Digital ignition control method of small-size four-stroke engine

A four-stroke engine, ignition control technology, applied in the direction of engine ignition, spark ignition controller, automatic control, etc., can solve problems such as difficult to ignite exhaust gas, achieve the effects of saving time and procedures, saving resources, and improving ignition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

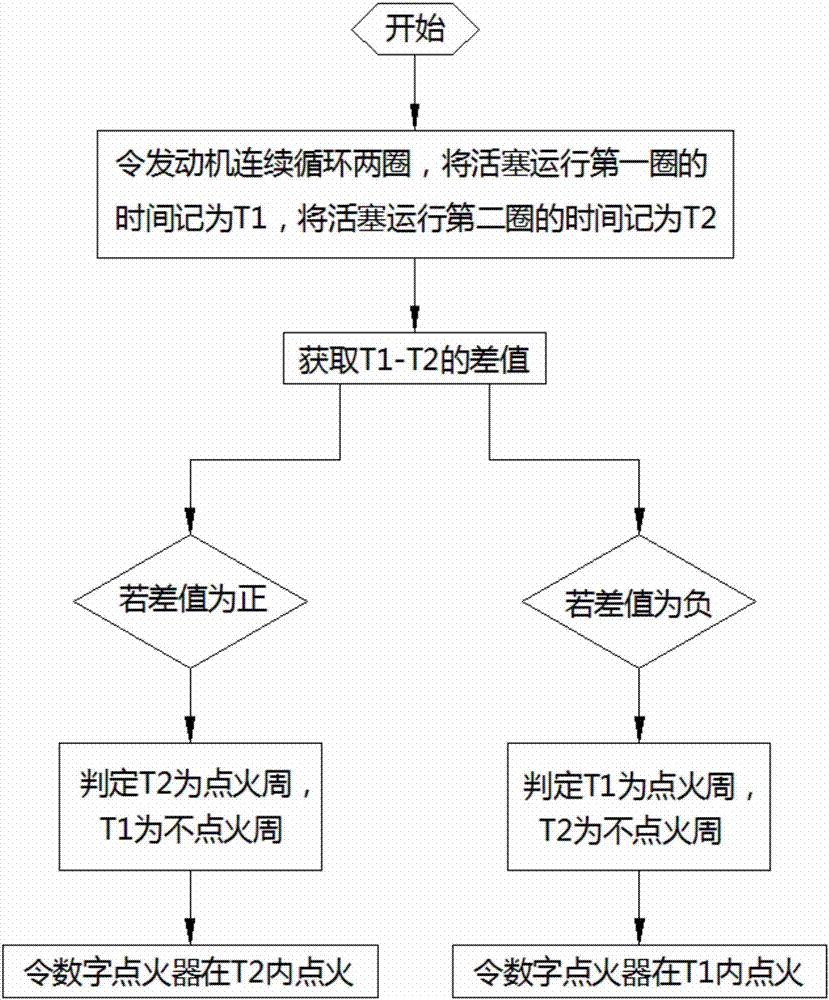

[0027] Such as figure 1 As shown, the digital ignition control method of the small four-stroke engine provided by Embodiment 1 of the present invention includes the following steps:

[0028] Step 1: Obtain the time for the piston in the small-scale four-stroke engine to continuously rotate for two laps, record the time for the first lap of the piston as T1, and record the time for the second lap of the piston as T2;

[0029] Step 2: Obtain the difference between T1 and T2;

