Patents

Literature

130results about How to "Reduce backflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

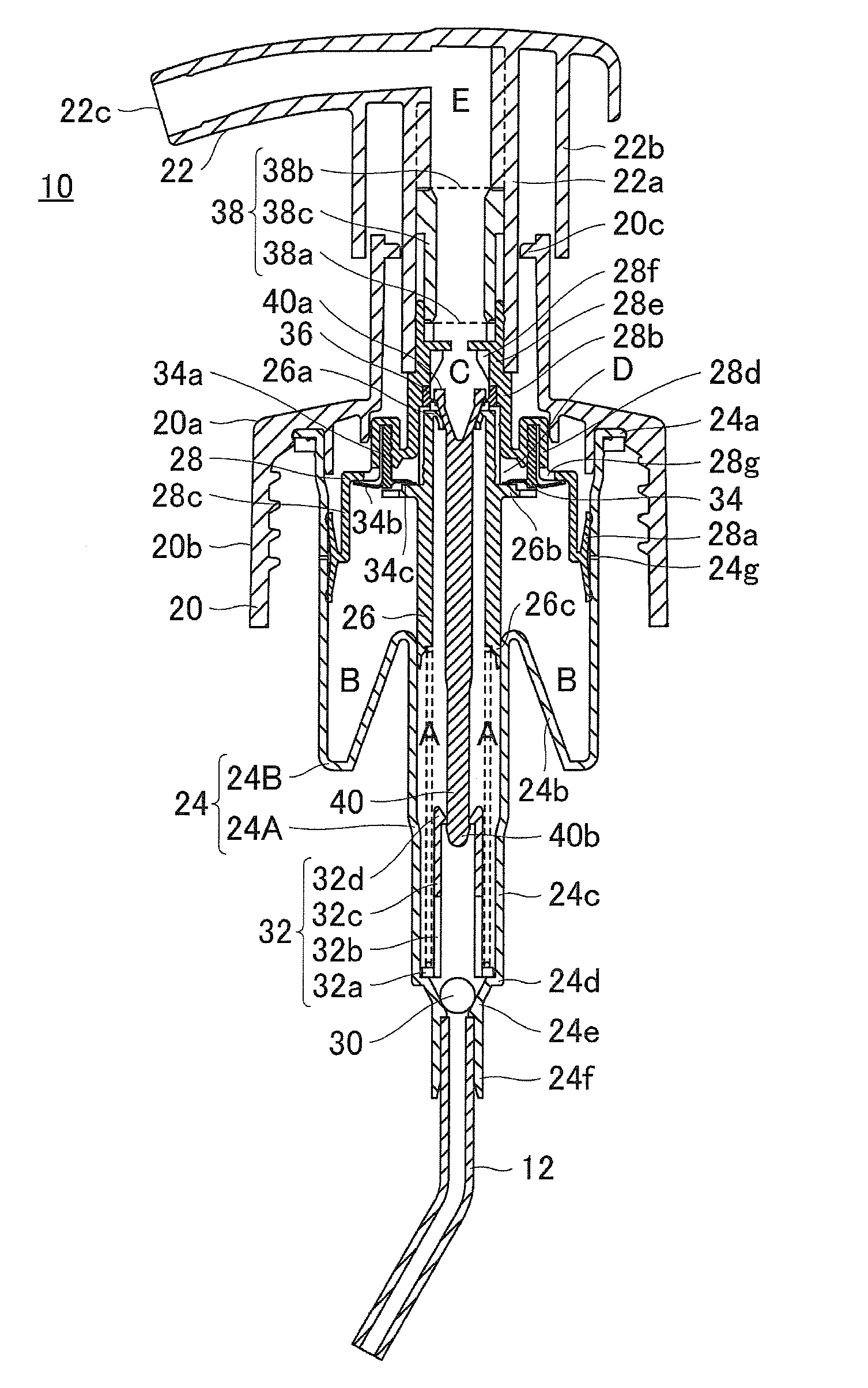

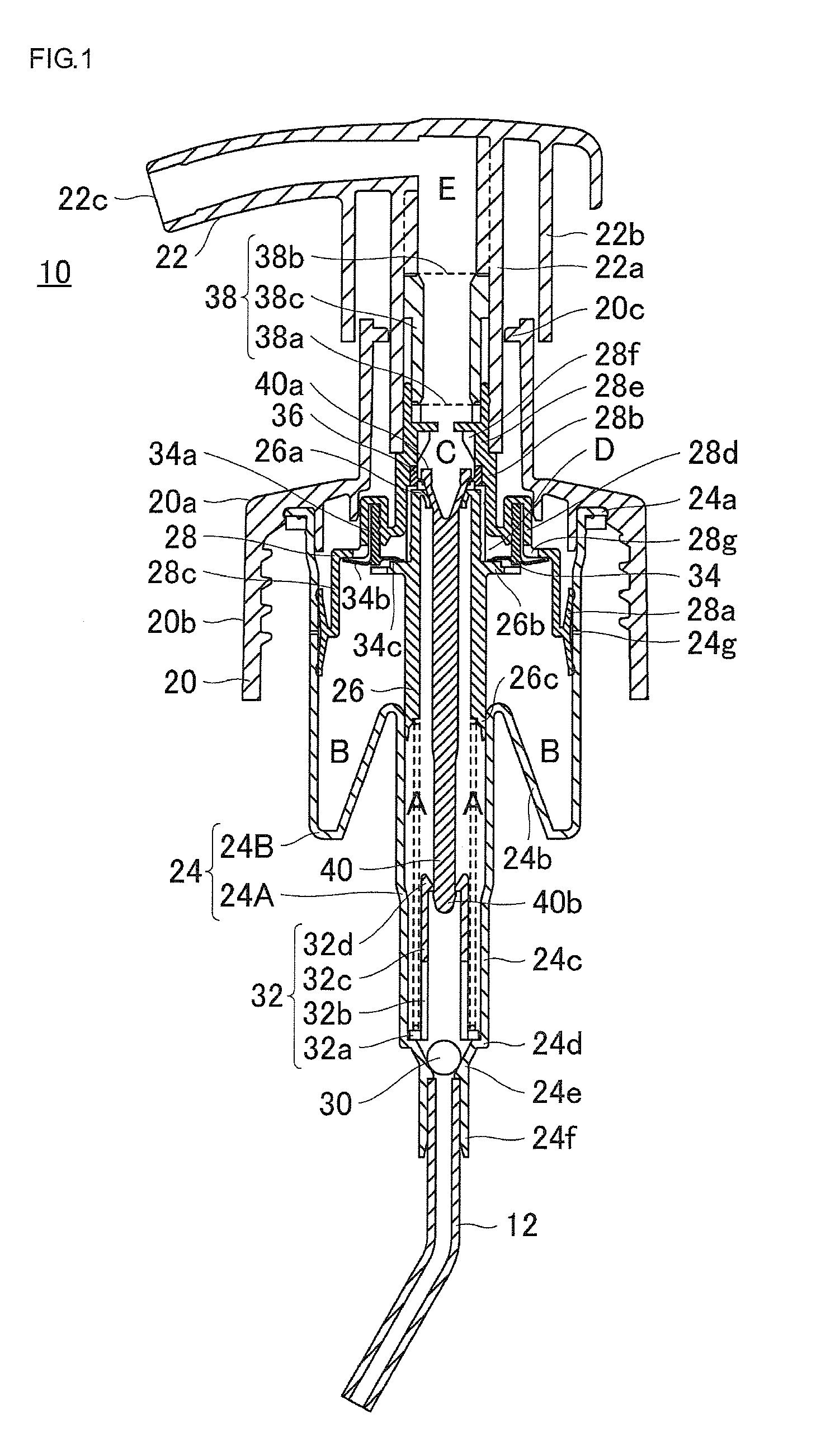

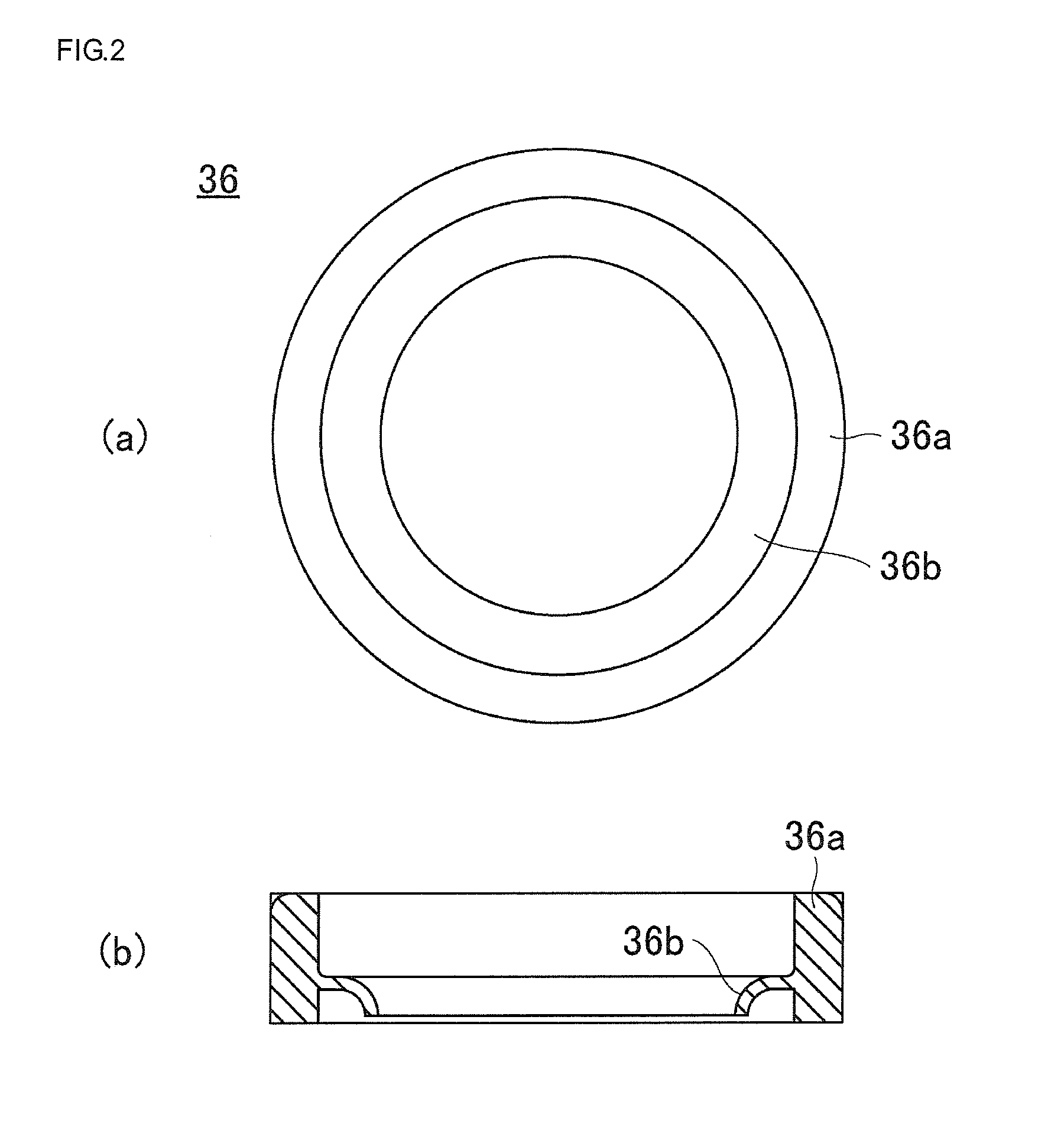

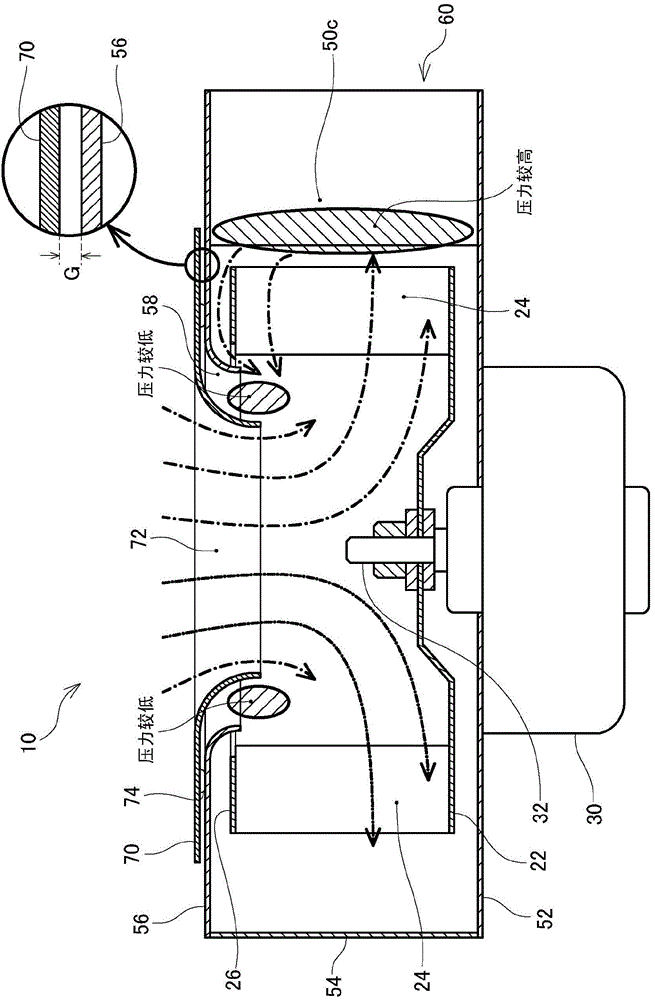

Foam-Dispensing Pump Container

ActiveUS20120241477A1Reduce backflowImprove usabilityClosuresLiquid transferring devicesBackflowNozzle

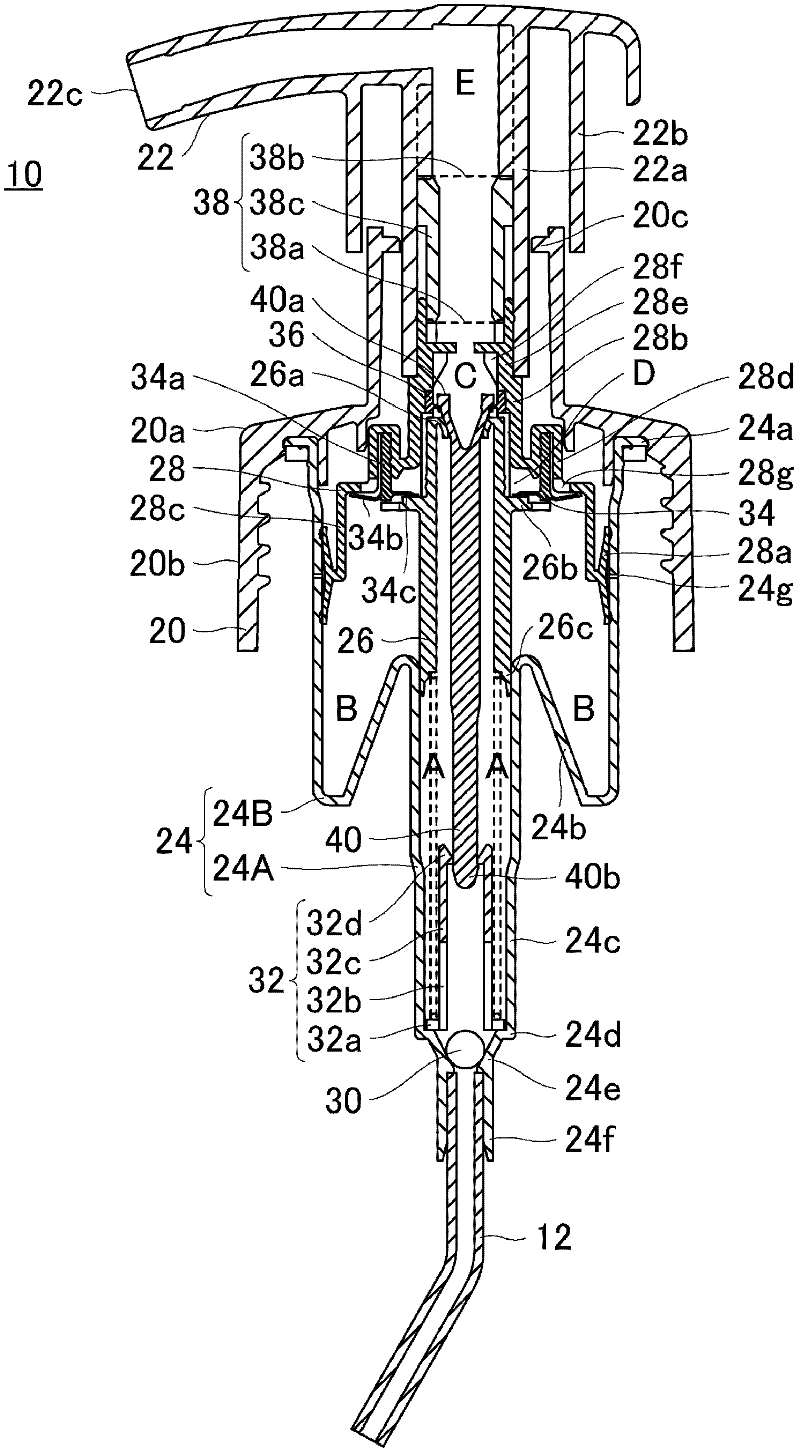

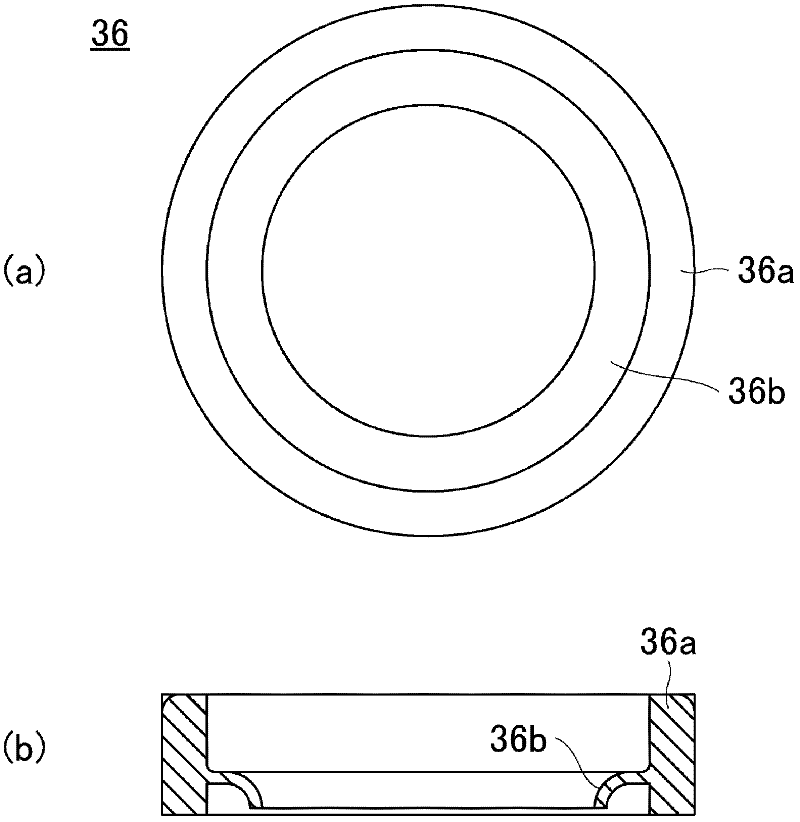

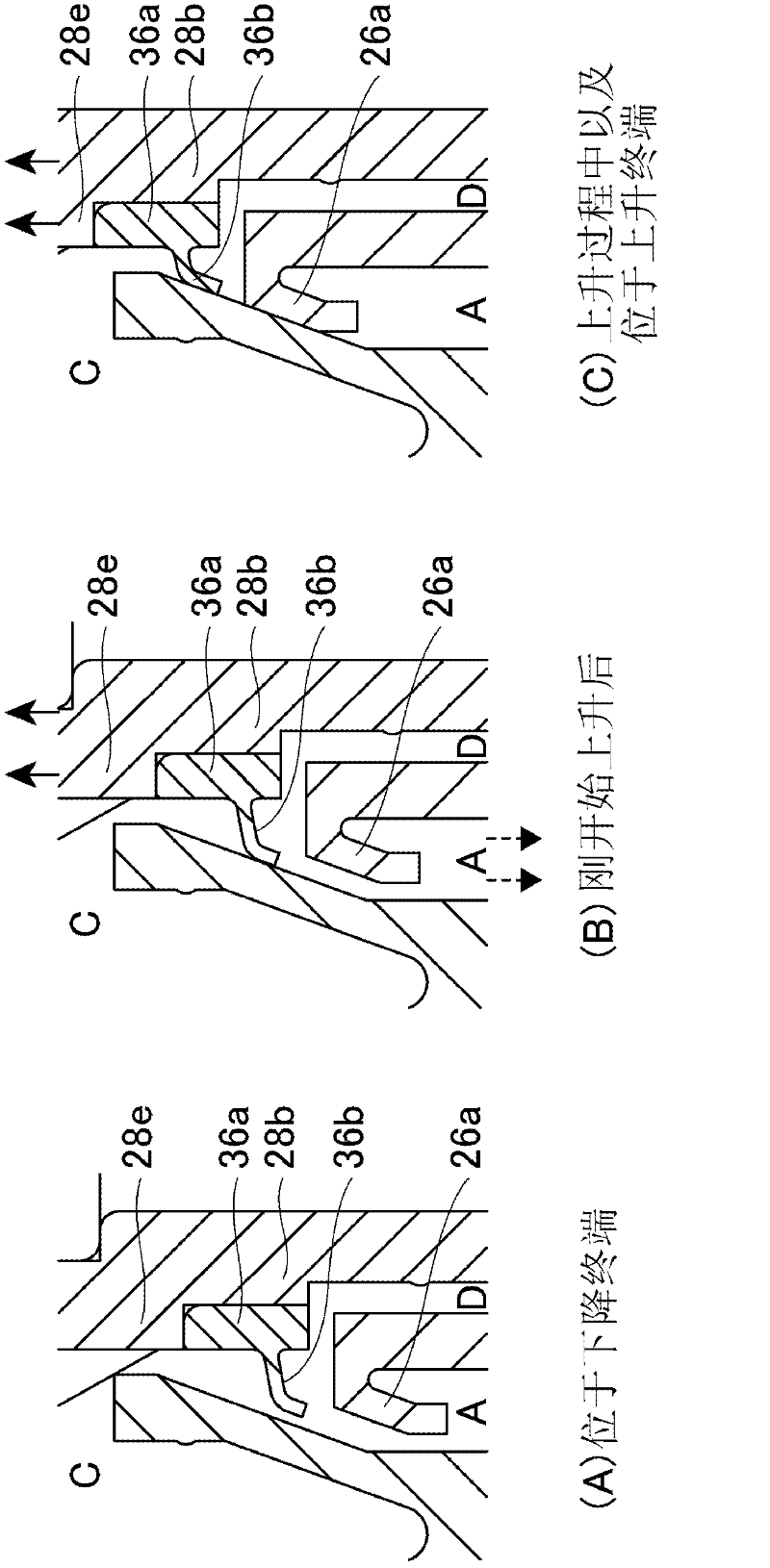

The foam-dispensing pump container according to the present invention has the valve seat portion which protrudes inwardly below the air-liquid mixing unit and which is formed of the flexible member that can come into contact with the outer peripheral face of the latch portion of the rod-shaped valve body, and immediately after the nozzle head starts rising, the flexible valve seat portion comes into contact with the rod-shaped valve body before the upper opening end of the liquid chamber comes into contact with the rod-shaped valve body, thereby significantly reducing a backflow of the foam or liquid into the air passage, and consequently improving the usability of the foam-dispensing pump container.

