Line-up type full-contact heat exchange tube

A heat exchange tube, full contact technology, applied in indirect heat exchangers, heat exchanger types, fixed tubular conduit assemblies, etc., which can solve problems such as large mass and waste of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

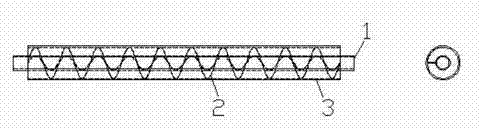

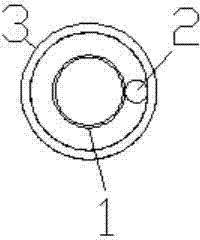

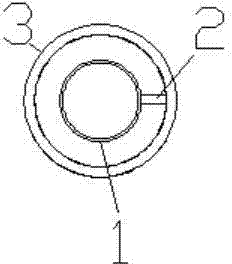

[0022] refer to figure 1 Shown: Line-up full-contact heat exchange tubes, including inner tube (1), spiral-guided range-extending ferrule (2), and outer tube (3). Both the inner tube (1) and the spiral-guided range-extending ferrule (2) are arranged inside the outer tube (3) and are concentric with the outer tube (3); the spiral-guided range-extending ferrule (2) is sleeved on On the outer wall of the inner tube (1) and placed inside the outer tube (3), a spiral guide channel is formed between the inner tube (1) and the outer tube (3); the inner tube (1) is a channel; the The tube wall of the inner tube (1) is a heat exchange conductor; the material of the inner tube (1), the spiral-guided range-extending ferrule (2), and the outer tube (3) is metal; the spiral-guided range-extending ferrule (2 ) is a spacer belt, spirally coiled on the inner tube (1); the cross-sectional area of the spacer belt is fin-type; the shape of the queuing-type full-contact heat exchange tube is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com