Preparation device and preparation method of glass fiber composite material for liquid hydrogen storage

A technology of glass fiber and composite materials, which is applied in the field of glass fiber, can solve the problems of strength assurance and damage of glass fiber composite materials, and achieve the effects of improving acid resistance, ensuring comprehensiveness and thoroughness, and reducing the possibility of thermal fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

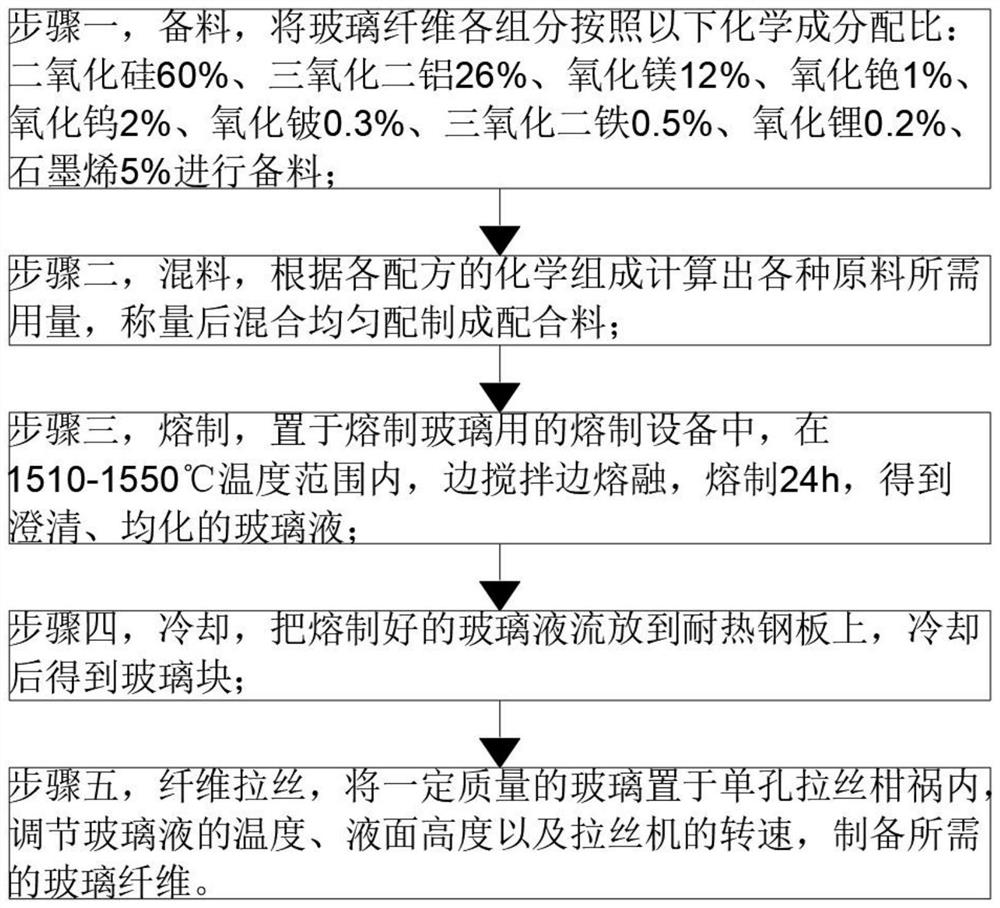

[0059] see figure 1 , the present invention provides a technical solution: a method for preparing a glass fiber composite material for liquid hydrogen storage, comprising the following steps,

[0060] Step 1, prepare materials, and distribute the components of glass fiber according to the following chemical composition: 60% silicon dioxide, 26% aluminum oxide, 12% magnesium oxide, 1% cesium oxide, 2% tungsten oxide, and 0.3% beryllium oxide , 0.5% of ferric oxide, 0.2% of lithium oxide, and 5% of graphene for material preparation;

[0061] Step 2, mixing materials, calculating the required amount of various raw materials according to the chemical composition of each formula, weighing and mixing evenly to prepare batch materials;

[0062] Step 3, melting, placed in the melting equipment for melting glass, in the temperature range of 1510-1550 ° C, melting while stirring, melting for 24 hours, to obtain clarified and homogenized glass liquid; change its main component content,...