Owner:DAIWA CAN

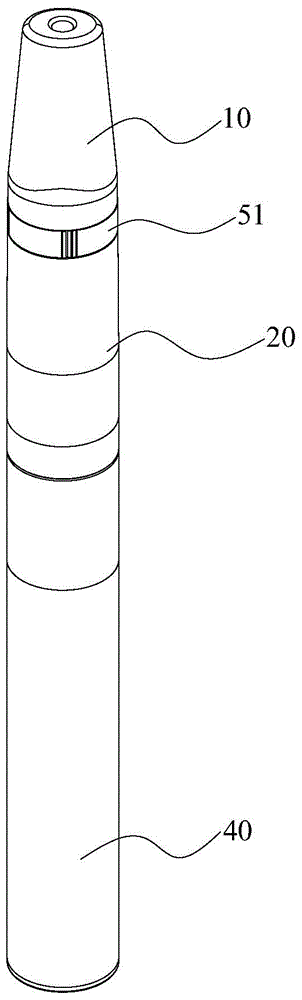

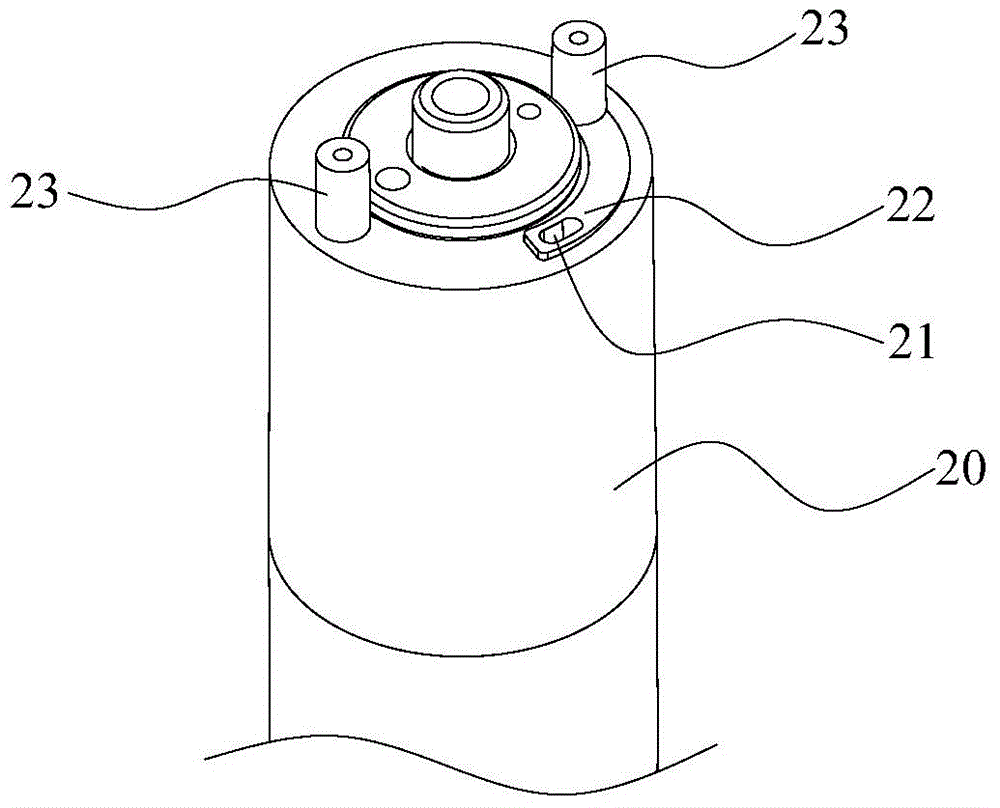

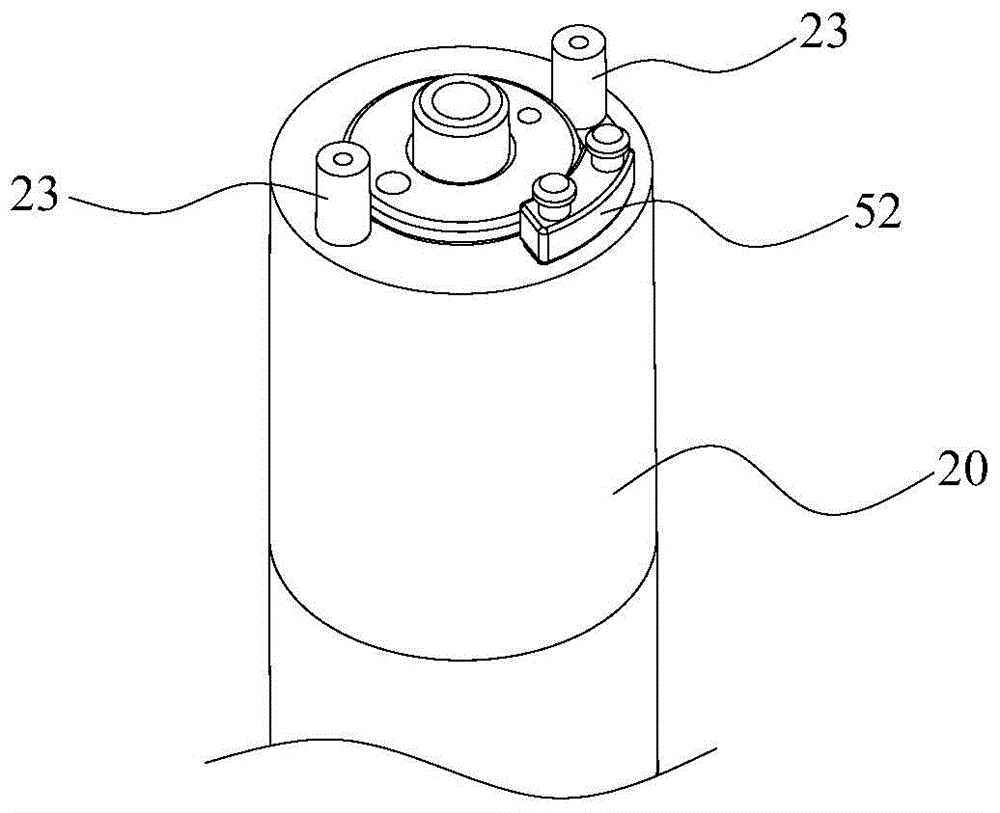

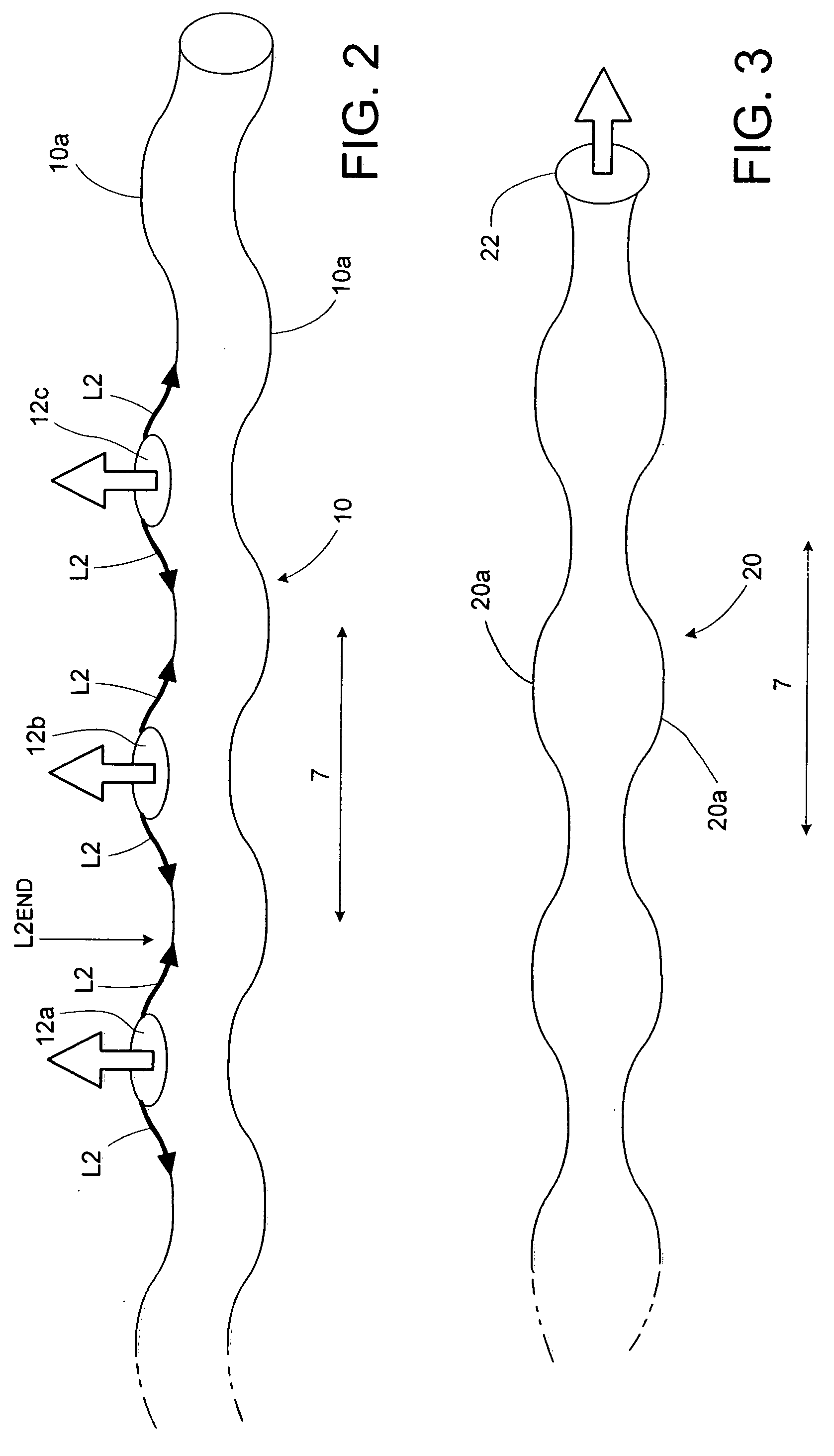

Electronic atomizing device with air inlet capable of being opened and closed

ActiveCN104470388AReduce backflowPrevent backflowRespiratorsMedical devicesElectric energyMaterial flow

The invention relates to an electronic atomizing device with an air inlet capable of being opened and closed. The device comprises a cigarette mouth (10), an atomizer (20) communicated with the cigarette mouth (10), and a battery assembly (40) supplying power to the atomizer (20). The upper part of the atomizer (20) is provided with the air inlet (21), and the atomizer (20) is communicated with the outside through the air inlet (21). An air inlet switching assembly (50), which is used for closing or opening the air inlet (21), is disposed between the atomizer (20) and the cigarette mouth (10). The air inlet (21) is located at the upper part of the atomizer (20) not close to a part below the atomizer (20), thereby reducing the conditions that liquor condensate and liquid flavor materials flow back when the device is placed in an inclined manner. Meanwhile, the air inlet (21) also can achieve complete sealing through the air inlet switching assembly (50), thereby completely preventing the liquor condensate and liquid flavor materials from flowing back to the outside and polluting the appearance of the device, and reducing the possibility of damage to the battery assembly (40).

Owner:SHENZHEN JIESHIBO TECH

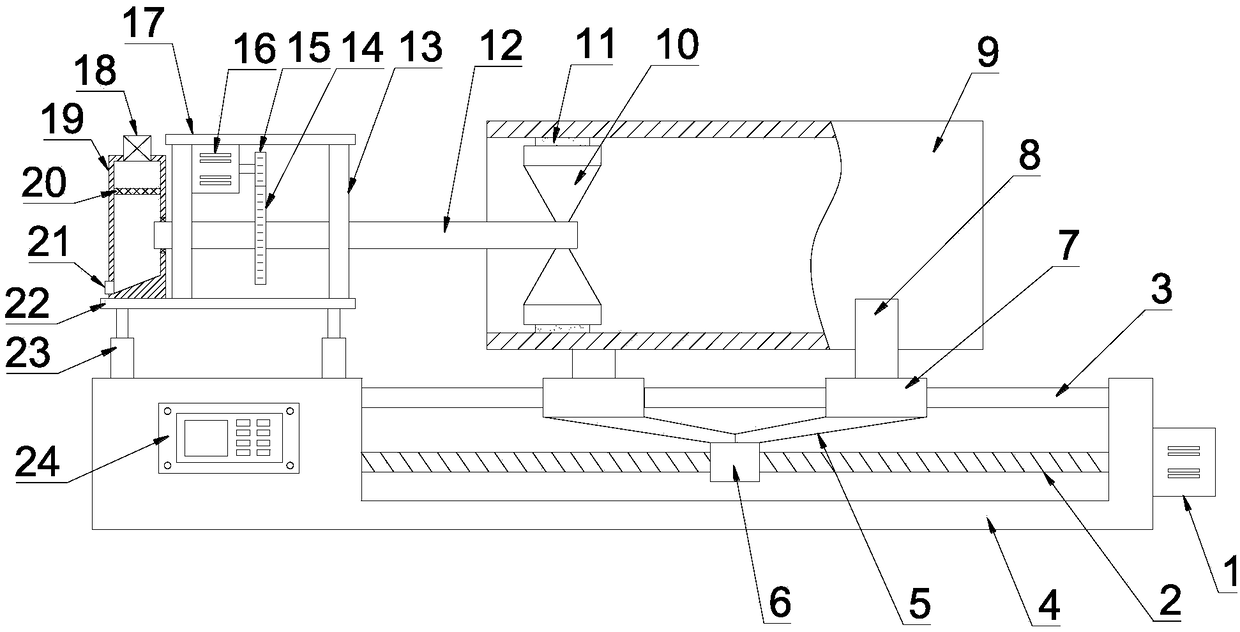

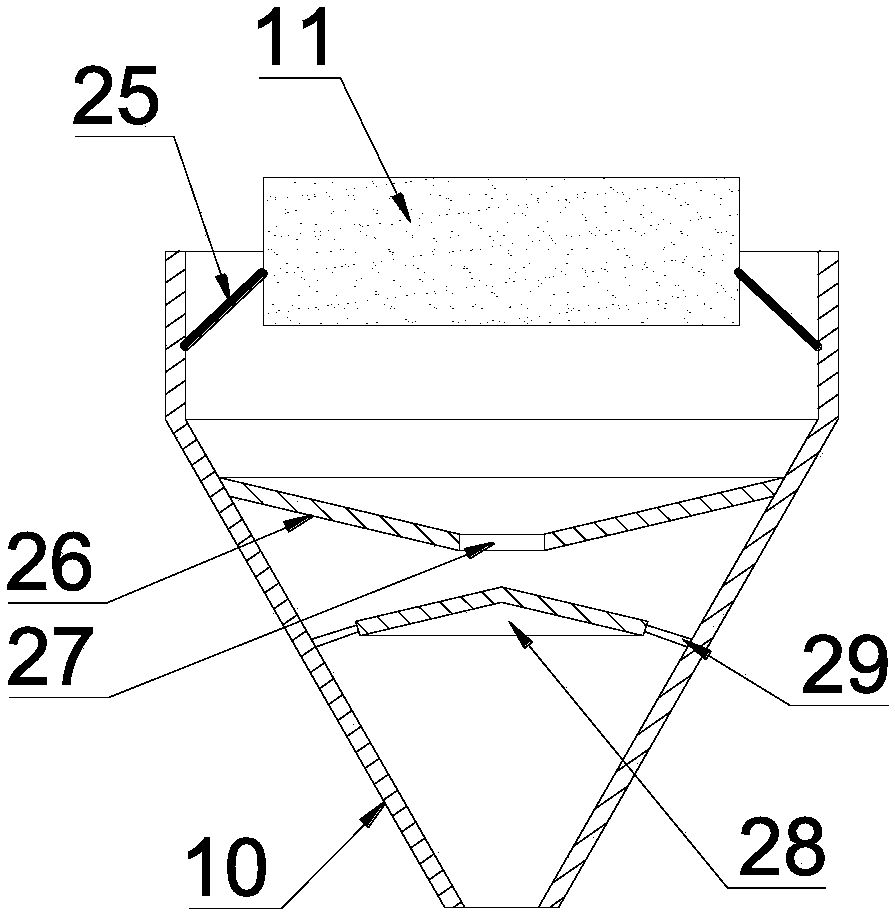

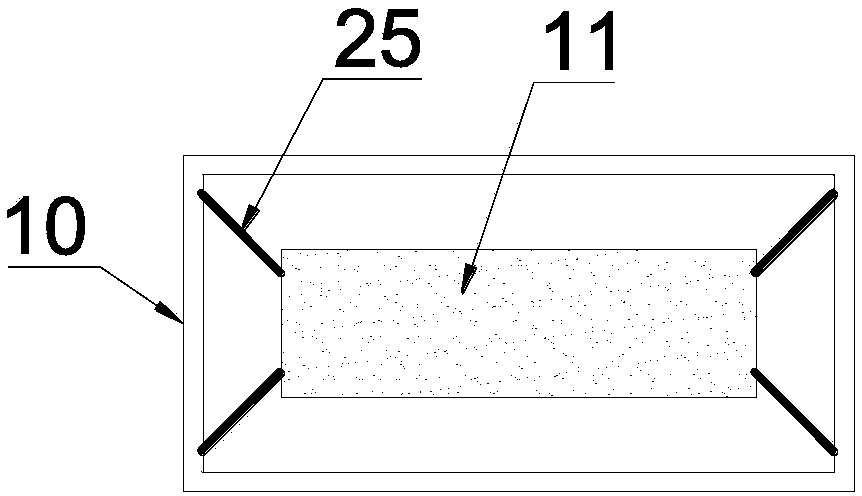

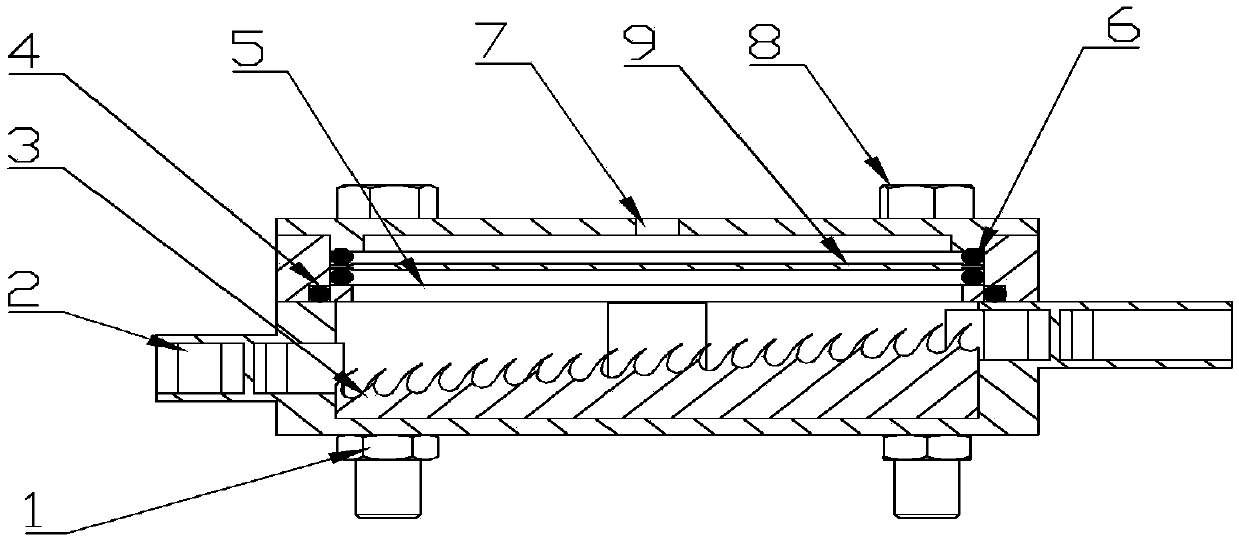

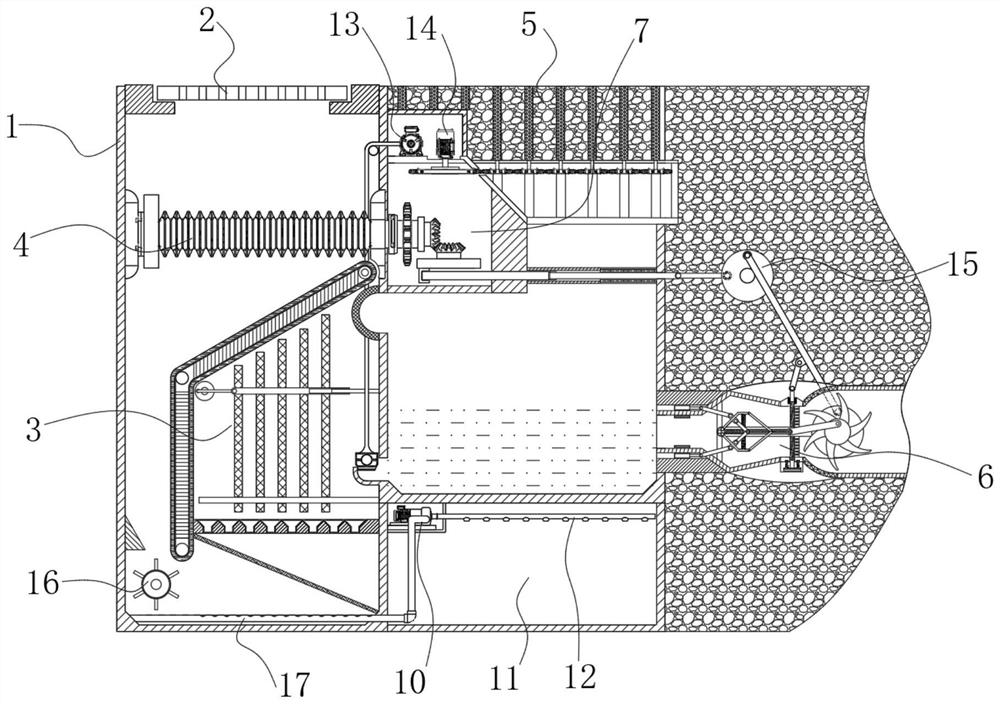

Synchronous efficient dust removal pipeline inner wall grinding device

InactiveCN108326646AGood for range grindingReduce backflowRevolution surface grinding machinesGrinding/polishing safety devicesArchitectural engineeringTelescopic cylinder

The invention discloses a synchronous efficient dust removal pipeline inner wall grinding device. The synchronous efficient dust removal pipeline inner wall grinding device comprises a base, a guide rod and a screw rod are arranged on the base, two sliding sleeves are arranged on the guide rod in a fit sliding manner, the upper sides of the two sliding sleeves are provided with supporting plates for bearing a pipeline, a lower mounting plate is arranged on the left side of the top of the base, multiple telescopic cylinders are arranged between the lower mounting plate and the base, an upper mounting plate is arranged above the lower mounting plate, a transverse shaft is arranged between the upper mounting plate and the lower mounting plate, multiple grinding cylinders are fixedly arrangedon the right end of the transverse shaft, the outer ends of the grinding cylinders are provided with grinding columns in an elastic supporting manner through multiple springs, the inner sides of the grinding cylinders are provided with upper conical plates and lower conical plates, a dust removal box is arranged at the left end of the transverse shaft, and an exhaust fan is arranged on the top ofthe dust removal box. Operation control is facilitated, the grinding machine adapts to grinding of different pipelines, the grinding effect is good, efficiency is high, dust is synchronously removed,and the higher application and popularization value is achieved.

