Kitchen range fire cover

A technology for fire covers and stoves, which is applied to household appliances, household stoves/stoves, combustion methods, etc., can solve problems such as unfavorable heating uniformity and flame separation of gas stoves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

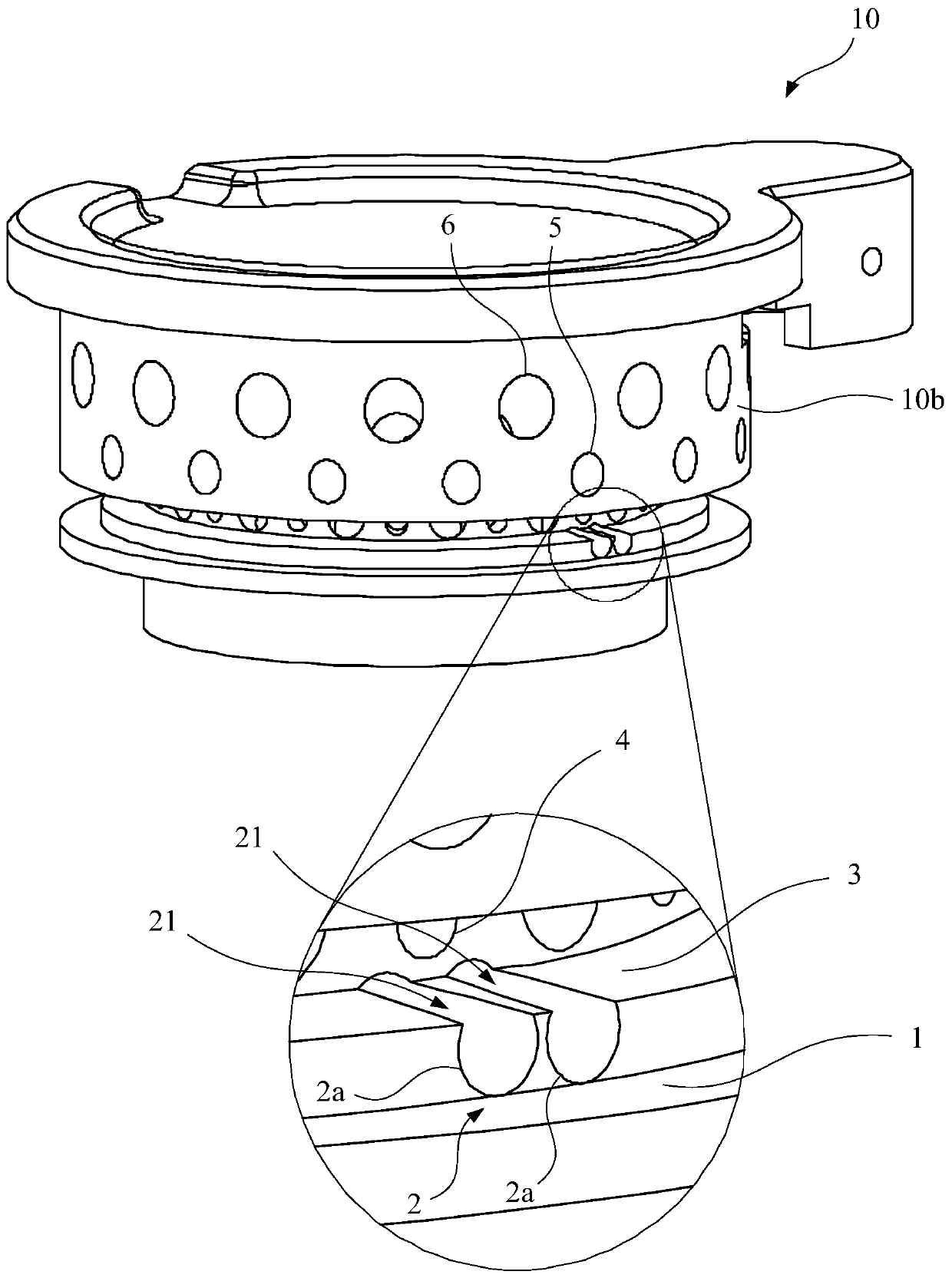

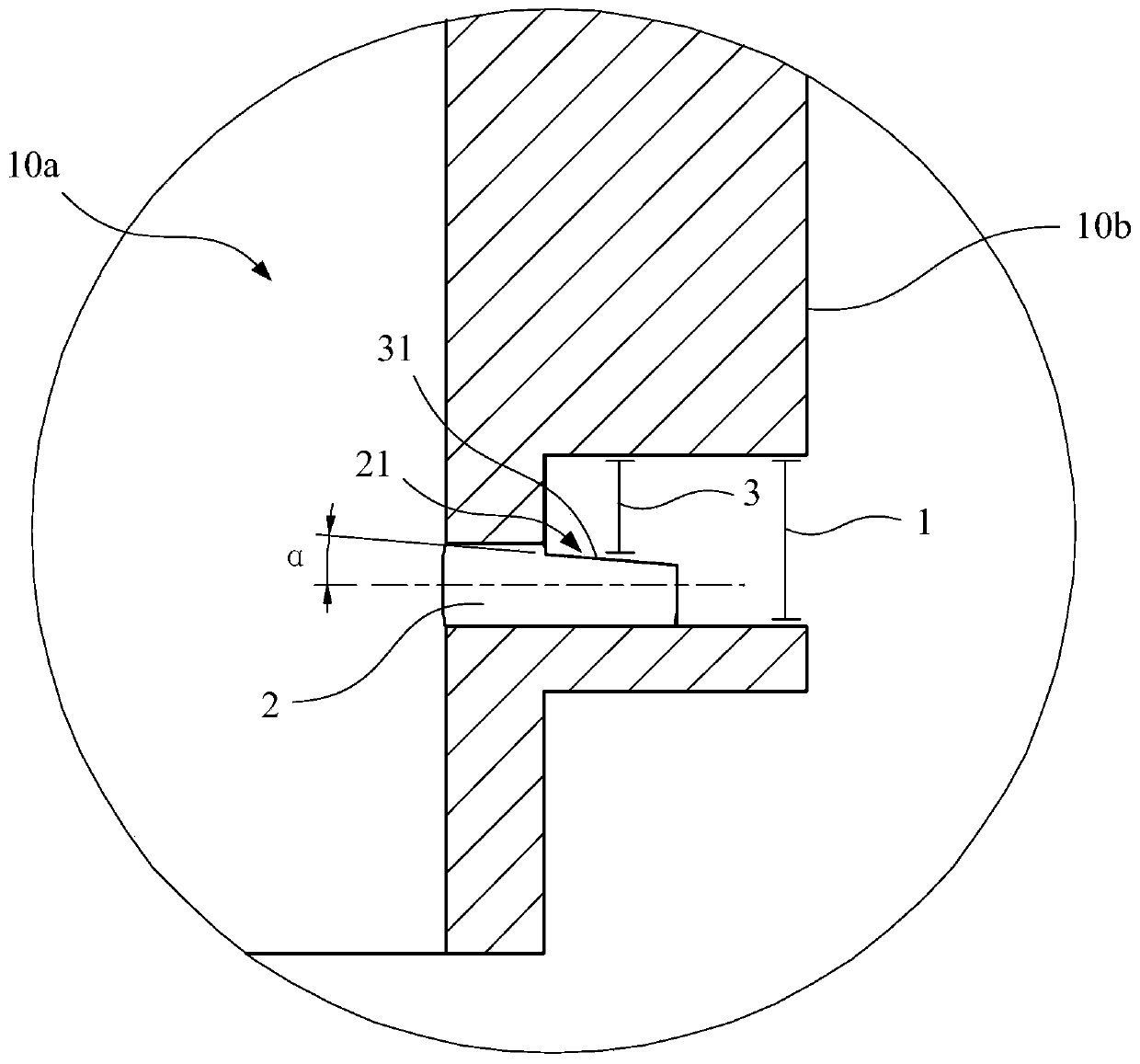

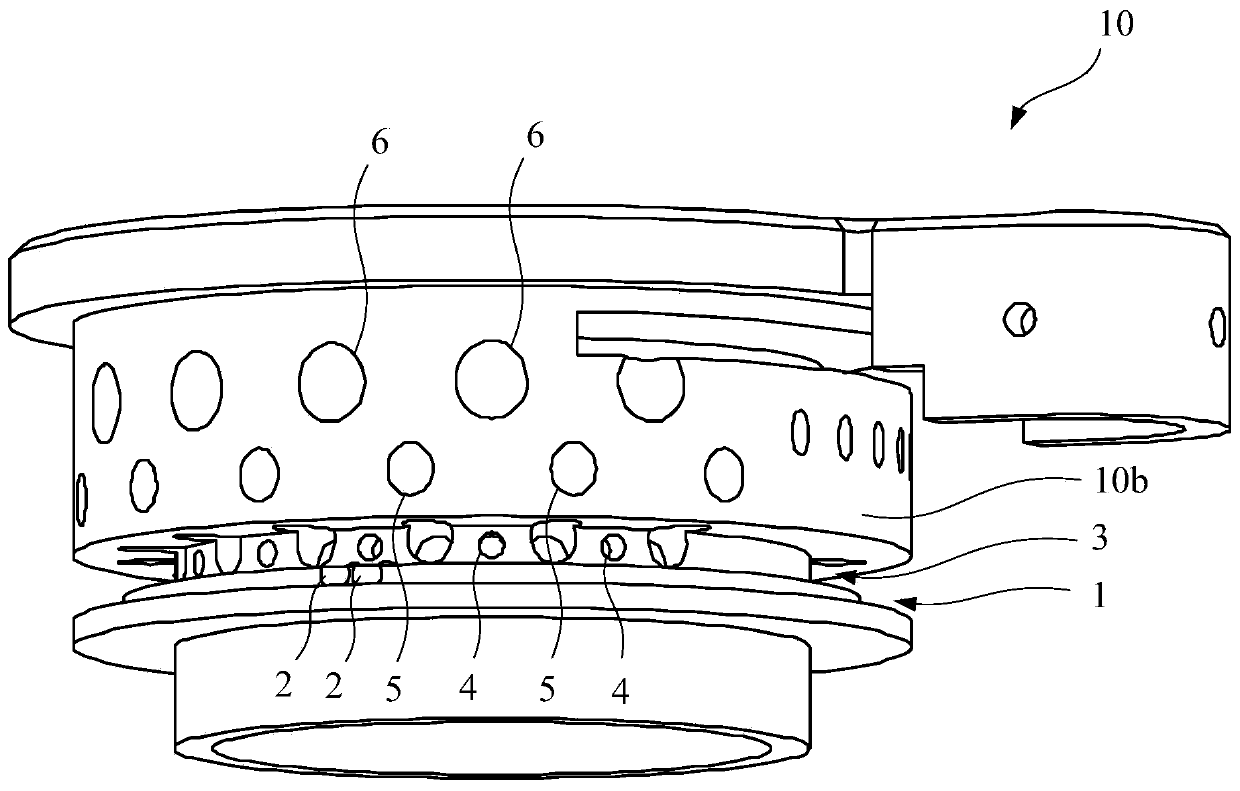

[0039] Such as figure 1 and figure 2 As shown, the present invention provides a cooker fire cover 10, which is an inner ring fire cover, and its surface has a flame groove 1 communicating with a gas chamber 10a. The cooker fire cover 10 also has an ignition hole 2 and a groove 3. Wherein, the groove 3 is arranged corresponding to the ignition hole 2, and the opening 2a of the ignition hole 2 on the side wall 10b of the cooker fire cover 10 is located in the flame groove 1, and the groove 3 is in contact with one side of the opening 2a of the ignition hole 2, And the hole side wall of the ignition hole 2 is cut to form an open space 21 on one side of the ignition hole 2 .

[0040] The open space 21 can make the ignition hole 2 increase the size of the opening 2a of the ignition hole 2 to the outside world under the premise o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com