlorine hydride synthesis furnace; the air inlet of the ignition gun is connected in series with an ignition air pipeline; the hydrogen inlet of the ignition gun is connected in series with an ignition hydrogen pipeline; and the input end of the ignition hydrogen pipeline is simultaneously connected with the those of the hydrogen inlet pipeline and the nitrogen inlet pipeline. The automatic ignition system provided by the invention has the advantages as follows the structure is compact; the operation is safe and reliable; the system doesn't need to be in direct contact with hydrogen when the furnace is ignited, can automatically detect and finish the whole ignition process so long as an ignition key is pressed, and thus is very safe and convenient.

Owner:NANTONG STAR GRAPHITE EQUIP CO LTD

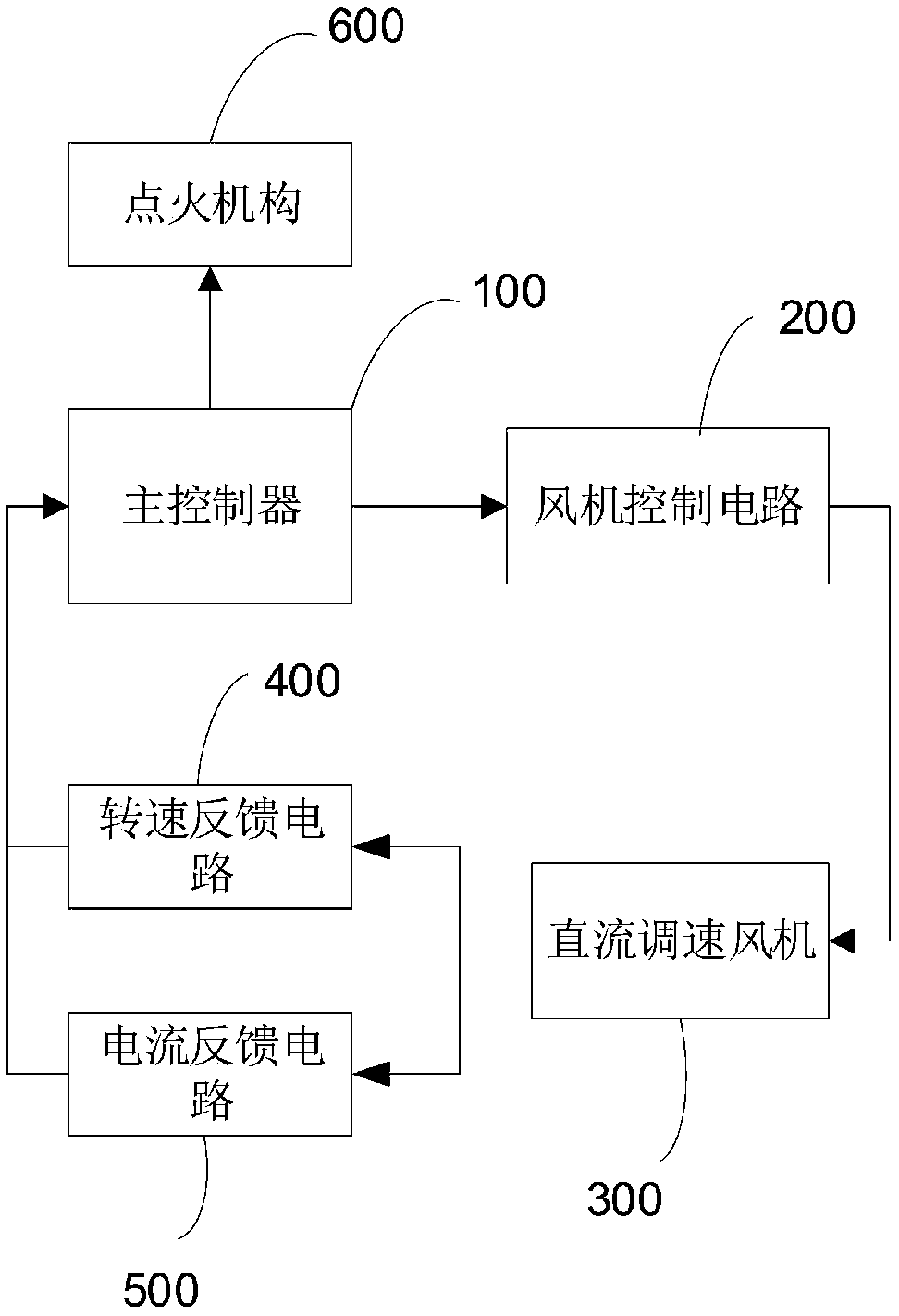

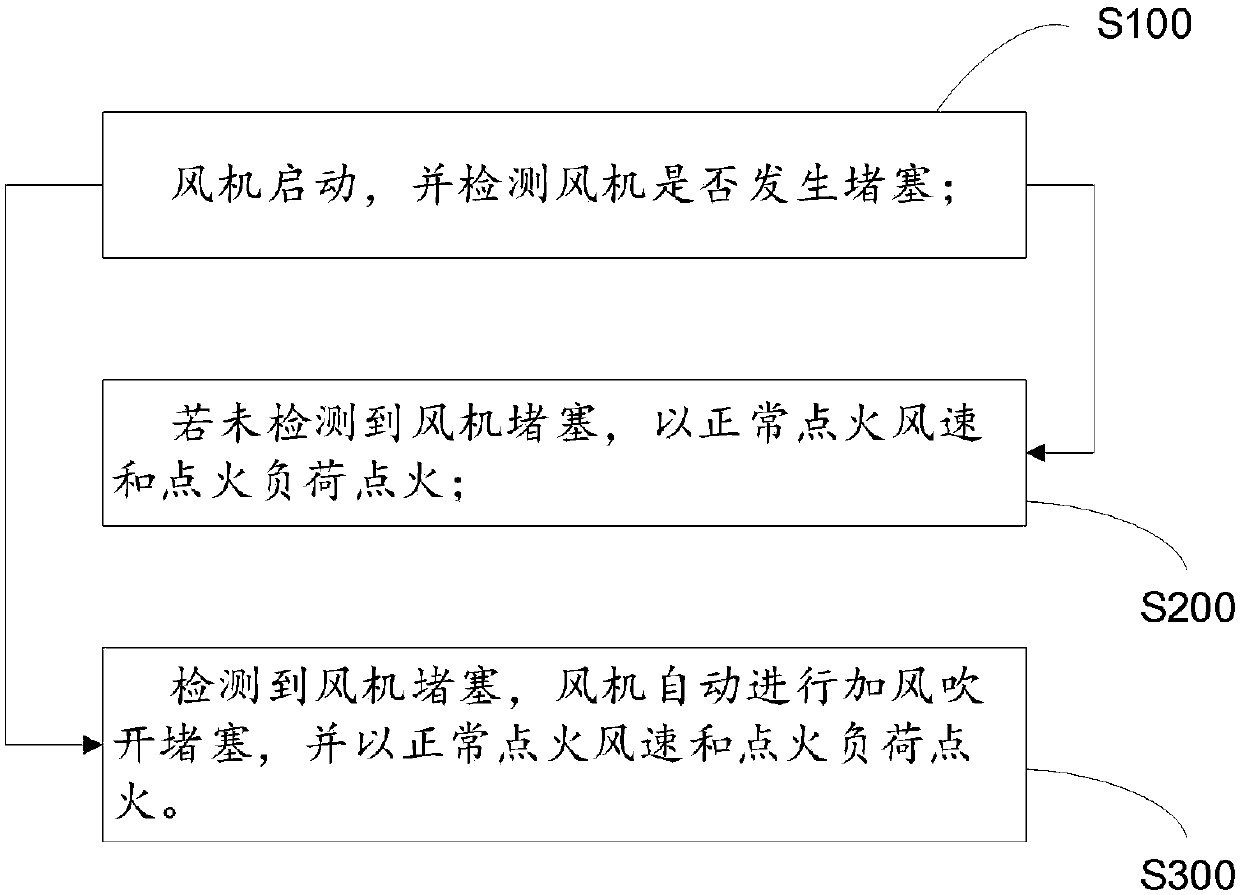

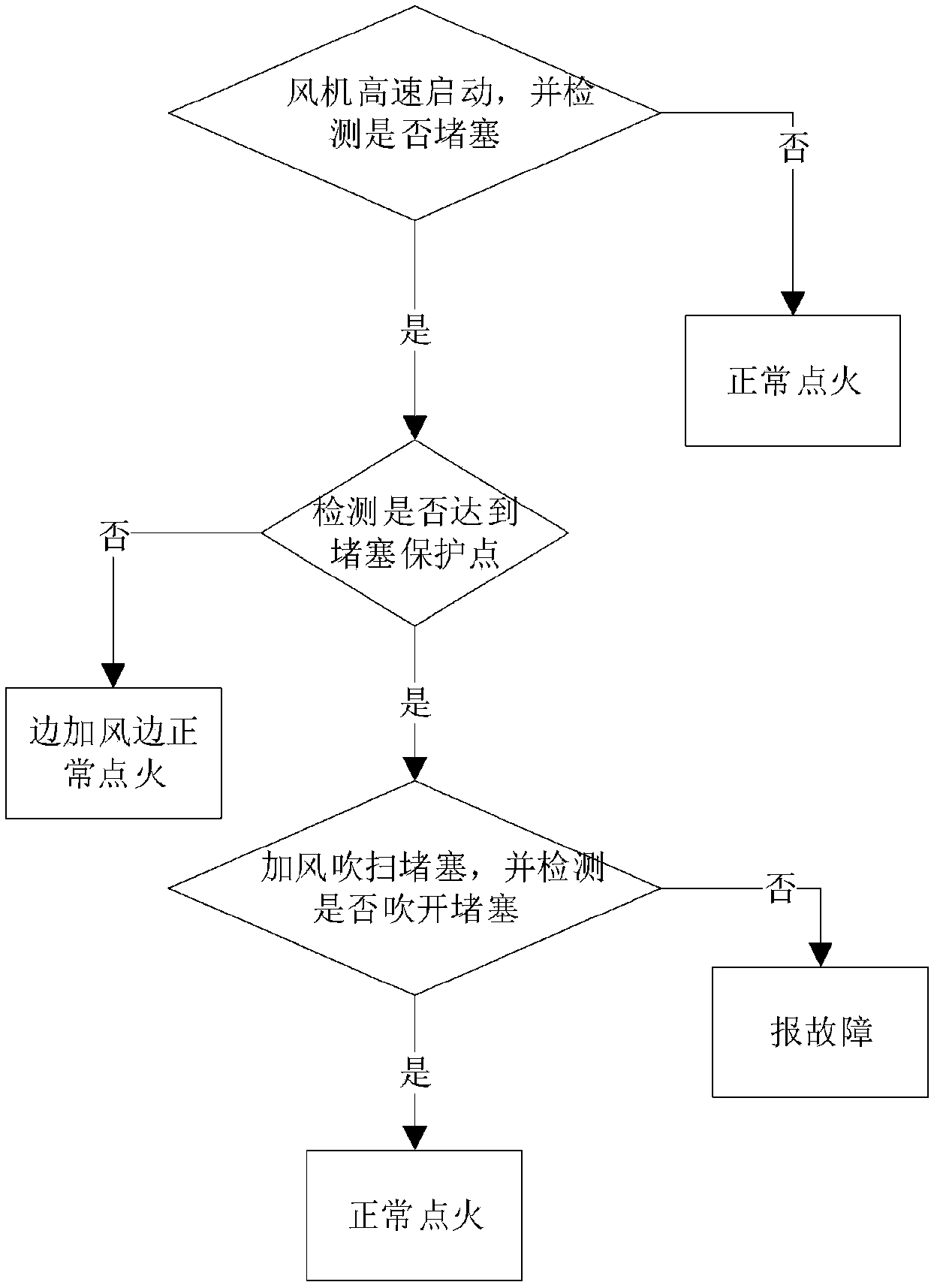

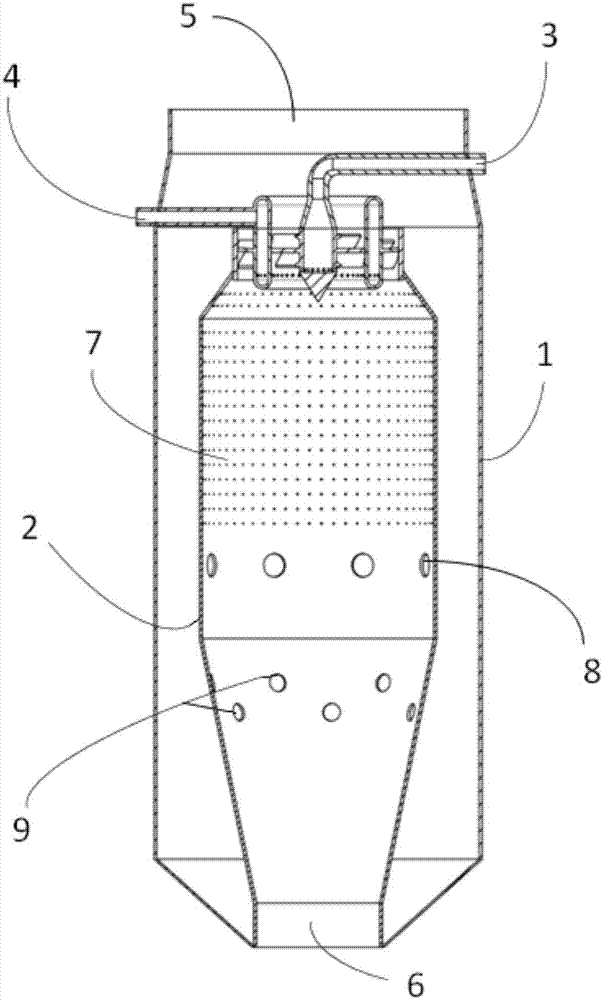

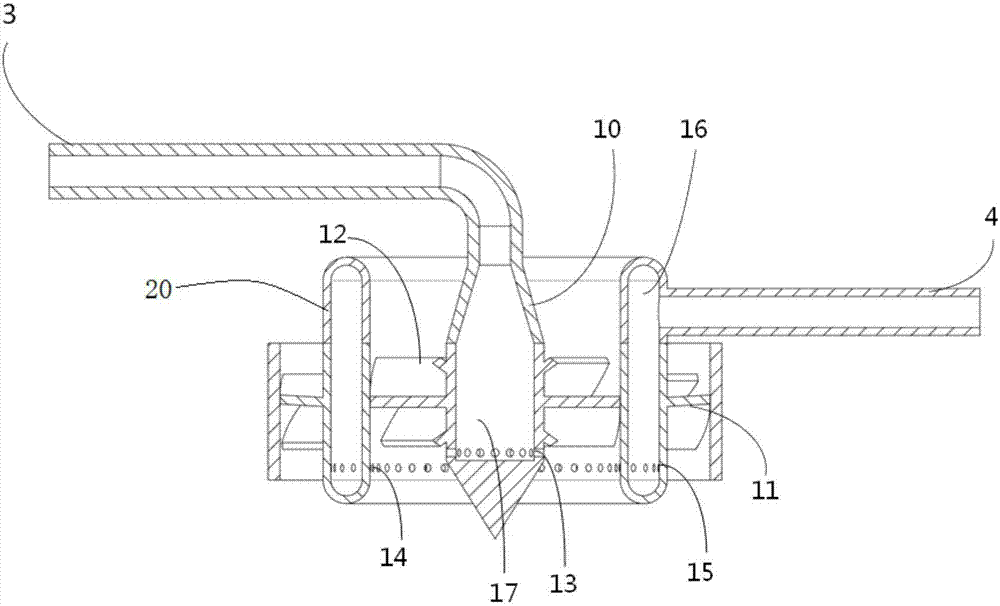

Gas water heater ignition self-detecting control system and method

The invention provides a gas water heater ignition self-detecting control system and method. The gas water heater ignition self-detecting control system comprises a main controller, a direct current speed adjusting fan, a fan control circuit, a rotating speed feedback circuit, a current feedback circuit and an ignition mechanism. The control end of the main controller is connected with the ignition mechanism and connected with the input end of the fan control circuit. The output end of the fan control circuit is connected with the input end of the direct current speed adjusting fan. The inputend of the main controller is connected with the output end of the rotating speed feedback circuit and the output end of the current feedback circuit. The input end of the rotating speed feedback circuit and the input end of the current feedback circuit are connected with the output end of the direct current speed adjusting fan. According to the technical scheme, whether blocking occurs or not canbe detected fast, meanwhile, the wind pressure resisting performance is improved, and normal safe use of users can be ensured.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

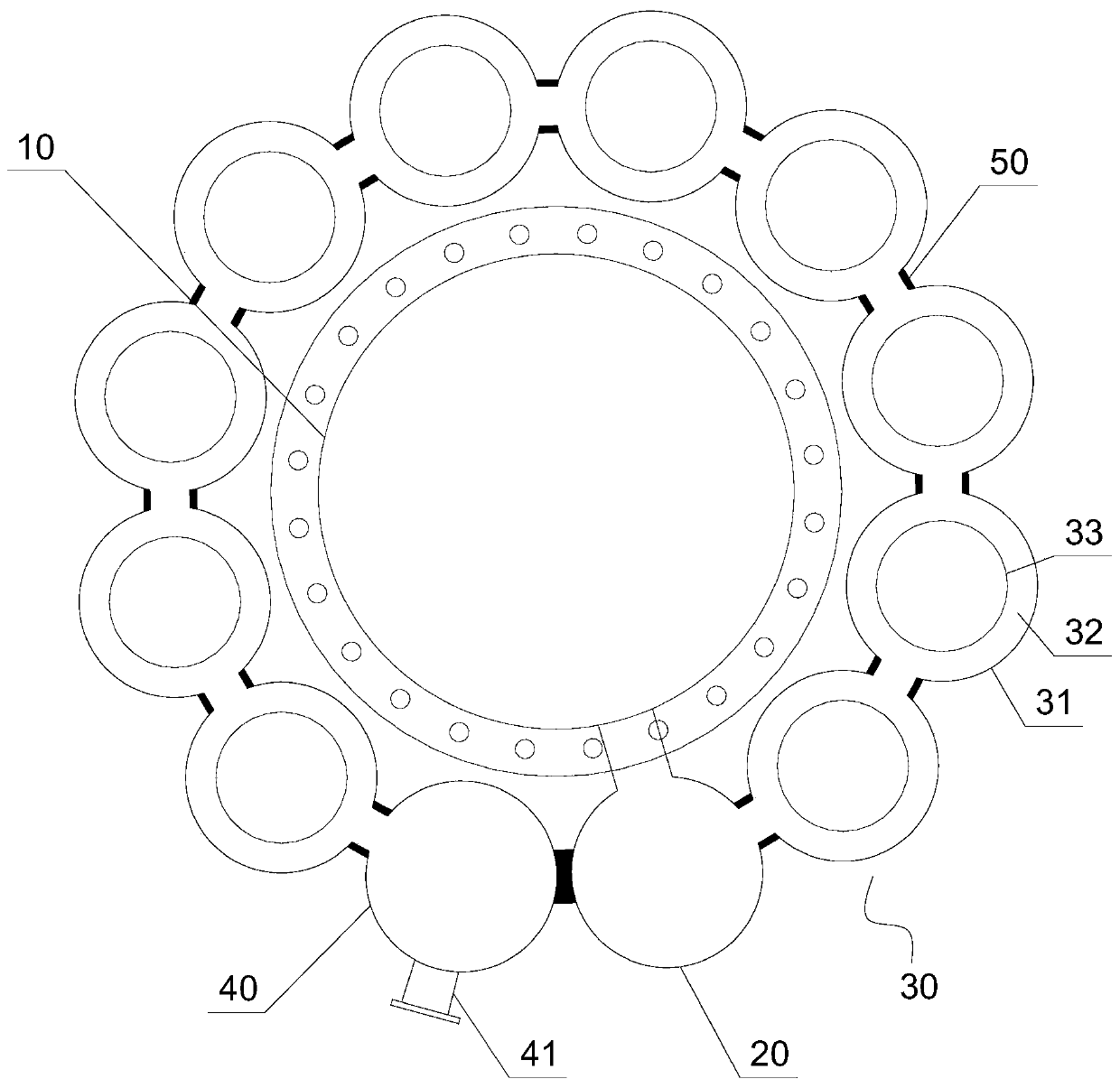

Low-nitrogen-emission combustion chamber and gas turbine including combustion chamber

InactiveCN106969380ASmooth ignitionSteady speed upContinuous combustion chamberNitrogen oxidesCombustion chamber

The invention relates to a low-nitrogen-emission combustion chamber and a gas turbine including the combustion chamber. The combustion chamber comprises a combustion chamber head part and a combustion chamber cylinder connected up and down; the combustion chamber head part includes a secondary gas mechanism, a main gas mechanism encircled at the external of the secondary gas mechanism, and an air inlet formed above the secondary gas mechanism and the main gas mechanism; the combustion chamber cylinder includes an inner flame cylinder for respectively communicating with the secondary gas mechanism, the main gas mechanism and the air inlet, and an outer flame cylinder encircled at the external of the inner flame cylinder and communicating with the air inlet; and a combustion chamber outlet is formed in the bottom of the inner flame cylinder. Compared with the prior art, the combustion chamber can prominently reduce the nitrogen oxide emission of a micro gas turbine combustion chamber, improves the combustion efficiency, and realizes wide-load, low-emission and high-efficiency stable operation under 40-100%; and the gas flows in a main gas pipe and a secondary gas pipe are adjusted, so that the simple cycle and the bring-back thermal cycle can be flexibly converted, and the economy is excellent.