Owner:何天行

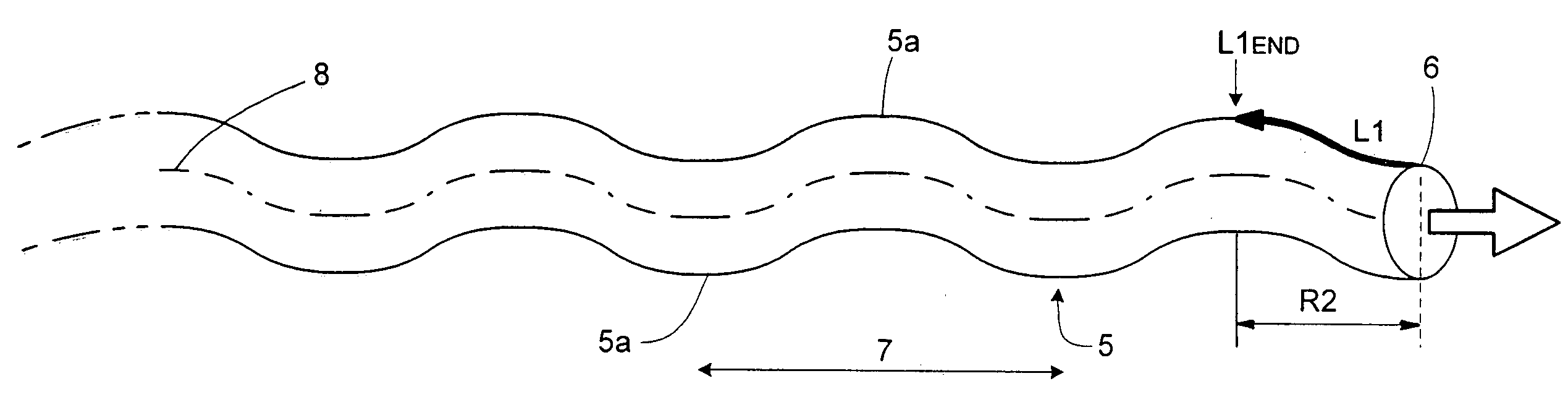

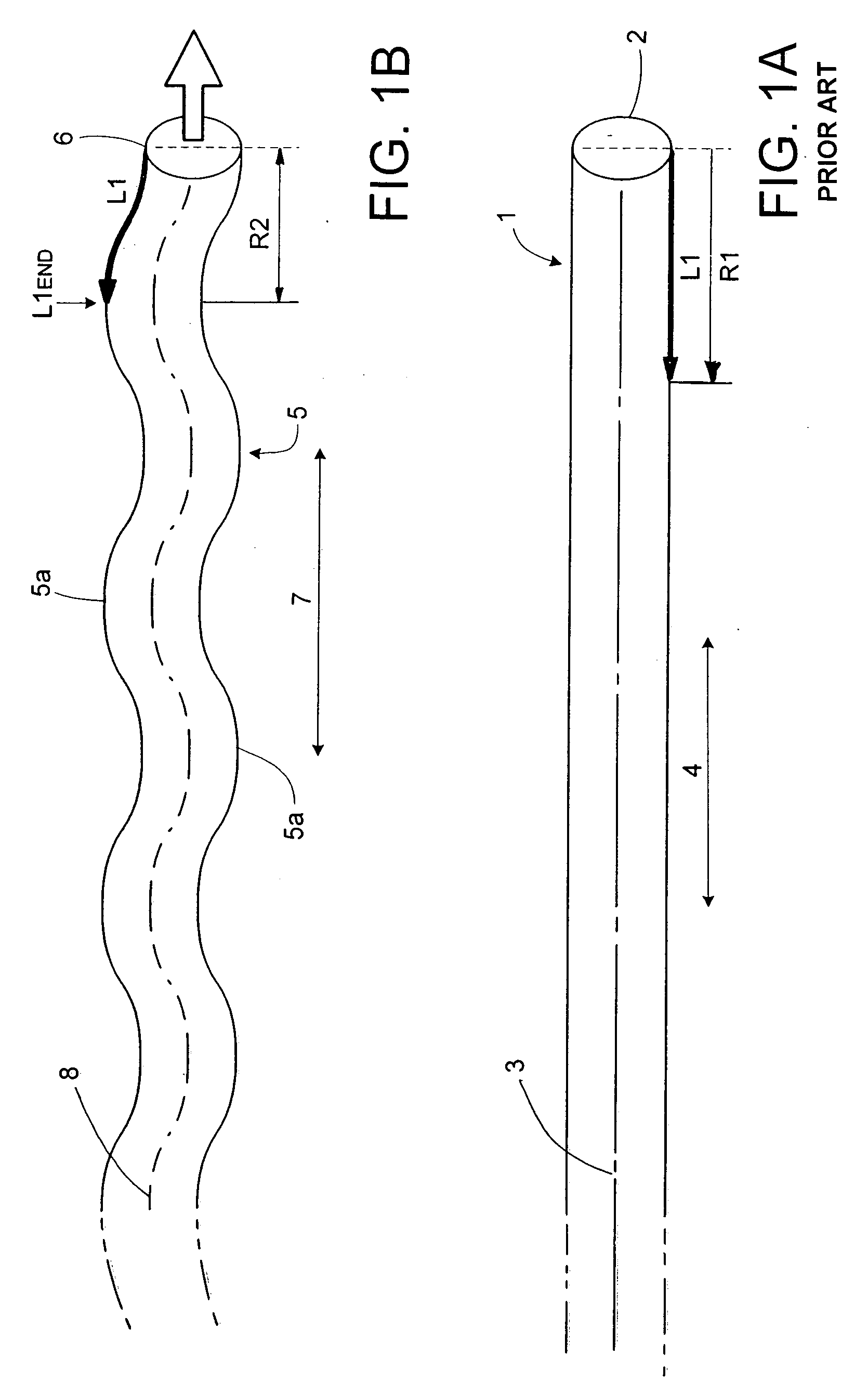

Intracranial catheter

InactiveUS20060253101A1Increase supplyImprove predictabilityCatheterPath lengthElectrical resistivity and conductivity

A catheter having an outer profile which is formed such that a path length along an outer surface of the catheter is greater than the corresponding length of the catheter, and to a method for determining the shape of a catheter, and wherein the elasticity and / or conductivity of the tissue into which the catheter is to be introduced is taken into account in order to determine the outer profile of the catheter.

Owner:BRAINLAB

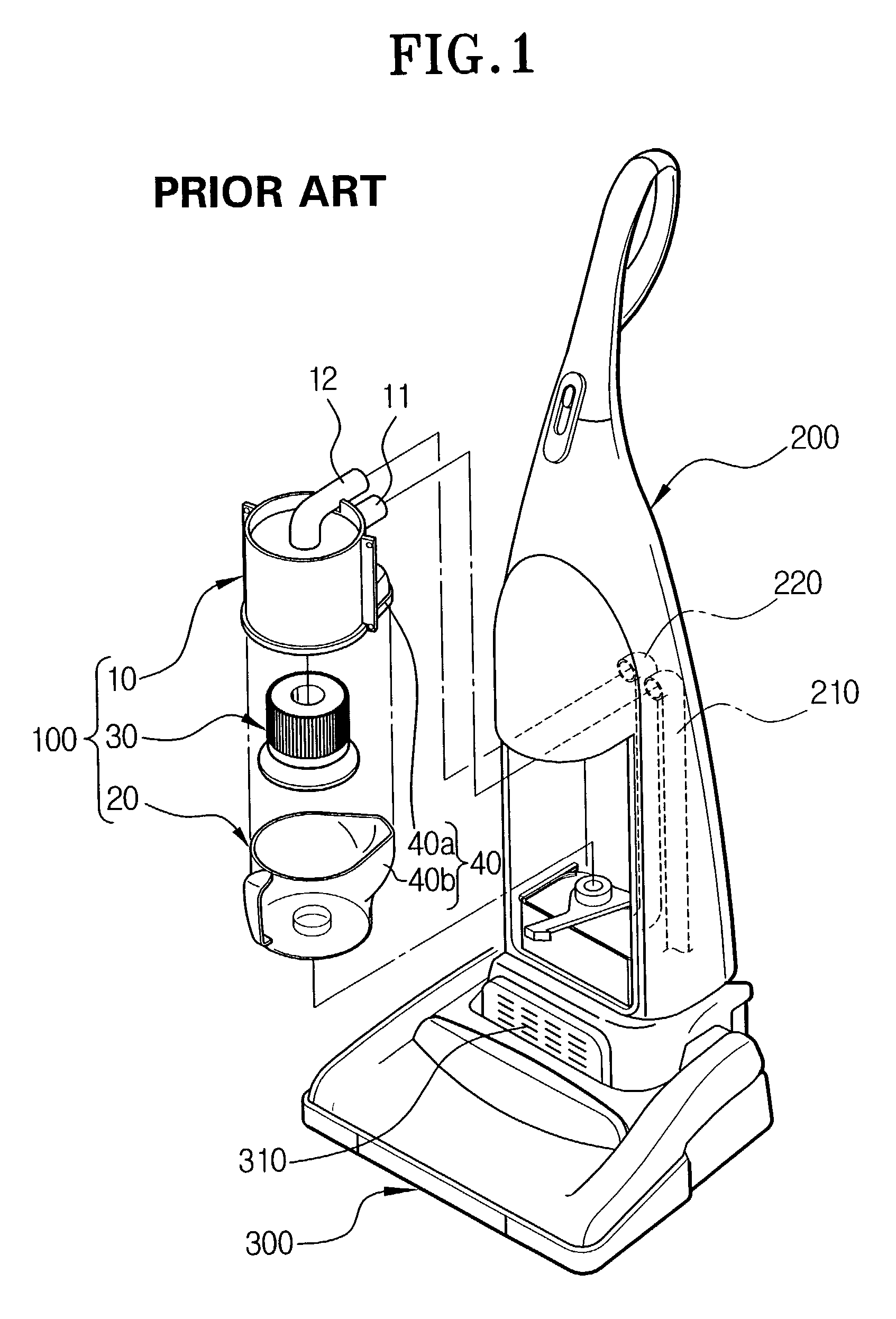

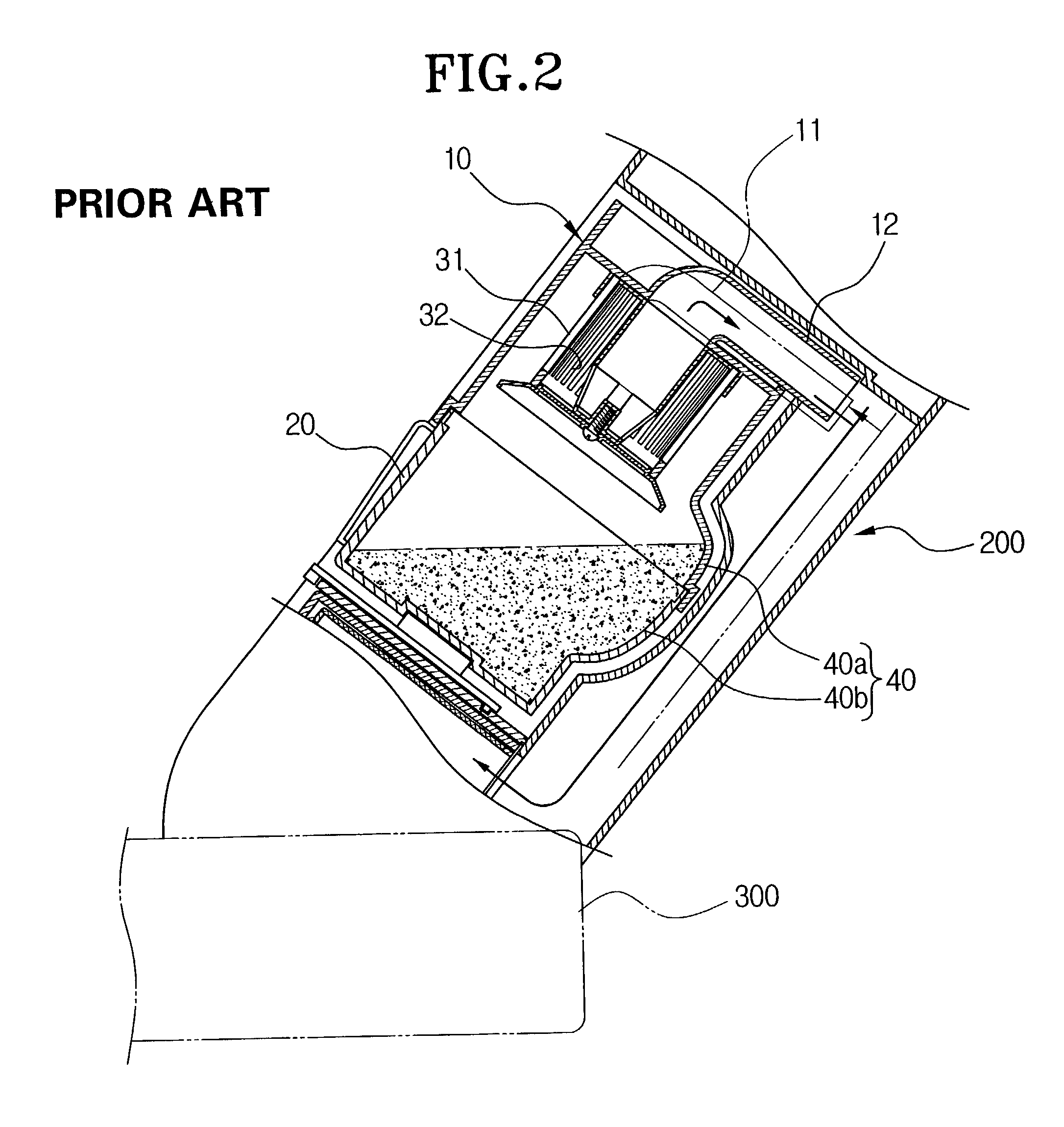

Vacuum cleaner with ultraviolet sterilization lamp

InactiveUS6968595B2Reduce the amount requiredStable collectionCombination devicesAuxillary pretreatmentCycloneUltraviolet

The cyclone-type dust collecting apparatus for a vacuum cleaner can reduce reverse flow of dirt and kill any bacteria in the dirt-collecting receptacle. The cyclone-type dust-collecting apparatus has a protruding flow path formed on the front side of the cyclone body and a lamp-positioning groove depressed inwardly at one side of the dirt-collecting receptacle for an ultraviolet lamp disposed in the cleaner body to apply ultraviolet rays radiated into the dirt-collecting receptacle. Accordingly, various bacteria inside the dirt collecting receptacle can be killed as the ultraviolet lamp disposed in the lamp positioning groove of the dirt collecting receptacle continuously applies the ultraviolet rays into the dirt collecting receptacle while the cleaner is on. Moreover, reverse flow of the dirt through the protruding flow path can be reduced as the storage level of the dirt stored near the protruding flow path of the dirt collecting receptacle is lowered and the space between the dirt near the protruding flow path of the dirt collecting receptacle and the cyclone body is expanded.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

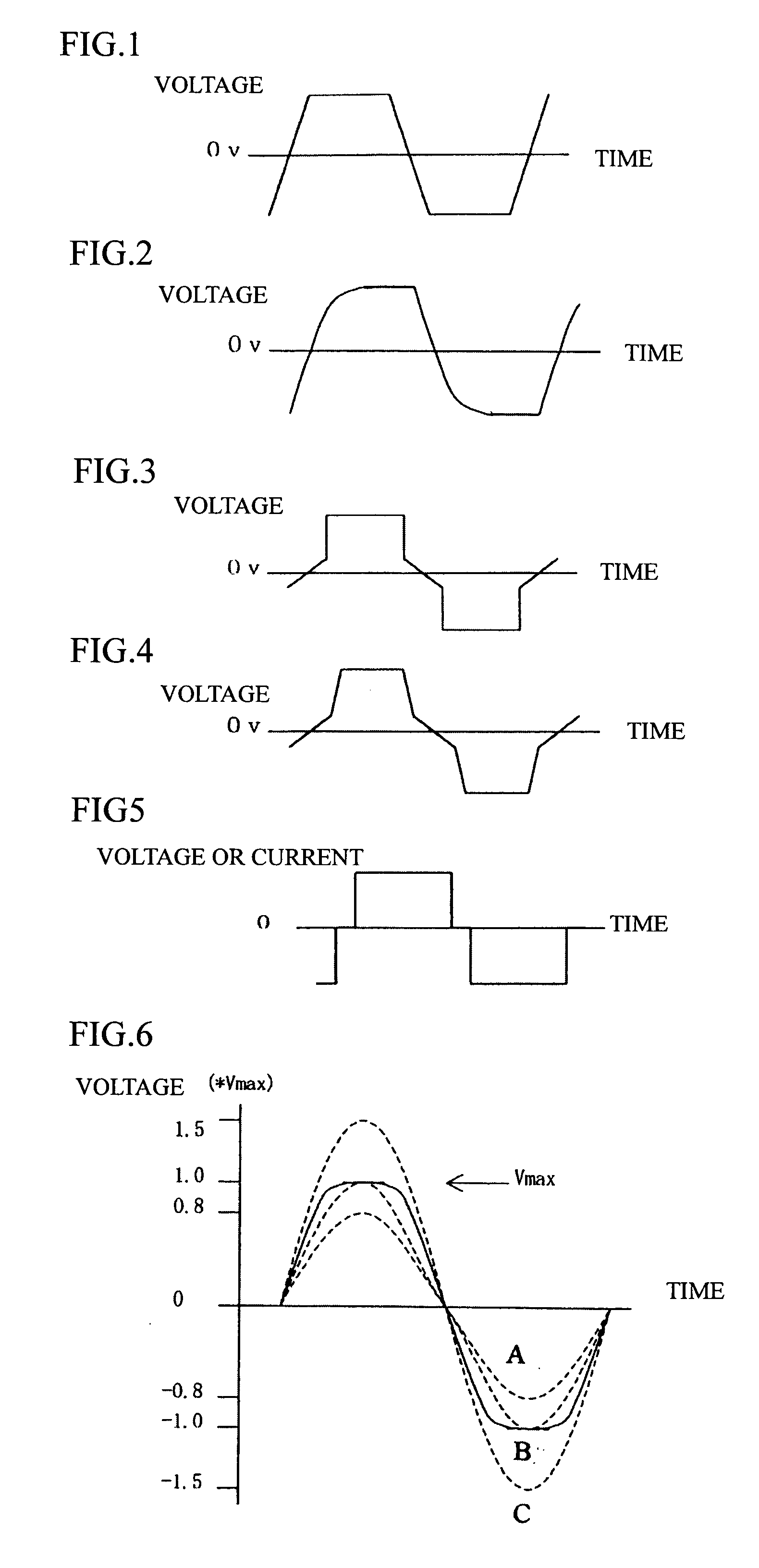

Electromagnetic pump driving method

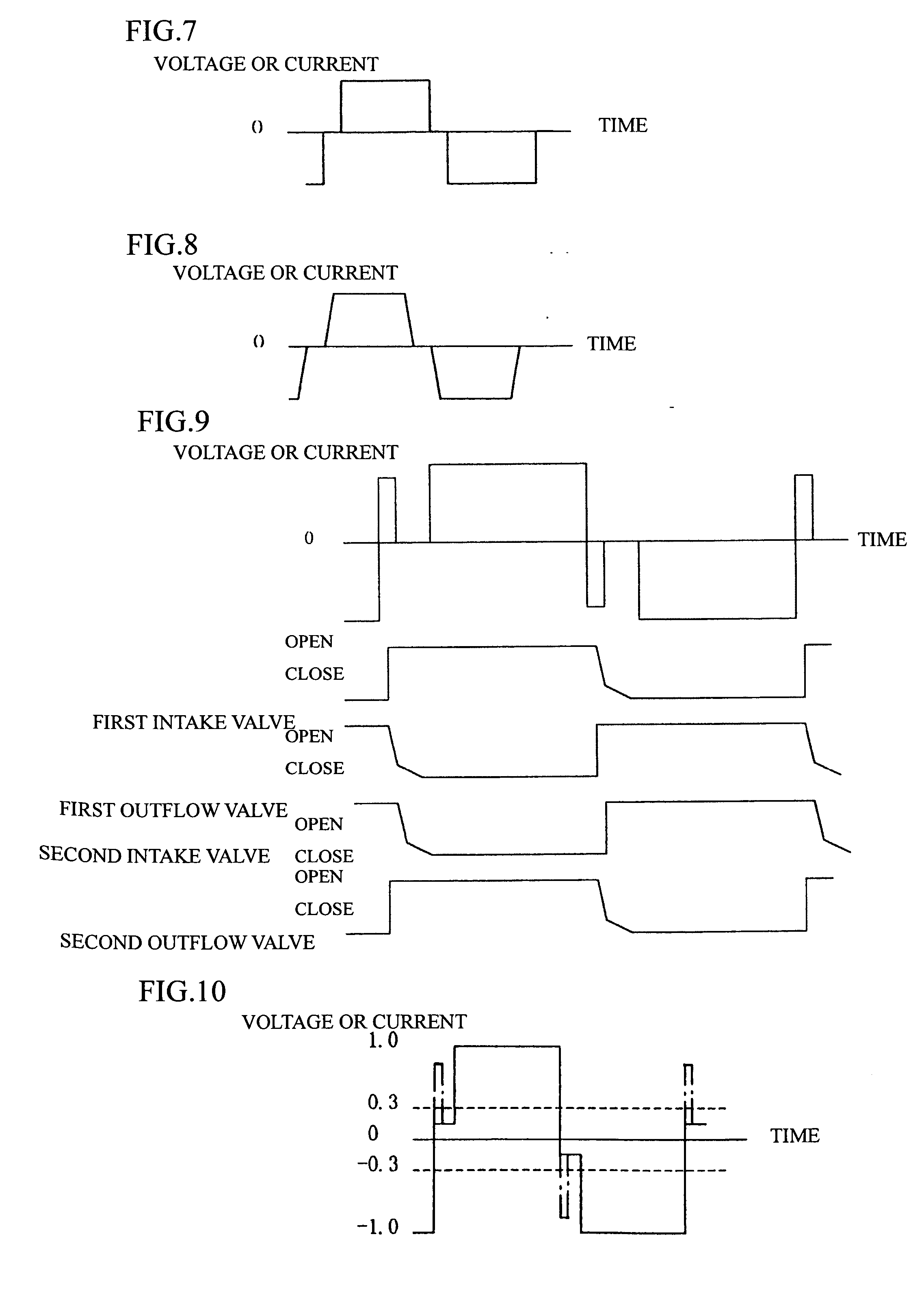

InactiveUS20070025861A1Reducing production of noiseReduce vibrationAC motor controlMotor parameterPump chamberElectrical polarity

There is provided a method of driving an electromagnetic pump where noise and vibration that accompany abrupt fluctuations in pressure inside a pump chamber are reduced. A pulse voltage is applied alternately on a positive side and a negative side to drive the electromagnetic coil such that a change in voltage that occurs when the polarity of the pulse voltage is inverted has a continuous slope at least between the positive side and the negative side.

Owner:SHINANO KENSHI

Foam-dispensing pump container

The invention provides a foam-dispensing pump container which is improved when the foam or liquid backflows to the inside of a pump after being dispensed to reduce the usability. The foam-dispensing pump container according to the present invention has the valve seat portion which protrudes inwardly below the air-liquid mixing unit and which is formed of the flexible member that can come into contact with the outer peripheral face of the latch portion of the rod-shaped valve body, and immediately after the nozzle head starts rising, the flexible valve seat portion comes into contact with the rod-shaped valve body before the upper opening end of the liquid chamber comes into contact with the rod-shaped valve body, thereby significantly reducing a backflow of the foam or liquid into the air passage, and consequently improving the usability of the foam-dispensing pump container.

