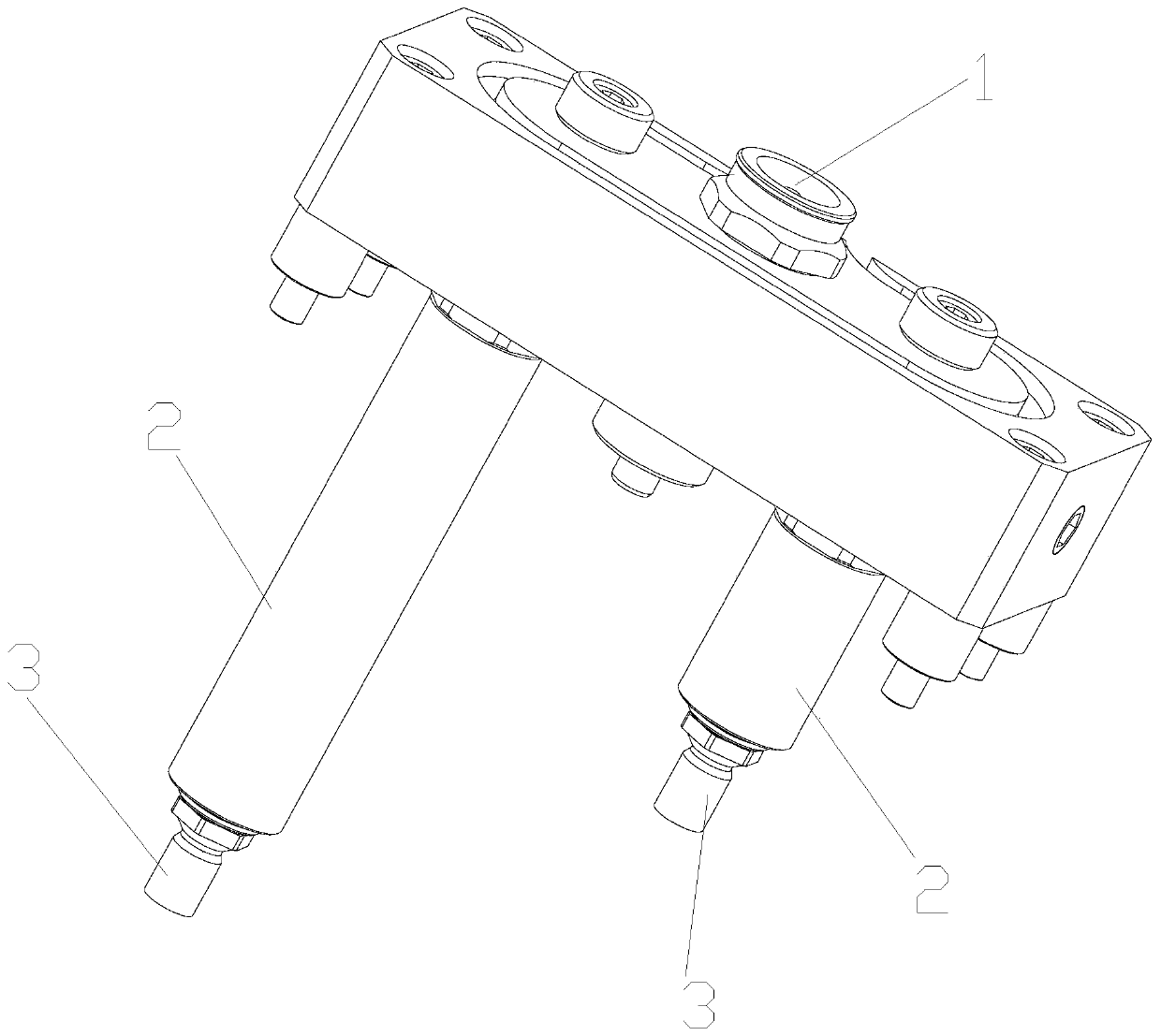

Hot runner flow and flow length adjusting insert and hot runner system

A technology of hot runner and flow rate, which is applied in the field of hot runner flow and flow length adjustment inserts and hot runner systems, and can solve problems such as difficult injection molding, difficulty in maintaining consistent balance between hot runner points, and large differences in path length. Achieve the effect of increasing the flow length, shortening the gap, and uniform discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