Owner:TONGJI UNIV

Ethanol engine cold-starting device and method

ActiveCN101144456AImproved cold start performanceDriving Emissions and EconomicsElectrical controlMachines/enginesElectric energyCombustion chamber

The invention discloses an ethanol cold starting device and a cold starting method. The device comprises an engine cylinder cover, a heater, a cold starting signal lamp, a solenoid valve, a water sensor and a heater temperature sensor, wherein, the heater is installed at the position near to the spark plug in the cylinder cover combustion chamber; the heater, the solenoid valve, the cold starting signal lamp and the battery as well as the key switch are connected in a circuit in series, the engine electric controlling unit ECU judges whether to use the device through the temperature fed back by the water temperature sensor. When the temperature fed back by the water temperature sensor is below-15degrees below zero centigrade, the ECU can switch on the solenoid valve. When the key switch is closed, the circuit is switched on, and the heater can heat the self temperature to more than 700 centigrade within 10 seconds through the electricity of the battery and heat the air in the cylinder, to reach the purpose of smooth ignition under low temperature. Through the above device and method, the problem of the cold starting of high proportion ethanol gasoline is well solved, and thereby to promote the emission and the economical efficiency to be improved.

Owner:CHERY AUTOMOBILE CO LTD

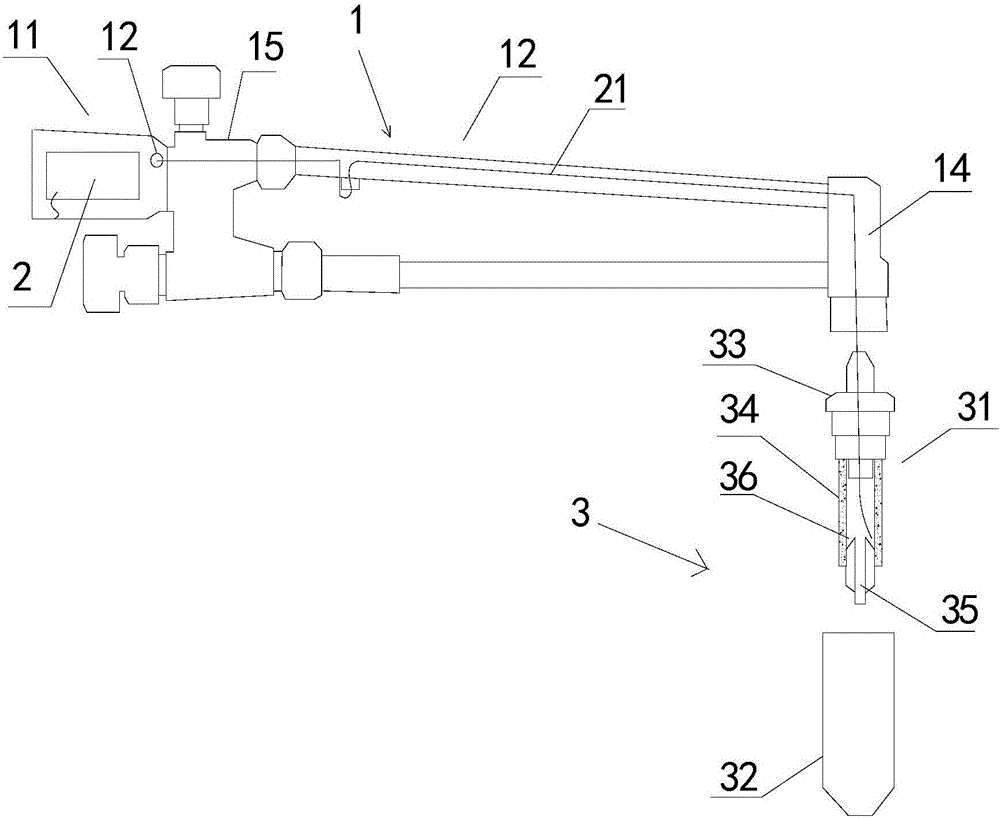

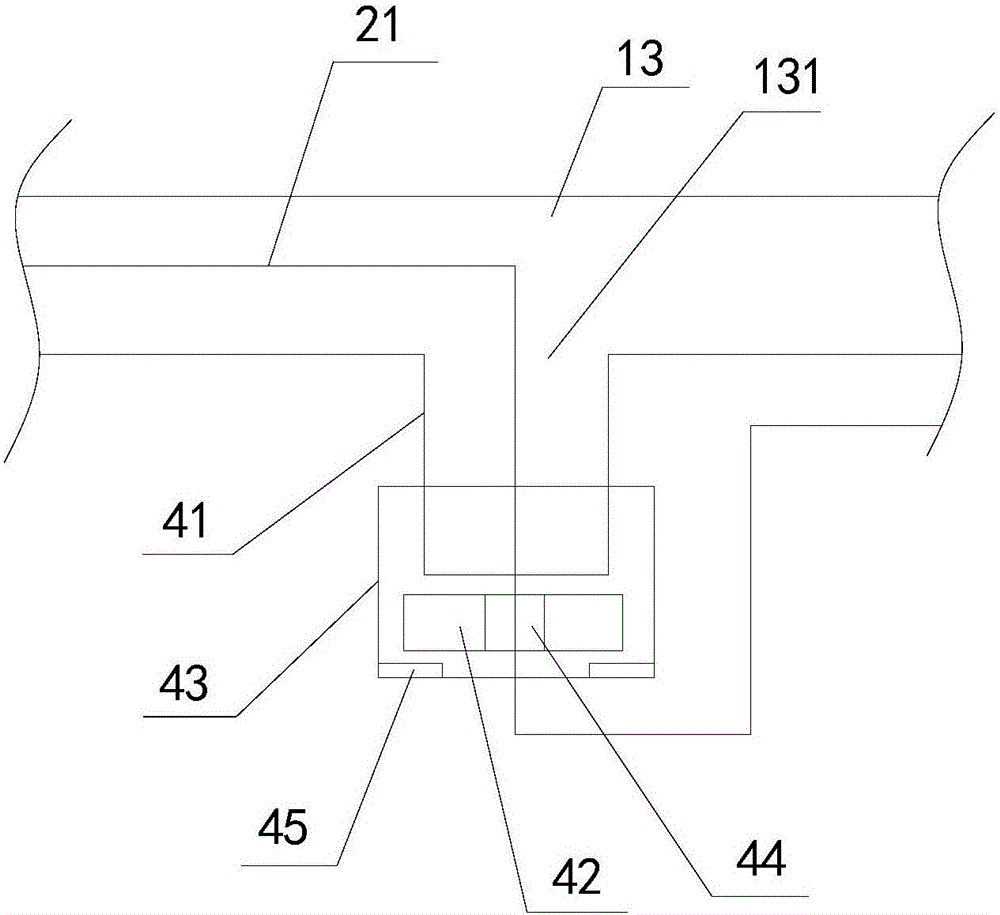

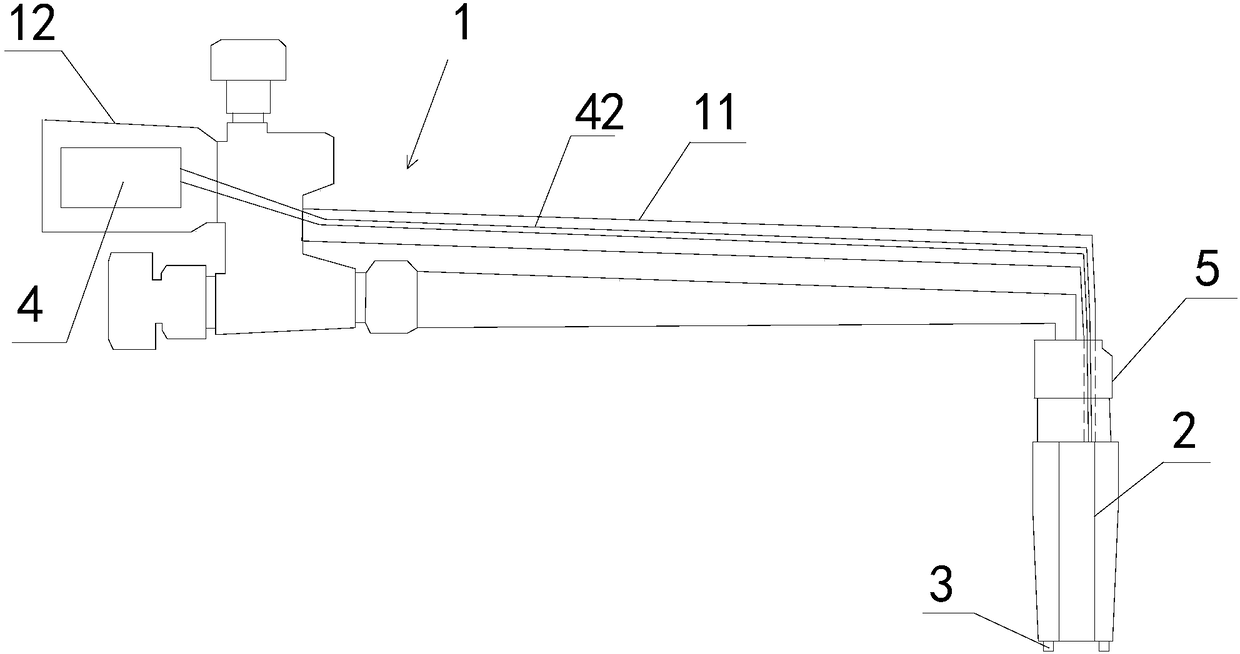

Electronic automatic internal ignition device of cutting torch

PendingCN106765303AAvoid Burn HazardsSmooth ignitionElectric spark ignitersGaseous fuel burnerElectricityDirect-current discharge

The invention discloses an electronic automatic internal ignition device of a cutting torch. The electronic automatic internal ignition device of the cutting torch comprises a cutting torch body, a cutting nozzle and a direct current discharge device arranged on the cutting torch body. The cutting nozzle comprises a nozzle core and a nozzle cap sleeving the nozzle core. The nozzle core comprises a nozzle cap connecting threaded port, an insulator and an oxygen outlet nozzle which are connected in sequence. One electrode of the direct current discharge device is electrically connected with the oxygen outlet nozzle, the other electrode of the direct current discharge device is electrically connected with the nozzle cap, and electric sparks can be generated between the nozzle cap and the oxygen outlet nozzle. By arranging the insulator, insulation between the oxygen outlet nozzle and the cutting torch body is achieved, and the insulator serves as one electrode of the direct current discharge device. The nozzle cap serves as the other electrode of the direct current discharge device, discharge between the oxygen outlet nozzle and the nozzle cap is achieved, and electric sparks are generated for ignition. Through the ignition mode, burning injuries to an operator can be avoided, and ignition can be conducted smoothly under the condition of outdoor strong wind.

Owner:徐慕庆

Efficient nano-enviornmental-protecting economical burner

InactiveCN101029731AEfficientHave synergyCombustion using catalytic materialCombustion apparatusComposite ceramicNano al2o3

This invention relates to nanometer oil-saving burning device of high efficiency of environment protection. The character is in that the materials used are silica gel, soot carbon and nanometer far IR material which has nanometer titanium oxide, silicon oxide, ferric oxide, zinc oxide, aluminum oxide, magnesia, composite ceramics powder. The oil-saving device of this invention utilizes the resonance theory of the latest nanometer technology so as to thin the oil and gas molecule and to reduce the resistance when conducting electricity. This can efficiently improve the burning efficiency of oil, electricity and gas so as to recover the horsepower, lower the oil consumption, reduce the waste gas and lower the noise.