Owner:DAIWA CAN

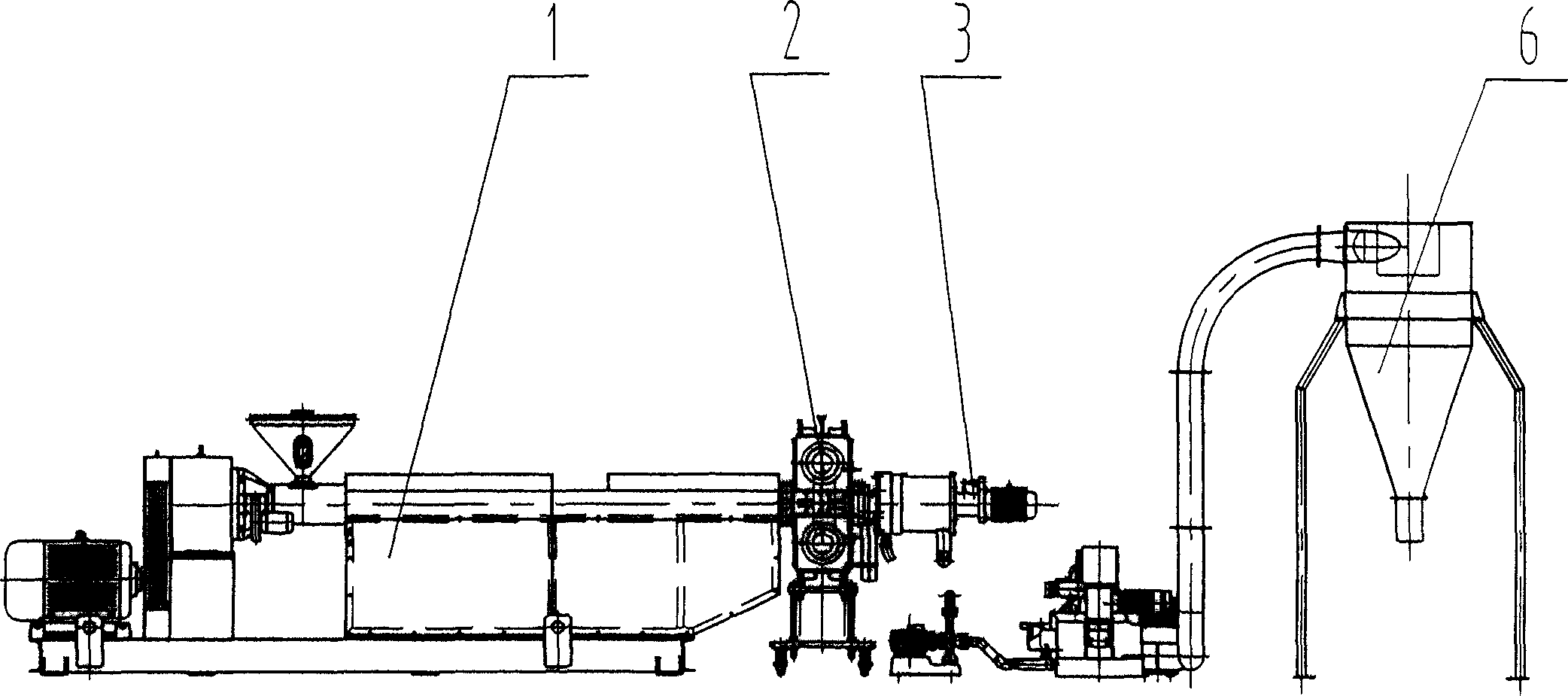

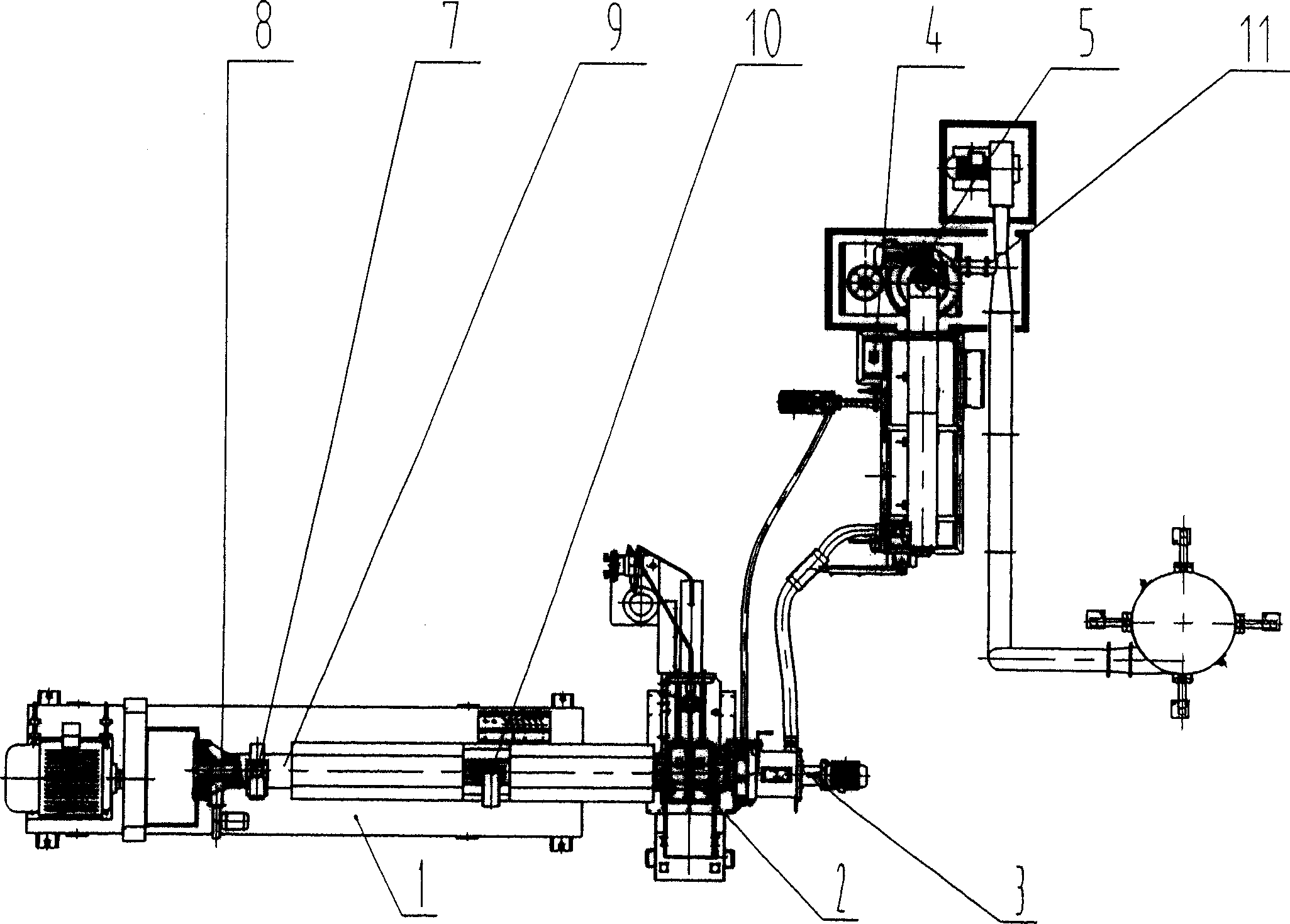

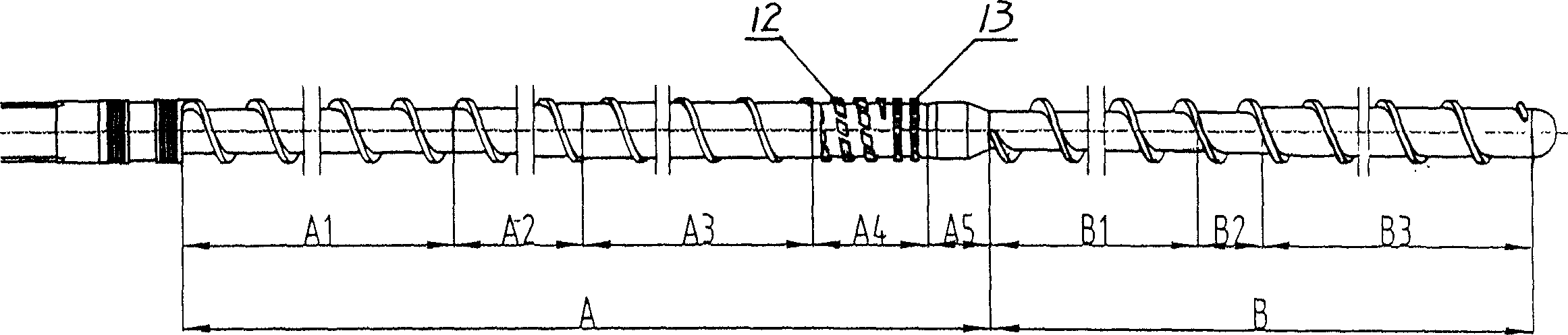

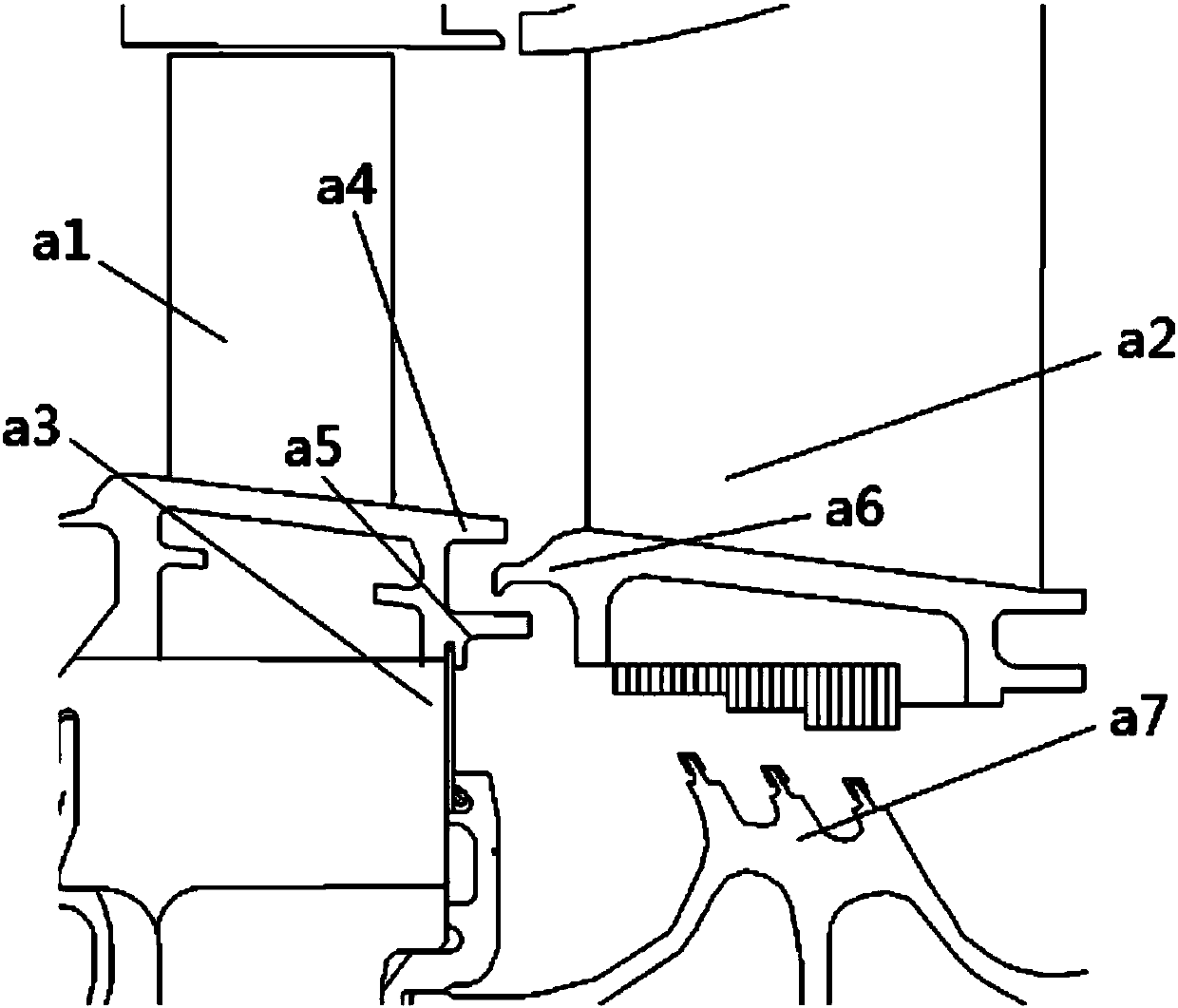

Regeneration pelletizer for worn-out plastic

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

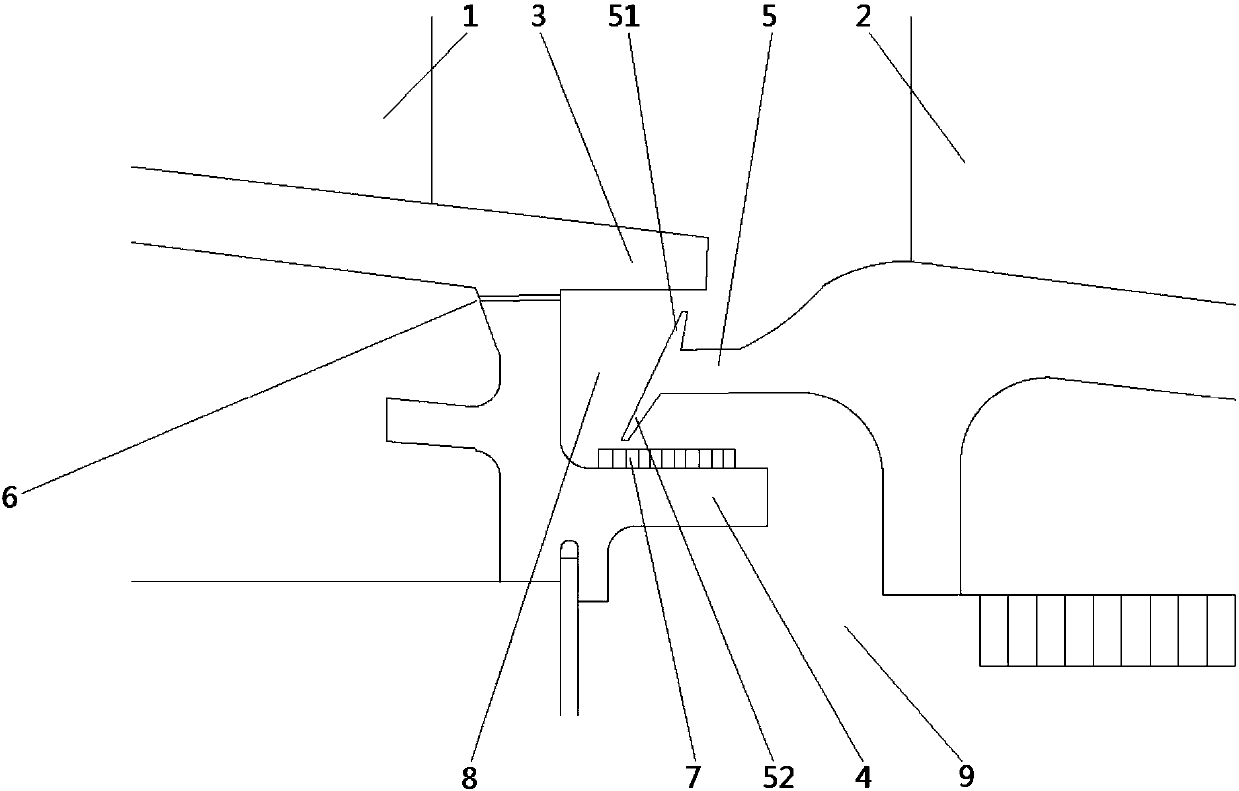

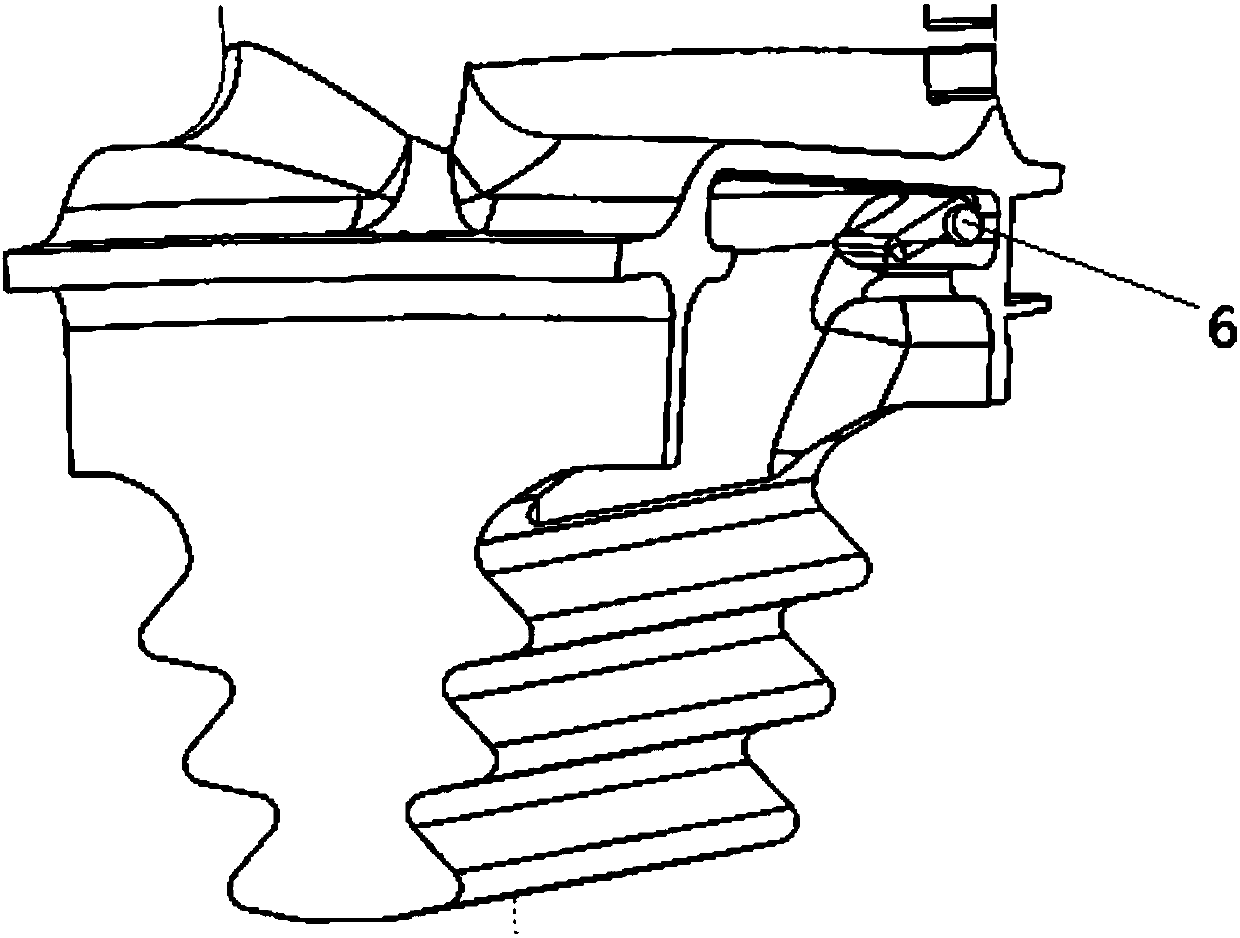

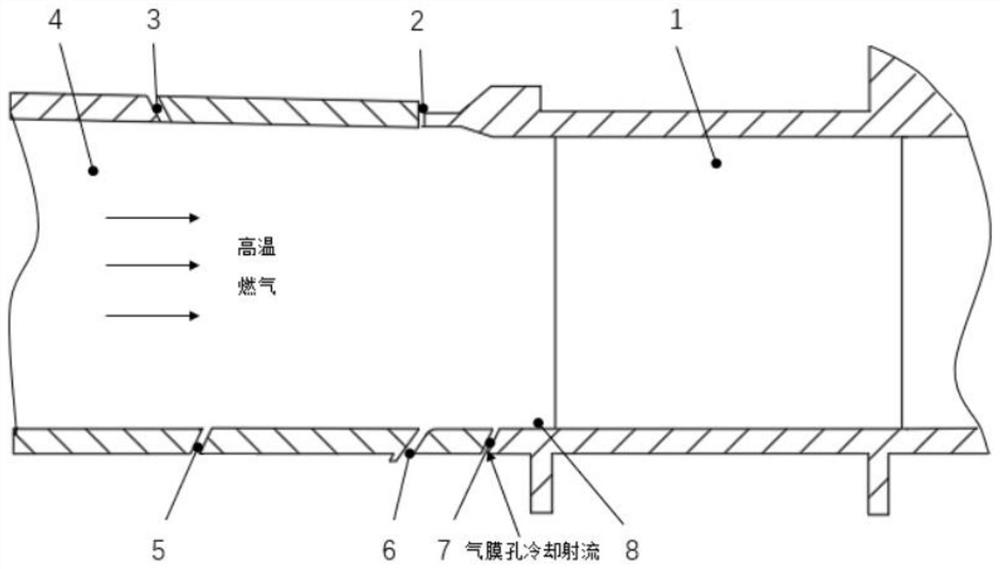

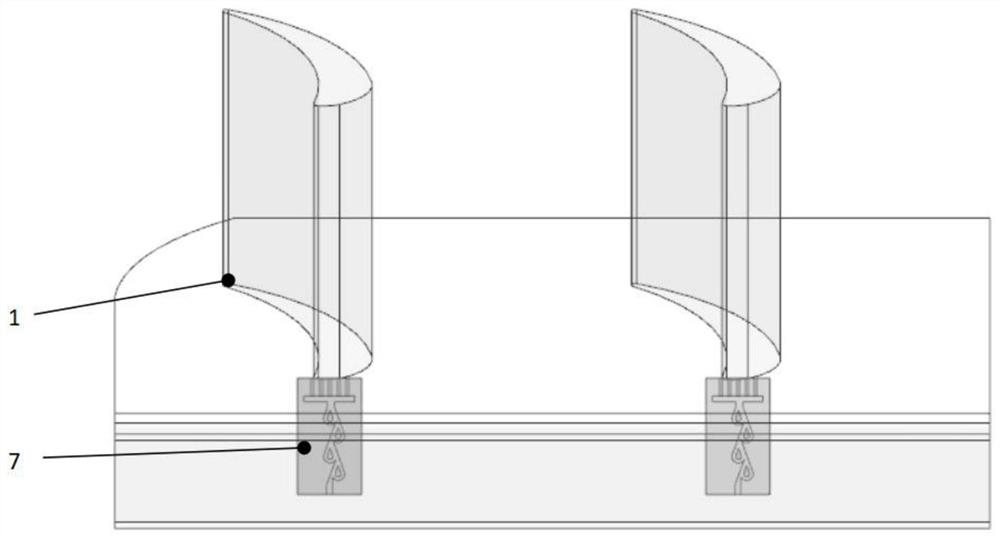

Wheel flange sealing structure, turbine and gas turbine

ActiveCN107869362ASmooth dischargeSpeed up the flowLeakage preventionGas turbine plantsEngineeringHigh pressure

The invention relates to a wheel flange sealing structure, a turbine and a gas turbine. The wheel flange sealing structure comprises a first flange plate (3), a second flange plate (4) and a third flange plate (5), wherein the first flange plate (3) and the second flange plate (4) are arranged at the root part of a movable blade (1), and the third flange plate (5) is arranged at the root part of aguiding blade (2). The first flange plate is closer to the movable blade compared with the second flange plate. The third flange plate extends into an opening formed between the first flange plate and the second flange plate, and the third flange plate forms a first chamber (8) for circulation of sealing gas at least with the first flange plate and the second flange plate. The first chamber (8) is provided with an injector hole (6). The injector hole (6) is used for injecting high-pressure gas into the first chamber (8), wherein the pressure of the high-pressure gas is higher than that of thesealing gas, so that the sealing gas is driven to flow out of the first chamber (8) through jet action of the high-pressure gas. According to the wheel flange sealing structure, the jet action of thehigh-pressure gas is introduced in by forming the injector hole, flowing of the sealing gas is accelerated, the using amount of the sealing gas is decreased, the sealing effect is improved, the requirement for the sealing pressure difference is reduced, and backward flow of main gas is reduced.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

