Sparking plug of ethyl alcohol-gasoline flexible fuel engine

A flexible fuel and spark plug technology, applied in the field of spark plugs, can solve the problems of general thermal conductivity, ablation, and poor thermal conductivity of the metal electrodes of spark plugs, and achieve the effect of reducing anti-inflammatory effect, ensuring heat transfer performance, and increasing energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below through specific examples. It should be understood that the following examples are exemplary only, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be construed as an explanation of the technical solution of the present invention. Program limitations.

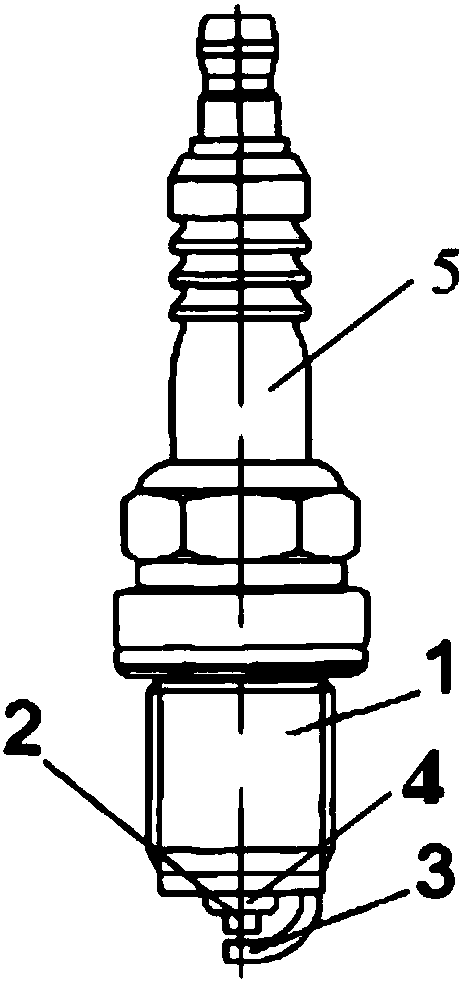

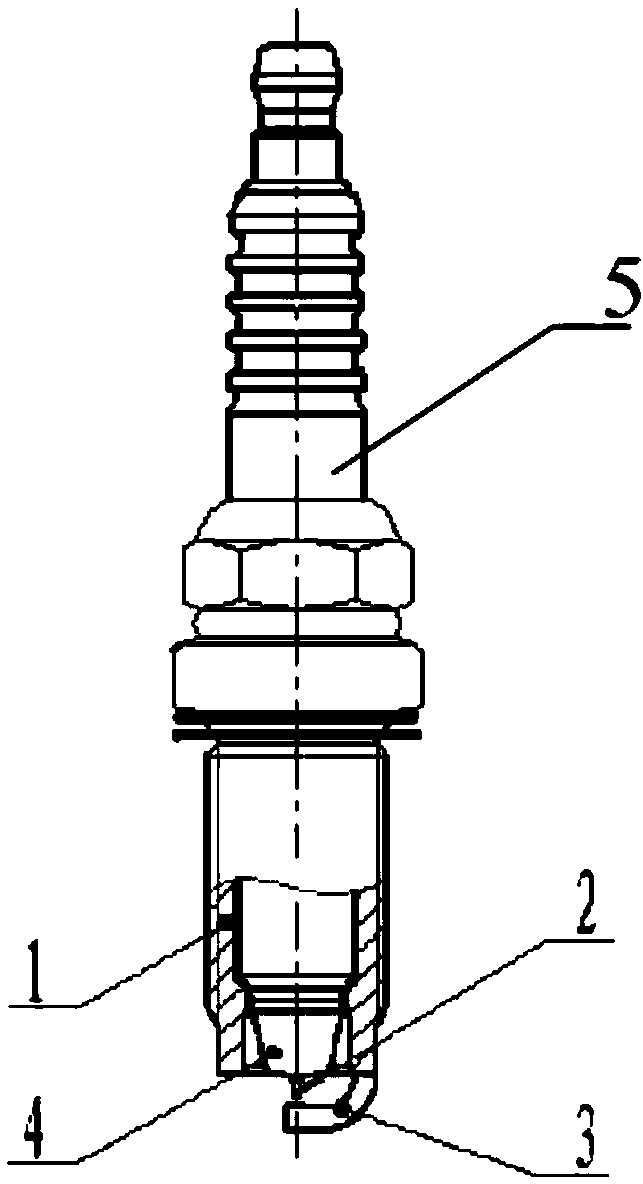

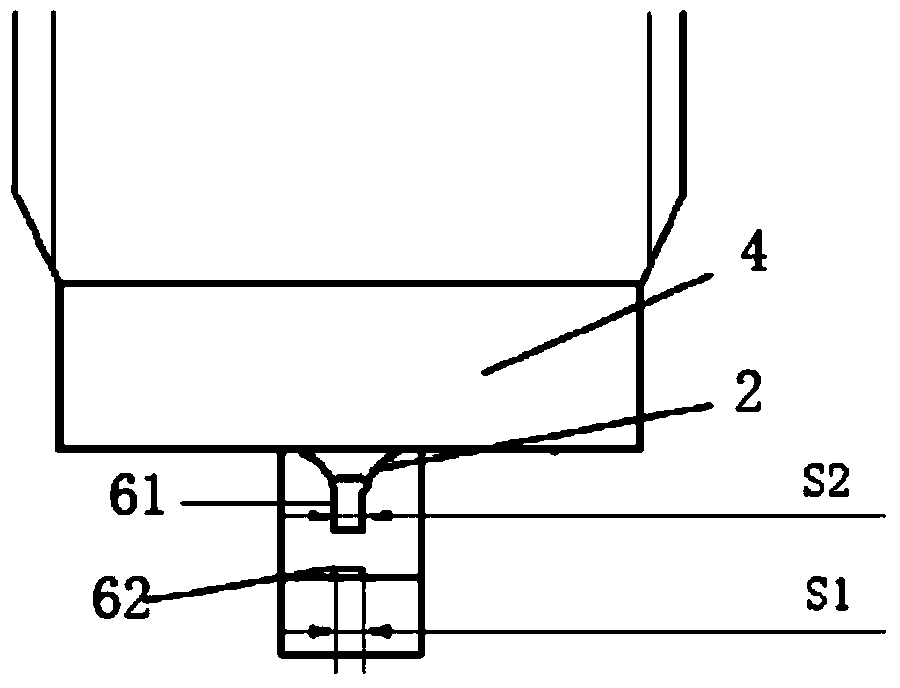

[0028] Such as Figure 2 to Figure 3 As shown, the ethanol-gasoline flexible fuel engine spark plug includes: a metal shell 1 , a center electrode 2 , a side electrode 3 , an insulator 4 , and a spark plug body 5 .

[0029] The metal shell 1 is located at the front end of the spark plug body 5, and the outer diameter of the metal shell 1 can be changed to 10mm or 14mm according to the needs of the engine. The center electrode is located in the metal shell, and the material of the center electrode is not within the protection scope of this application, because any material that can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com