Owner:广东拓扑中润科技发展有限公司

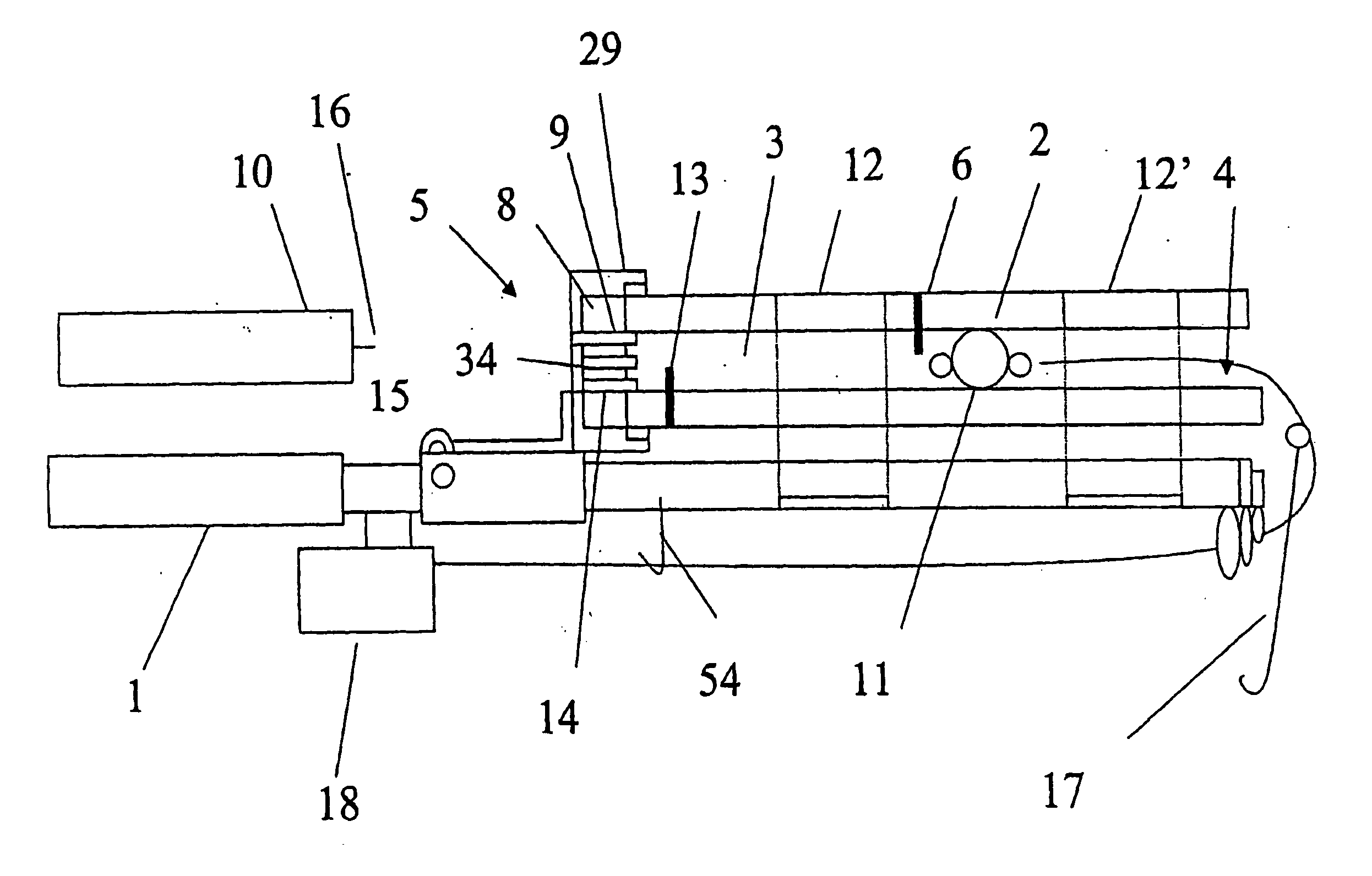

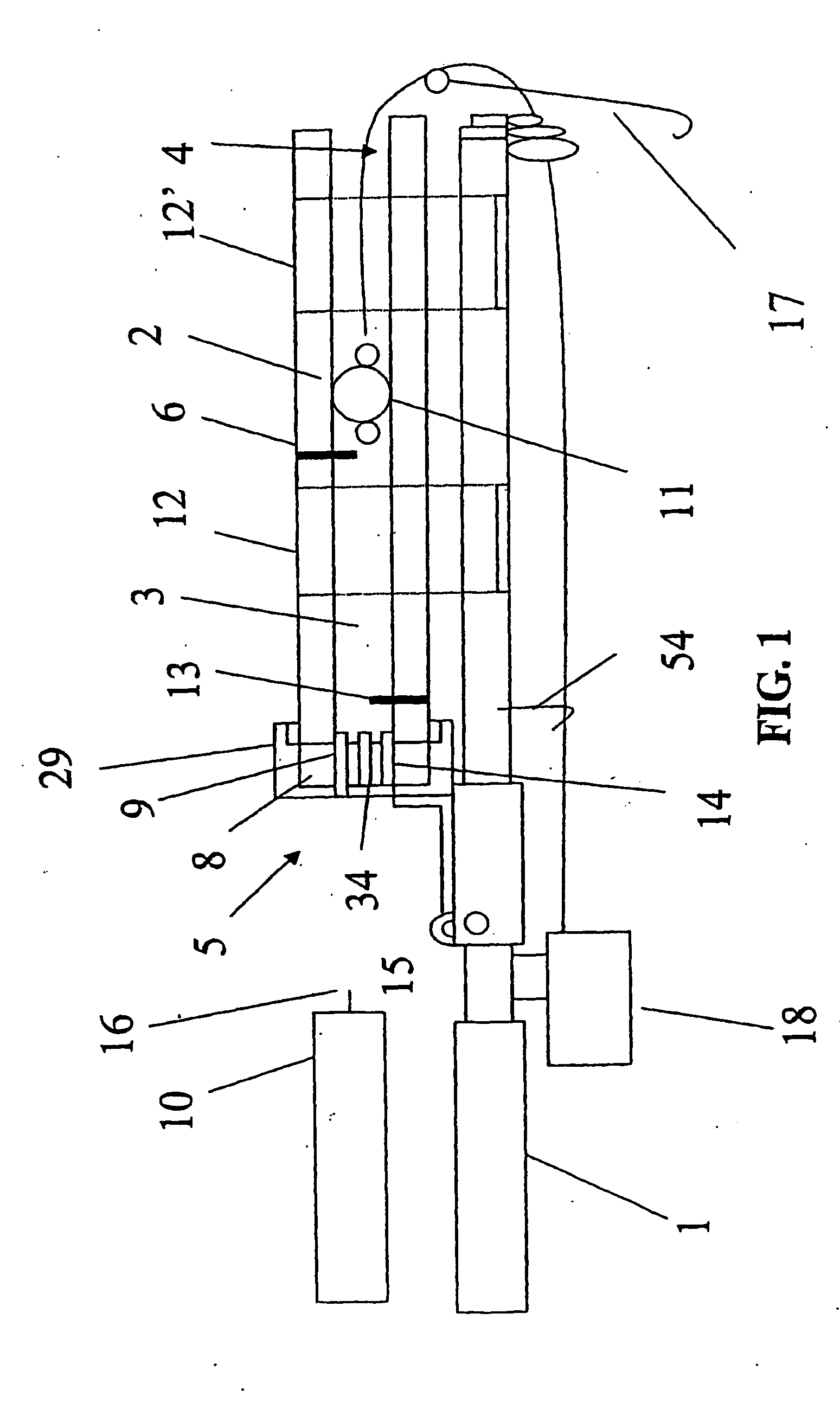

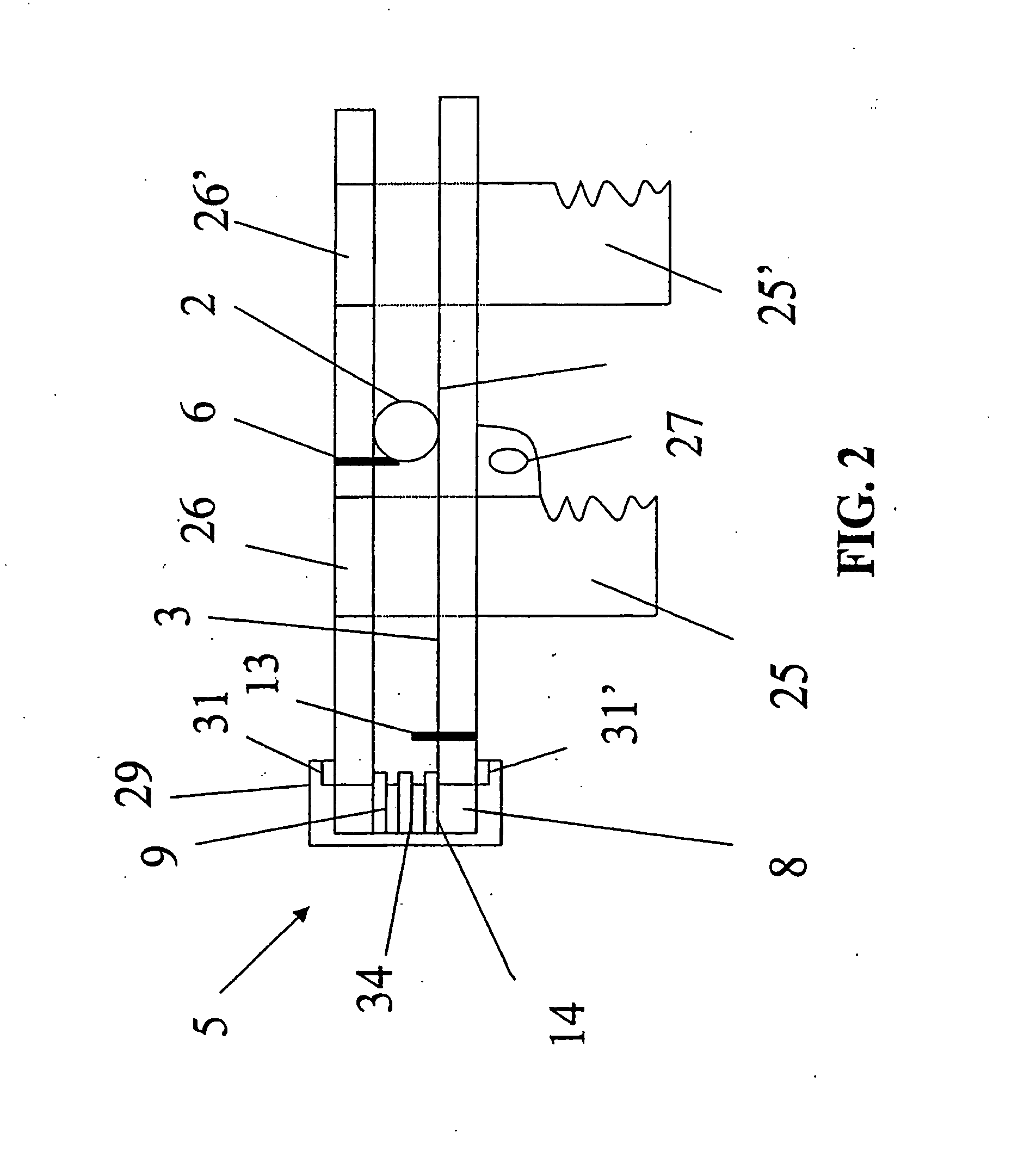

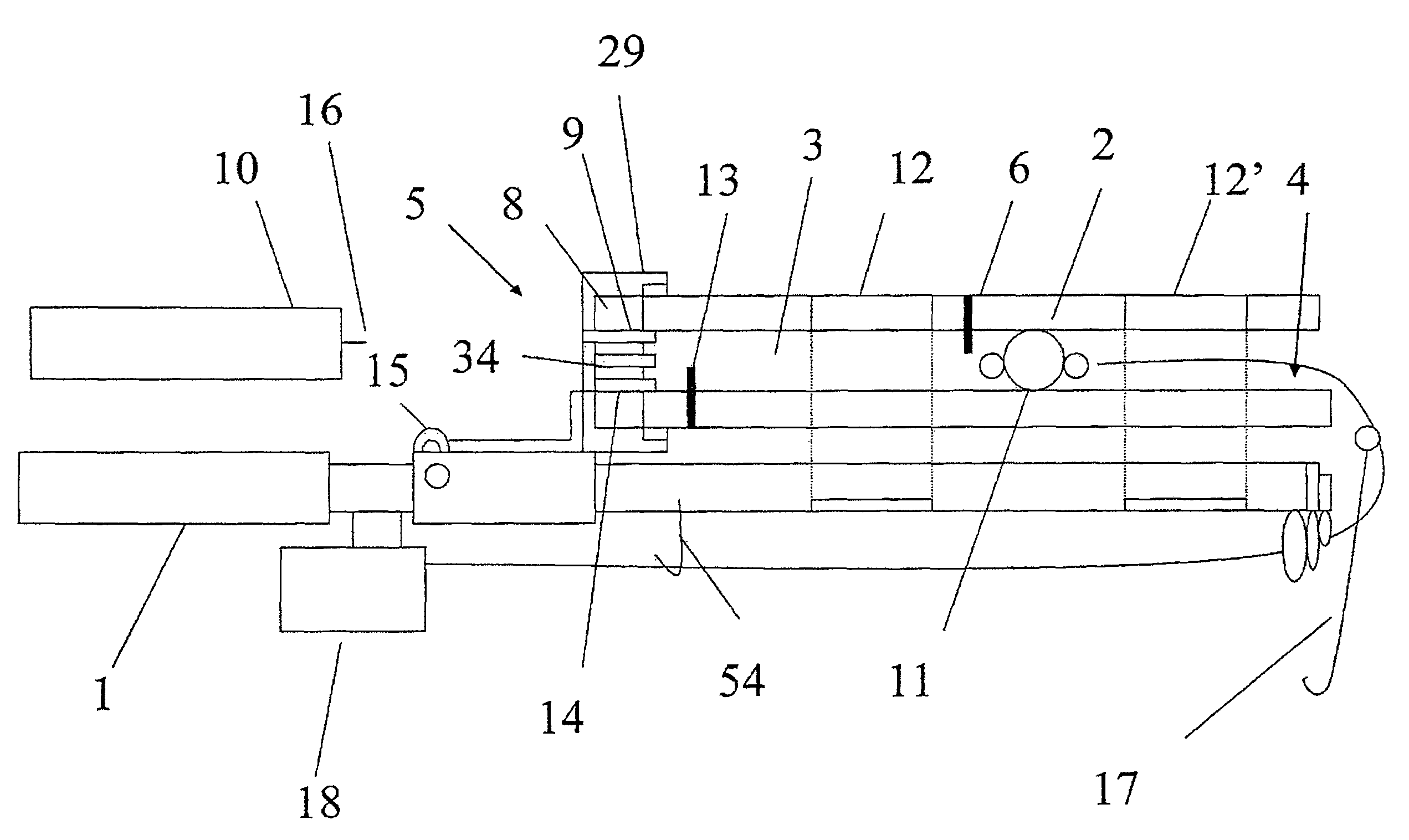

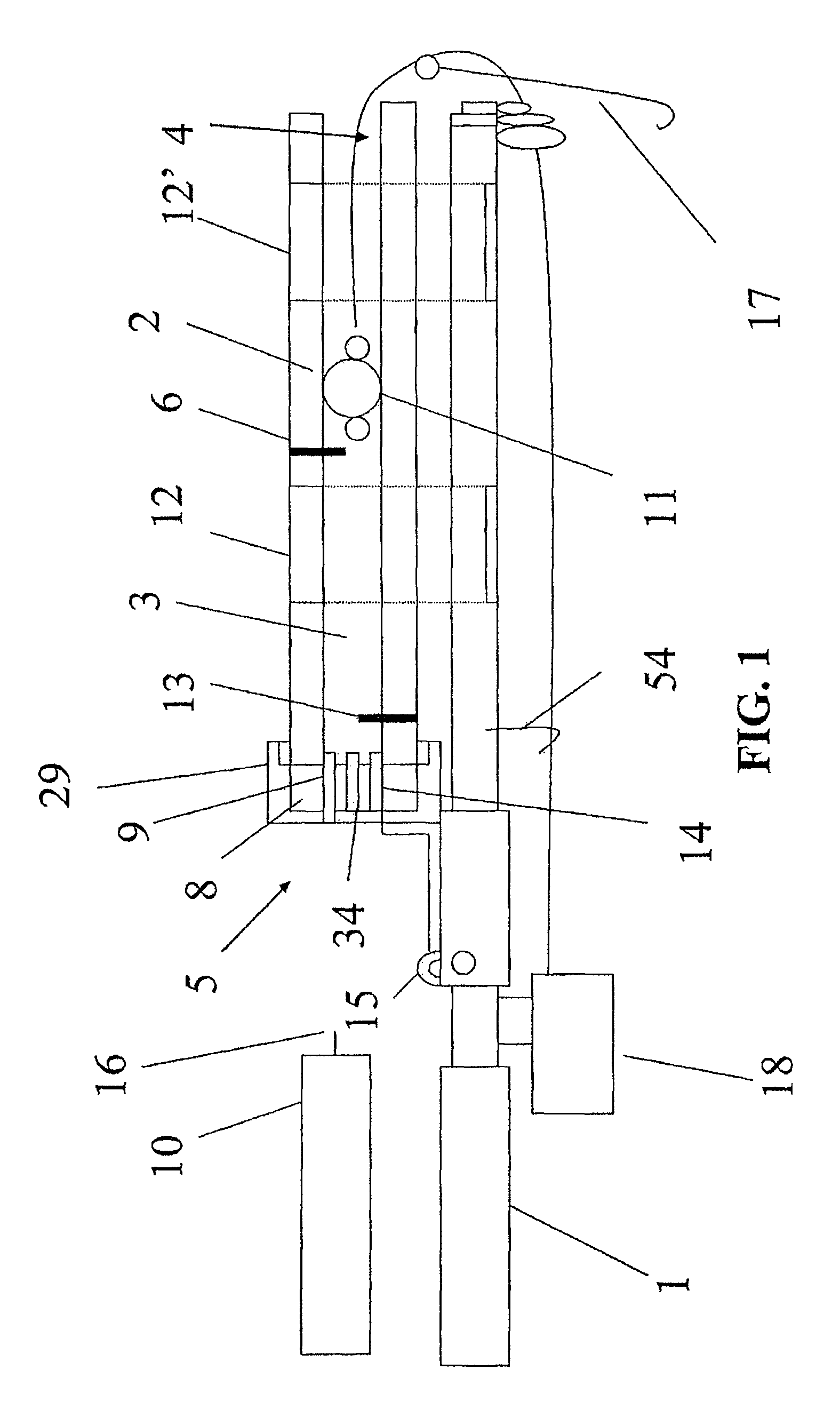

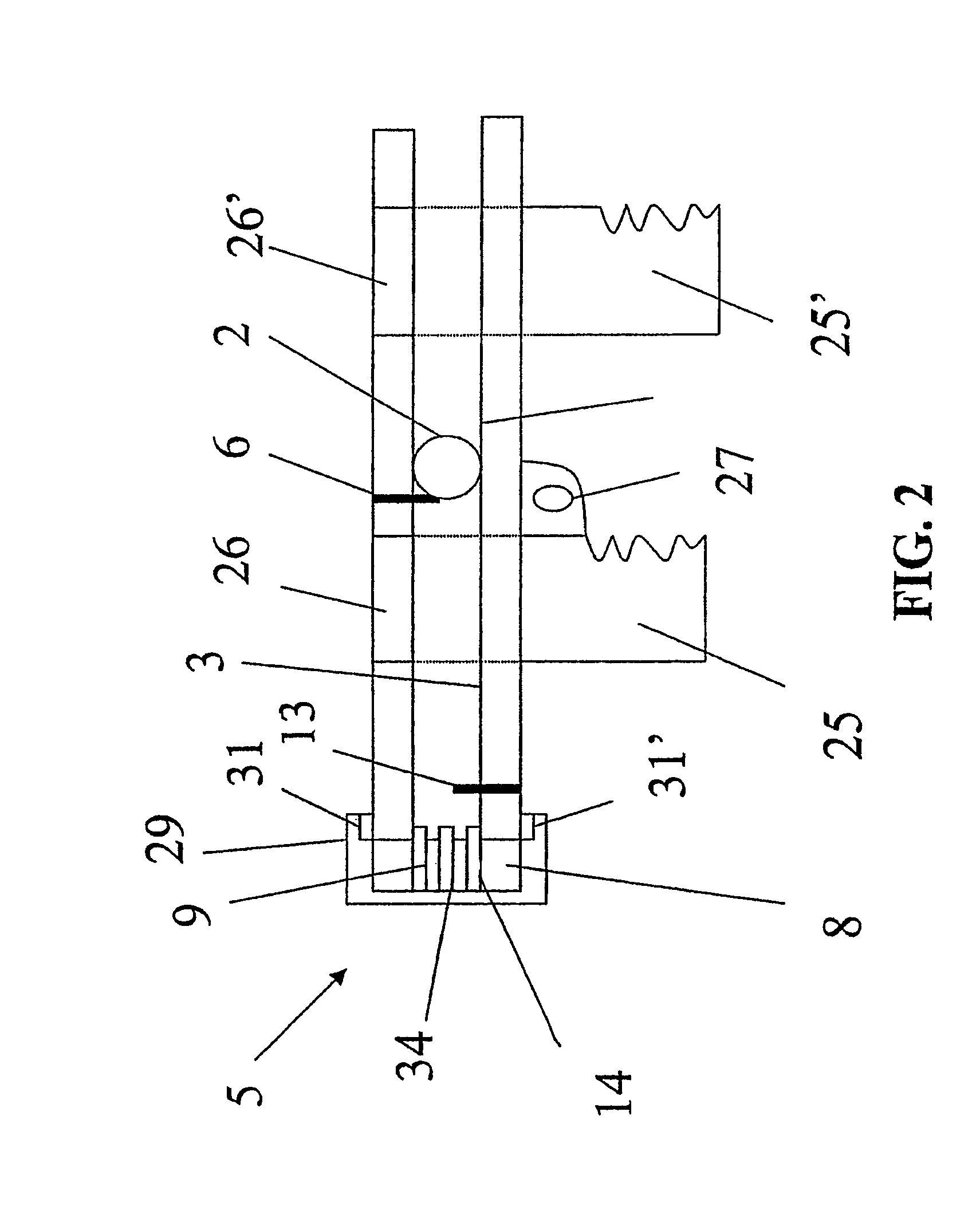

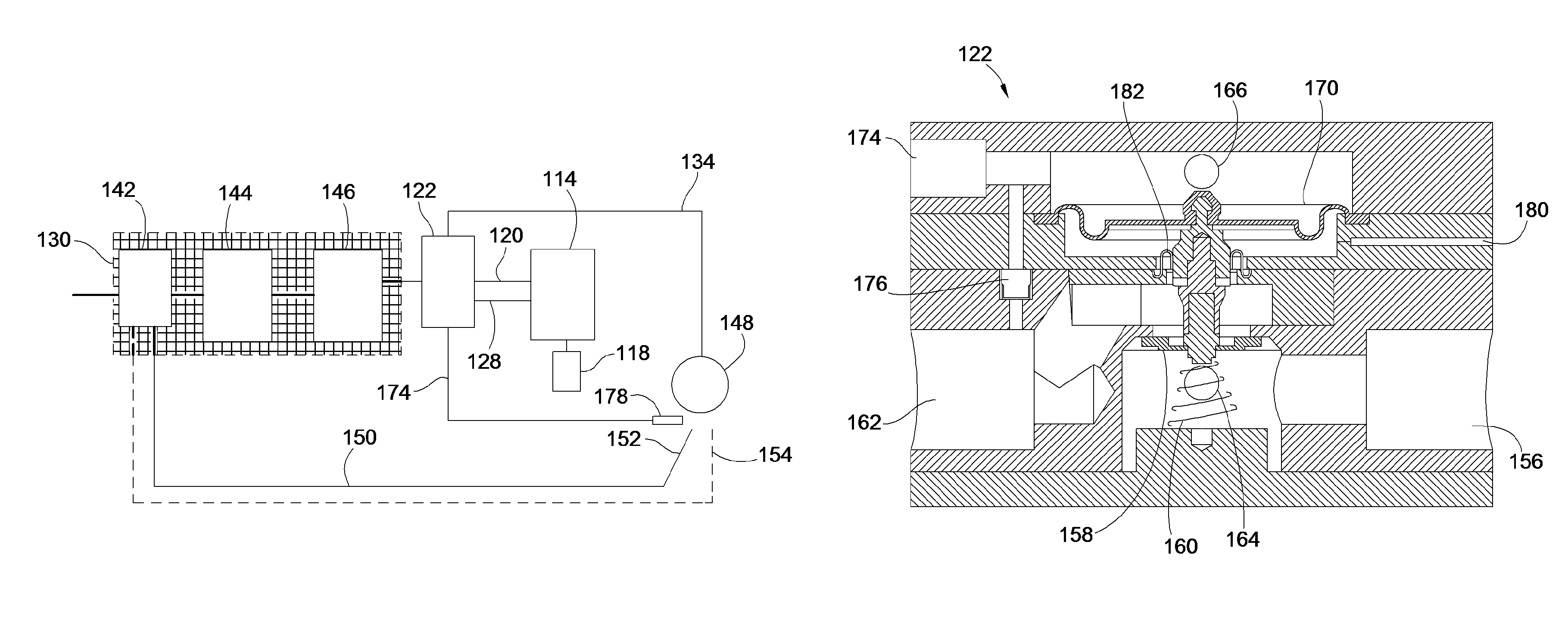

Apparatus and method for fishing

An apparatus for releasable attachment to a fishing rod, said apparatus including: a barrel having a first end and a releasably sealed first region; wherein the first region of the barrel includes a space within the barrel substantially bounded by a second end of the barrel and a protrusion disposed inside the barrel; and a means of selectably adjusting the volume of the first region including adjusting the position of the protrusion along a length of the barrel; and wherein when the protrusion is disposed inside the barrel, it extends radially-inwardly of the barrel in a substantially transverse orientation to an elongate axis of the barrel; and a means of controllably feeding a propellant into the releasably sealed first region; and a means of expanding the propellant whereby the said expansion of the propellant causes a projectile disposed within the barrel to be propelled outwardly of the barrel via the first end.