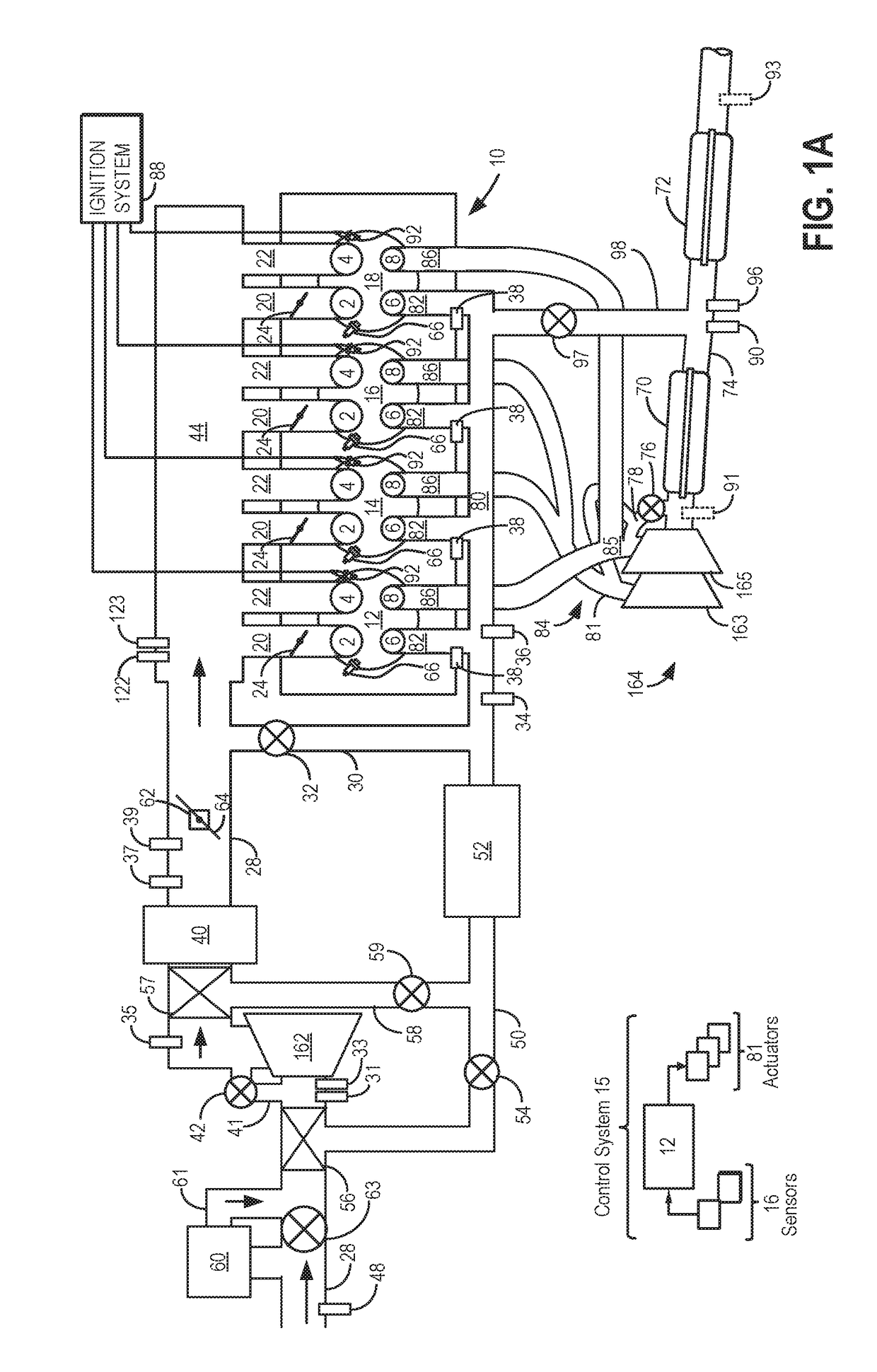

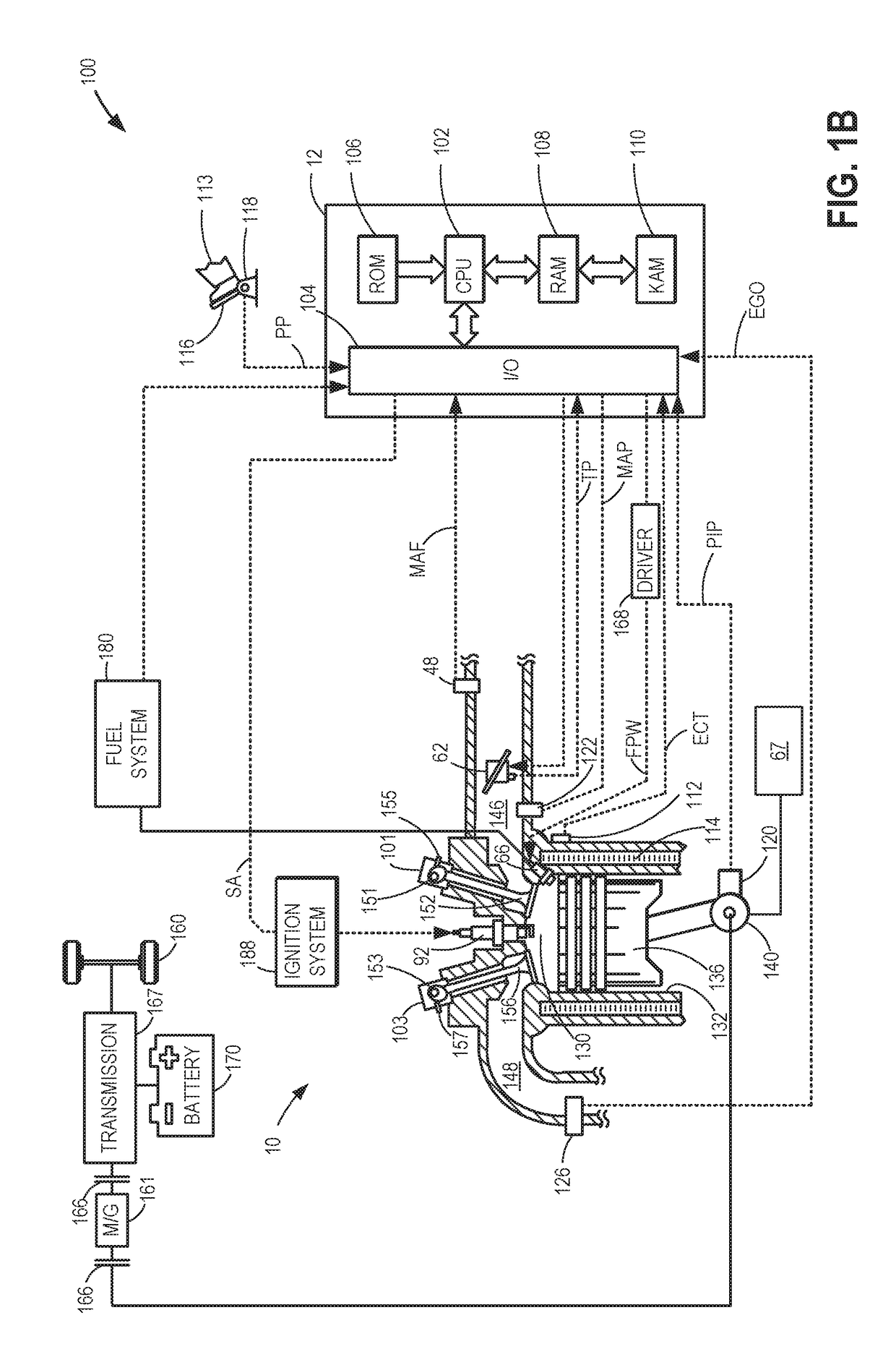

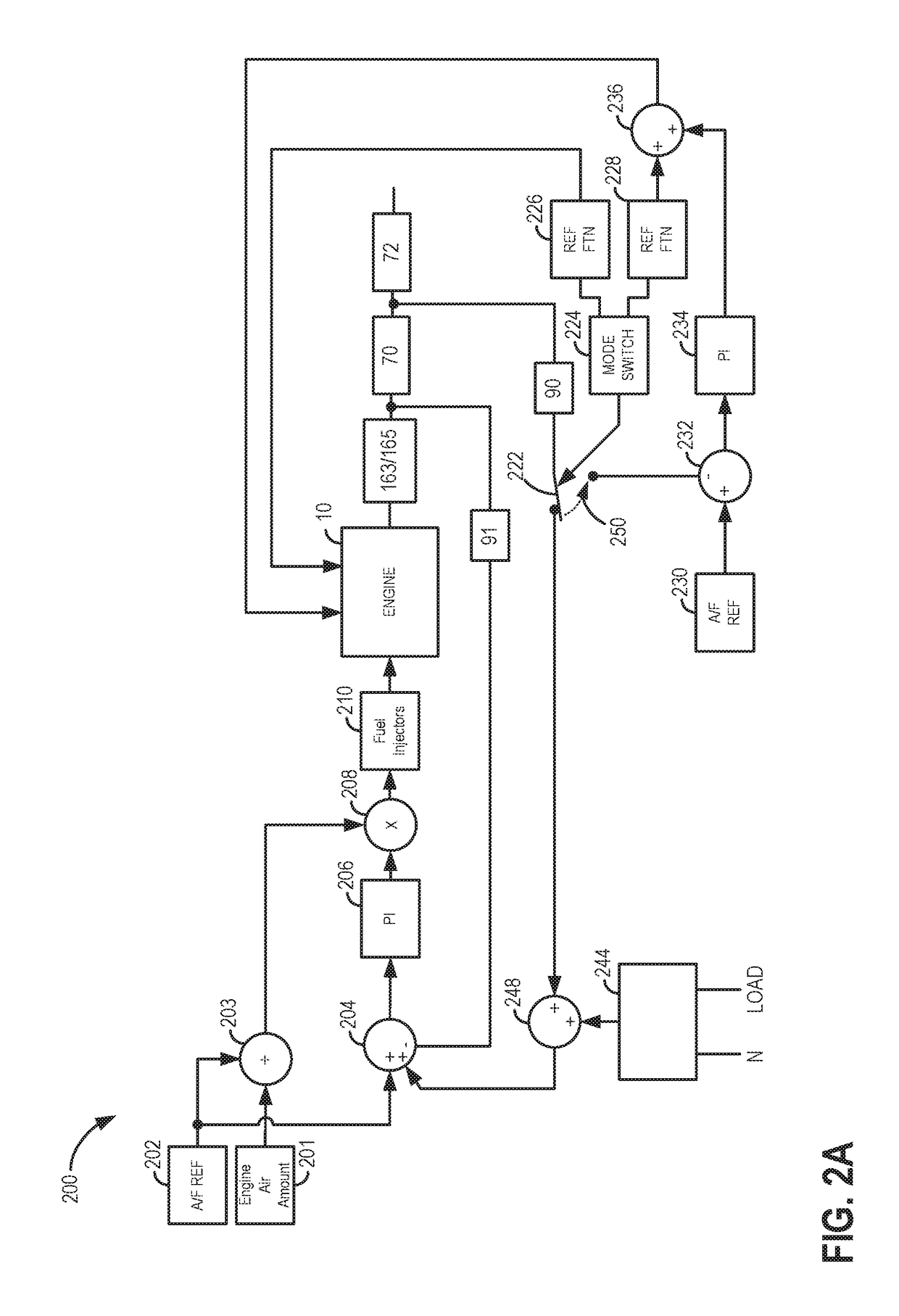

Systems and methods for a split exhaust engine system

InactiveUS10190507B2Increase engine power densityReduce knockingElectrical controlInternal combustion piston enginesExhaust valveExhaust gas recirculation

Methods and systems are provided for operating a split exhaust engine system that provides blowthrough air and exhaust gas recirculation to an intake passage via a first exhaust manifold and exhaust gas to an exhaust passage via a second exhaust manifold. In one example, one or more valves of a set of first exhaust valves coupled to the second exhaust manifold may be deactivated in response to select engine operating conditions, while maintaining active all valves of a set of second exhaust valves coupled to the first exhaust manifold. The select engine operating conditions may include one or more of a deceleration fuel shut-off condition, a part throttle condition, and a cold start condition.

Owner:FORD GLOBAL TECH LLC

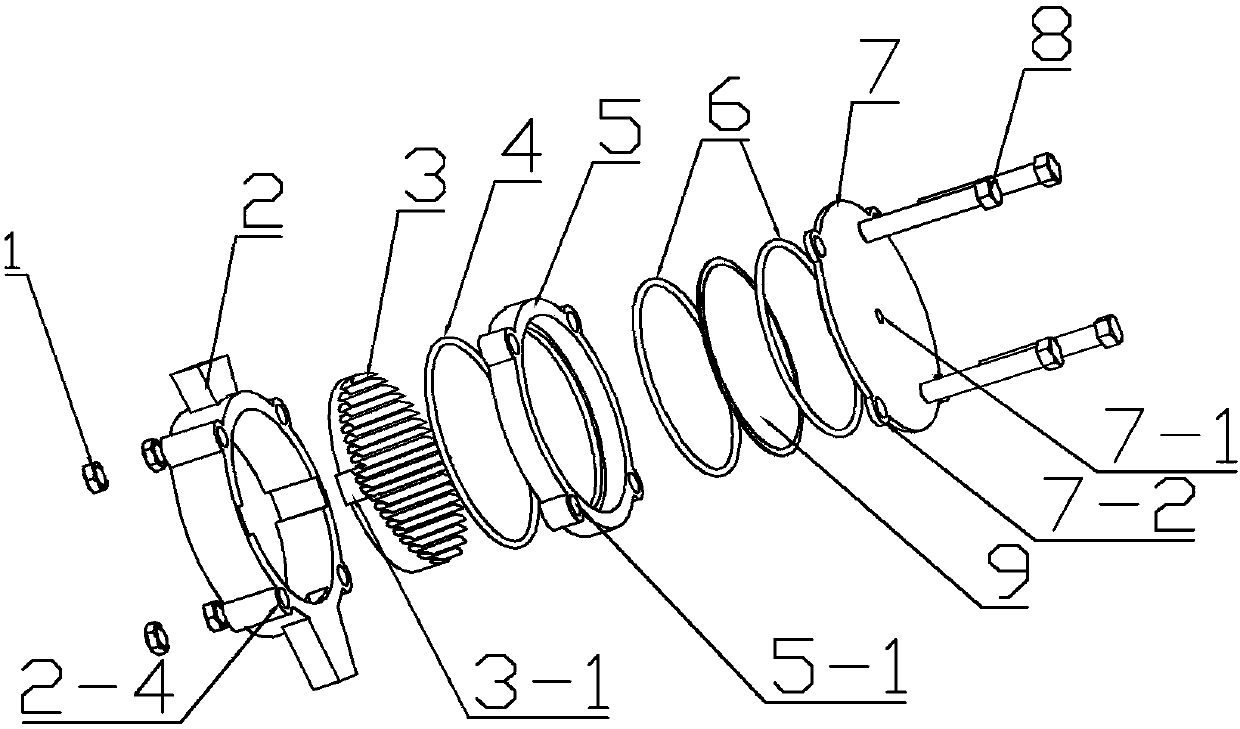

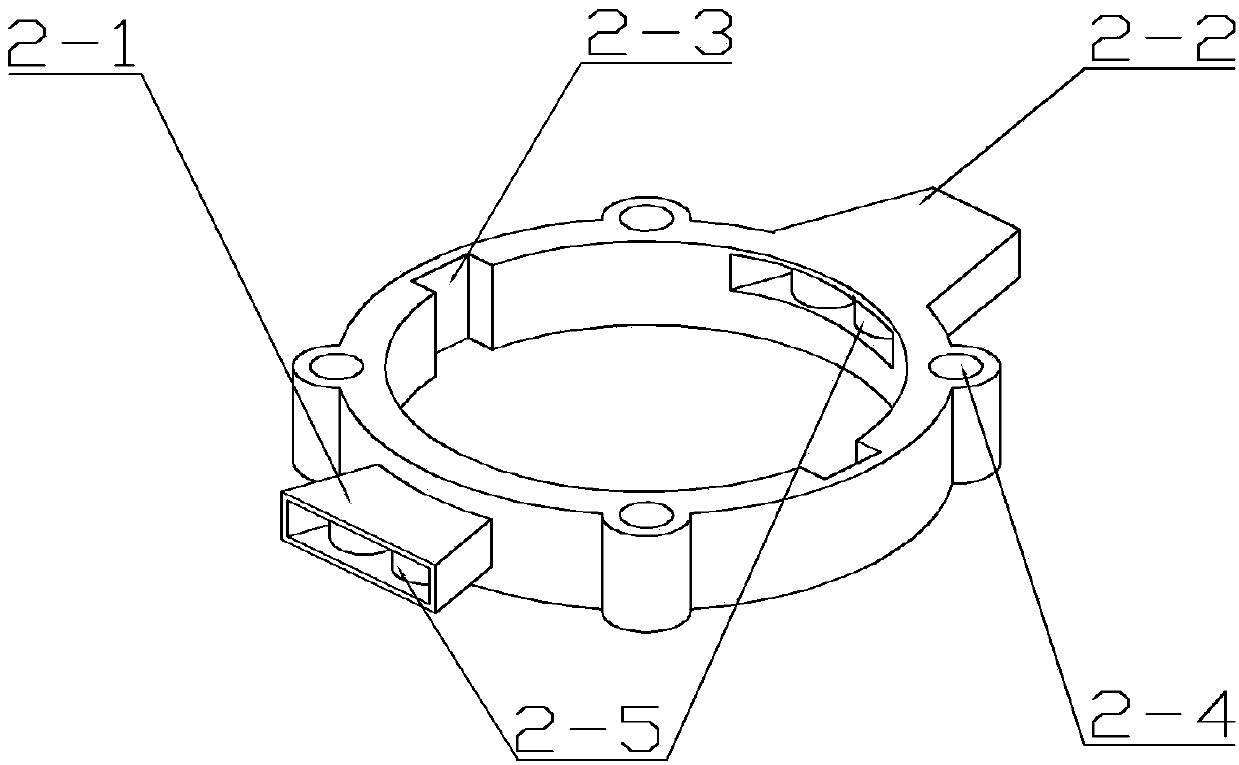

Multi-bluff body composite valve-less piezoelectric pump

InactiveCN108050049AEasy to enter liquidGood drainagePositive displacement pump componentsFlexible member pumpsElectricityEngineering

The invention discloses a multi-bluff body composite valve-less piezoelectric pump which comprises a pump cover, a piezoelectric vibrator, hook-type bluff bodies, a middle pump body and a lower pump body with semicircle shell bluff bodies. A liquid outlet runner and a liquid inlet runner of the lower pump body are provided with the semicircle shell bluff bodies. According to the multi-bluff body composite valve-less piezoelectric pump, the piezoelectric vibrator applies electric signals, the piezoelectric vibrator generates stretchable deformation, liquid enters a liquid inlet when the piezoelectric vibrator deforms to the pump cover, and the liquid is discharged from a liquid outlet when the piezoelectric vibrator deforms to the lower pump body; and when the liquid is sucked into the lower pump body, backflow happens at the liquid outlet. The multi-bluff body composite valve-less piezoelectric pump is provided with the multiple hook-type bluff bodies, front and back taper structures and the semicircle shell bluff bodies, the backflow effect is reduced, and the flow of the valve-less piezoelectric pump is improved.

Owner:CHANGCHUN UNIV OF TECH

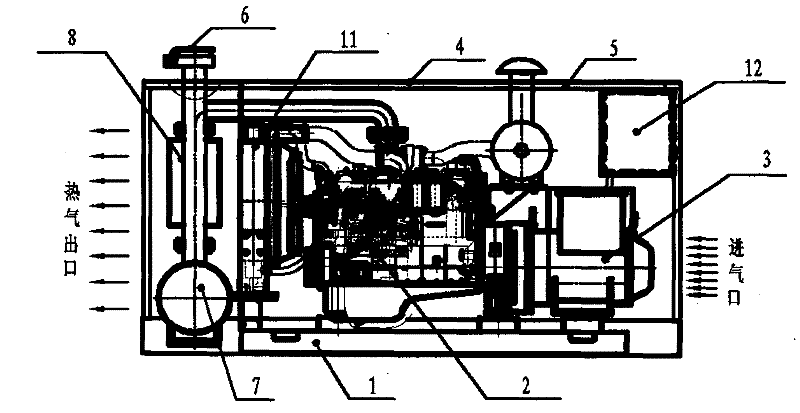

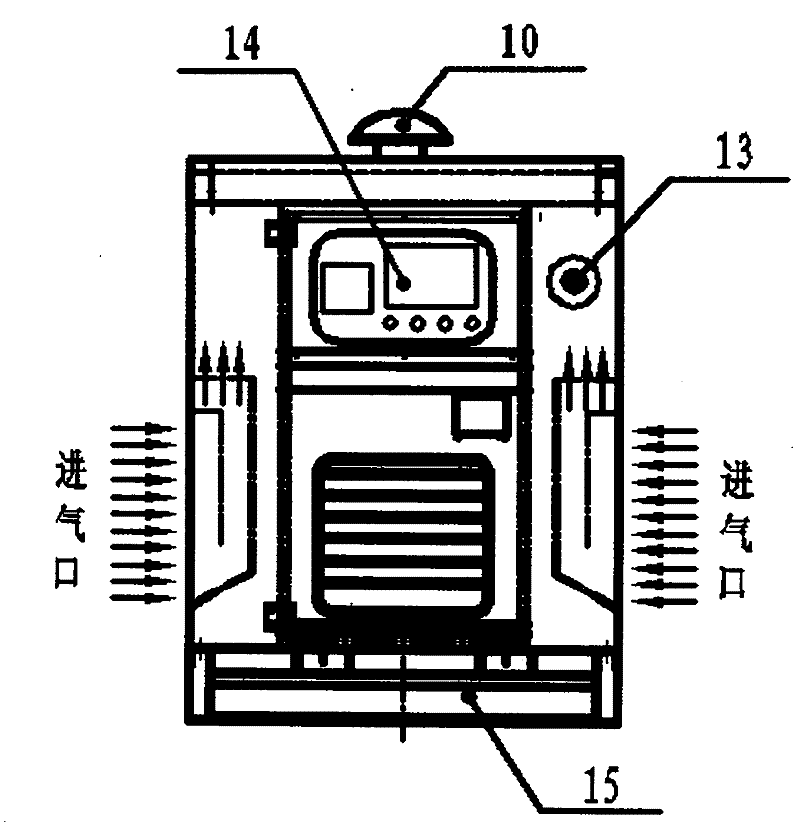

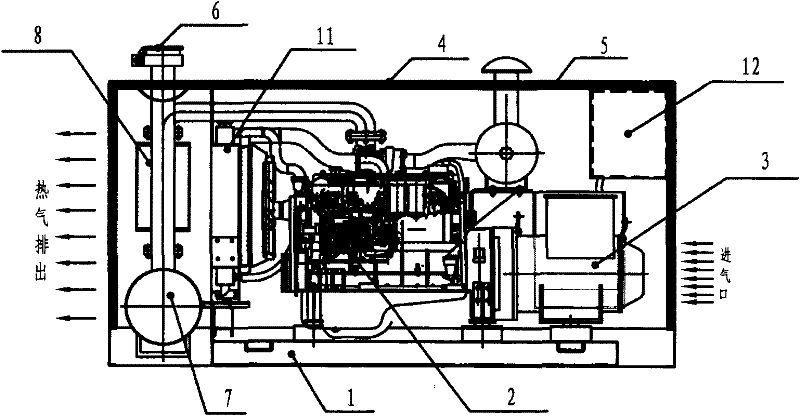

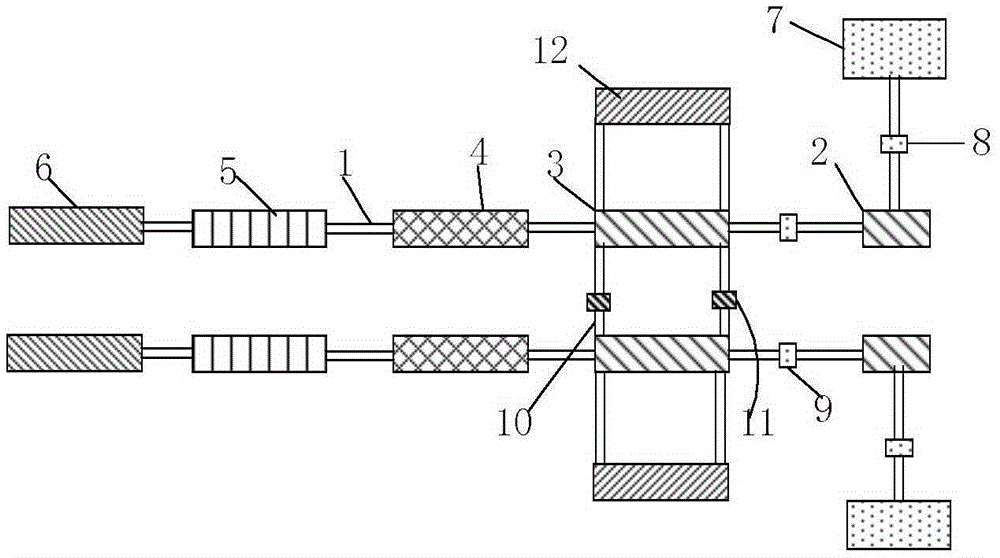

Novel energy-saving low noise diesel generator set

InactiveCN102182552AReduce noise sourcesReduce different noiseMachine framesInternal combustion piston enginesLow noiseDiesel generator

The invention discloses a novel energy-saving low noise diesel generator set. The diesel engine power is between 30kw and 130kw and the corresponding generator power is between 20kw and 100kw, the diesel engine is a supercharged intercooled diesel engine of which the rated rotary speed is 1000r / min and the fuel consumption is 205-210g / kw.h, thus obviously saving energy; the exhaust pipe adopts a divided exhaust pipe, 20mm space is reserved between the height of the baffle and the flange plane of the supercharger arranged on the exhaust manifold, thus effectively avoiding the influences on the supercharger efficiency due to excessively high temperature caused by the crossed exhaust gas of the engine; a silenced case body is added to the engine set, a high-performance shock absorber is adopted, an efficient PUR (poly urethane resin) type antiflaming sound absorbing sheet is pasted in the case body and a labyrinth type inlet air mulffer device made from a high-efficiency damping material is adopted to reduce the source of noises. Experimental results show that the energy-saving low noise diesel generator set can operate reliably for a long time with a controllable noise value of 65-70dB(A) at one meter).

