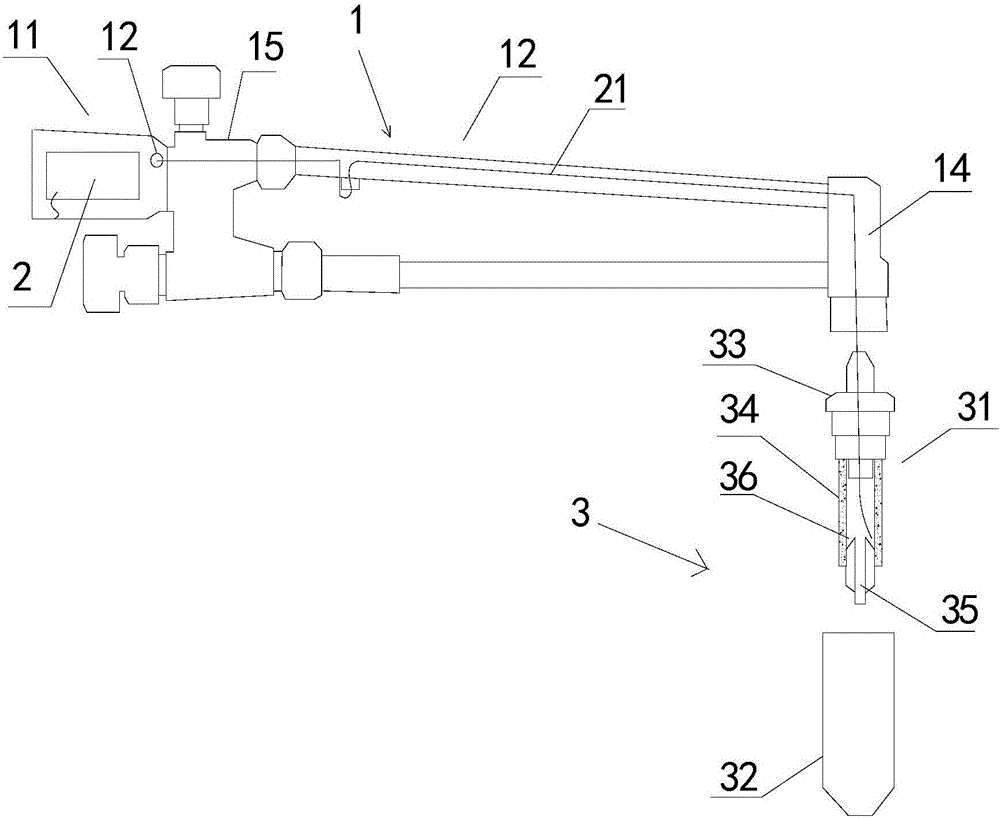

Electronic automatic internal ignition device of cutting torch

An ignition device and cutting torch technology, applied in the field of cutting torches, can solve the problems of burns, inability to work, and difficulty in igniting ignition personnel, and achieve the effect of avoiding burn hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

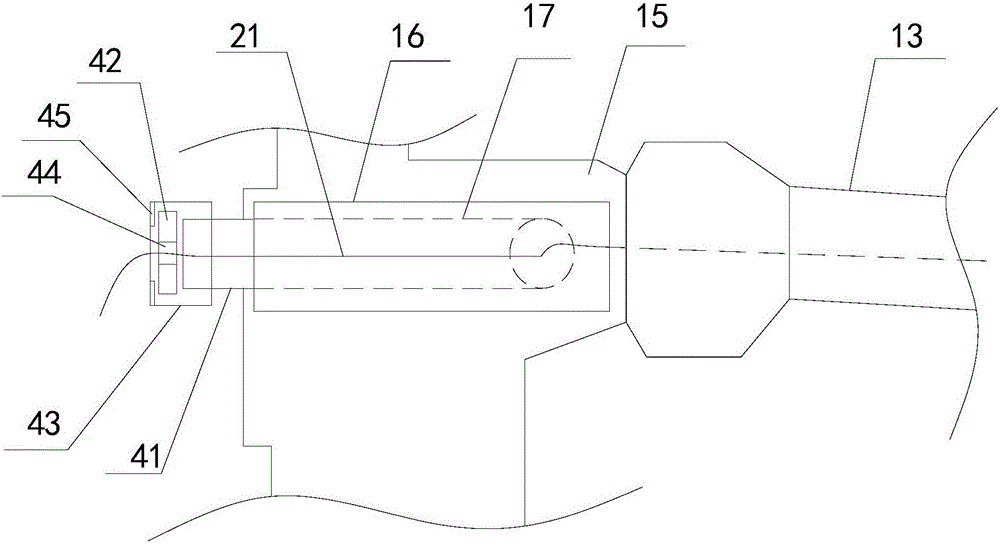

[0022] Embodiment two, such as image 3 As shown, the torch body 1 can also include an oxygen valve 15, the oxygen valve 15 is located between the handle 11 and the oxygen pipe 13, the side wall of the oxygen valve 15 is integrally formed with a thickened part 16, and a supply wire can be opened in the thickened part 16 21 through the third perforation 17, one end of the third perforation 17 communicates with the end of the oxygen valve 15 close to the oxygen pipe 13, the other end of the third perforation 17 is used for the penetration of the wire 21 and is provided with a sealing device, the sealing device can seal the third The perforation 17 is sealed to prevent air leakage. In this way, the wire 21 passes through the fourth through hole 12 of the handle 11 and then passes through the third through hole 17 , crosses the oxygen valve 15 and enters into the oxygen tube 13 . And oxygen pipe 13, converging head 14 and cutting nozzle 3 are all interlinked, therefore, lead wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com