Owner:MAMAE TAUTOFI TAURIKI

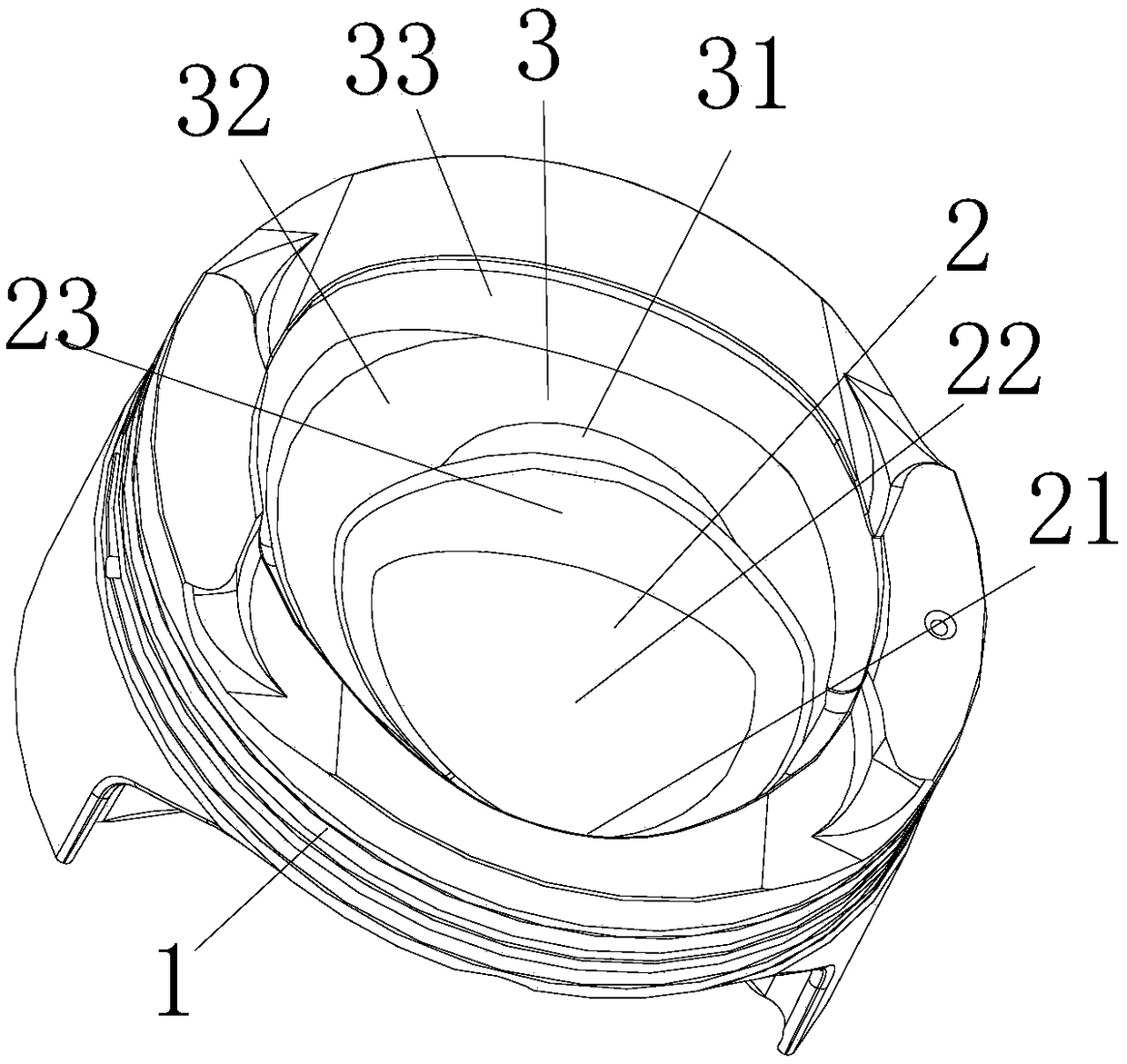

Kitchen range fire cover

ActiveCN110220194AAvoid flowing intoAvoid accumulationDomestic stoves or rangesGaseous fuel burnerEngineeringFuel gas

The invention discloses a kitchen range fire cover. The surface of the kitchen range fire cover is provided with a flame groove which communicates with a flue gas cavity, the kitchen range fire coveris further provided with an ignition hole and a groove, the groove corresponds to the ignition hole, an opening, on the side wall of the kitchen range fire cover, of the ignition hole is located in the flame groove, the groove makes contact with one side of the opening of the ignition hole, the hole side wall of the ignition hole is cut through, and therefore an opening space is formed on one sideof the ignition hole. According to the kitchen range fire cover, since the ignition hole is formed in the flame groove which communicates with the fuel gas cavity, and the groove is formed in one side of the ignition hole, the opening side of the ignition hole for the outside world is improved, the fuel gas amount of the ignition hole at the opening position is increased, and smooth ignition of akitchen range is ensured. In addition, the diameter of the ignition hole does not need to be increased by means of the structure, the low flow speed of flue gas can be kept at the opening position ofthe ignition hole, the flame leaving condition is avoided, flame stability during ignition is ensured, and the flame stabilizing effect is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

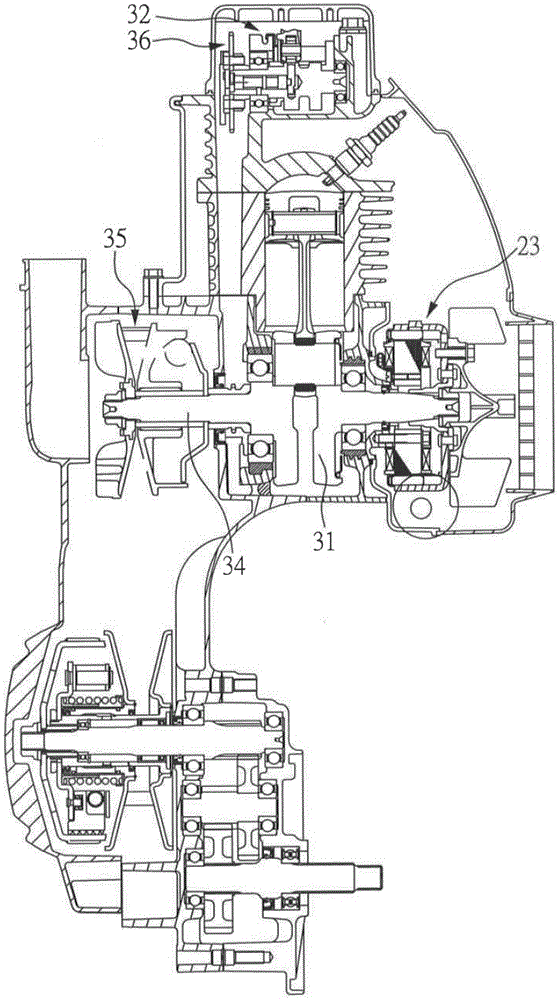

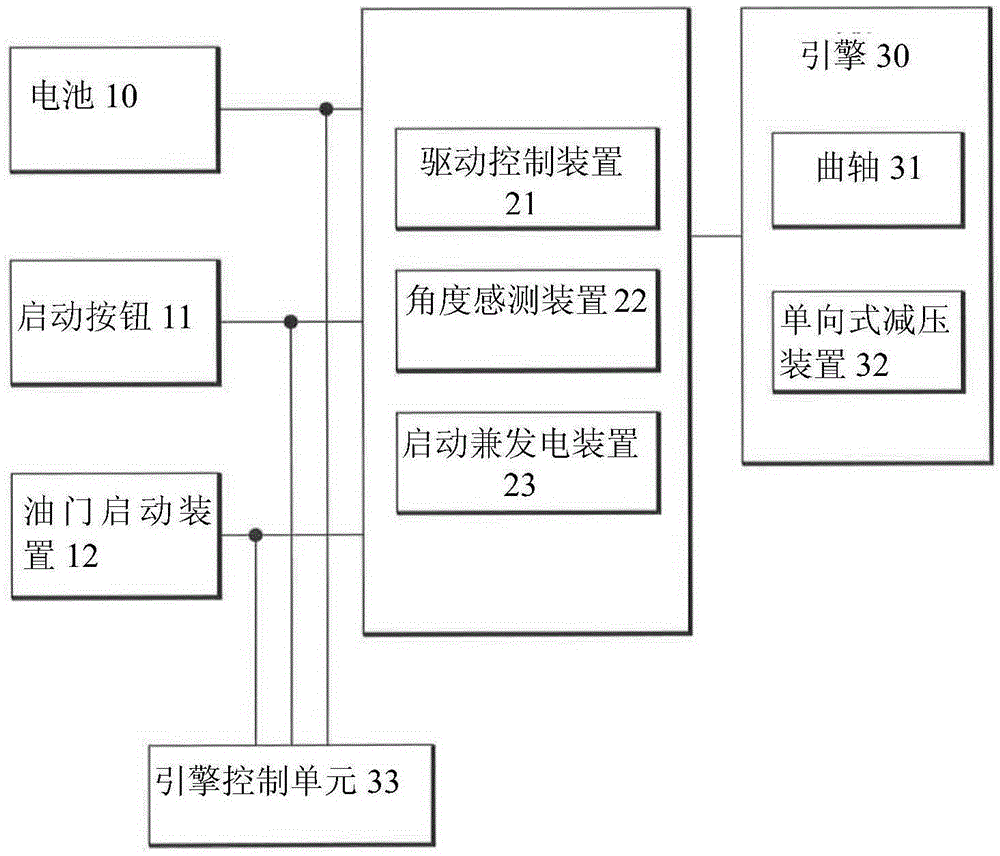

Engine starting and stopping running control method

ActiveCN106545420AImprove riding performanceIncrease inertiaEngine controllersMachines/enginesRotation - actionPressure reduction

The invention relates to an engine starting and stopping running control method. A starting control method comprises the steps that A, whether an engine starting signal is received or not is judged; B, a bent axle is driven to reversely rotate within a certain angle range, and a pressure reduction device is made to act; C, the bent axle is driven to forwards rotate, an engine is made to be started, whether the rotation speed of the bent axle is larger than the engine starting threshold rotation speed or not is judged, if the rotation speed of the bent axle is larger than the engine starting threshold rotation speed, the step D is executed, if the rotation speed of the bent axle is not larger than the engine starting threshold rotation speed, the step C is executed, whether the time of driving exceeds the preset time or not is judged, if the time of driving exceeds the preset time, driving is stopped, the step A is executed, and if the time of driving does not exceed the preset time, the step C is executed; and D, driving is stopped, and a power generation mode is executed. A stopping running control method comprises the steps that A, the angle of the bent axle is detected before the engine stops running, and whether the spontaneous reverse rotation action exists or not is judged, wherein if the spontaneous reverse rotation action exists, the step B is executed, and if the spontaneous reverse rotation action does not exist, the step C is executed; B, the spontaneous reverse rotation action is controlled, the bent axle reversely rotates within a certain angle range, and control is stopped after the pressure reduction device acts; and C, the bent axle is driven to forwards rotate within a certain angle range, then the bent axle is driven to reversely rotate within a certain angle range, and control is stopped after the pressure reduction device acts.

Owner:SANYANG IND CO LTD

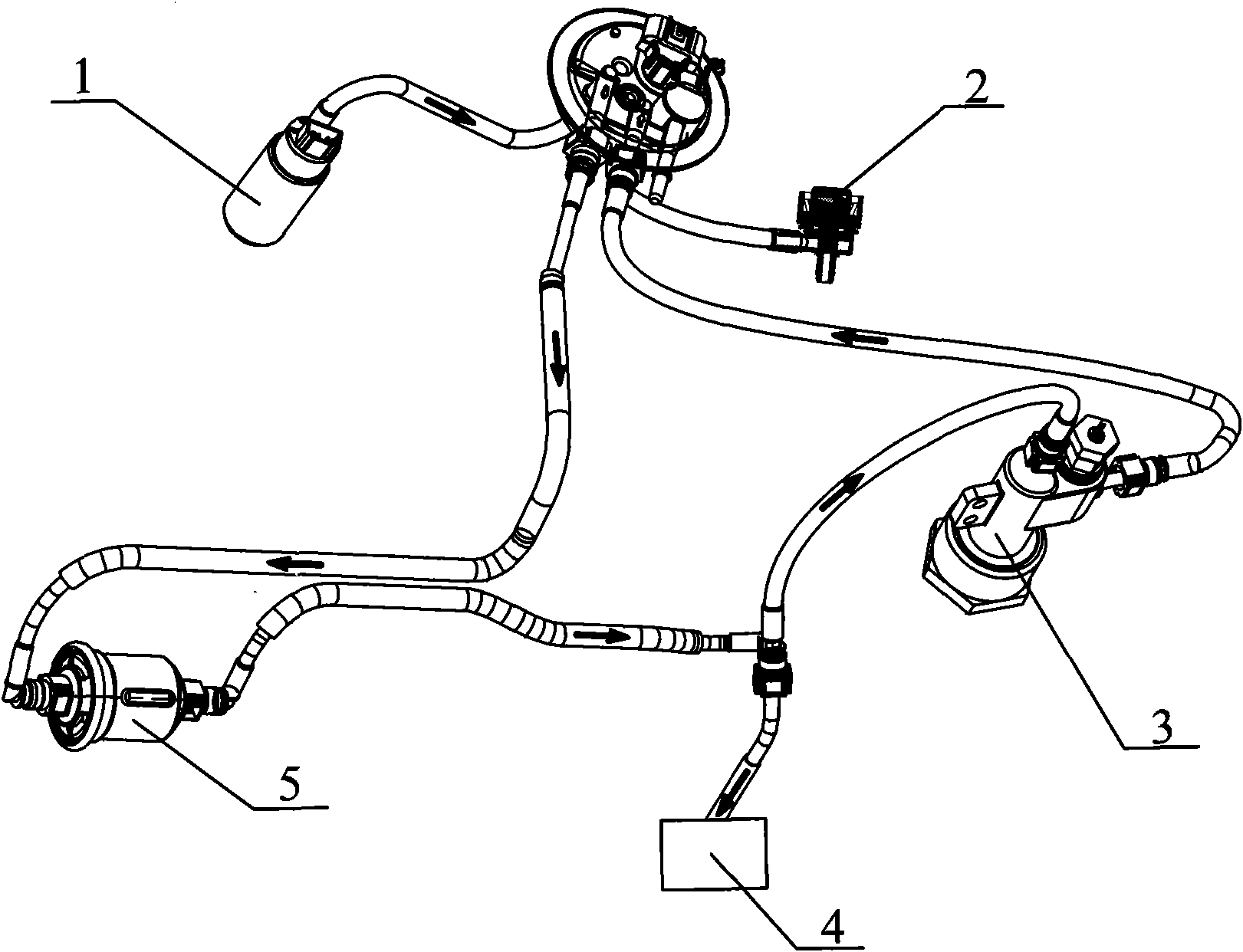

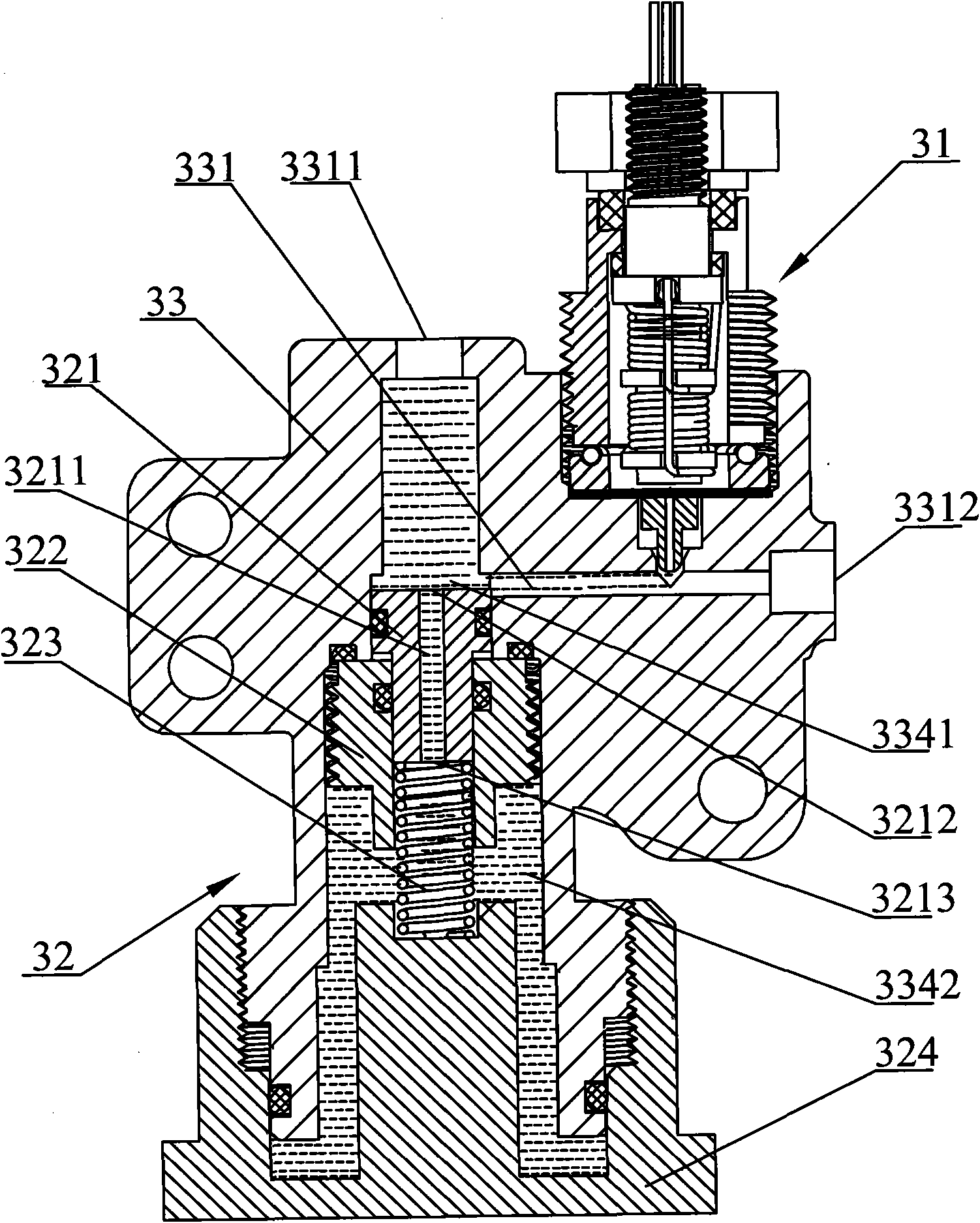

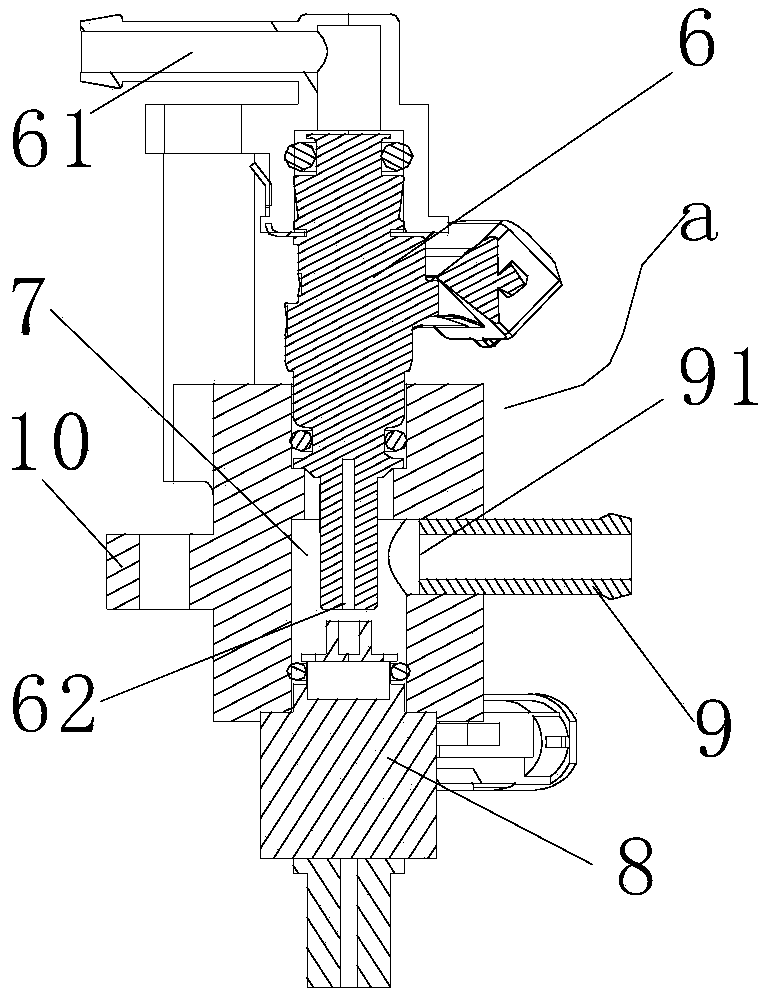

Pressure regulating valve for oil supply line of engine

ActiveCN102116231ASmooth ignitionIncrease pressureEngine controllersMachines/enginesHigh pressureOil supply

The invention provides a pressure regulating valve for an oil supply line of an engine. The pressure regulating valve provided by the invention comprises a valve body, a valve plug and an iron core coil assembly, wherein the valve body is provided with a through channel; the valve plug is used for regulating the opening degree of the channel; the iron core coil assembly is used for operating the valve plug to regulate the opening degree of the channel; the magnetic force of the iron core coil assembly is controlled by the ignition switch of the engine; when the engine is ignited, the opening degree of the channel of the valve body is regulated to the minimum; and when the engine is started completely, the channel is completely started by the valve plug under the magnetic action of the iron core coil assembly. Compared with the existing pressure regulating device for the oil supply line of the engine, the pressure regulating valve provided by the invention is additionally arranged in the oil supply line of the engine, so that at the ignition stage of the engine, the opening degree of the oil supply line is regulated to the minimum by the pressure regulating valve, thus the pressure in the oil supply line increases instantly, high-pressure oil is provided for the ignition of the engine, and the engine can be ignited smoothly.