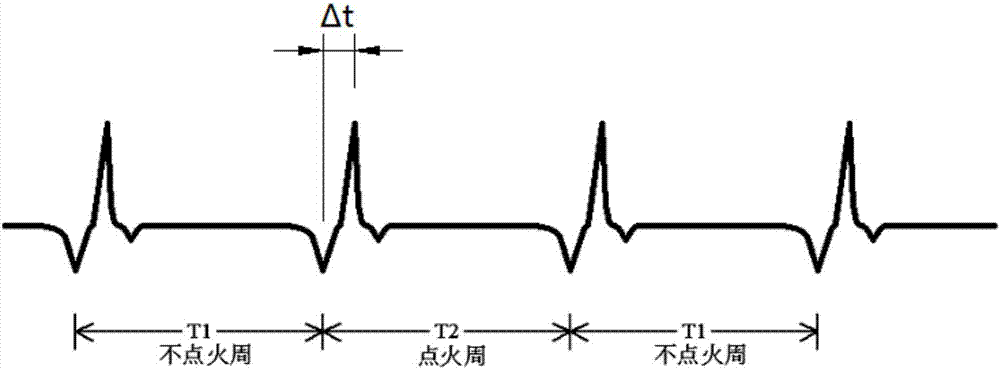

[0030] Step 3: If the difference between T1-T2 is positive, determine that the second circle corresponding to T2 is the ignition cycle, and the first circle corresponding to T1 is the non-ignition cycle, so that the digital igniter ignites in T2;

[0031] If the difference between T1-T2 is negative, it is determined that the first turn corresponding to T1 is an ignition cycle, and the second turn corresponding to T2 is a non-ignition cycle, so that the digital igniter is ignited in T1.

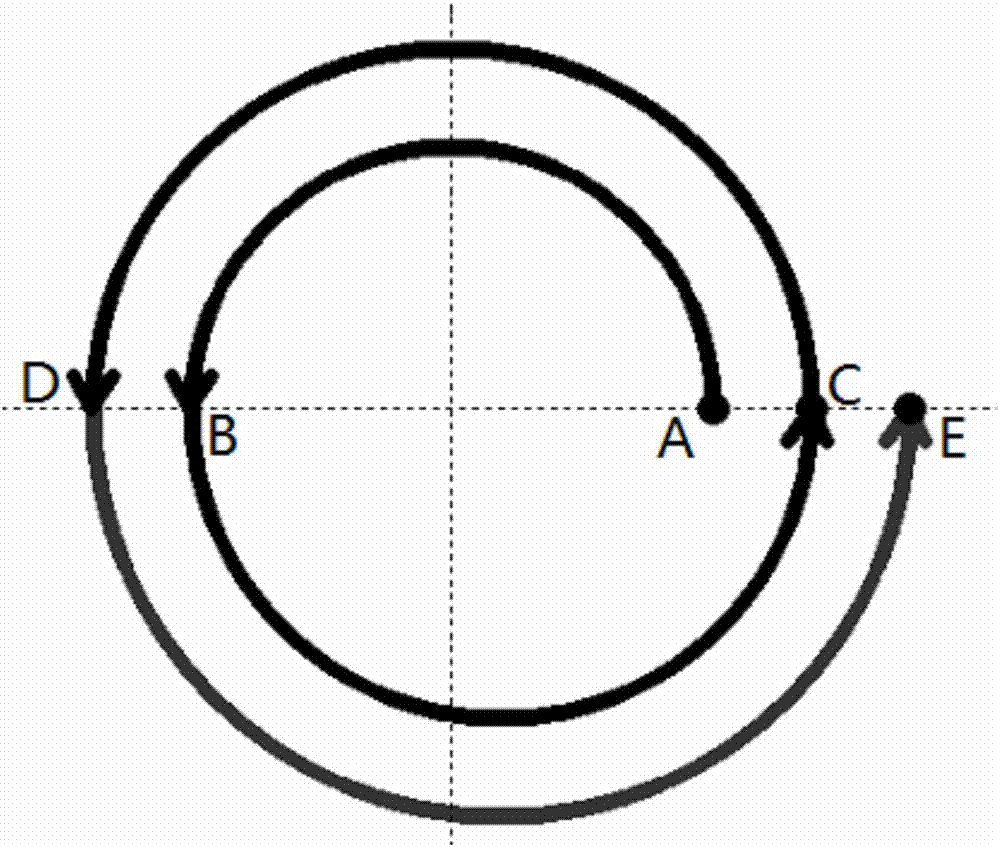

[0032] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com