Heat accumulating type fuel gas and fuel coal steel scrap melting furnace

A melting furnace and regenerative technology, applied in furnaces, crucible furnaces, furnace components, etc., can solve problems such as scrap steel smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

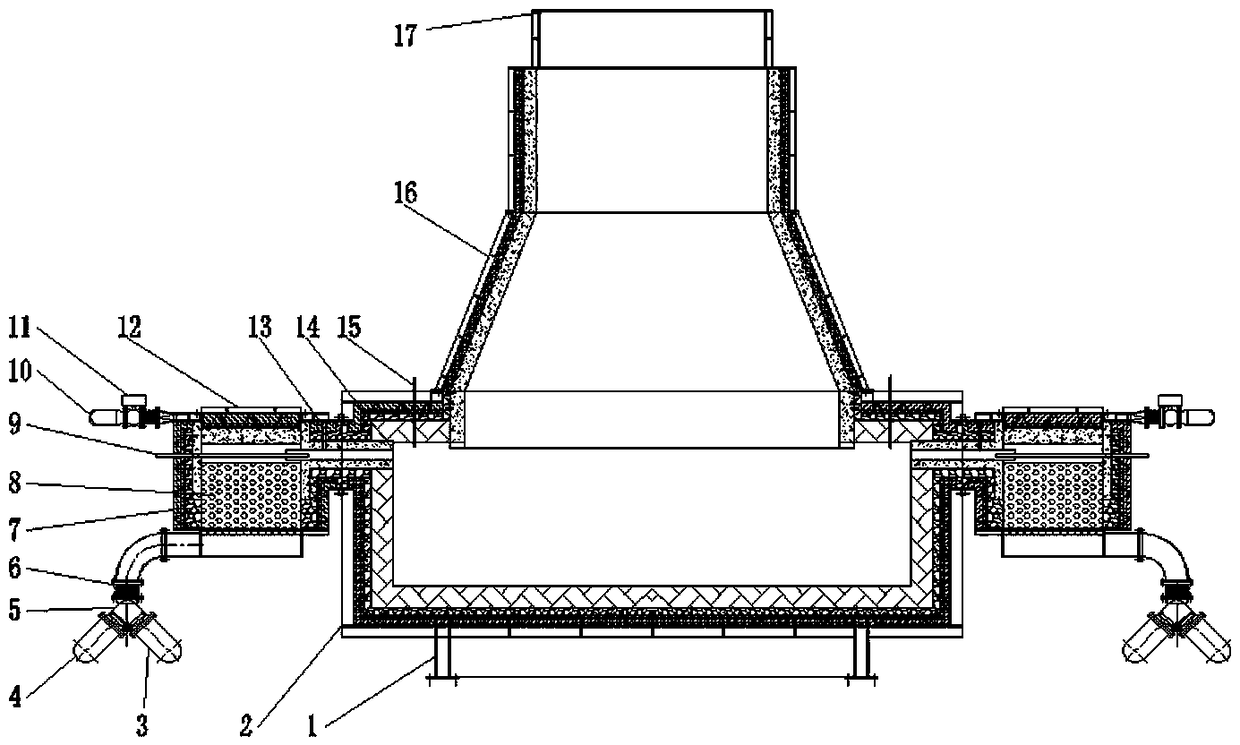

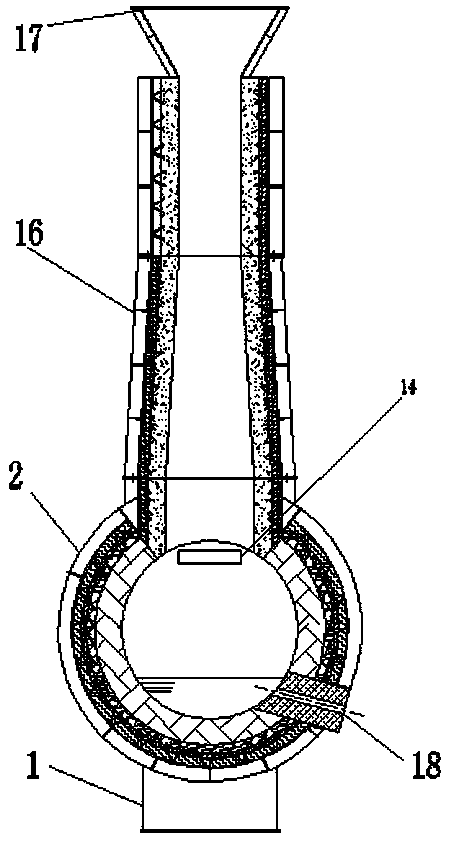

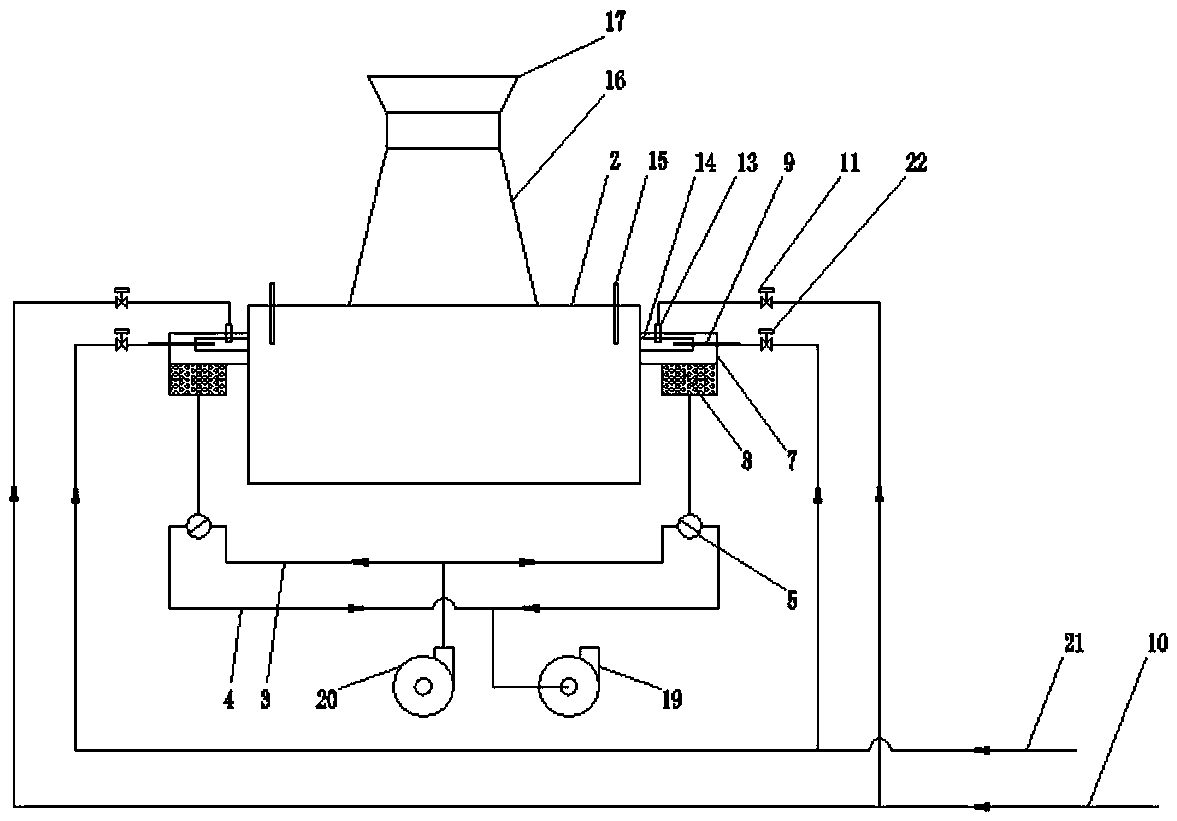

[0011] Such as figure 1 , 2 As shown, a regenerative gas-fired coal-fired scrap steel melting furnace includes a base 1, a furnace body 2, and a feeding channel 16. The base 1 is located below the furnace body 2, and the feeding channel 16 is located above the furnace body 2. The feeding channel 16 communicates with the furnace body 2, the furnace body 2 is provided with a tap hole 18, the side of the furnace body 2 is provided with a heating device, the heating device communicates with the furnace body 2 through the burner nozzle 14, and a high-voltage electronic point is set in front of the burner nozzle 14 Musket 15.

[0012] The body of furnace 2 is cube-shaped or spherical.

[0013] The heating device is a pulverized coal spray gun 9 .

[0014] The heating device is a gas main pipe 10 and a gas nozzle 13 communicated through a gas shut-off valve 11 .

[0015] The feeding channel 16 is an inverted cone, and a feeding port 17 is arranged on the upper part of the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com