Owner:BYD CO LTD

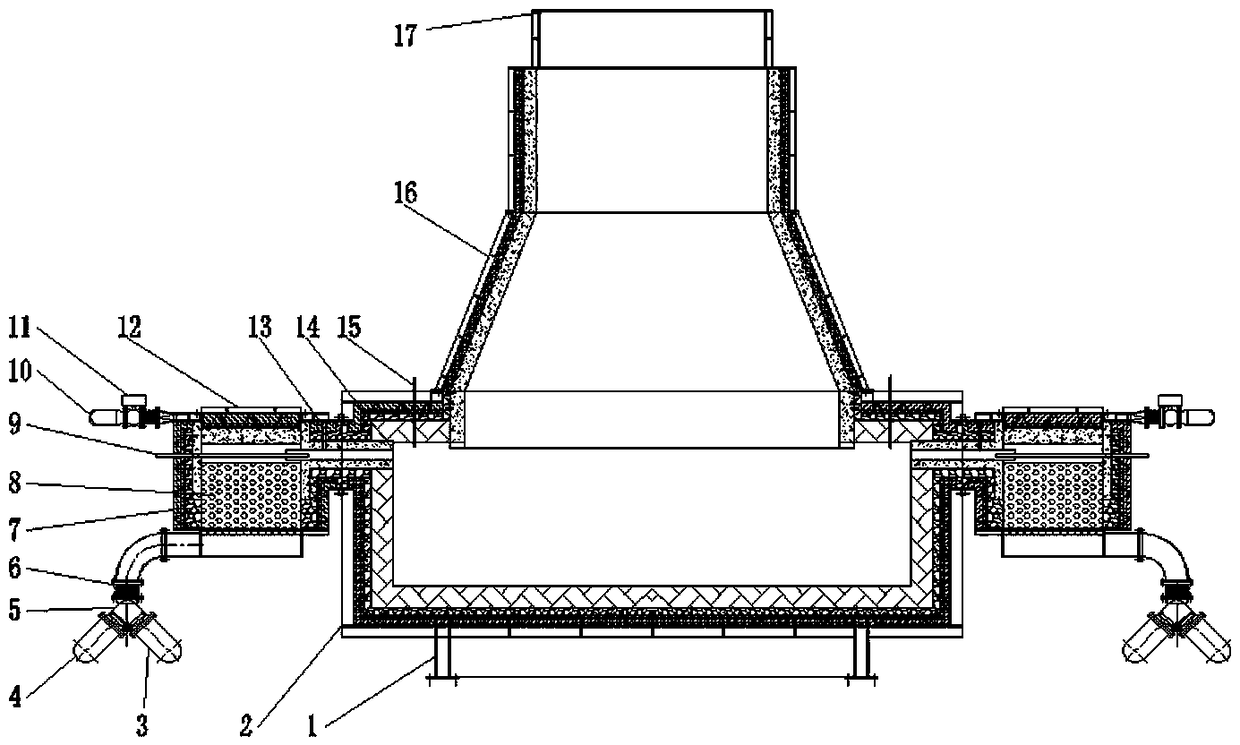

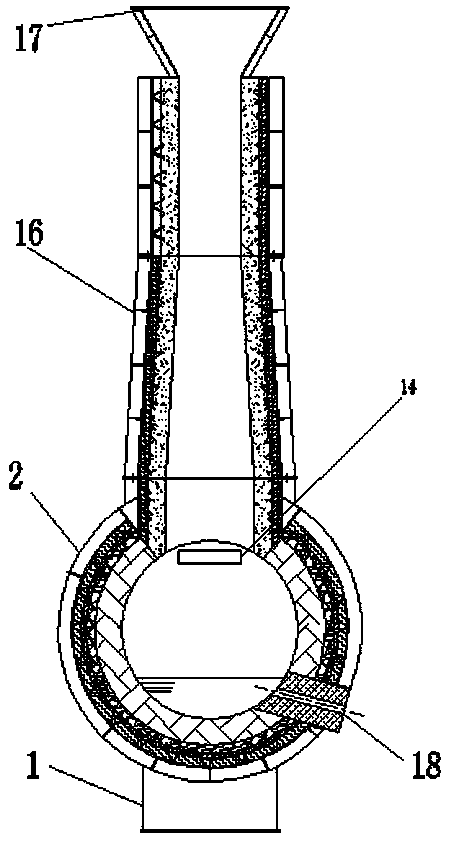

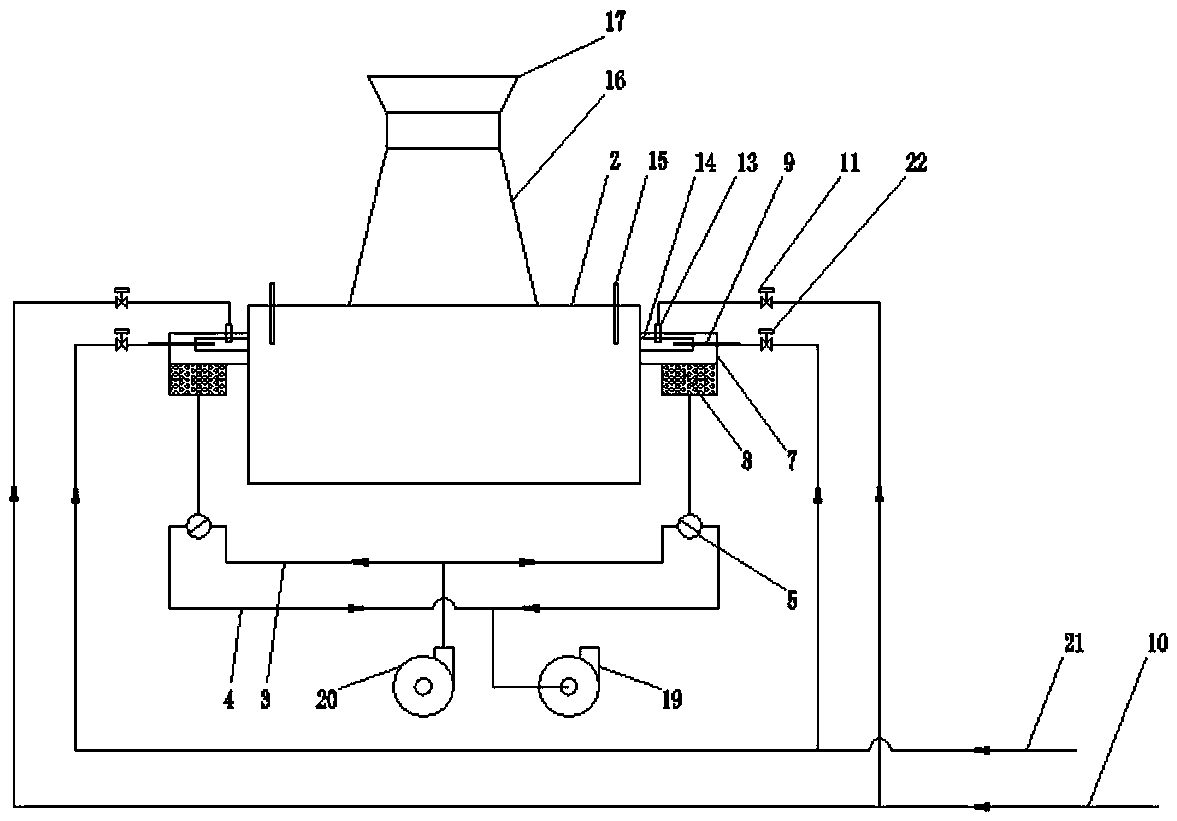

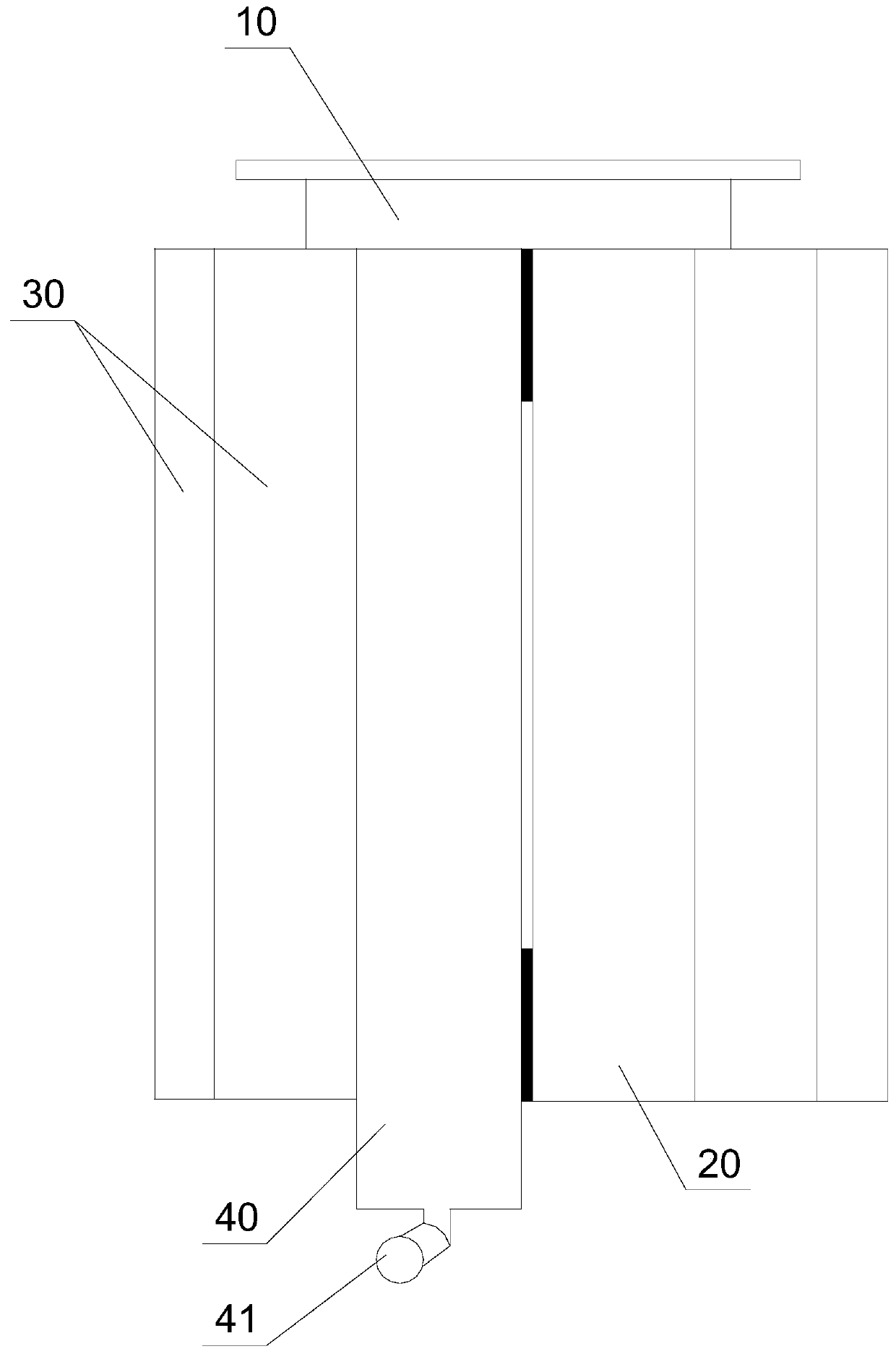

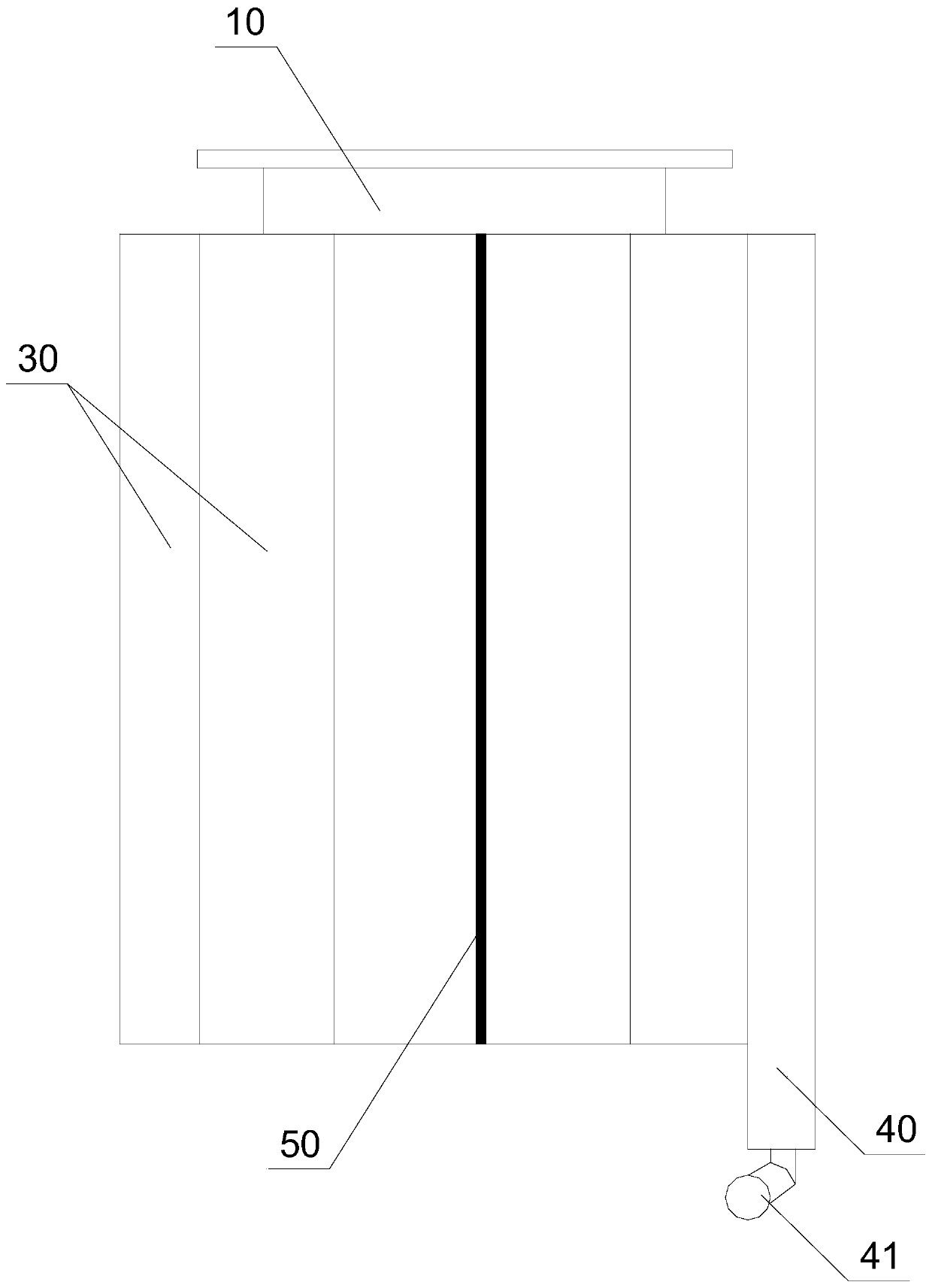

Heat accumulating type fuel gas and fuel coal steel scrap melting furnace

PendingCN108800926ASmooth ignitionExtend your lifeCharge manipulationCrucible furnacesMolten steelHigh pressure

The invention relates to iron and steel smelting equipment, in particular to a heat accumulating type fuel gas and fuel coal steel scrap melting furnace which solves the problem of steel scrap smelting. The technical scheme is as follows: the Heat accumulating type fuel gas and fuel coal steel scrap melting furnace comprises a base, a furnace body and a charging channel. The base is located belowthe furnace body, the charging channel is arranged above the furnace body and communicates to the furnace body, a tap hole is formed in the lower part of the furnace body, a heating device is arrangedon the side face of the furnace body and communicates to the furnace body through a nozzle spray head, and a high voltage electronic burning torch is arranged in front of the nozzle spray head. According to the system, steel scrap is added intermittently and is heated continuously to be melted, and molten steel is discharged intermittently. According to the heat accumulating type fuel gas and fuel coal steel scrap melting furnace, the steel scrap can be melted with a low cost: the cost is saved by 400-500 yuan / ton compared with that of directly using an electric furnace.

