battery system

A technology for battery packs and battery boxes, applied in the field of battery pack systems, which can solve problems such as rising battery internal pressure, affecting battery performance, and destroying battery boxes, achieving the effects of less demand, avoiding the danger of burning, and enhancing the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

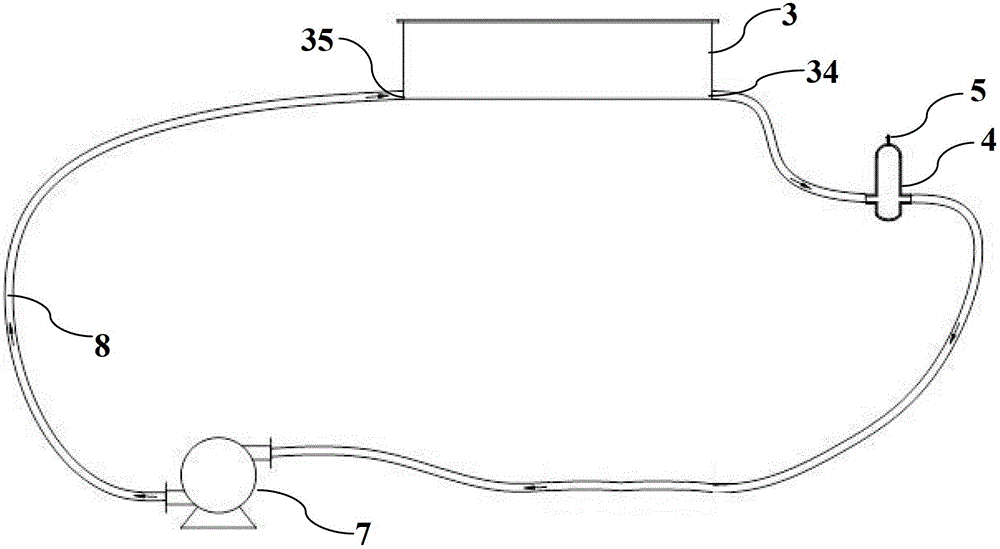

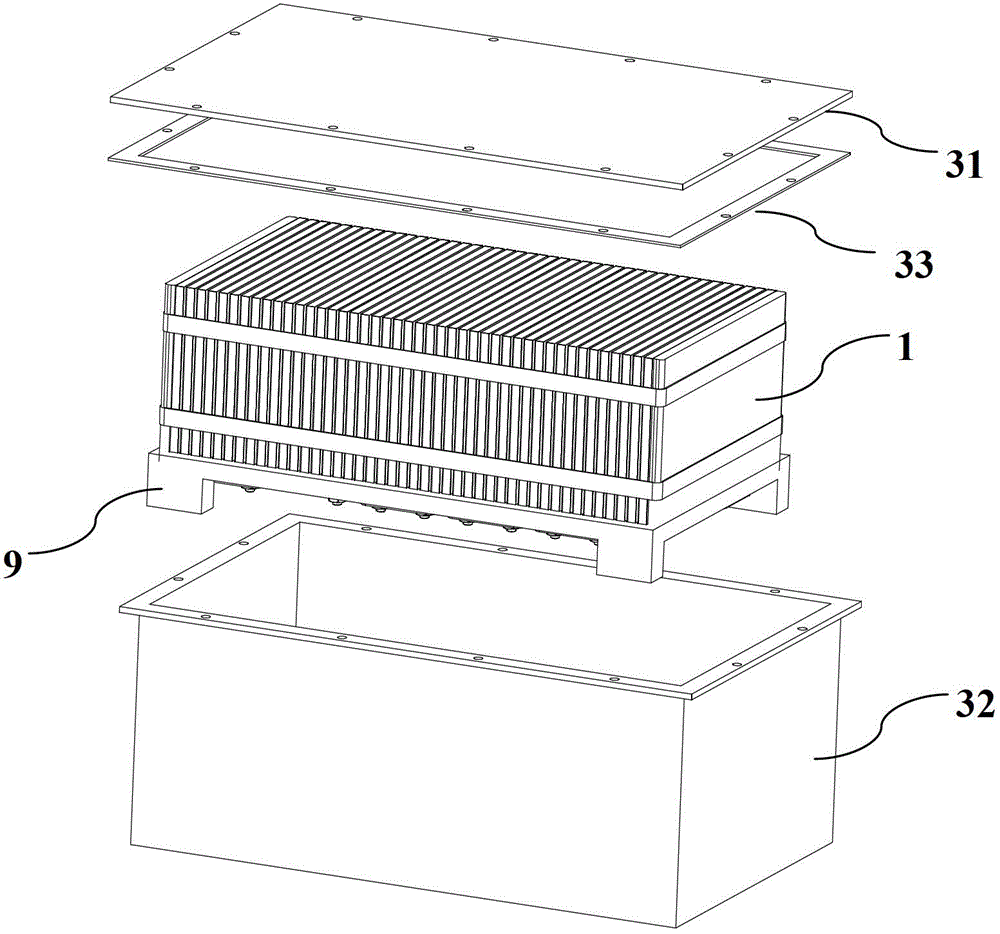

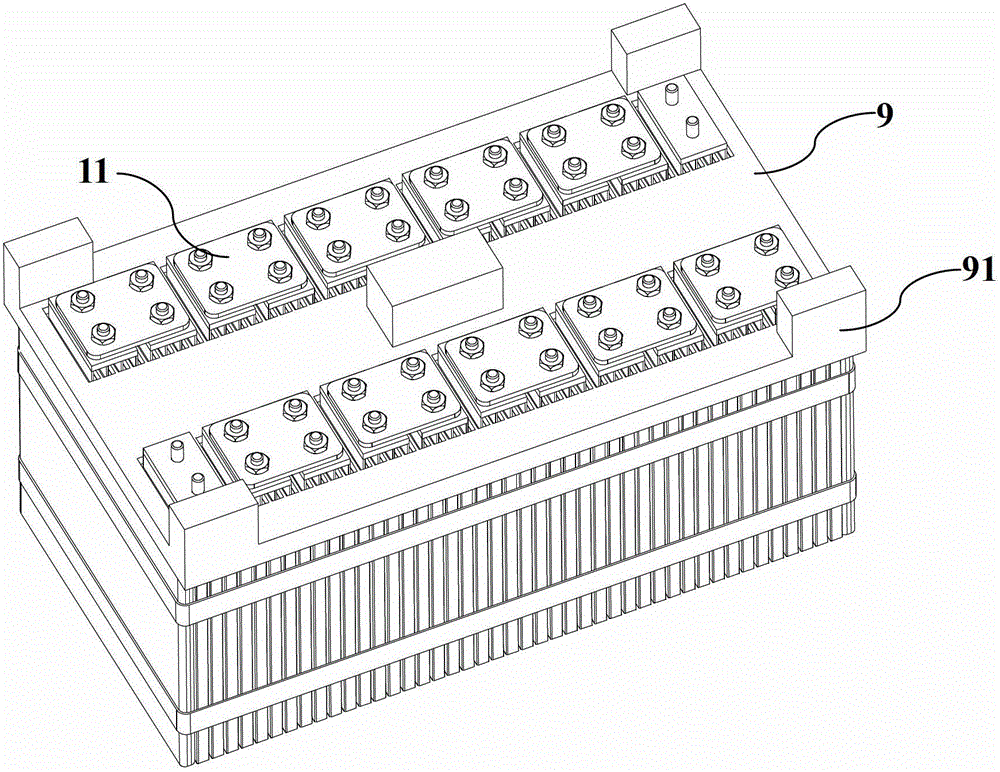

[0026] Such as Figure 1-Figure 5 As shown, the battery box 3 is composed of a box body 32 and a cover plate 31, and a sealing rubber pad 33 is used between the box body 32 and the cover plate 31 to seal the gap between the box body 32 and the cover plate 31, which can effectively seal the box body. Parts in 32 are isolated from air. A sheet battery is placed in the box 32, and several sheet batteries are stacked together to form a battery cell 1, and a spacer 6 is clamped between every two adjacent battery cells 1. In this solution, the spacer 6 Use a woven net, which is a plastic woven net whose warp and latitude lines are not on the same plane as the isolation component 6, which can well separate the battery cells 1, and can accelerate the circulation of the sealing solution 2, making the electrolyte more stable. It is easy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com