Owner:LIUZHOU HENGDA POWER MACHINERY MFG

Anti-backflow method and device for grid-connected power generation system

ActiveCN102868181AReduce the possibilityReduce backflowDc network circuit arrangementsSingle network parallel feeding arrangementsEngineeringElectric fence

Owner:EAST GRP CO LTD

Fresh water supply method for rainwater and groundwater resource

InactiveCN1528989AImprove qualityReduce the degree of impactWater conservationDrinking water installationWater resourcesFresh water

The invention refers to plain water supplying method for rain water and ground water resources; it selects a impounded area, and rig flooding well from one to one hundred of millions on the area, there sets a filter at the water entrance of the well; when meeting with moderate rain or heavy rain, storm rainfall or supergiant storm rainfall, the rain water is poured into the well through the filter directly, and afflux into ground water, thus the water impounded area will has rich ground water. The rain water turns into ground water, and the ground water is turned into plain water. The ground water can be used for edible water through simple process, or uses hyperfiltration technology to decrease the salinity of ground water. And it can supply plain water in drought years. The cost of ground is decreased, and the price of ground water can be decreased from 5-10 yuan per ton to 2-4 yuan per ton.

Owner:安逢龙

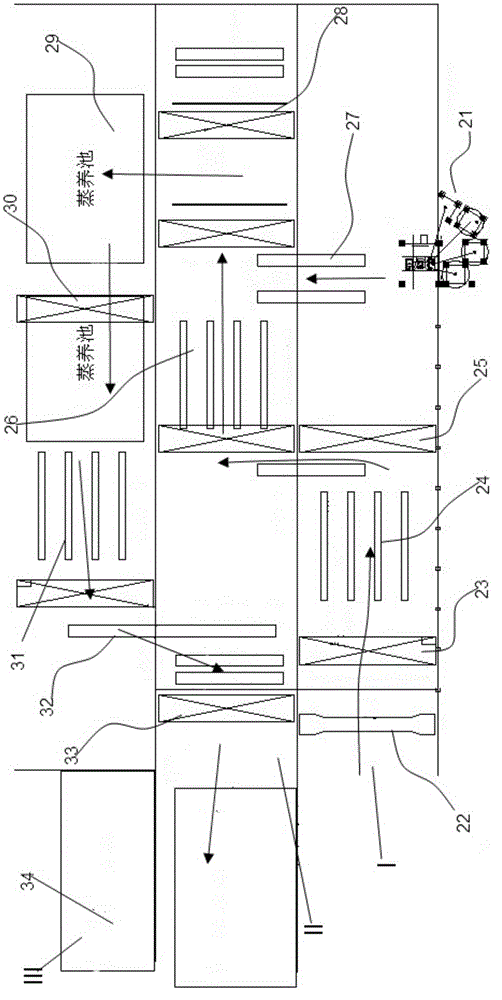

Prestressed concrete anti-corrosion pipe pile automatic assembly line operation platform

ActiveCN103624872BEmission controlSimple and fast operationCeramic shaping plantsInformatizationOperational system

Owner:JIANGSU DONGPU PILE

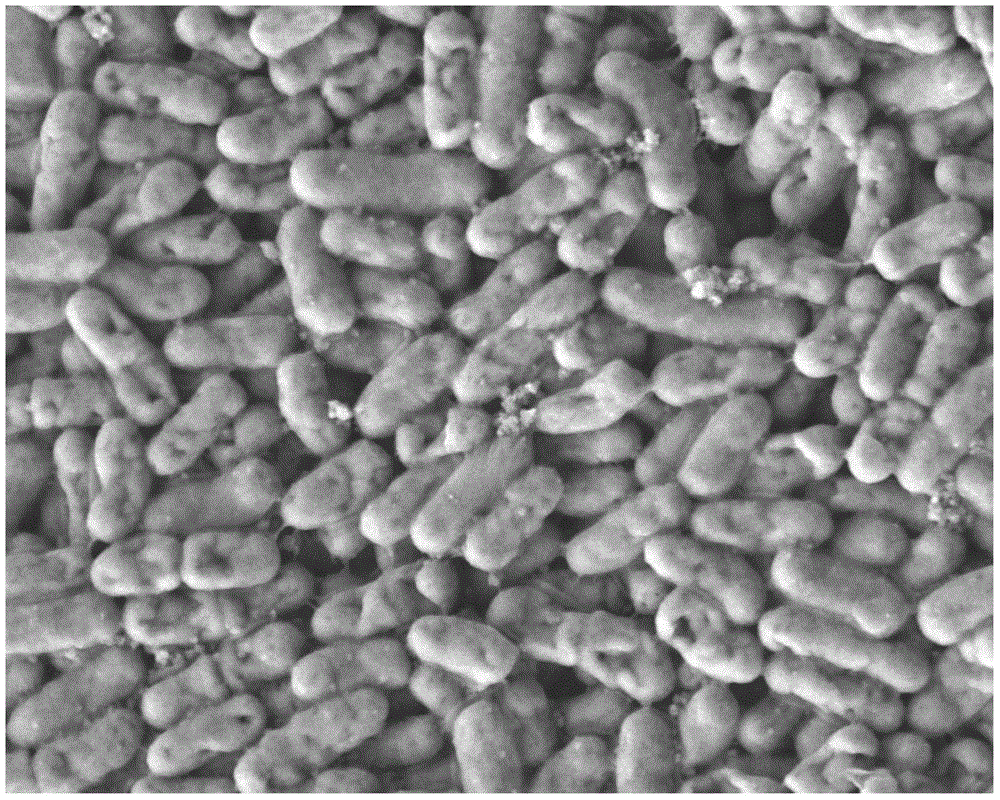

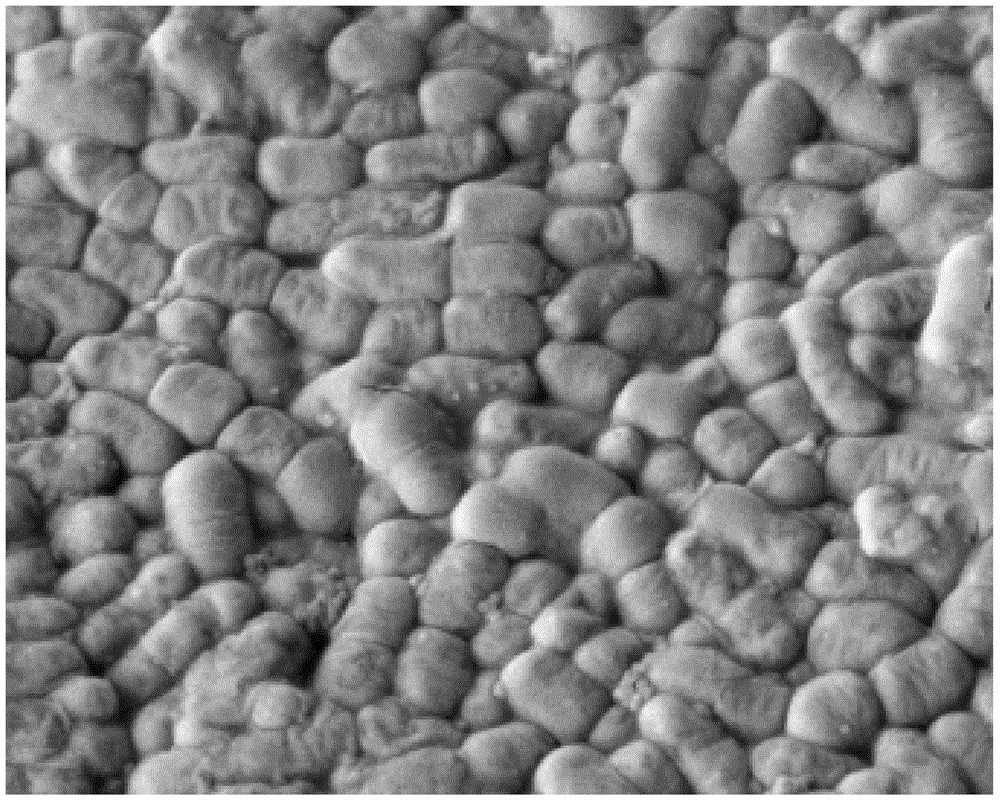

Lactic acid bacterium composition for protecting gastrointestinal mucosa and preparation method of lactic acid bacterium composition

InactiveCN104974963AImprove immunityImprove protectionBacteriaDigestive systemLactobacillus rhamnosusLactobacillus salivarius

The invention discloses a lactic acid bacterium composition for protecting the gastrointestinal mucosa. The lactic acid bacterium composition comprises the following components in parts by weight: 5-20 parts of bifidobacterium lactis, 0.5-2 parts of bifidobacterium infantis, 8-25 parts of lactobacillus rhamnosus, 3-20 parts of lactobacillus acidophilus, 3-20 parts of lactobacillus plantarum and 8-25 parts of lactobacillus salivarius. The invention further discloses a processing method for the lactic acid bacterium composition. The processing method comprises the following steps: (1), preparing sclerotia; (2), embedding non-reducing sugar; (3), embedding skimmed milk; and (4), freeze-drying. The lactic acid bacterium composition provided by the invention has the advantages of adjusting gastrointestinal microorganisms to be balanced and protecting the gastrointestinal mucosa.

Owner:HK GOOD ALLY BIOTECH CO LTD

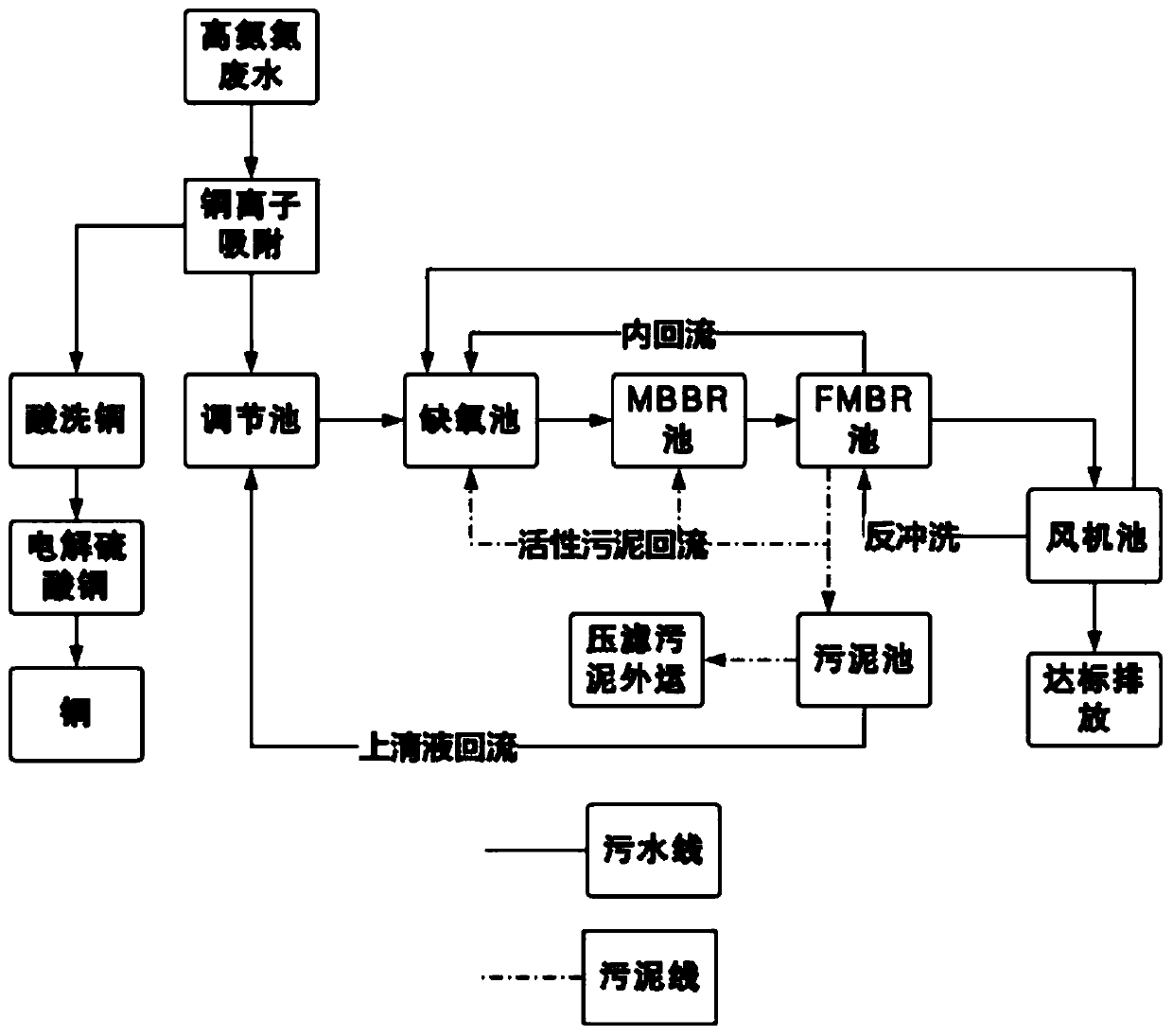

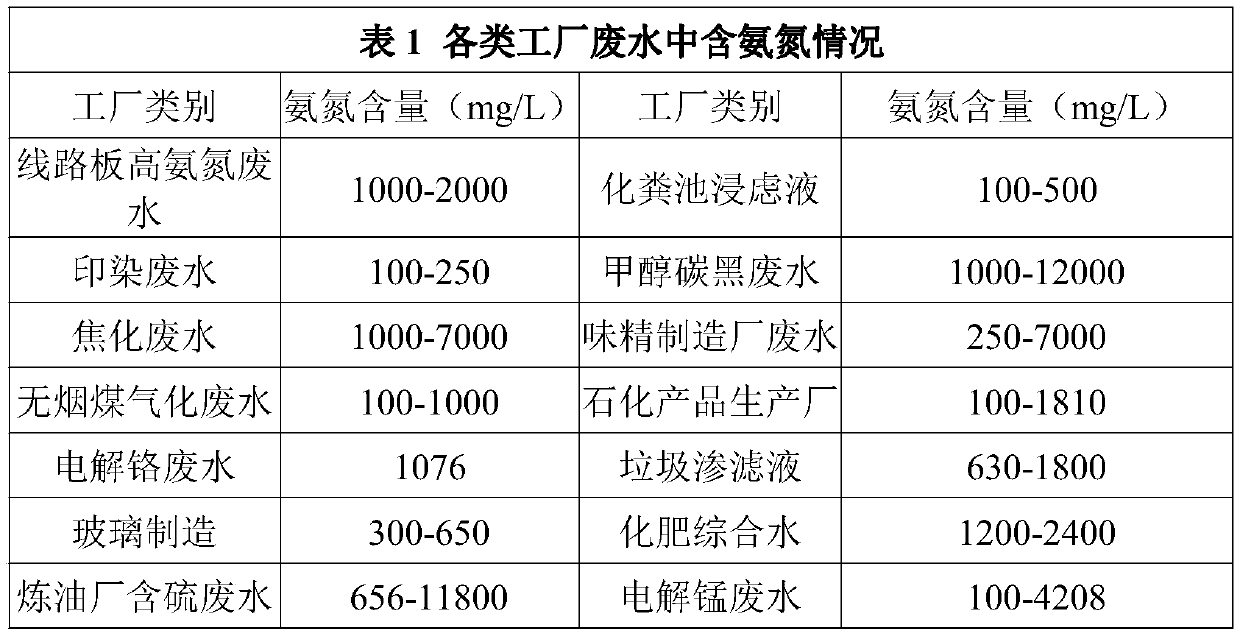

Treatment method for wastewater with high ammonia nitrogen content

InactiveCN110217949APromote degradationEfficient decarbonization capacityWater/sewage treatment by irradiationSpecific water treatment objectivesAutomatic controlSludge

The invention provides a treatment method for wastewater with high ammonia nitrogen content. According to the invention, after copper ions in the wastewater with high ammonia nitrogen content are adsorbed, obtained wastewater is converged to enter an adjusting pool; the amount and quality of the wastewater are adjusted in the adjusting pool; adjusted wastewater in the adjusting pool is lifted to amembrane treatment system through a lift pump, and then quantitatively pumped to an anoxic pool through a metering pump; a denitrification site is provided; an aeration tray is arranged in the anoxicpool to avoid sludge from sedimentation; a mixed solution in the anoxic pool automatically flows into MBBR which provides a nitrification-denitrification site; effluent of the MBBR automatically flows into an FMBR membrane pool for solid-liquid separation of a large amount of suspended solids; nitrogen is removed through the following three ways in an FMBR treatment process: 1) nitrification-denitrification, 2) short-range nitrification-denitrification, and 3) anaerobic ammonia oxidation; sludge remaining in the FMBR membrane pool is discharged to a sludge pool; after sludge is treated through a submerged air blower pool, treated sludge is discharged to a comprehensive pool for further treatment; thus, the removal rate of ammonia nitrogen reaches 99% or above, and high treatment efficiency and good effluent water quality are achieved; equipment is compact and occupies small land area; and automatic control is easily realized, and operation management is simple.

Owner:深圳市臻鼎环保科技有限公司

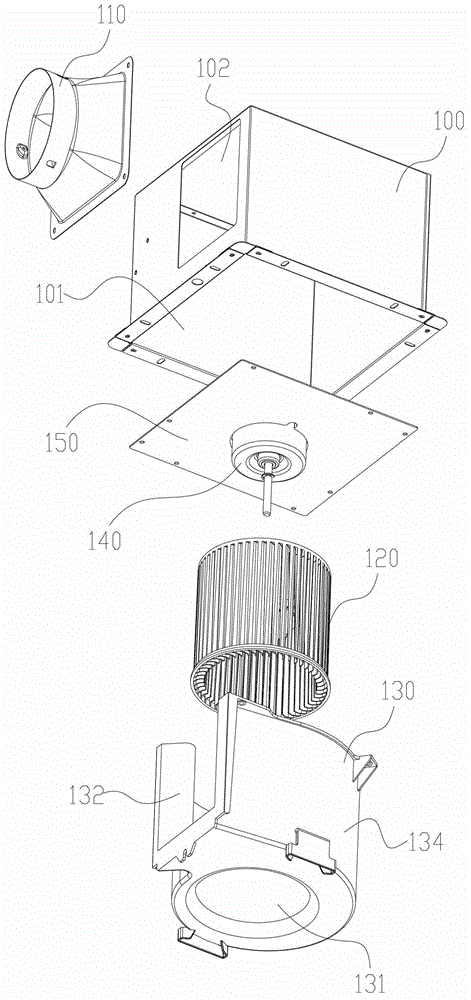

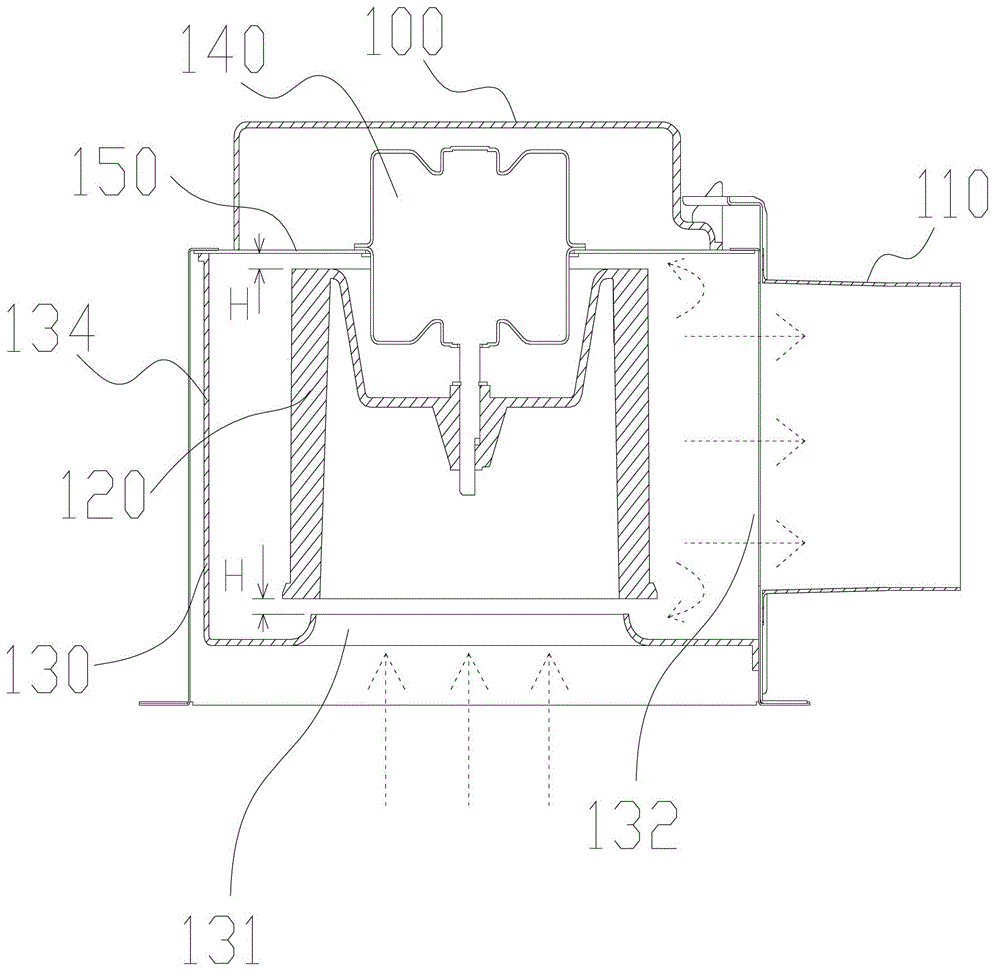

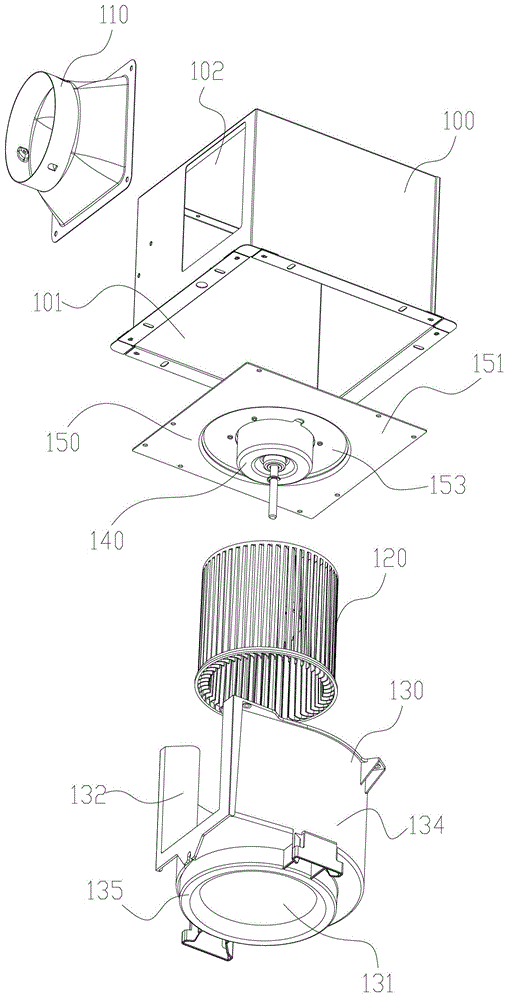

Ceiling type ventilation fan

ActiveCN103334960AIncrease air pressureReduce reflux and abnormal soundsPump componentsLighting and heating apparatusSnail shellDrive motor

The invention discloses a ceiling type ventilation fan. The ceiling type ventilation fan comprises an air ventilating structure. The air ventilating structure comprises a multi-vane impeller, a snail shell, an impeller drive motor and a motor installation frame. The snail shell comprises a shell body, an air inlet and an air outlet. The multi-vane impeller is arranged inside the shell body in the vertical direction. The motor installation frame is arranged above the multi-vane impeller and is separated from the multi-vane impeller. The bottom middle area, away from the direction of the multi-vane impeller, of the shell body protrudes and forms a first concave portion. The air inlet is formed in the bottom of the first concave portion, and the air inlet and the first concave portion form a first annular boss-shaped structure. The lower end of the multi-vane impeller extends into the first annular boss-shaped structure, is opposite to the air inlet, and is further isolated from the inner wall of the first concave portion and the air inlet. Under the conditions that the ventilation fan is communicated with a long outdoor pipeline or the external wind pressure is large, the multi-vane impeller can be prevented from touching the motor installation frame or the snail shell, and when the multi-vane impeller of the same performance is adopted, air reverse flow and abnormal sounds are reduced.