Owner:忻州立泊装备制造有限公司

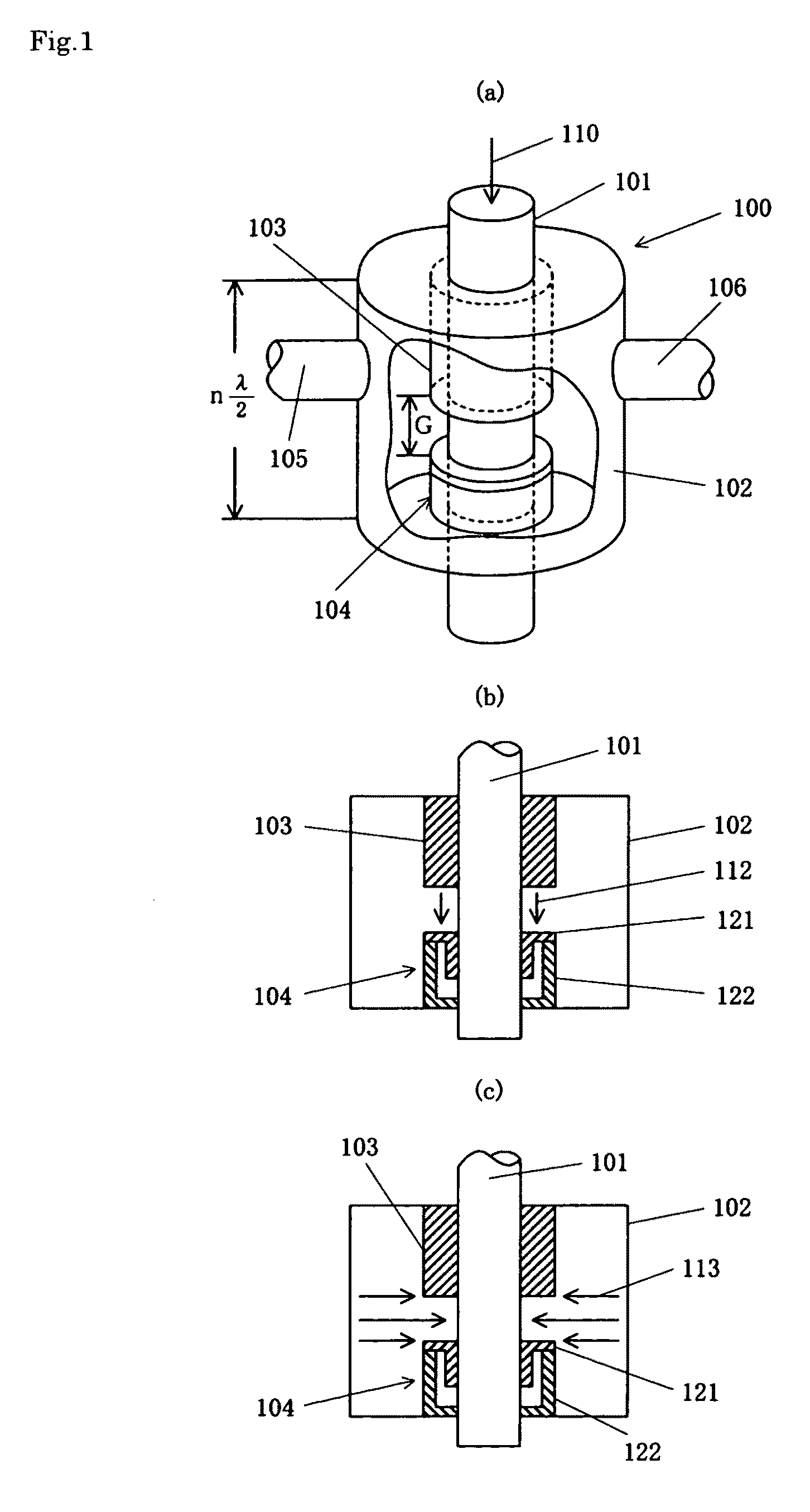

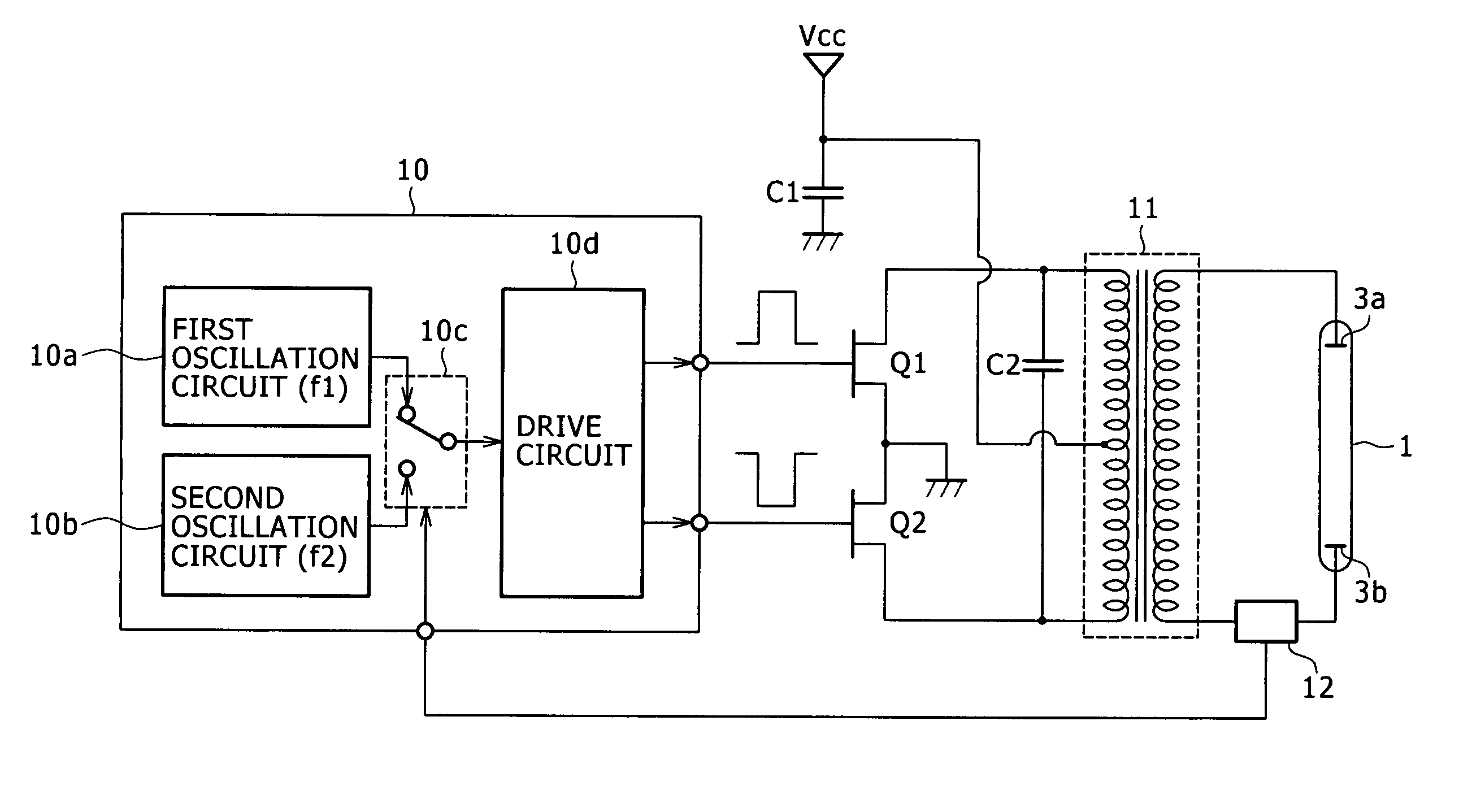

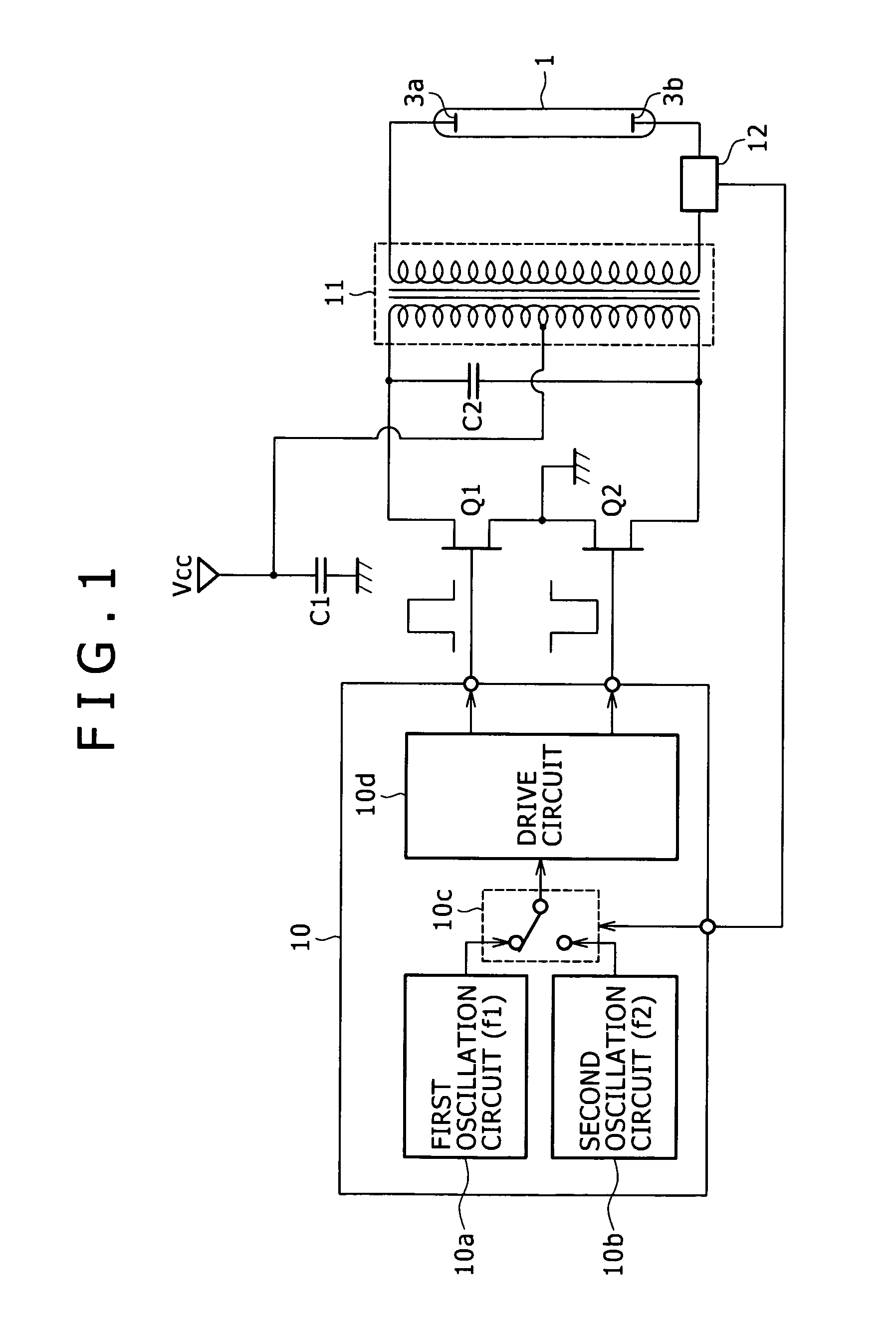

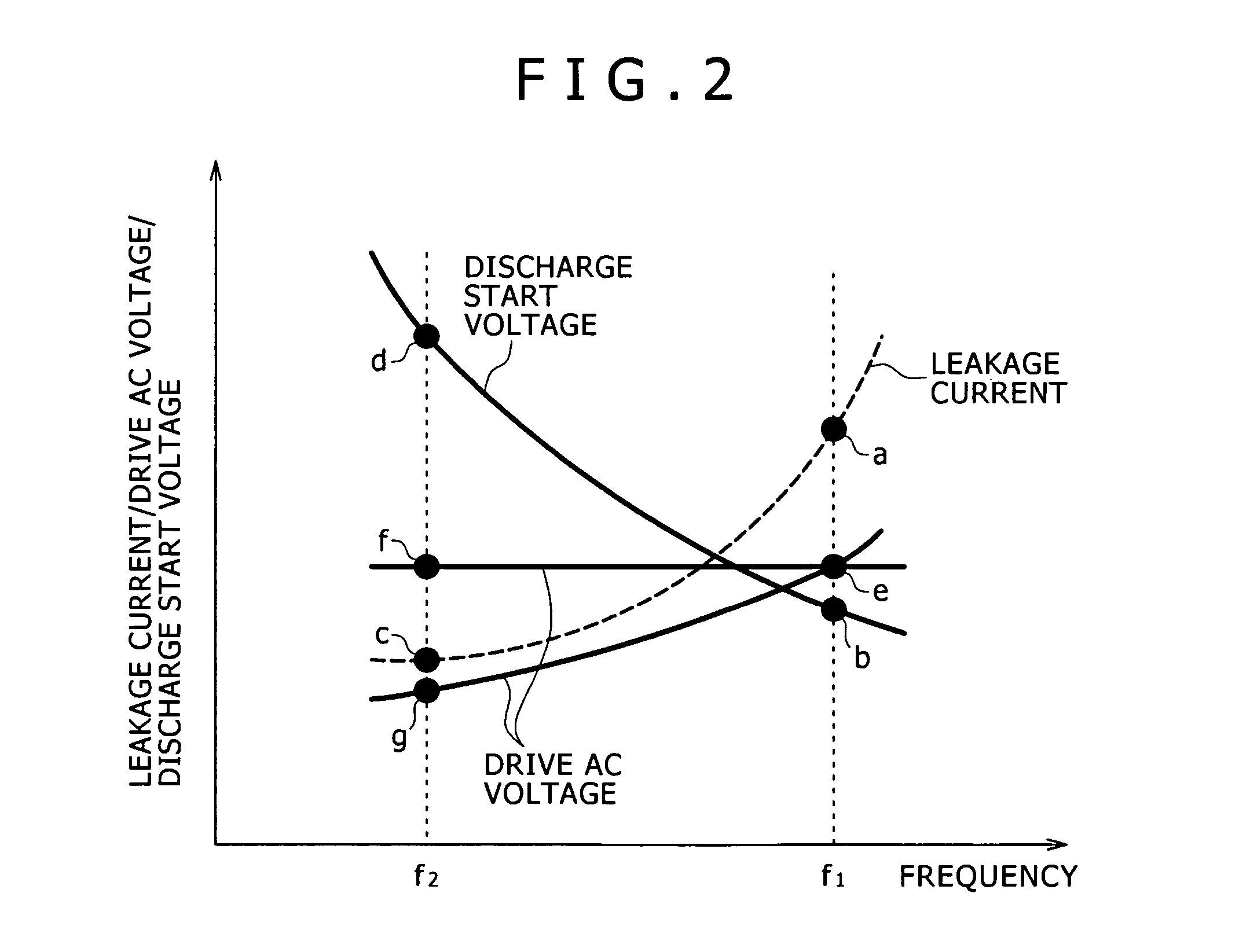

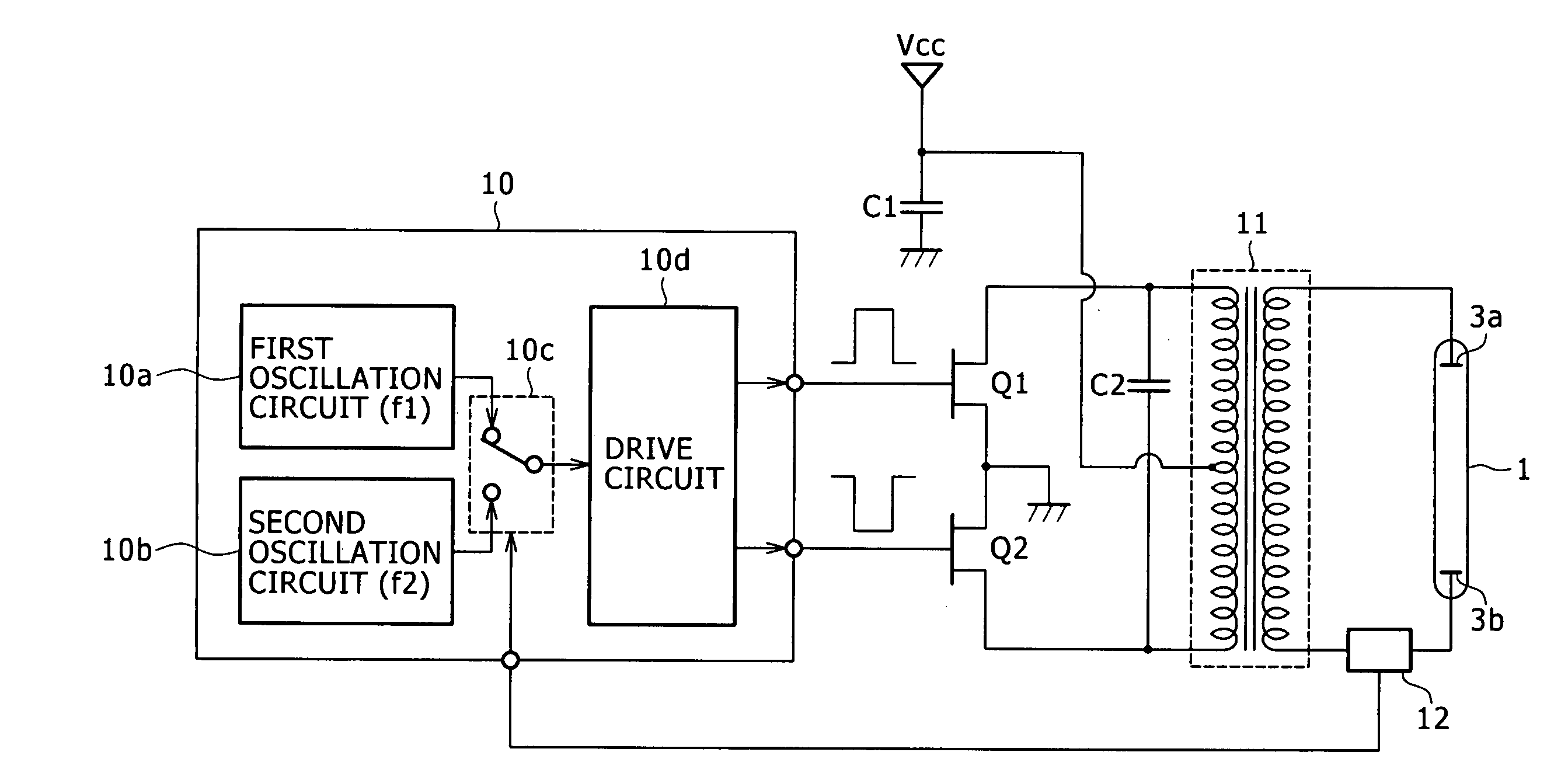

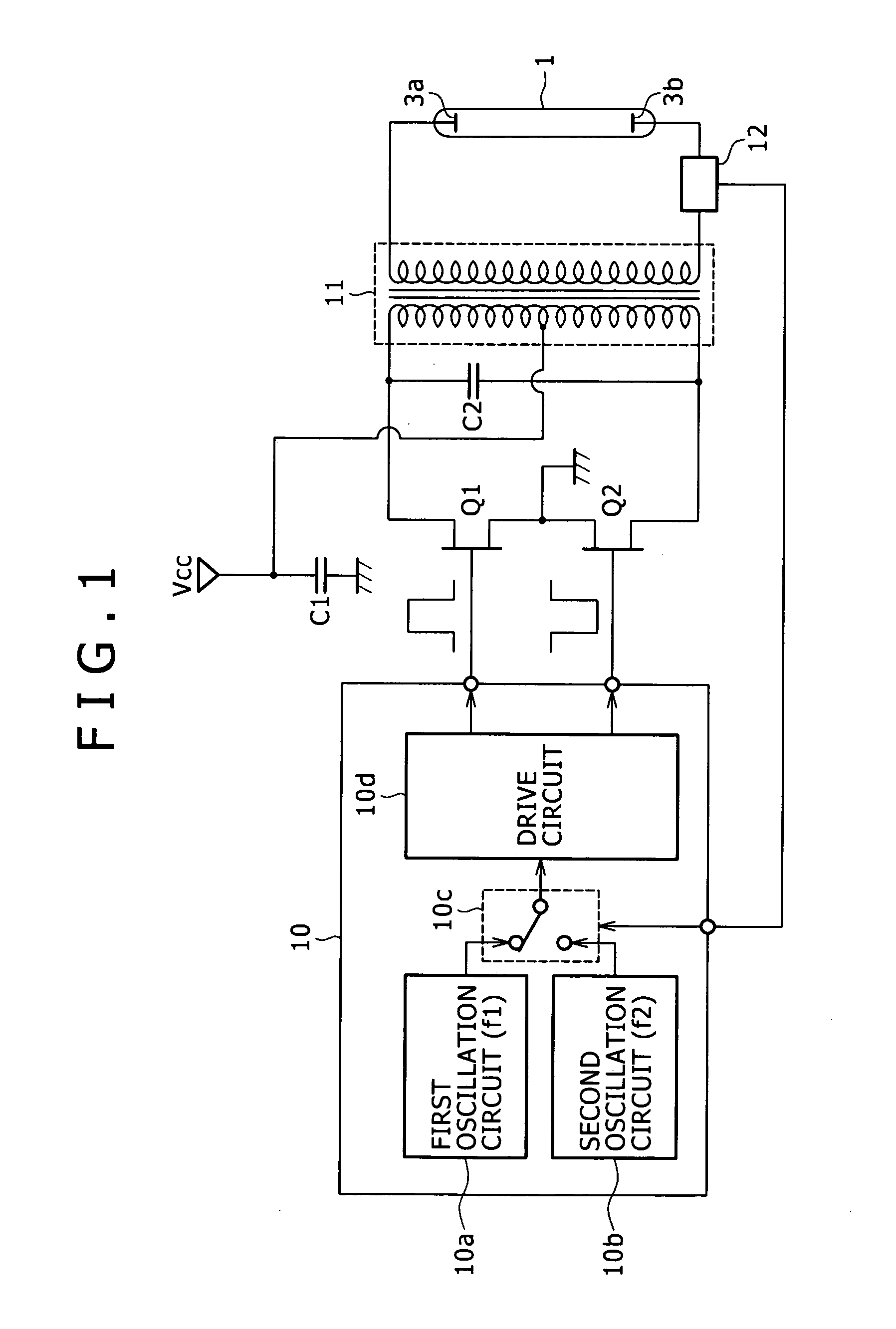

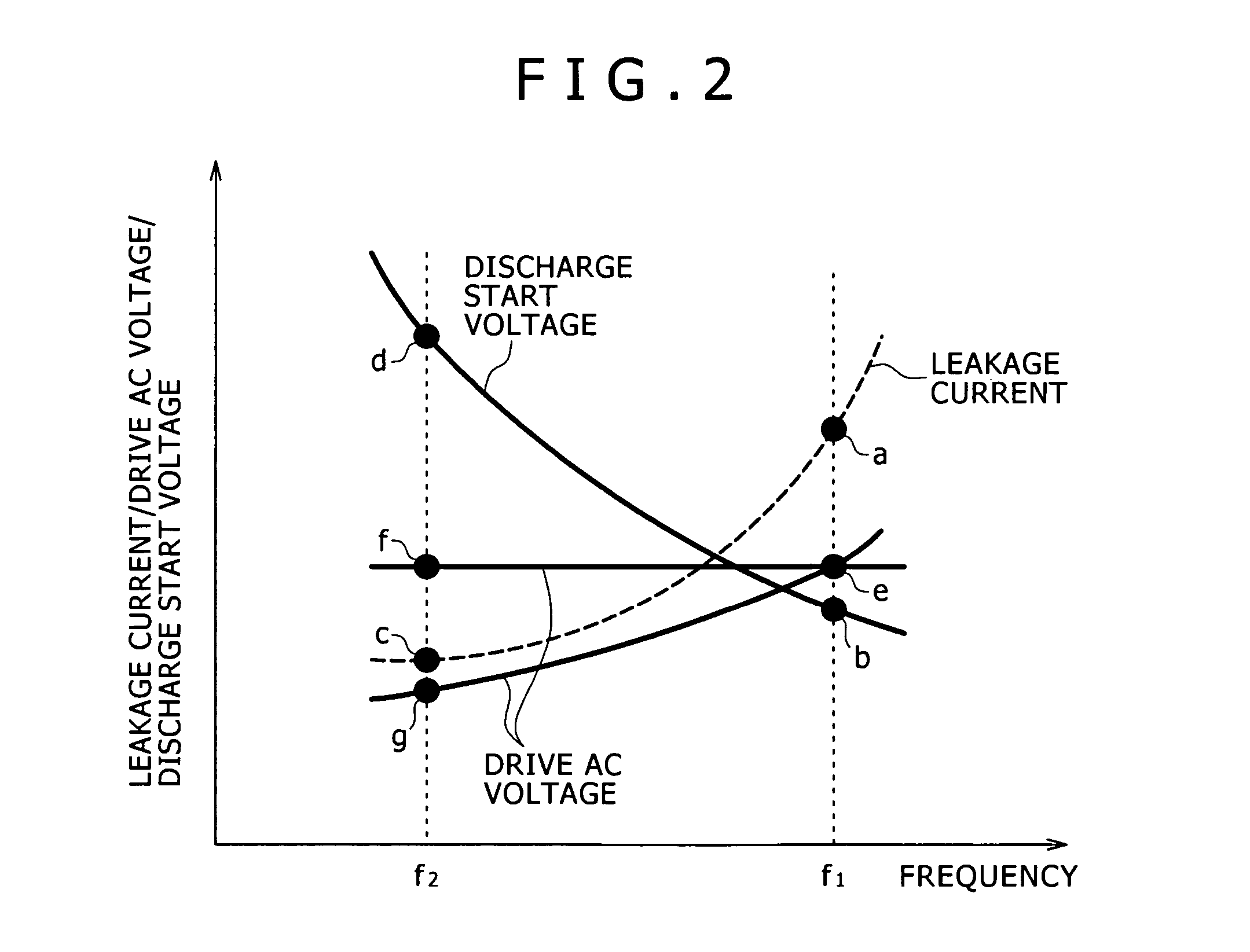

Cold cathode fluorescent discharge lamp apparatus and operating method for same

InactiveUS7315138B2Smooth ignitionSuppression amountTransformersElectric light circuit arrangementCold cathodeAlternating current

A discharge lamp operating device includes a voltage application unit that applies to a discharge lamp an alternating-current (AC) voltage for operation of the discharge lamp, and a frequency setting unit that sets a frequency of the AC voltage to a first frequency for ignition of the discharge lamp and sets the frequency of the AC voltage to a second frequency during operation of the discharge lamp after the ignition. In the discharge lamp operating device, the second frequency is lower than the first frequency.