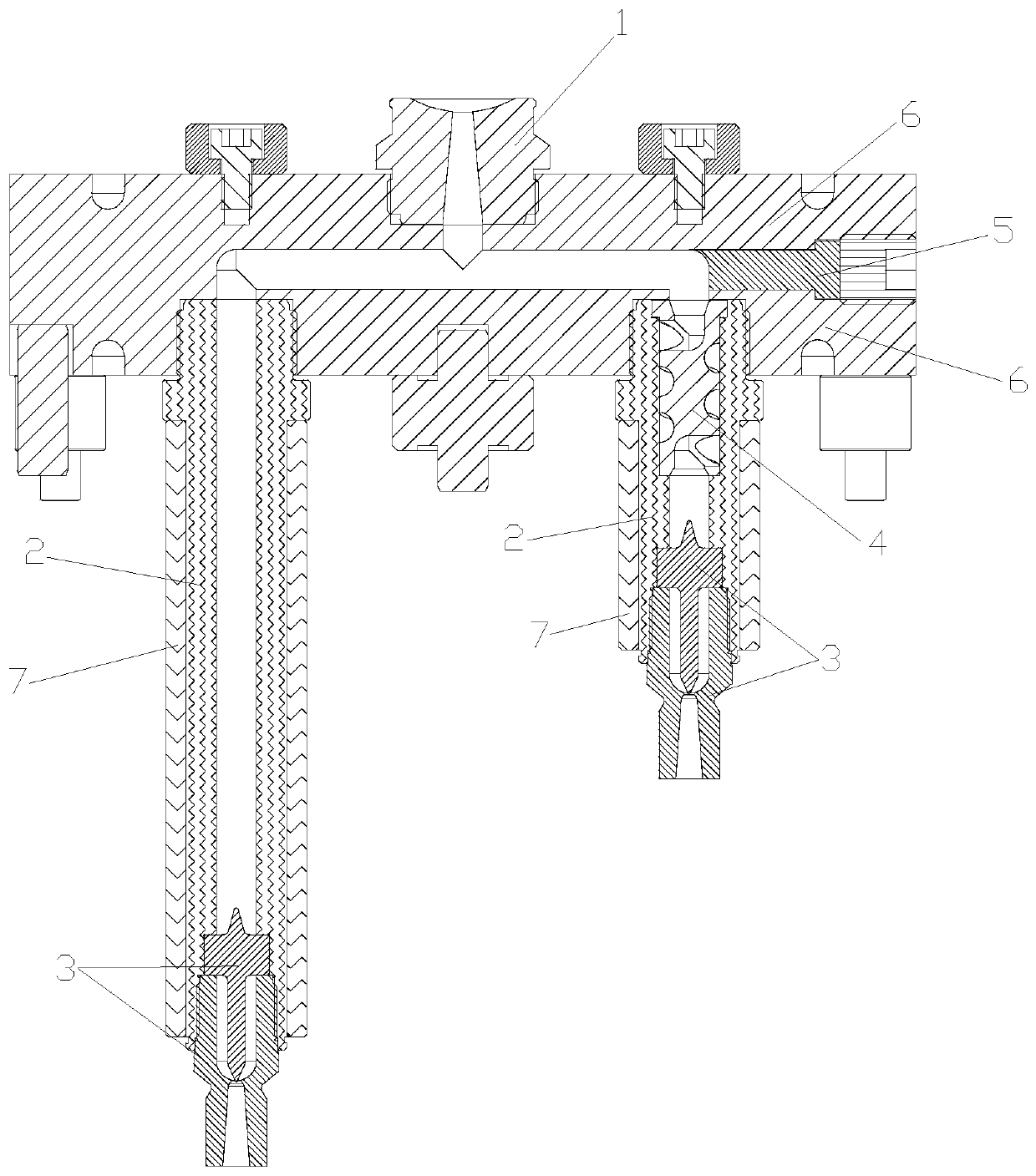

[0017] Below in conjunction with each accompanying drawing, the present invention is described in detail.