Owner:FOSHAN CITY NANHAI POPULA FAN

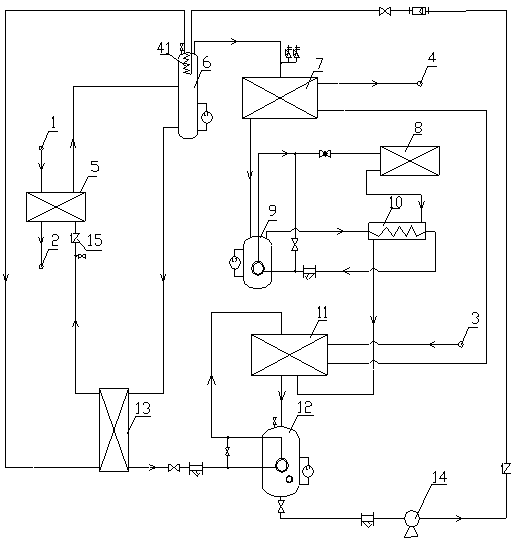

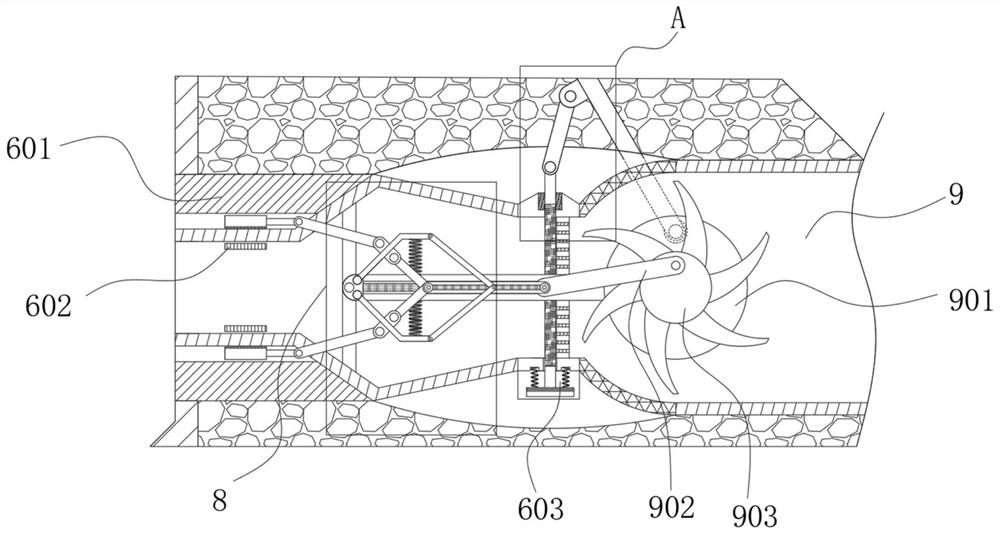

Wide and narrow passage plate type flooded generator and falling film absorber, and ammonia water absorption refrigerator

ActiveCN103983046AImprove heat transfer efficiencySignificant temperature fluctuationsBoilers/analysersEnergy efficient heating/coolingVapor–liquid separatorDifferential pressure

The invention discloses a wide and narrow passage plate type flooded generator, a wide and narrow passage plate type falling film absorber and an ammonia water absorption refrigerator. Waste heat passes through wide waste heat passages of the wide and narrow passage plate type flooded generator and then are used for heating concentrated ammonia water reversely flowing from narrow concentrated ammonia water passages to generate a gas-liquid mixture entering a gas-liquid separator, water-containing ammonia is separated and is condensed to form liquid ammonia in a plate type condenser after being purified by a fractional condenser, and the liquid ammonia is delivered into a liquid ammonia tank; liquid ammonia discharged from the liquid ammonia tank enters a heat exchange tube of a subcooler, and is supplied to a plate type evaporator and evaporated to form cold ammonia after being subjected to further heat exchange with cold ammonia discharged from the plate type evaporator, the cold ammonia enters the subcooler to be subjected to further heat exchange with the liquid ammonia in the heat exchange tube, enters a concentrated ammonia water outlet header on the lower part of the wide and narrow passage plate type falling film absorber under the action of differential pressure, rises along narrow diluted ammonia water passages, and is absorbed by diluted ammonia water which is discharged from the gas-liquid separator and cooled by a solution heat exchanger to form concentrated ammonia water, and the concentrated ammonia water enters a concentrated ammonia water tank, and is pumped into the wide and narrow passage plate type flooded generator through a solution pump.

Owner:TAISHAN GROUP

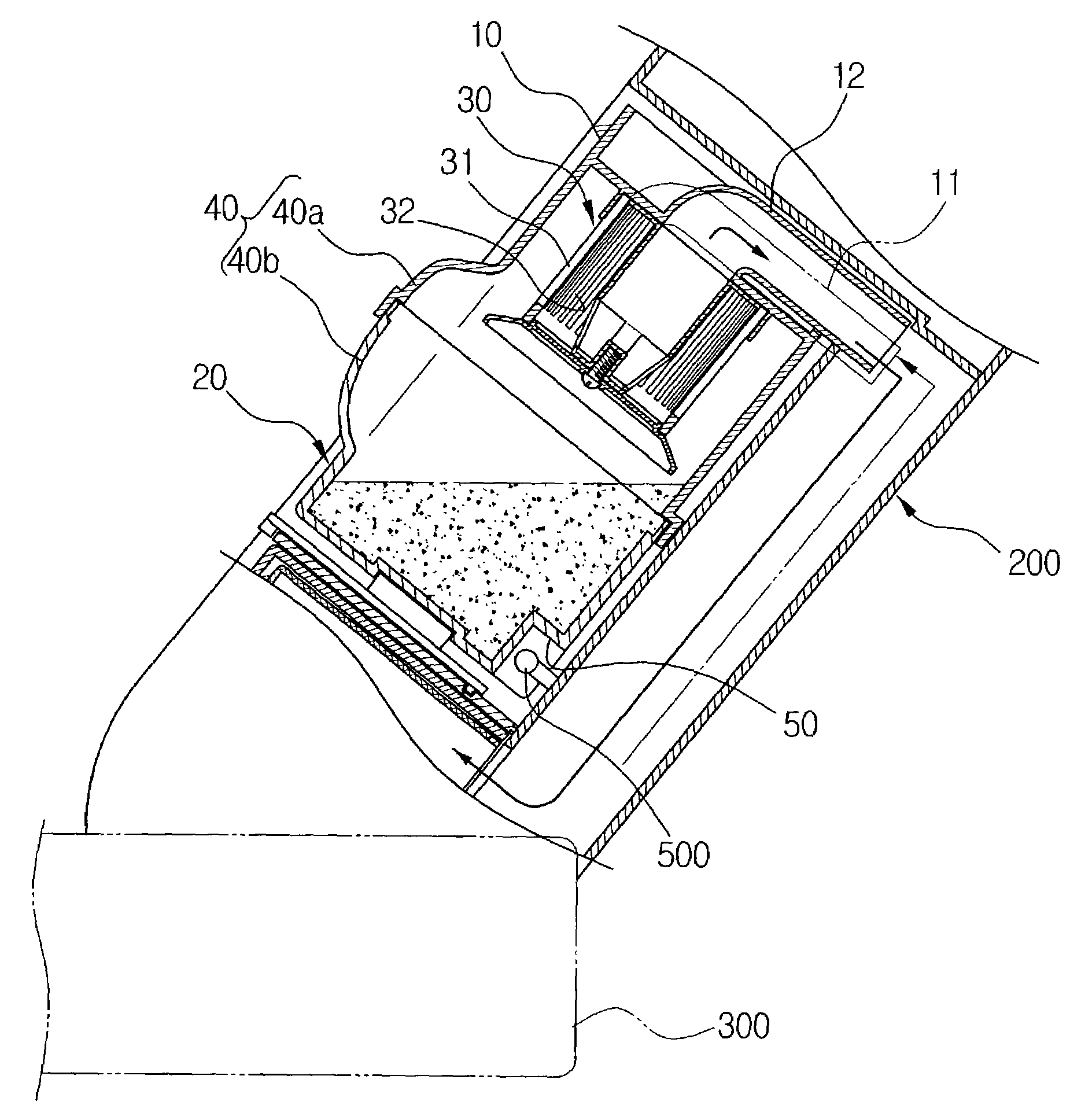

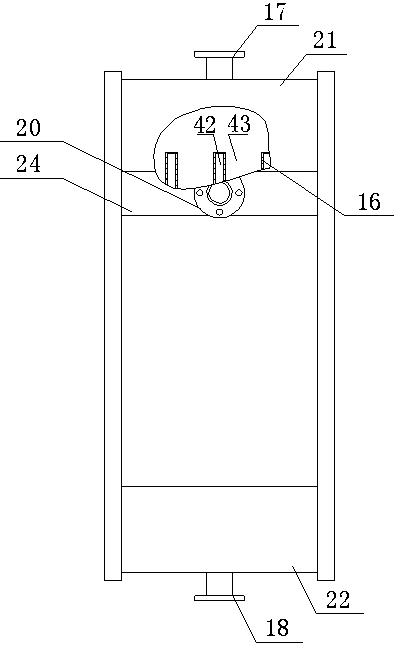

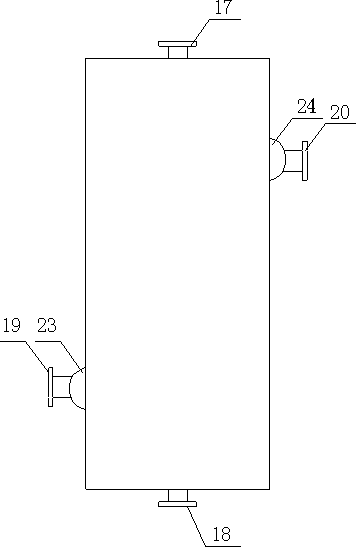

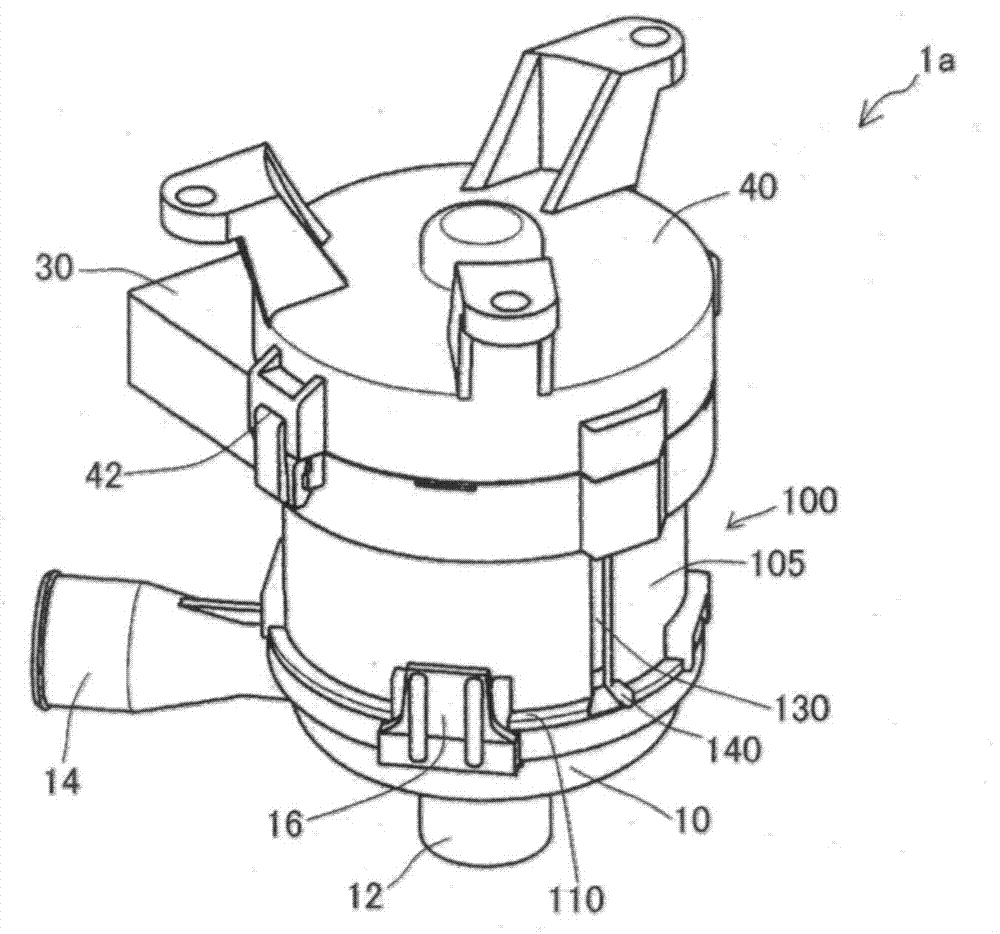

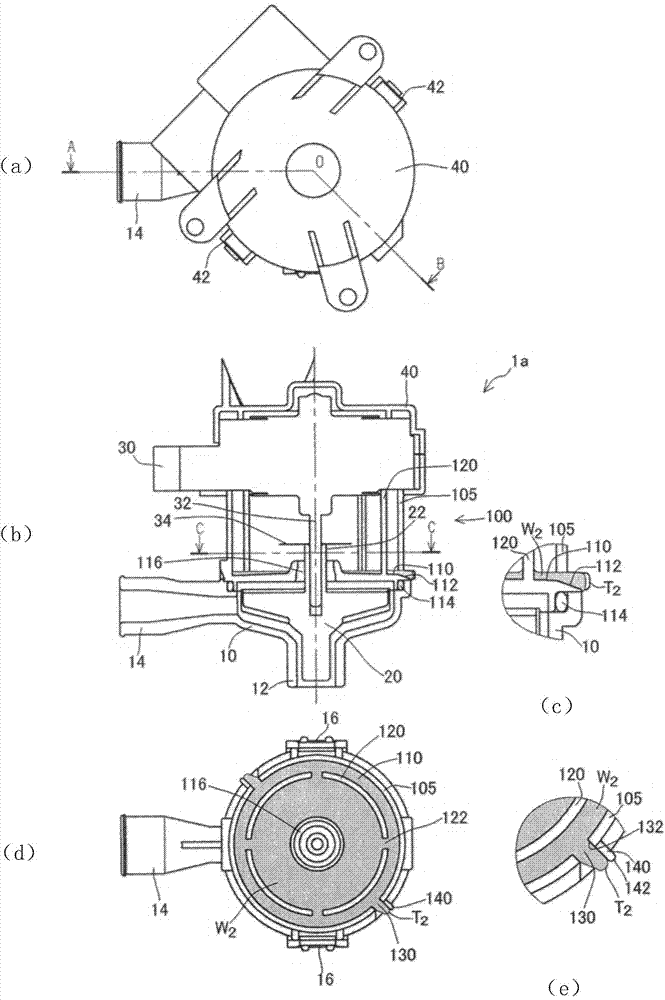

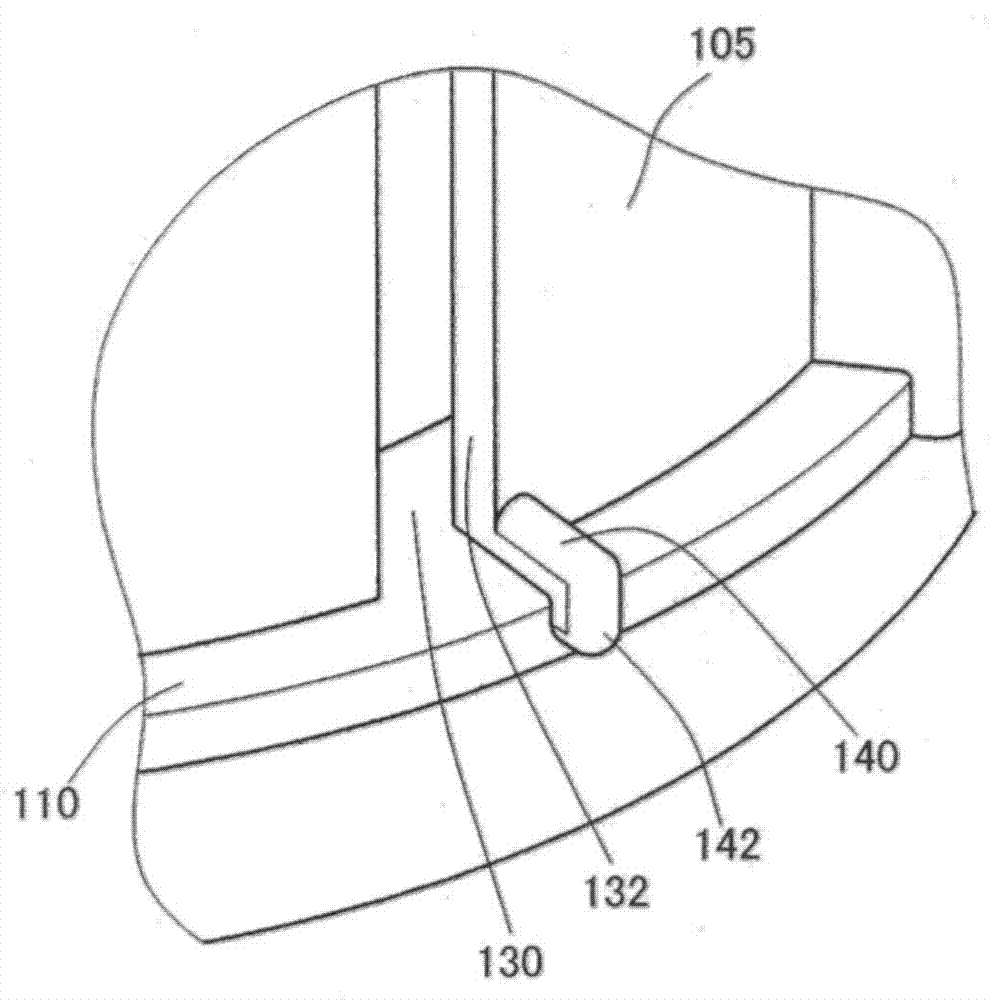

Drain pump

ActiveCN104514728AReduce backflowEliminate bad situationsPump componentsLighting and heating apparatusElectric motorWater pumping

A drain pump (1a) includes rotating blades (20) inside a pump case (10), and is driven by a motor (30). A motor lower case (100), which is mounted at the upper part of the pump case (10) and supports the motor (30), includes: an inner cylinder (120) and an outer cylinder (105). When the pump is stopped, return water from a water pumping pipe spouts out through an opening (116) of a lid (110). Residual water (W2) on the upper surface of the lid (110) is drained through inner cylinder slits (122) and drainage slits (130). At this time, the residual water (W2) is discharged to the external smoothly under the action of surface tension generated by guide parts (ribs) (140). By using the drain pump provided by the present invention, residual water of the drain pump mounted to an inner unit of an air conditioner can be effectively discharged.