Owner:SONY CORP

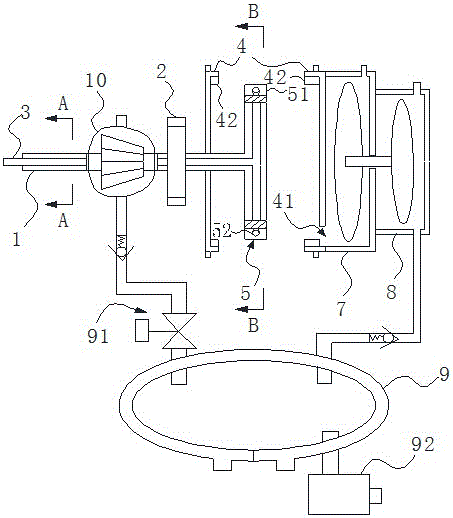

a turbine

ActiveCN104963774BReverse propulsion can be sufficientReasonable useGas turbine plantsHydro energy generationExhaust valveSpray nozzle

The invention provides a novel turbine. The novel turbine comprises a wheel shaft, a power output wheel, a housing and a wheel disc. The wheel shaft and the wheel disc are hollow structures fixed and communicated with each other and form a rotor body of the turbine. The outer surface of the wheel disc is uniformly provided with multiple hollow gears along a circumferential direction, the hollow gears extends along a tangential direction and gear openings are turbine nozzles. The housing is provided with an exhaust channel with an exhaust valve. The inner wall of the housing is uniformly provided with multiple raised lines extending along an axial direction. The top of each one of the raised lines and the tops of the wheel tooth form slidable seal contact so that a supercharging propulsion chamber is arranged between the two adjacent rotary gears in the housing. The novel turbine effectively solves the problem of turbine pressure loss-caused energy loss, prevents influence on blades in a high temperature and high pressure environment and prolongs a wheel disc service life.

Owner:邓小波

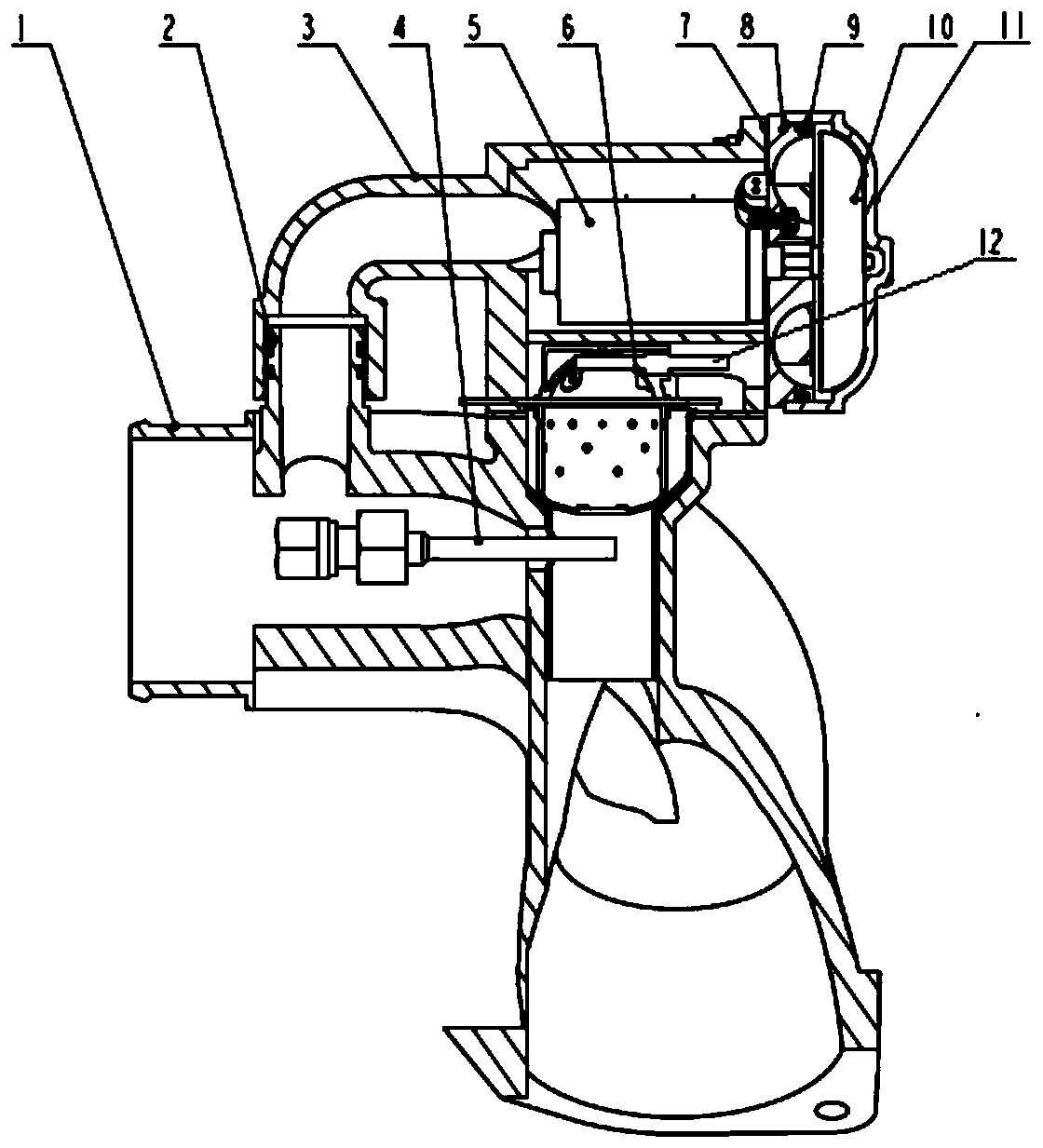

Shock wave combustion-supporting pre-combustion chamber structure of gas engine

InactiveCN112211714AWell mixedSmooth ignitionInternal combustion piston enginesShock waveCombustion chamber

The invention aims to provide a shock wave combustion-supporting pre-combustion chamber structure of a gas engine and belongs to the technical field of engines. The shock wave combustion-supporting pre-combustion chamber structure comprises a gas injection valve, a gas injection valve mounting seat, a pre-combustion chamber and a spark plug. The gas injection valve is mounted on the gas injectionvalve mounting seat through a gas valve pressing plate; a fuel gas inlet is formed in the gas injection mounting seat; one end of the pre-combustion chamber is connected with an outlet of the gas injection valve, a pre-combustion chamber spray hole outlet is formed in the other end of the pre-combustion chamber, and the diameter of the middle of the pre-combustion chamber is smaller than that of the two ends of the pre-combustion chamber; the spark plug is installed in the middle of the pre-combustion chamber, and a spark plug lead is led out through a cylinder cover inner through hole. According to the shock wave combustion-supporting pre-combustion chamber structure, multi-stage reflection superposition of gas jet shock waves in the pre-combustion chamber is achieved, mixing of gas and the air is promoted, combustion flames are promoted to be sprayed into a main combustion chamber, and the ignition stability of the gas engine and the heat efficiency of the whole engine are improved.

Owner:SHANDONG JIAOTONG UNIV

Valve body for gas stove

ActiveCN102588665BSmooth ignitionExtended service lifeOperating means/releasing devices for valvesEngineeringMechanical engineering

The present invention relates to a valve body for a gas stove, comprising a housing and a valve core, wherein inside the valve core there is provided a valve needle, above the valve needle there is provided a knob rod, the lower portion of the valve needle abuts against a boss at one end of a top rod, the other end of the top rod is provided with a push arm abutting against one end of an electromagnetic valve, a child lock on the valve body is unlocked in the process of pressing down the knob rod and a gas pipe is got through in a manner of rotation, the knob rod enables the actuation surfaces inside the valve body to mutually absorbed in the pressing-down process of the knob rod, the knob rod is pressed down to unlock the child lock using a stroke called as A, the knob is pressed down to enable the actuation surfaces inside the electromagnetic valve to mutually absorbed using a stroke called as B, and all the strokes of pressing down the knob rod are called as C (C>=A>=B). The valve body for a gas stove can ensure the absorption of the actuation surfaces inside the electromagnetic valve before unlocking the child lock, and also can ensure the smooth of the igniting, is provided with a function of buffer, can protect the top electromagnetic valve mechanism from being damaged by the action of an acting force, and enables the service life of the top electromagnetic valve mechanism to be prolonged.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Apparatus and method for fishing

An apparatus for releasable attachment to a fishing rod, said apparatus including:a barrel having a first end and a releasably sealed first region;wherein the first region of the barrel includes a space within the barrel substantially bounded by a second end of the barrel and a protrusion disposed inside the barrel; anda means of selectably adjusting the volume of the first regionincluding adjusting the position of the protrusion along a length of the barrel; and wherein when the protrusion is disposed inside the barrel, it extends radially-inwardly of the barrel in a substantially transverse orientation to an elongate axis of the barrel; anda means of controllably feeding a propellant into the releasably sealed first region; anda means of expanding the propellant whereby the said expansion of the propellant causes a projectile disposed within the barrel to be propelled outwardly of the barrel via the first end.

Owner:MAMAE TAUTOFI TAURIKI

Aviation heavy oil engine and aircraft

PendingCN108757209ASmooth and even ignition and combustionFully ignitedFuel injection apparatusMachines/enginesAviationCombustion chamber

The invention discloses an aviation heavy oil engine and an aircraft. A concave guiding portion which is sunken relative to the top surface of a piston is formed in the top surface of the piston, theoutermost point of the outer side face outward in the radial direction exceeds or is flush with the fuel injection direction of a fuel injection assembly, and the extension surface exceeds the ignition position of a center spark plug inwards and in the radial direction. The top surface of the piston and the concave guiding portion which is sunken relative to the top surface of the piston and corresponding to the injection direction of the fuel injection assembly guide fuel injected-into to the ignition area of the spark plug, the top surface of the piston is optimized, so that a combustion chamber is optimized, the compression ratio is changed, the risk of knock is reduced, the tumble effect is enhanced, a relatively complete atomization mixing of heavy oil is realized, uniform burning mixture is formed after good mixing, fuel can be efficient combusted, the power, economy and emission performances of an engine which the heavy oil is applied to are ensured, and energy saving, environmental protection and low cost after the heavy oil is applied to the engine are achieved.

Owner:CHONGQING LONCIN ENGINE +1

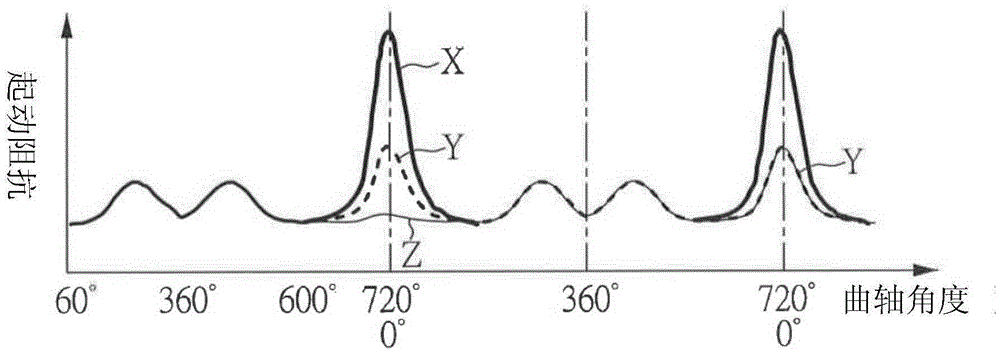

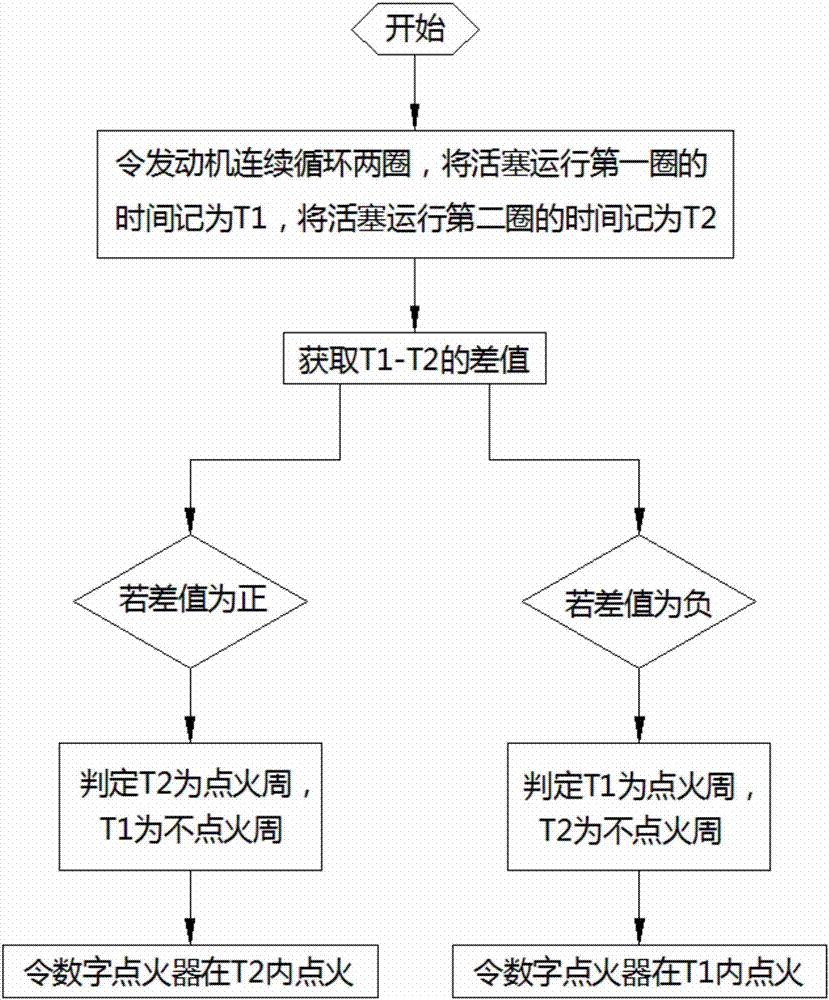

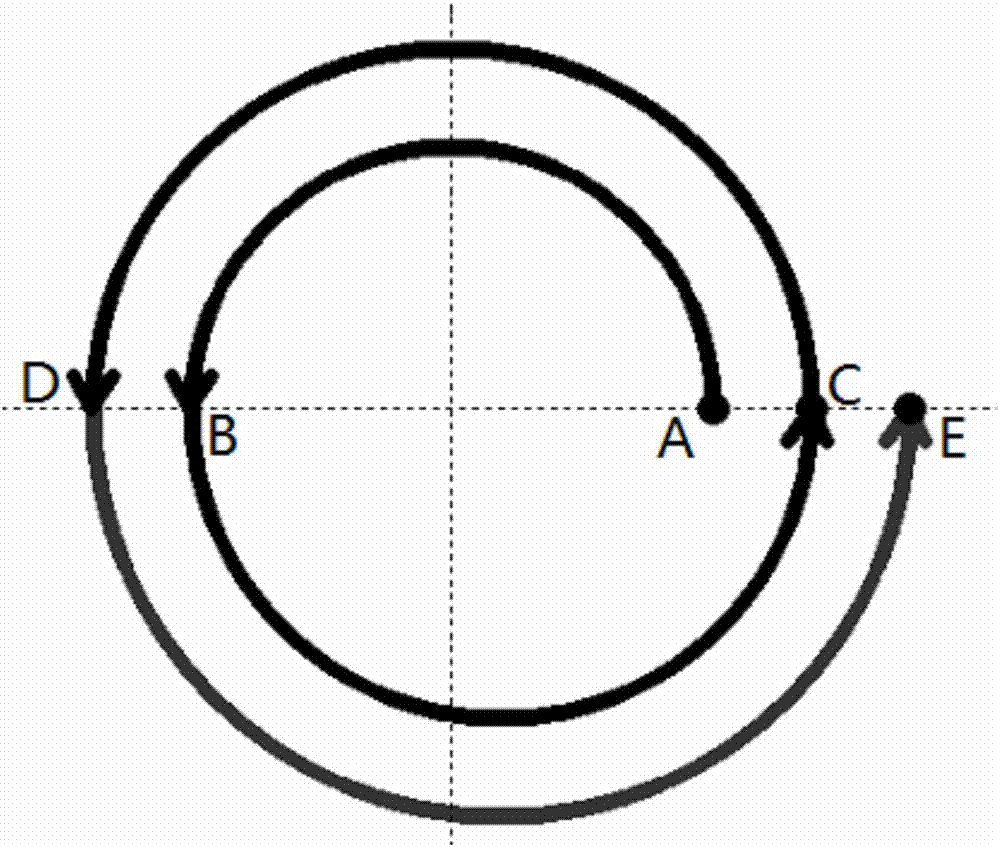

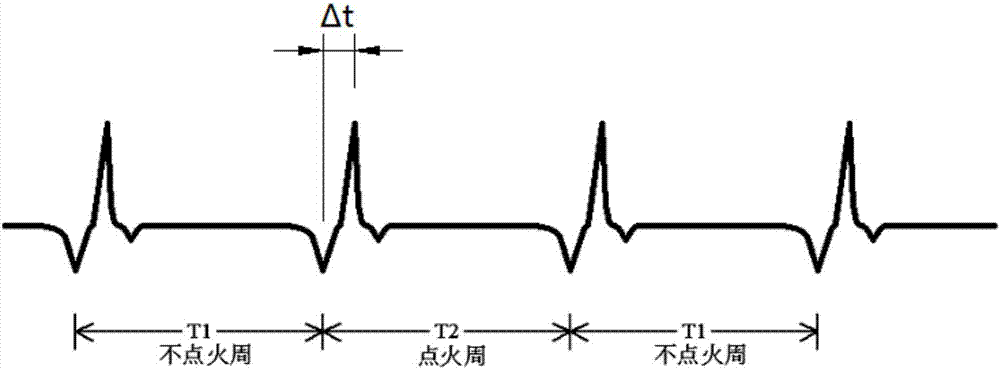

Digital ignition control method of small-size four-stroke engine

InactiveCN107201979AImprove ignition efficiencySave resourcesMachines/enginesIgnition automatic controlAutomotive engineeringContinuous operation

The invention discloses a digital ignition control method of a small-size four-stroke engine, and belongs to the technical field of engine ignition control. The digital ignition control method comprises the following steps that 1, the time for a piston inside the small-size four-stroke engine to continuously operate two circles is obtained, the first-circle operation time of the piston is denoted as T1, and the second-circle operation time of the piston is denoted as T2; 2, the difference value between T1 and T2 is obtained; and 3, if the difference value in the step 2 is a positive number, the second circle corresponding to T2 is judged to be an ignition circle, the first circle corresponding to T1 is judged to be a non-ignition circle, and a digital igniter is made to ignite in T2, if the difference value in the step 2 is a negative number, the first circle corresponding to T1 is judged to be an ignition circle, the second circle corresponding to T2 is judged to be a non-ignition circle, and the digital igniter is made to ignite in T1. According to the digital ignition control method of the small-size four-stroke engine, the ignition circle and the non-ignition circle are judged through the difference between the two circles of continuous operation of the piston, the purpose that ignition is conducted only within the ignition circle in the cycling operation process of the small-size four-stroke engine is achieved, and the operation principle of the engine is met.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

Discharge lamp operating device, discharge lamp operating method, light source device, and display

InactiveUS20070024206A1Smooth ignitionAmount of leakage is suppressedTransformersElectric light circuit arrangementEngineeringLight source

A discharge lamp operating device includes a voltage application unit that applies to a discharge lamp an alternating-current (AC) voltage for operation of the discharge lamp, and a frequency setting unit that sets a frequency of the AC voltage to a first frequency for ignition of the discharge lamp and sets the frequency of the AC voltage to a second frequency during operation of the discharge lamp after the ignition. In the discharge lamp operating device, the second frequency is lower than the first frequency.