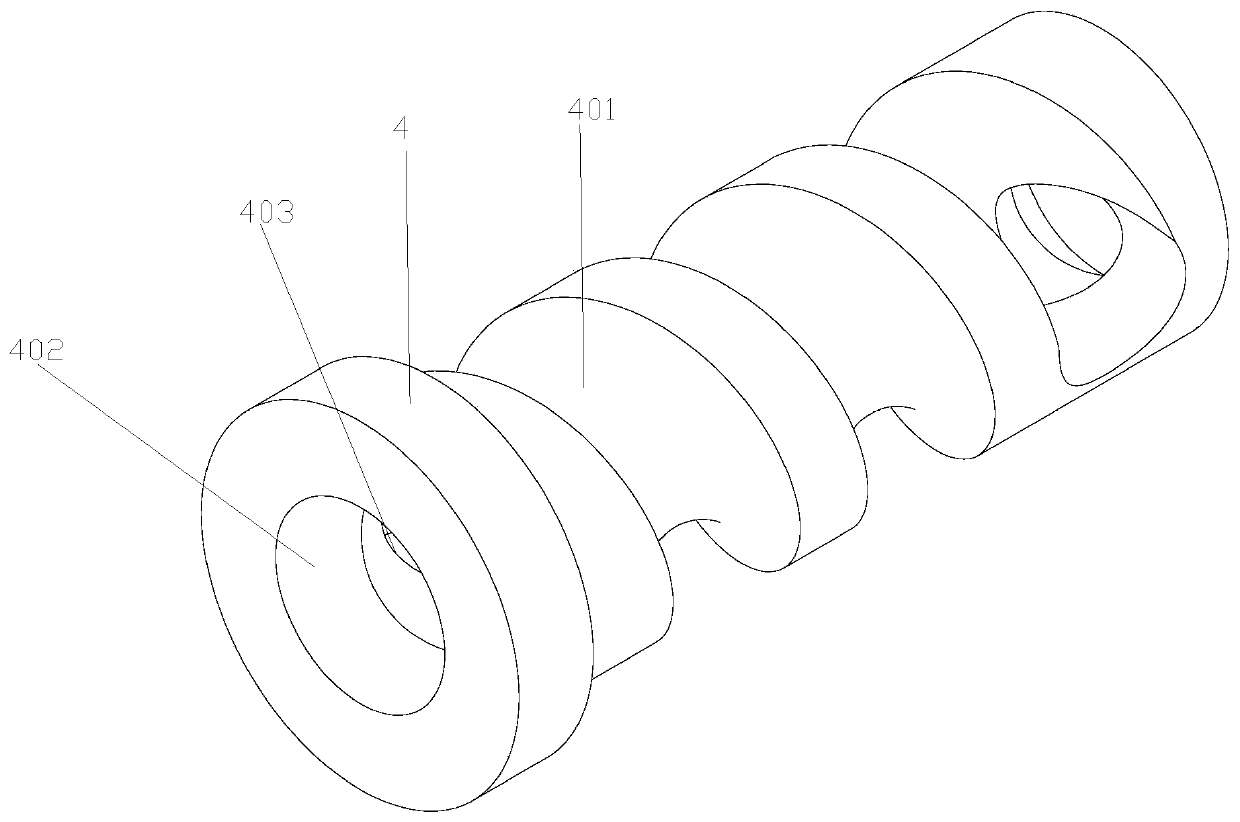

[0018] as attached figure 2 As shown, a hot runner flow and flow length adjustment insert includes a columnar base 4, the two ends of the base 4 are respectively provided with feed holes 402, and the outer wall of the base 4 is provided with a spiral slideway 401, the slideway 401 Unicom material hole 402.

[0019] After the insert is installed in the relatively short channel tube, the base 4 is provided with a spiral slideway 401, which changes the original linear flow path in the channel tube into a spiral curved flow path, so that This increases the flow length of the plastic raw material in the shorter runner barrel, which shortens the difference in the flow length of the two strands of plastic raw material in the two long and short runner barrels, making the discharge more uniform and shortening the hot runner point. The distance between points and points, the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com