Engine starting and stopping running control method

A control method and stop operation technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of high cost of control devices, difficult to achieve angle positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

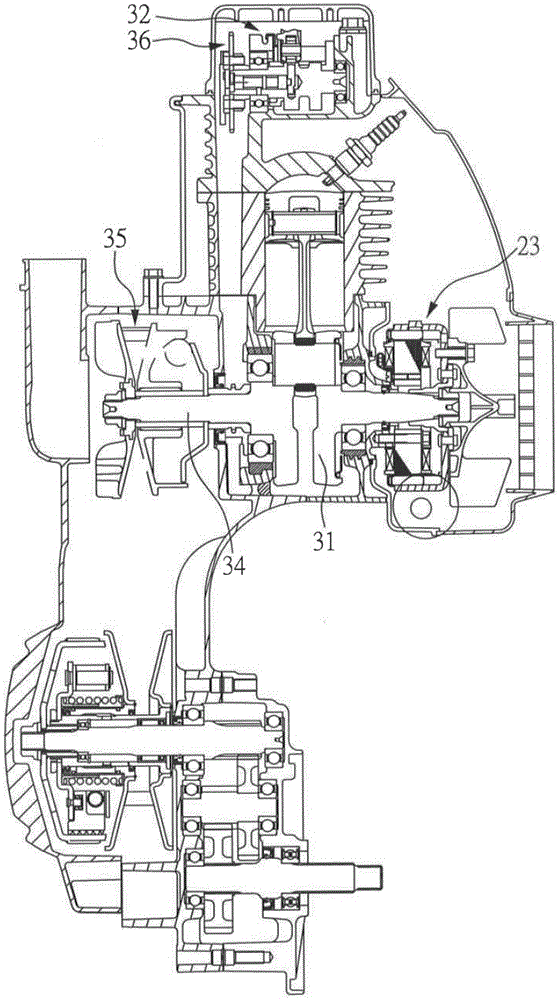

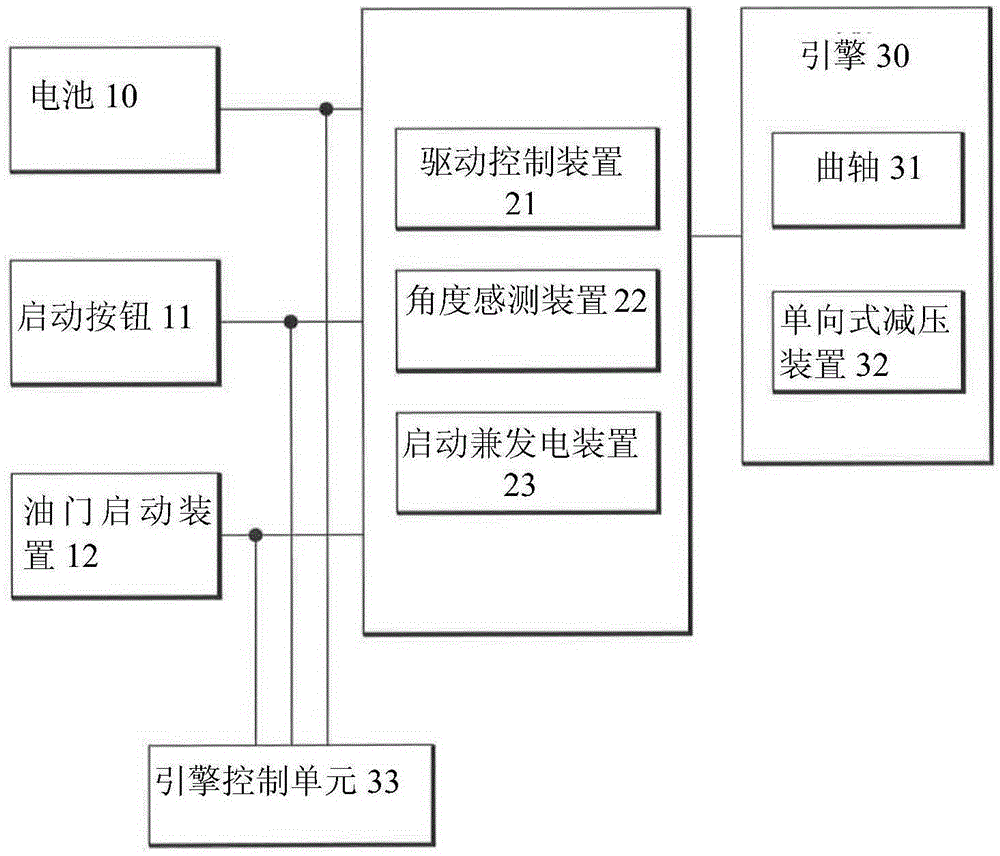

[0060] In order to make it easier for those skilled in the art to understand and realize the present invention, the embodiments of the present invention are described in conjunction with the accompanying drawings.

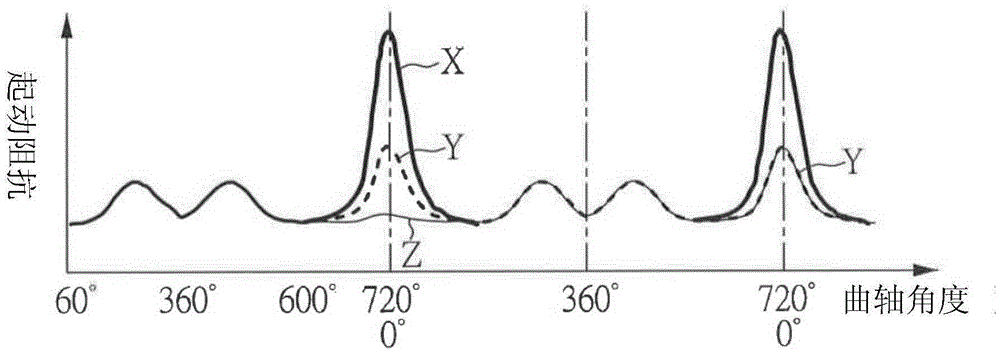

[0061] The so-called engine decompression device is generally used to leak part of the gas pressure during the compression stroke of the engine piston to reduce the engine resistance. Please refer to figure 1 The comparison chart of the crankshaft angle position and the starting impedance of the starting and generating device. As shown in the figure, the coordinates on the vertical axis represent the starting resistance of the forward rotation of the starting and generating device, and the coordinates on the horizontal axis represent the rotation angle of the crankshaft. This embodiment adopts the working principle of a four-stroke engine, which is distinguished according to the position of the piston in the cylinder. Therefore, it reaches the top dead center (T.D....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com