Low-nitrogen-emission combustion chamber and gas turbine including combustion chamber

A combustion chamber and nitrogen emission technology, which is applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems that the combustion chamber cannot be used interchangeably and increase the production cost, so as to reduce the emission of nitrogen oxides, improve the combustion efficiency, and improve the economy good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

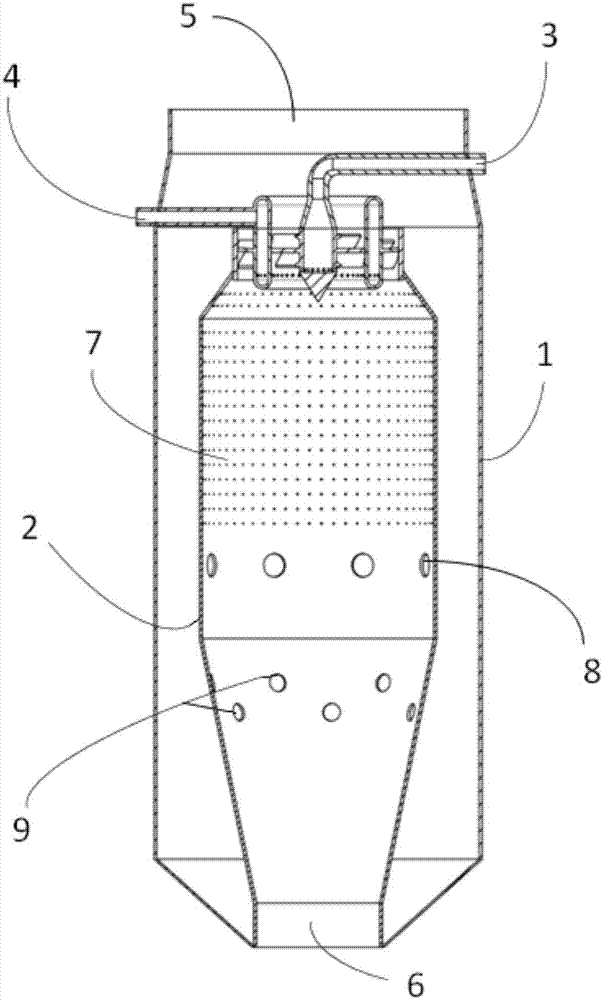

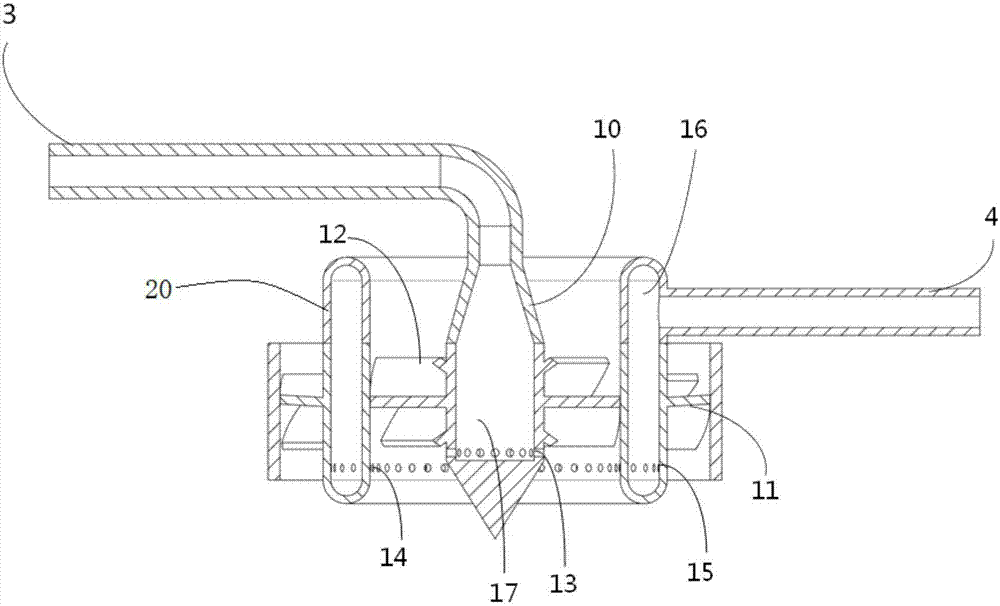

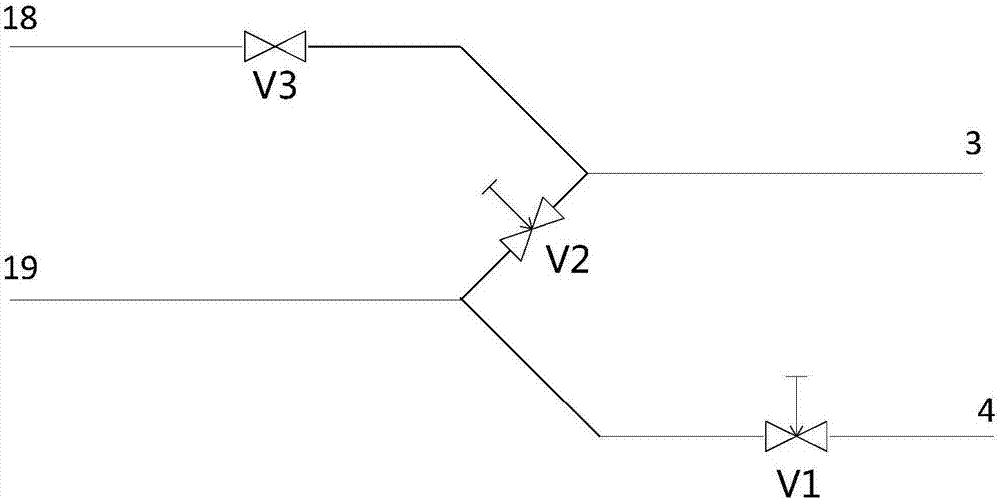

[0034] A gas turbine comprising such as figure 1 The shown low nitrogen emission combustor, which includes a combustor head and a combustor cylinder connected up and down, such as figure 2 As shown, the head of the combustion chamber includes an auxiliary gas mechanism, a main gas mechanism arranged outside the auxiliary gas mechanism, and an air inlet 5 arranged above the auxiliary gas mechanism and the main gas mechanism. The main gas mechanism, the inner flame tube 2 connected with the air inlet 5, and the outer flame tube 1 which is arranged outside the inner flame tube 2 and communicated with the air inlet 5, the bottom of the inner flame tube 2 is provided with a combustion chamber outlet 6, and the gas The gas enters the interior of the inner flame tube 2 through the auxiliary gas mechanism and the main gas mechanism respectively, mixes with the air entering through the air inlet 5 and burns, and finally discharges through the outlet 6 of the combustion chamber.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com