Embodiment 2

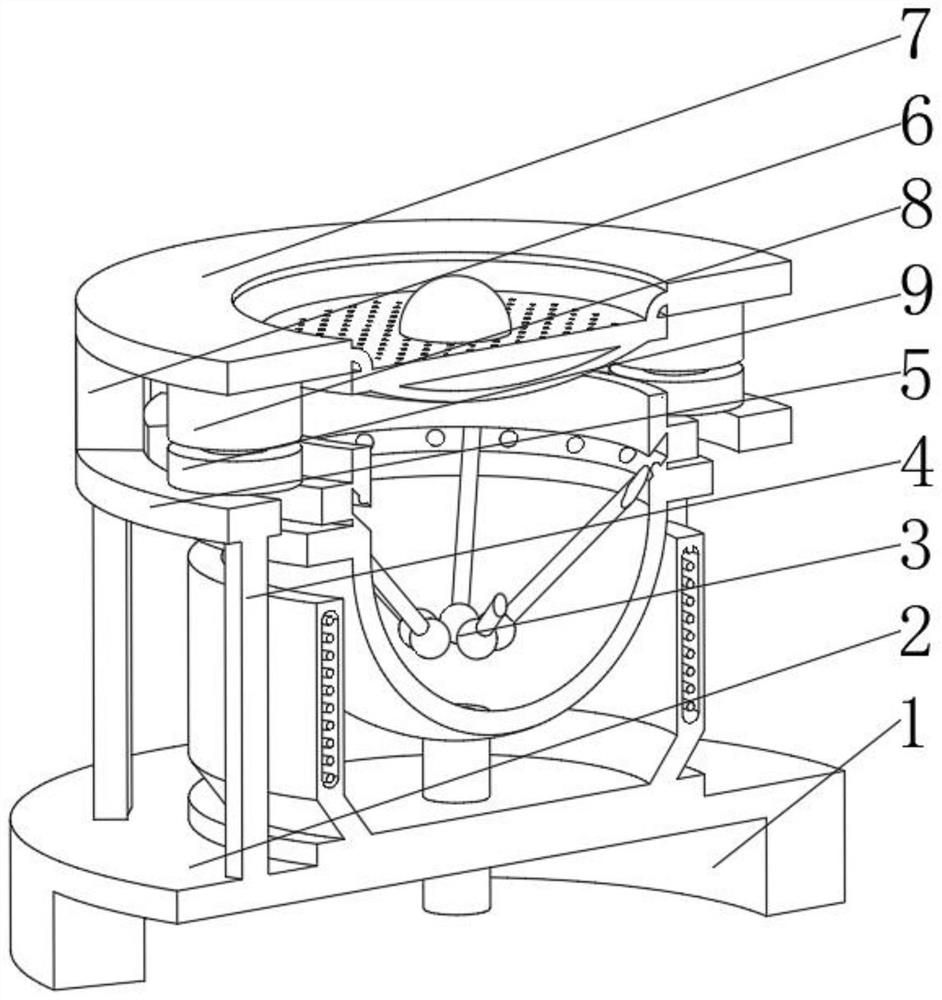

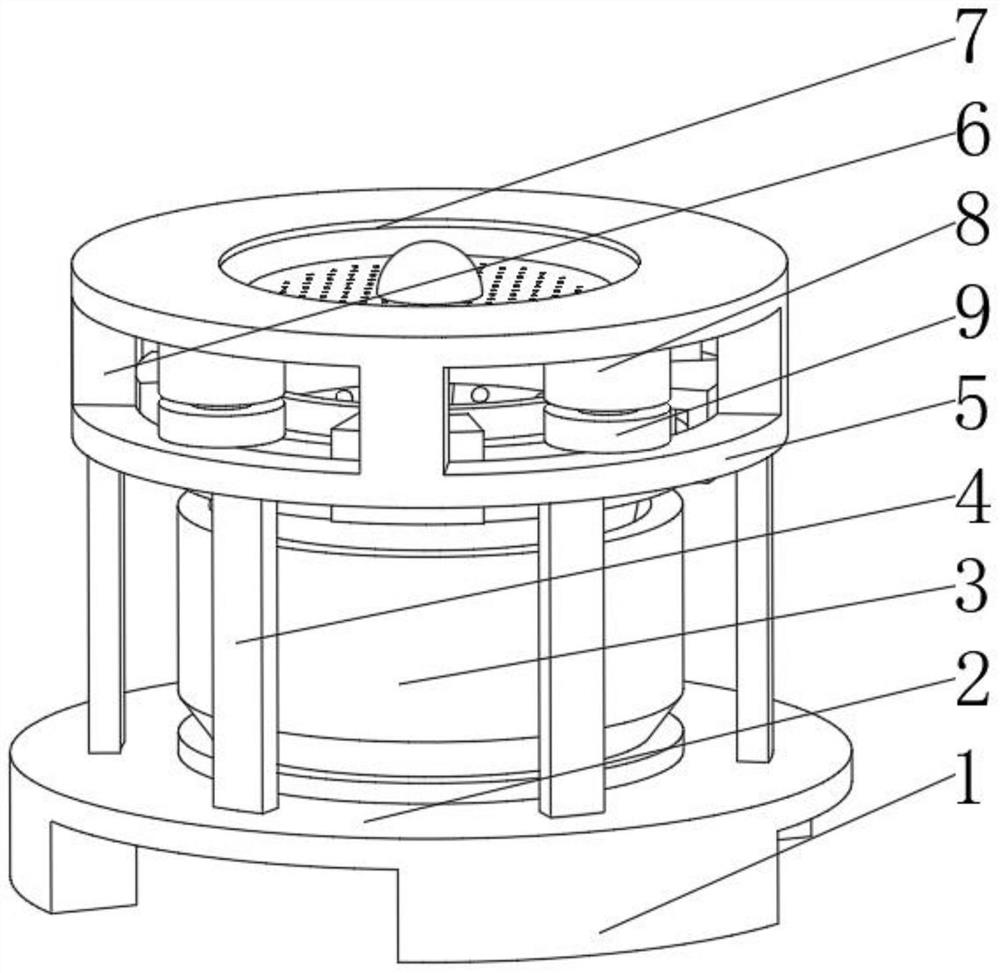

[0066] see Figure 2-6 , the present invention provides a technical solution: a glass fiber composite material preparation device for liquid hydrogen storage, comprising:

[0067] The base 1 and the carrying plate 2, the base 1 has an arc-shaped block, and the carrying plate 2 is installed on the top of the base 1;

[0068] The melting device 3 is installed in the middle of the top of the carrier plate 2, and the melting device 3 includes:

[0069] Heat insulation board 31, heat insulation board 31 has a circular main board;

[0070] A round tube valve 32, the round tube valve 32 is installed in the middle of the heat shield 31;

[0071] The shielding ring plate 33, the shielding ring plate 33 is installed on the top of the heat insulation board 31, and the shielding ring plate 33 is annular to surround the round tube valve 32, the setting of the shielding ring plate 33 protects the heating coil 34 and prevents the heating coil 34 Direct contact with the environment, protec...

Embodiment 3

[0096] see Figure 2-6 On the basis of Embodiment 2, the present invention provides a technical solution: a method for using melting equipment, comprising the following steps,

[0097] Step 1: Put the raw material of the glass fiber composite material into the crucible furnace 351 in the melting device 3, and inject water into the counterweight ball 74 in the capping device 7, so that the weight of the counterweight ball 74 increases;

[0098] Step 2: The weight of the weight ball 74 increases to drive the cover 73 to move vertically downward, so that the elastic arc plate 72 stretches, and the spherical shell cover 76 moves downward, and fits with the top limit ring plate 356 in the melting device 3 , the crucible device 35 is sealed;

[0099] Step 3: Start the heating coil 34 in the melting device 3, and use the eddy current heating to heat the raw material of the glass fiber composite material in the crucible furnace 351 to realize melting;

[0100] Step 4: Start the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com