Owner:SONY CORP

Micro-pilot for gas appliance

InactiveUS8454352B2Save energyEmission reductionMechanical apparatusCombustion valves/nozzle/pumpsCombustorFuel gas

A micro pilot for a gas hot water heater is provided. The micro pilot provides a flame that is substantially smaller than a typical pilot in a hot water heater during standby operation of the burner. Just prior to allowing gas to flow to the burner upon a call for heat, a pilot flame of sufficient size to ensure ignition of the burner is provided. In one embodiment this larger pilot flame is produced by providing an additional amount of bleed gas to the pilot to increase flame size. In another embodiment, bleed gas is provided to a separate booster pilot, which is ignited by the micro pilot. The flame from the booster pilot is then used to ignite the main burner. This design allows for the micro pilot to be positioned closer to the flame trap of a flammable vapor resistant hot water heater to ensure smooth ignition of any such vapor.

Owner:INVENSYS CONTROLS AUSTRALIA

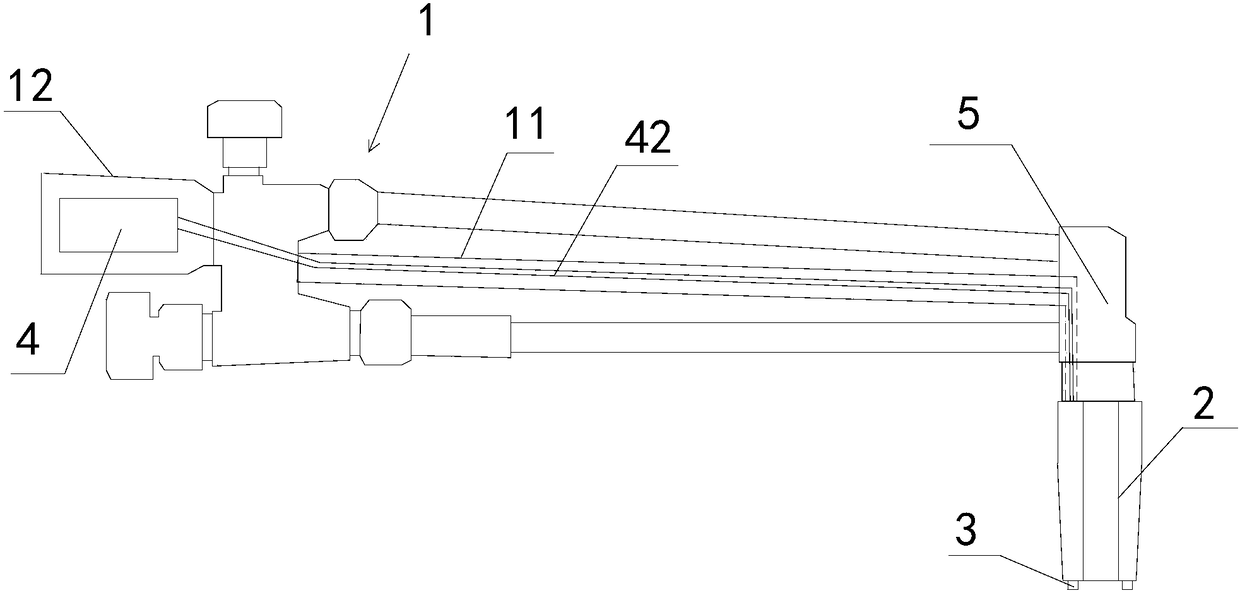

Automatic ignition type welding and cutting torch

PendingCN108381005AAvoid Burn HazardsSmooth ignitionGas flame welding apparatusElectrical and Electronics engineeringNozzle

The invention discloses an automatic ignition type welding and cutting torch. The automatic ignition type welding and cutting torch comprises a torch body, a torch nozzle, an ignition device and a direct current discharge device arranged on the torch body. The output end of the torch body is provided with a torch nozzle connection screw thread, and the torch nozzle is arranged on the torch nozzleconnection screw thread. The ignition device comprises an insulating tube arranged on the torch nozzle in a sleeving mode, and first penetrating holes are separately formed in the two opposite side walls of the insulating tube. The axes of the first penetrating holes are parallel to the axis of the insulating tube, and the first penetrating holes are internally provided with spray points. The positive and negative poles of the direct current discharge device are separately and electrically connected to the spray points through wires in a one-to-one correspondence mode, and the spray points candischarge and ignite at one end, away from the torch nozzle connection screw thread, of the torch nozzle. By arranging an insulator, the spray points is insulated from the torch body and the torch nozzle, and the two spray points separately serve as the positive and negative poles of the direct current discharge device, so that electric sparks can be generated between the two spray points for ignition, the ignition can avoid the burn hazard to operators, and the ignition can still be smoothly performed in the case of strong wind outside.

Owner:徐慕庆

Ignition system for smoke sprayers

ActiveCN104115808ASteady ejectionCooperate accuratelyInsect catchers and killersCombustion chamberFuel tank

The invention discloses an ignition system for smoke sprayers and belongs to the technical field of the smoke sprayers. The ignition system comprises a power supply, an ignition switch, an igniter, an oil tank, a carburetor, a sparking plug, an oil spray nozzle, a combustion chamber and an air pump, wherein the igniter and the air pump are electrically connected with the power supply respectively through the ignition switch, the igniter is electrically connected with the sparking plug, the air pump is respectively connected with the oil tank and the carburetor through air pipes, and check valves are respectively arranged on main paths of the air pipes and branch paths connected with the oil tank. The oil tank is connected with the oil spray nozzle through an oil supply pipe, and an oil supply valve is arranged on the oil supply pipe. The carburetor is connected with the combustion chamber, and the sparking plug and the oil spray nozzle are arranged on a connection pipe between the carburetor and the combustion chamber. By means of the air pump, pressurization of the oil tank is achieved, and air required by ignition is provided. Fuel oil is sprayed out stably under action of positive pressure, mixed fuel oil and the sparking plug are matched accurately, the success rate of ignition is high, and ignition operation is convenient and efficient. Meanwhile, continuous and stable operation of the smoke sprayers is achieved.

Owner:史文军 +1

Heat exchanger

PendingCN110132041ASmooth ignitionSufficient heat exchangeIndirect heat exchangersCombustion technology mitigationCombustion chamberPlate heat exchanger

The invention relates to a heat exchanger comprising a combustion chamber, a high-temperature smoke delivery pipe, multiple jacketed pipes and a condensation smoke discharge pipe. The high-temperaturesmoke delivery pipe, the multiple jacketed pipes and the condensation smoke discharge pipe are arranged in the circumferential direction of the combustion chamber. The combustion chamber communicateswith the high-temperature smoke delivery pipe. The multiple jacketed pipes sequentially communicate. Each jacketed pipe comprises an inner pipe, an outer pipe arranged outside the inner pipe in a sleeving manner, and an end cover. The high-temperature smoke delivery pipe communicates with one jacketed pipe, and the condensation smoke discharge pipe communicates with another jacketed pipe. By means of the heat exchanger, the heat exchange efficiency can be improved, the ignition success rate can be ensured, the structure is reasonably distributed, the device space occupation rate is decreased,and the device economy is improved.

Owner:周清桂

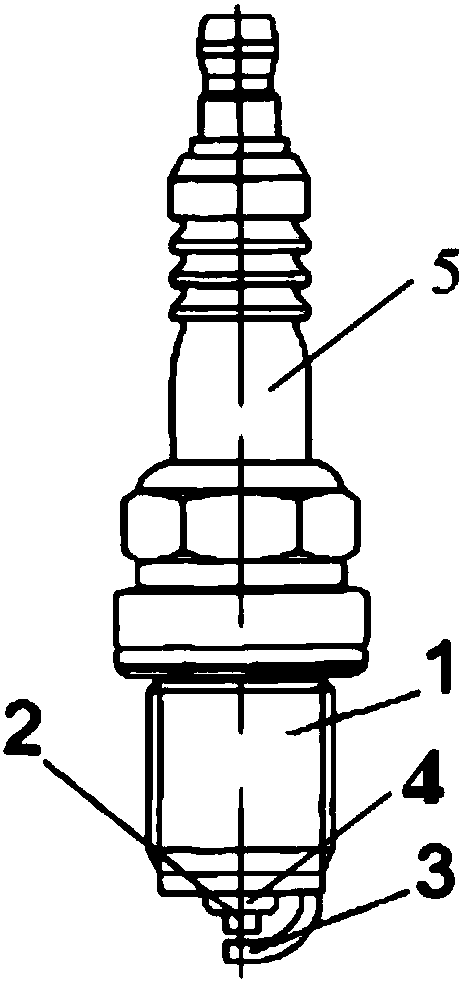

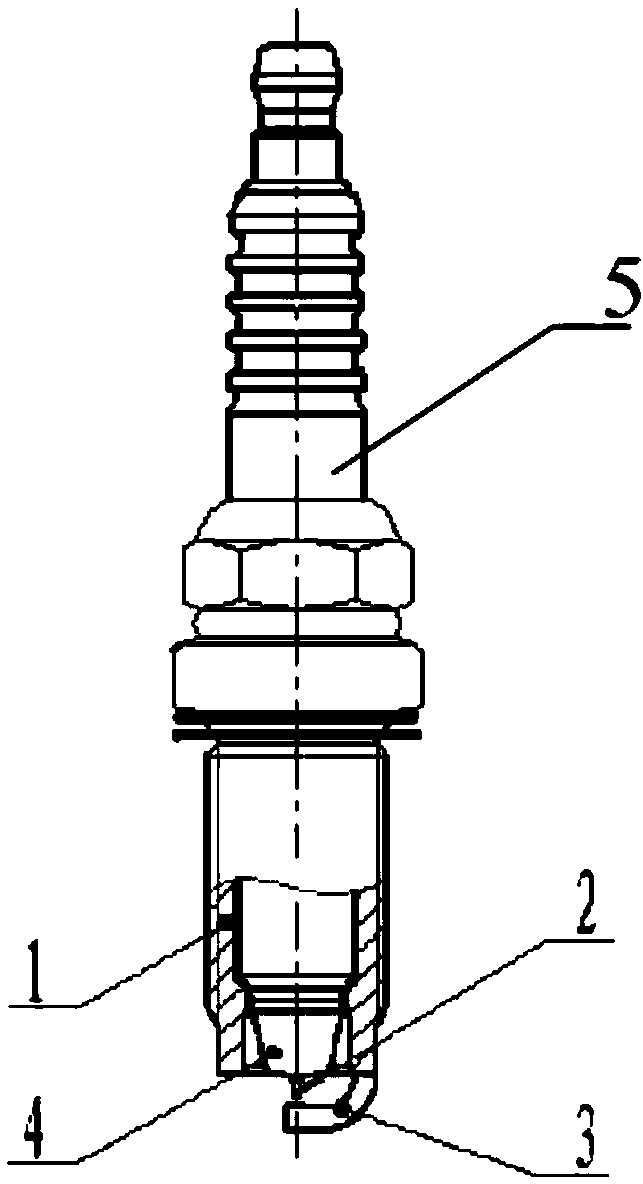

Sparking plug of ethyl alcohol-gasoline flexible fuel engine

The invention provides a sparking plug of an ethyl alcohol-gasoline flexibly proportioned fuel engine. A metal casing is positioned at the front end of a sparking plug body, a central electrode is located in the metal casing, an insulator is located between the central electrode and the metal casing, a side electrode is welded on one side of a front port of the metal casing, precious metal electrodes are welded on one side of the side electrode and at the top of the central electrode, and the side of the side electrode is near the central electrode. The horizontal width of the side electrode is longer than the vertical length of the side electrode, so that heat in an engine cylinder can be well transmitted, and the side electrode itself can be protected from being ablated by high temperatures; the side electrode is shorter than ordinary engine sparking plugs, and heat conduction effects of the side electrode are better; and the precious metal electrodes are located on the side electrode and the central electrode respectively, the size and the width of the precious metal electrodes are the same, and heat lost during ignition of the sparking plug is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Alcohol-based high-temperature gasifying fire control furnace

InactiveCN105202593ASave spacePromote gasificationBurnersDomestic stoves or rangesFurnace temperatureCombustion chamber

The invention relates to an alcohol-based high-temperature gasifying fire control furnace which comprises a furnace center, a fire control cover, a fire control ring, and a fire expansion plate, wherein the fire control cover is arranged above the furnace center; the fire control ring is arranged at the outer periphery at the upper part of the fire control cover; the fire expansion plate is arranged above the fire control ring; a first high-temperature gasifying combustion chamber is formed between the furnace center and the fire control cover; a second high-temperature gasifying combustion chamber is formed between the fire control cover and the fire control ring; a third high-temperature gasifying combustion chamber is formed among the fire expansion ring, a pot ring and an iron pot. The furnace has the advantages that the temperature of a main hearth can be improved by 150 to 200 DEG C based on the original temperature; the temperature of the furnace can exceed that of a diesel furnace by 200 DEG C, which overcomes the technical defect that the temperature of a national or international bio-alcohol oil furnace is lower than that of a diesel furnace; heat can be reserved and stored, so as to give full play to the combustion efficiency of fuel.

Owner:政和县星原节能燃料有限公司

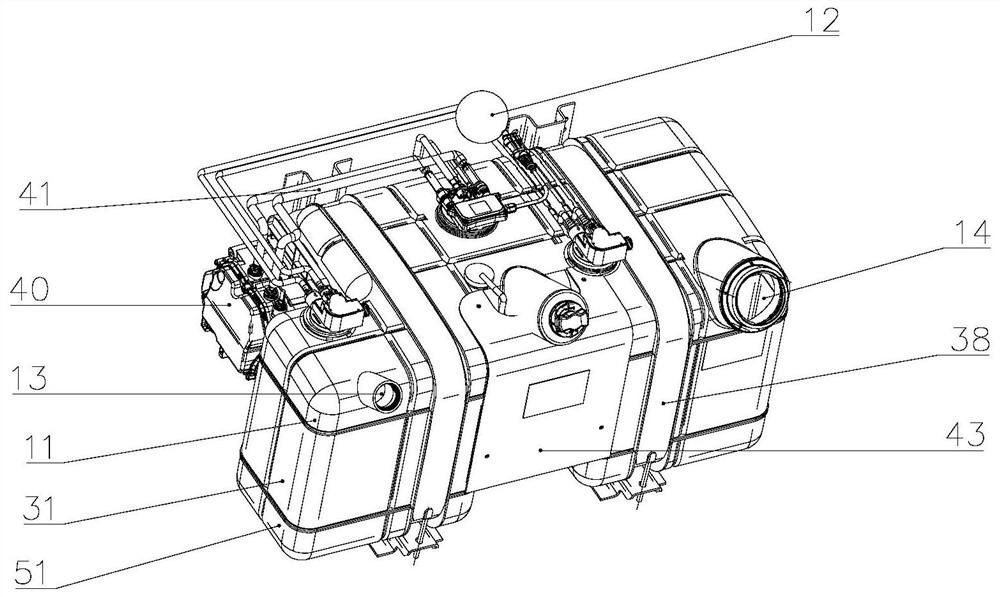

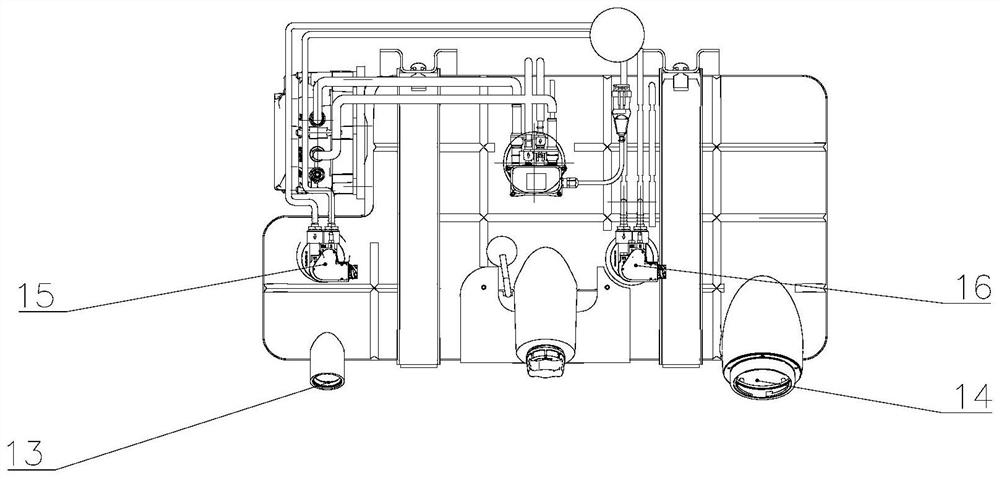

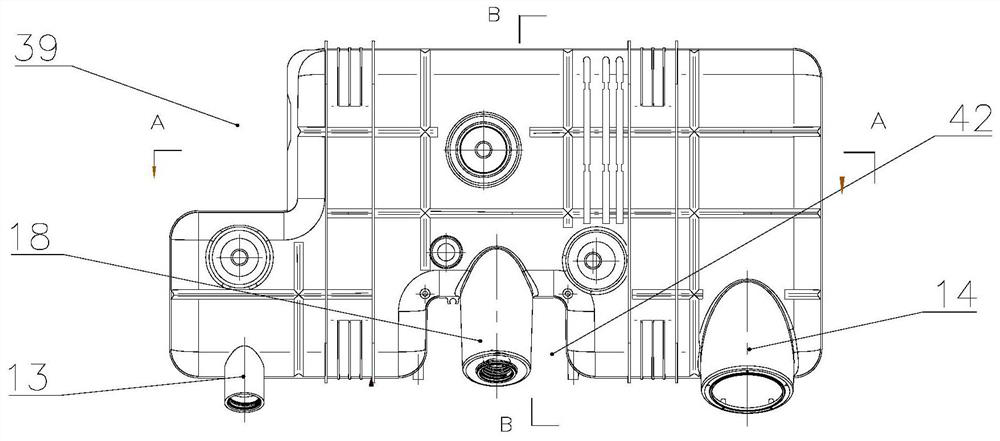

Double oil tanks and integrated double oil tank and urea tank assembly

ActiveCN113427999AImprove rigidityReduce surge phenomenonExhaust apparatusSilencing apparatusFuel tankFuel oil

The invention discloses double oil tanks and an integrated double oil tank and urea tank assembly, and belongs to the field of automobile parts. The double-oil-tank assembly comprises an oil tank shell, the oil tank shell defines a cavity, and the oil tank shell comprises an upper shell area on the upper portion, a middle shell area in the middle and a lower shell area on the lower portion; a middle grid rib structure is arranged in an area, corresponding to the height of the middle shell, in the cavity, the middle part of the cavity is divided into a plurality of middle grid cavities by the middle grid rib structure, the middle grid cavities are not communicated in the radial direction, the middle grid rib structure comprises a first middle grid cavity group and a second middle grid cavity group which are not communicated with each other, the bottom end of the first middle grid cavity group is provided with a first oil passing opening so as to be communicated with each other to form a first fuel oil cavity, the bottom end of the second middle grid cavity group is provided with a second oil passing opening so as to be communicated with each other to form a second fuel oil cavity, and the first fuel oil cavity and the second fuel oil cavity are connected through a conversion valve.

Owner:山东统亚模塑科技实业有限公司

Flame air inlet preheating low-temperature starting device

InactiveCN110374779AGood low temperature ignitabilitySmooth ignitionMachines/enginesEngine startersCombustorEngineering

The invention provides a flame air inlet preheating low-temperature starting device. An air inlet pipe, a heater shell, a flame temperature sensor, a draught fan and a combustor are included. The airinlet pipe is provided with a small air outlet pipe and a flange for installing the heater shell. One end of the heater shell sleeves the small air outlet pipe, and an installing flange at the other end is fixed to the flange of the air inlet pipe. The draught fan and the combustor are arranged in the heater shell. The flame air inlet preheating low-temperature starting device has good low-temperature ignition performance, and ignition can be smoothly conducted at the environment temperature of -40 DEG C; good ignition continuity is achieved, after ignition, influences from the engine rotationspeed and displacement are avoided, and the defect that after a current flame air inlet preheating device is ignited, the rotation speed of an engine is increased, and blowing-out is likely to happenis overcome. Long-time ignition can be achieved, the single-time ignition time can reach 30 min or above, and the defect that after the current flame air inlet preheating device is ignited, long-timecontinuous combustion cannot be achieved is overcome.

Owner:CHINA NORTH ENGINE INST TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com