Owner:FUJIKOKI MFG CO LTD

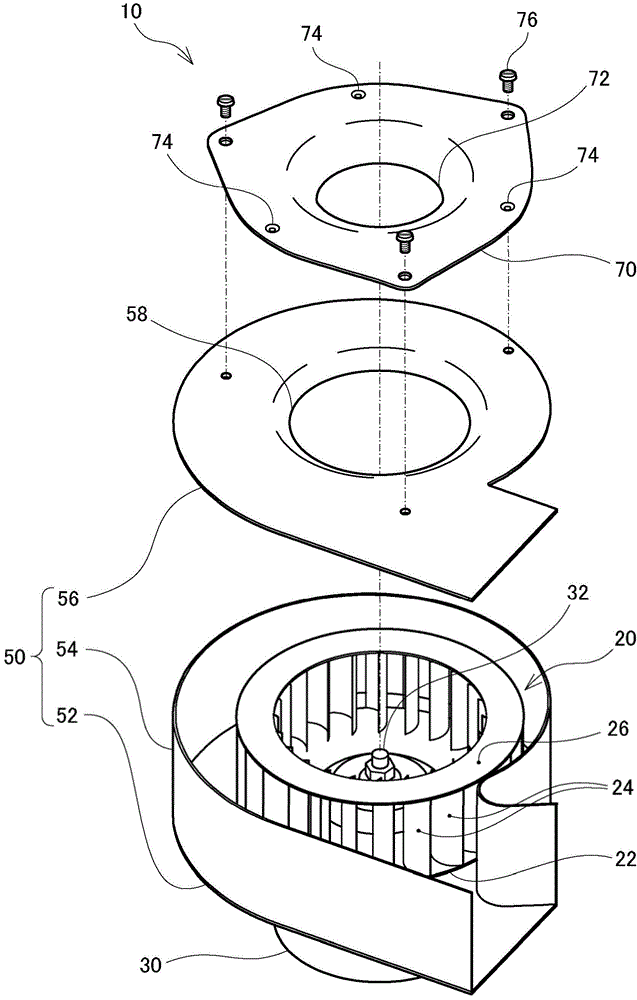

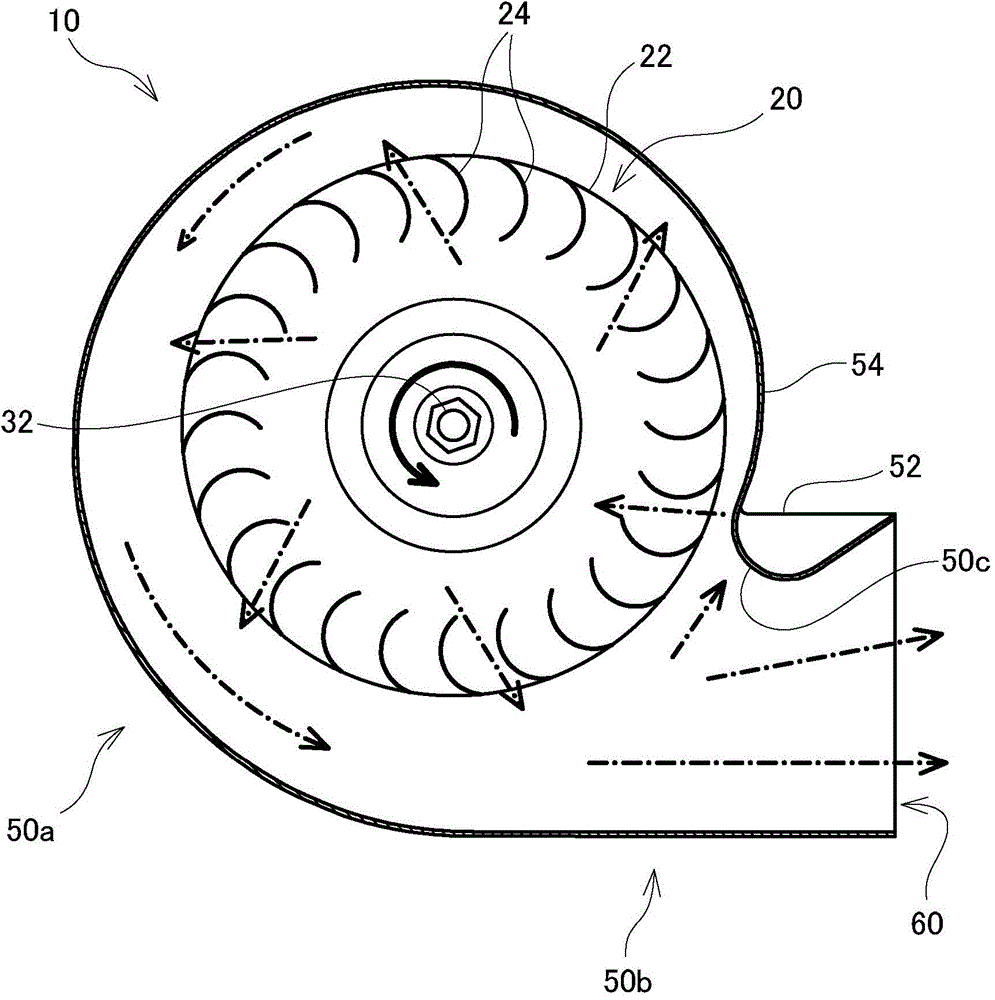

Centrifugal fan

The invention provides a centrifugal fan which can inhibit the noise of single centrifugal fan and acoustic resonance of a whole device comprising the centrifugal fan at the same time. A plurality of blades are radially arranged relative to a spindle so as to form a cylindrical impeller, and then the impeller is installed in a volute. A first opening part having a bell-shaped opening is arranged on a cover plate that covers the volute in the axial direction of the rotation shaft. A guiding plate having a second opening part with a bell-shaped opening is arranged in the first opening part and a gap is formed between the cover plate and the guiding plate. The gap is communicated with the atmosphere so as to reduce negative pressure formed between the top end of the second opening part and the blades of the propeller. So the reverse air flow, which causes the noise, from the outer side to the inner side of the impeller is reduced. The surface ratio of the gap to the opening part of the second opening part is 3 to 15%. The provided centrifugal fan can inhibit the noise of single centrifugal fan and acoustic resonance of a whole device comprising the centrifugal fan.

Owner:RINNAI CORP

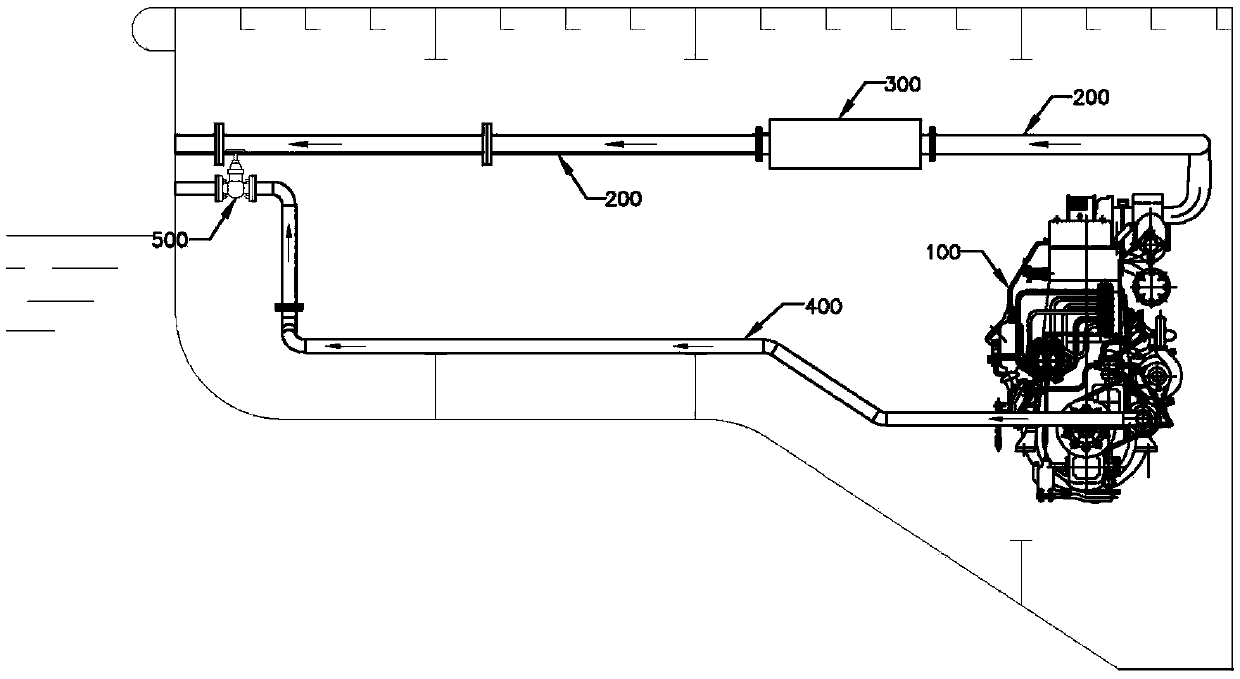

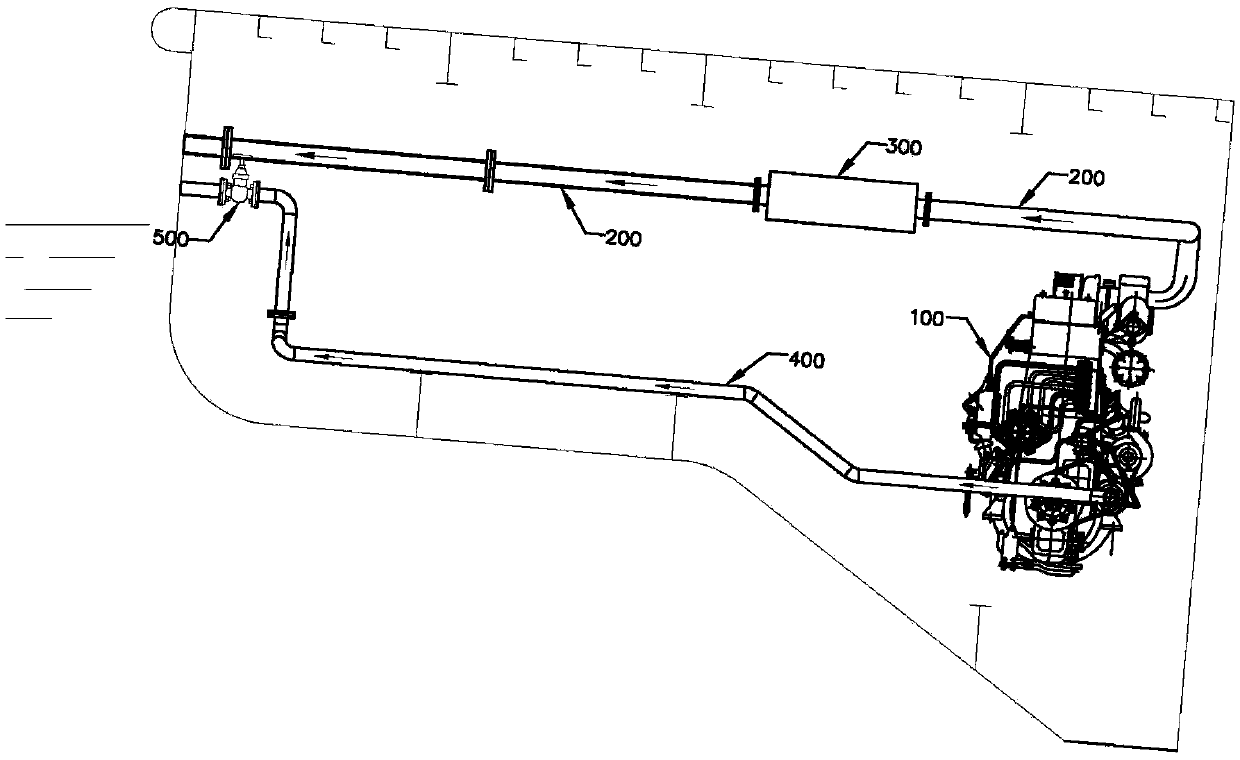

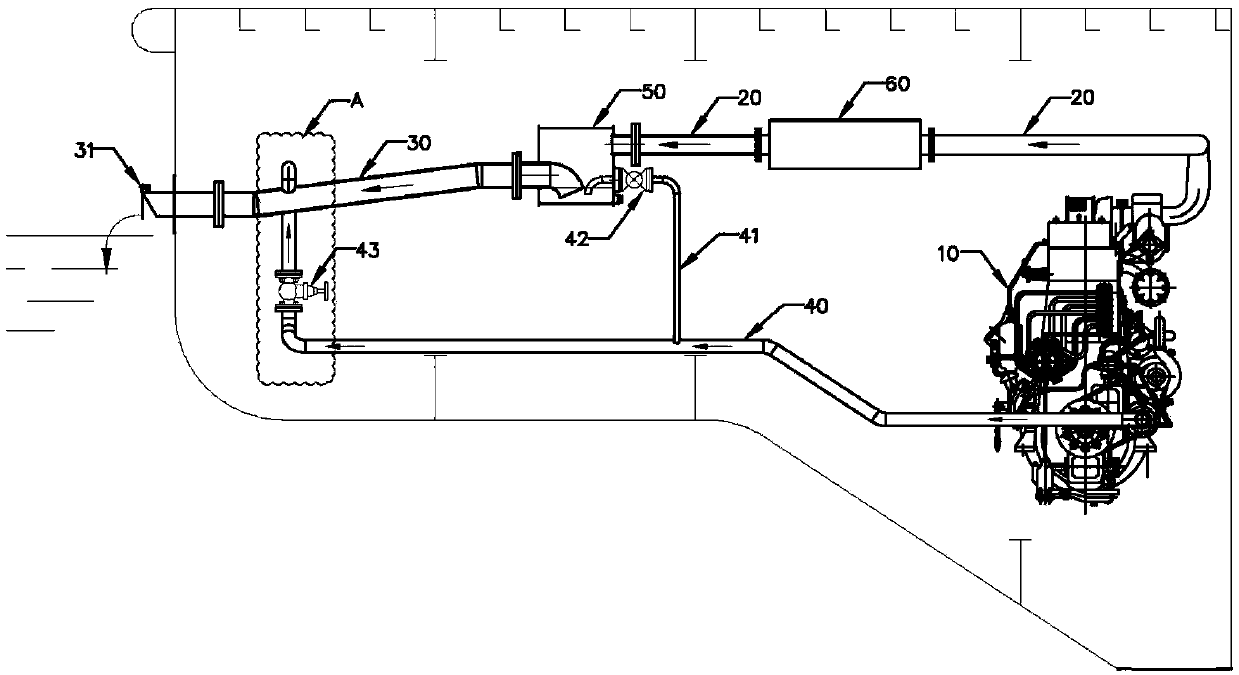

Ship exhaust system and wet exhaust apparatus thereof

ActiveCN108678848AReduce the temperatureWon't pour backExhaust apparatusSilencing apparatusEngineeringSulfide

The invention discloses a ship exhaust system and a wet exhaust apparatus thereof. The wet exhaust apparatus is connected in the ship exhaust system, and comprises a main body pipe, a gas inlet pipe,a water inlet pipe and a gas exhaust pipe, wherein the gas inlet pipe and the water inlet pipe are disposed at a first end surface of the main body pipe, the gas exhaust pipe is disposed at a second end surface of the main body pipe; the gas inlet pipe is connected to an outlet end of a first smoke exhaust pipe, the water inlet pipe is connected to a first outlet end of a seawater discharge pipe;the gas exhaust pipe is connected to an inlet end of a second smoke exhaust pipe, a first elbow is connected to the gas exhaust pipe; and the first elbow is disposed in the main body pipe, and the endopening of the first elbow is disposed downward, wherein the distance between the bottommost position at the end opening of the first elbow and a centerline of the gas exhaust pipe is between a radius of the gas exhaust pipe and a half of the exhaust backpressure of a diesel generator. According to the ship exhaust system and the wet exhaust apparatus thereof, the discharge of black smoke is effectively reduced, the emission of atmospheric sulfides is reduced, and waves are effectively prevented from flowing backwards to influence the diesel generator.

Owner:CHINA MERCHANTS HEAVY IND SHENZHEN +1

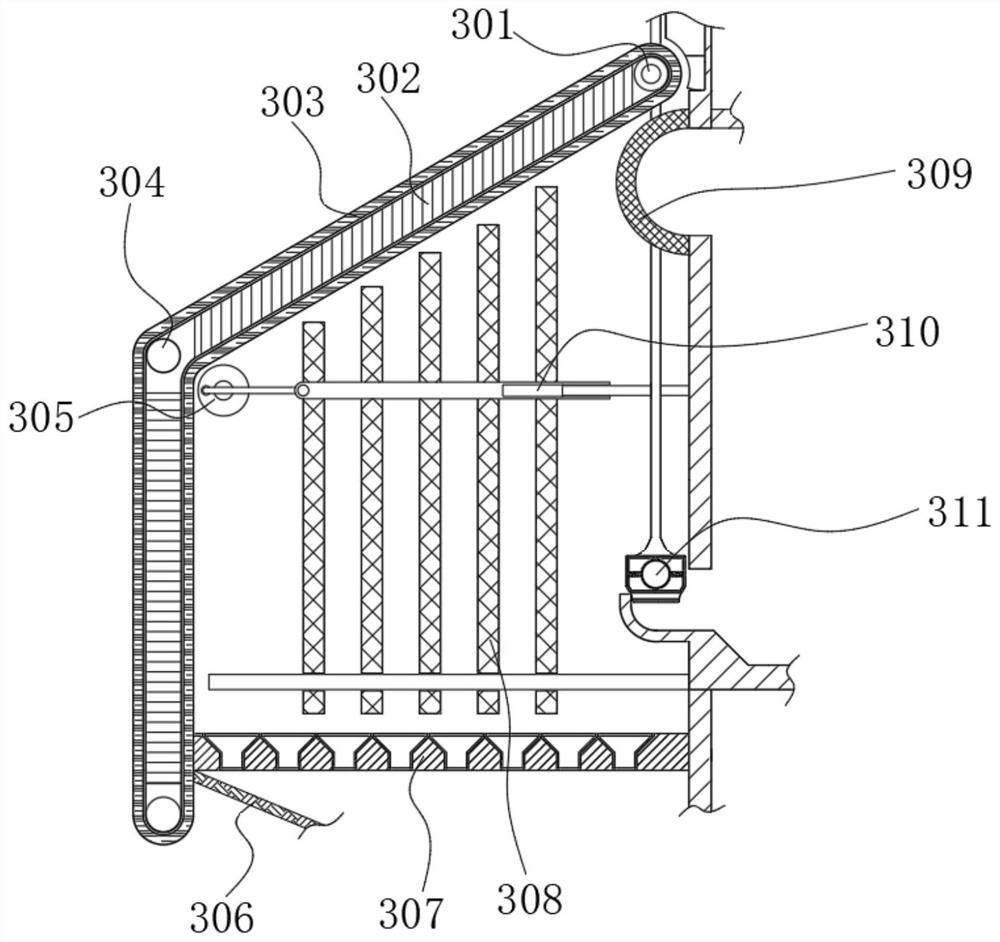

Rainwater flow-dividing type drainage device for sponge city construction

ActiveCN112095741ASave power resourcesWith water permeable functionFatty/oily/floating substances removal devicesSewerage structuresSludgeStormwater treatment

The invention discloses a rainwater flow-dividing type drainage device for sponge city construction. The rainwater flow-dividing type drainage device comprises a flow-dividing box shell, a flow-guiding filtering assembly, a sludge chamber, a water inlet pipe, a transmission box body and a drainage assembly, wherein a partition plate is arranged in the middle of the flow-dividing box shell to divide the flow-dividing box shell into a left rainwater treatment structure and a right rainwater treatment structure; a well lid is arranged at the upper end of the left part of the flow-dividing box shell; the flow-guiding filtering assembly is installed below the well lid; the water inlet pipe is arranged at the upper end of the right part of the flow-dividing box shell; the transmission box body is installed below the water inlet pipe; the sludge chamber is arranged at the lower end of the right part of the flow-dividing box shell; and the drainage assembly is arranged on the right side of theflow-dividing box shell, communicates with the box wall on the right side and relatively located above the sludge chamber.

Owner:LIAOCHENG UNIV

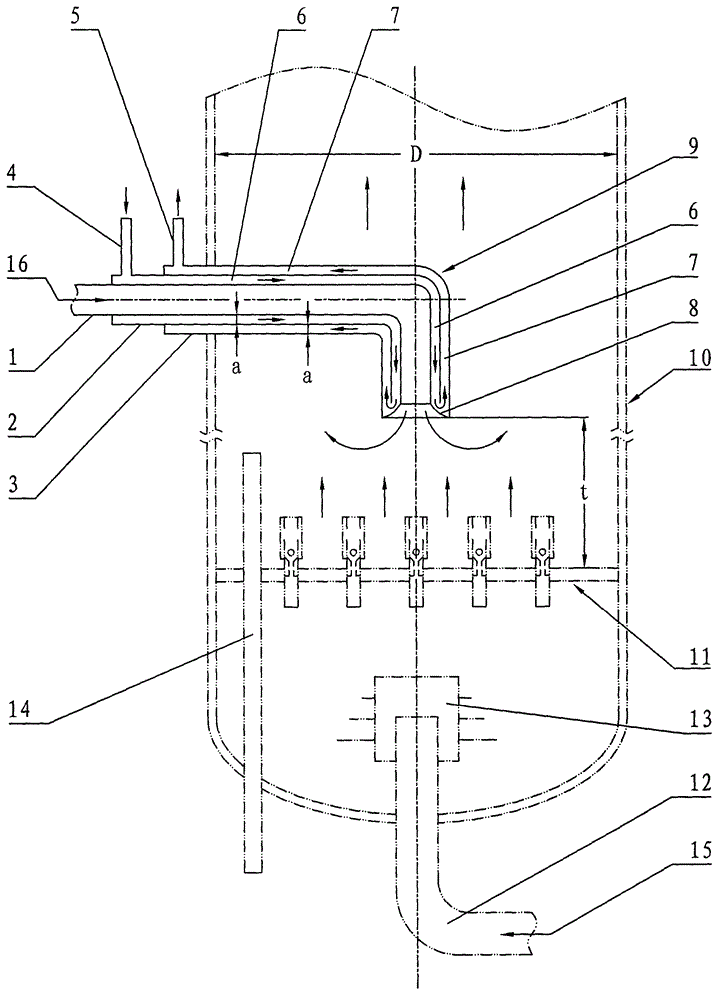

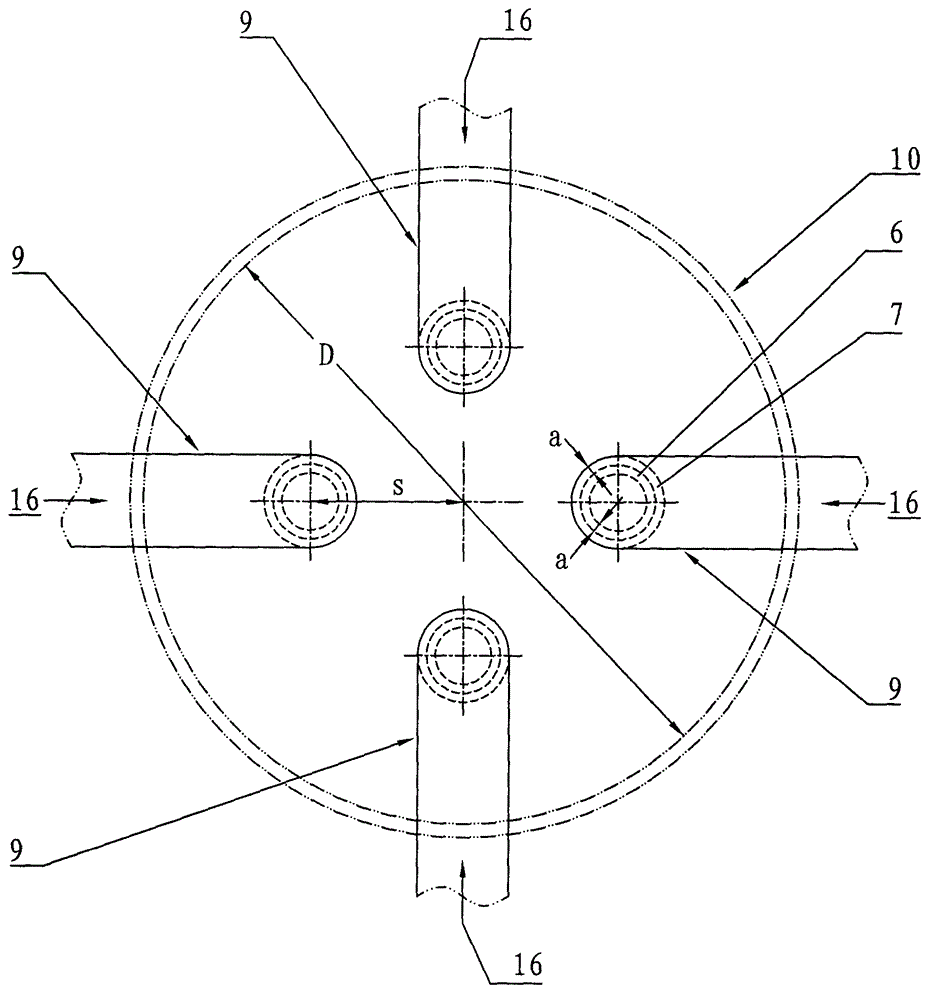

Oil inlet distribution tube for wood tar fluidized bed hydrogenation reactor

ActiveCN105879793AReduce the temperaturePrevent heating and cokingTar working-up by chemical refiningChemical/physical processesVertical tubeWater channel

The invention discloses an oil inlet distribution tube for a wood tar fluidized bed hydrogenation reactor, and the problem that for an existing oil inlet distribution tube, wood tar is prone to coking is solved. The oil inlet distribution tube (9) comprises an oil inlet tube (1) and a cooling water sleeve arranged outside the oil inlet tube (1) and is composed of a horizontal tube section and a vertical tube section, and the vertical tube section is located in the central area of a wood tar fluidized bed hydrogenation reactor (10). The cooling water sleeve comprises an inner sleeve (2) and an outer sleeve (3); a first cooling water channel (6) is formed between the inner sleeve and the oil inlet tube, and a second cooling water channel (7) is formed between the inner sleeve and the outer sleeve; a flared tube (8) is arranged on the portion, between the bottom end of the oil inlet tube and the bottom end of the outer sleeve, at the vertical tube section of the oil inlet distribution tube and serves as an outlet of the oil inlet distribution tube; the first cooling water channel is communicated with the bottom of the second cooling water channel. The oil inlet distribution tube for the wood tar fluidized bed hydrogenation reactor is used for conveying the wood tar into the fluidized bed hydrogenation reactor.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

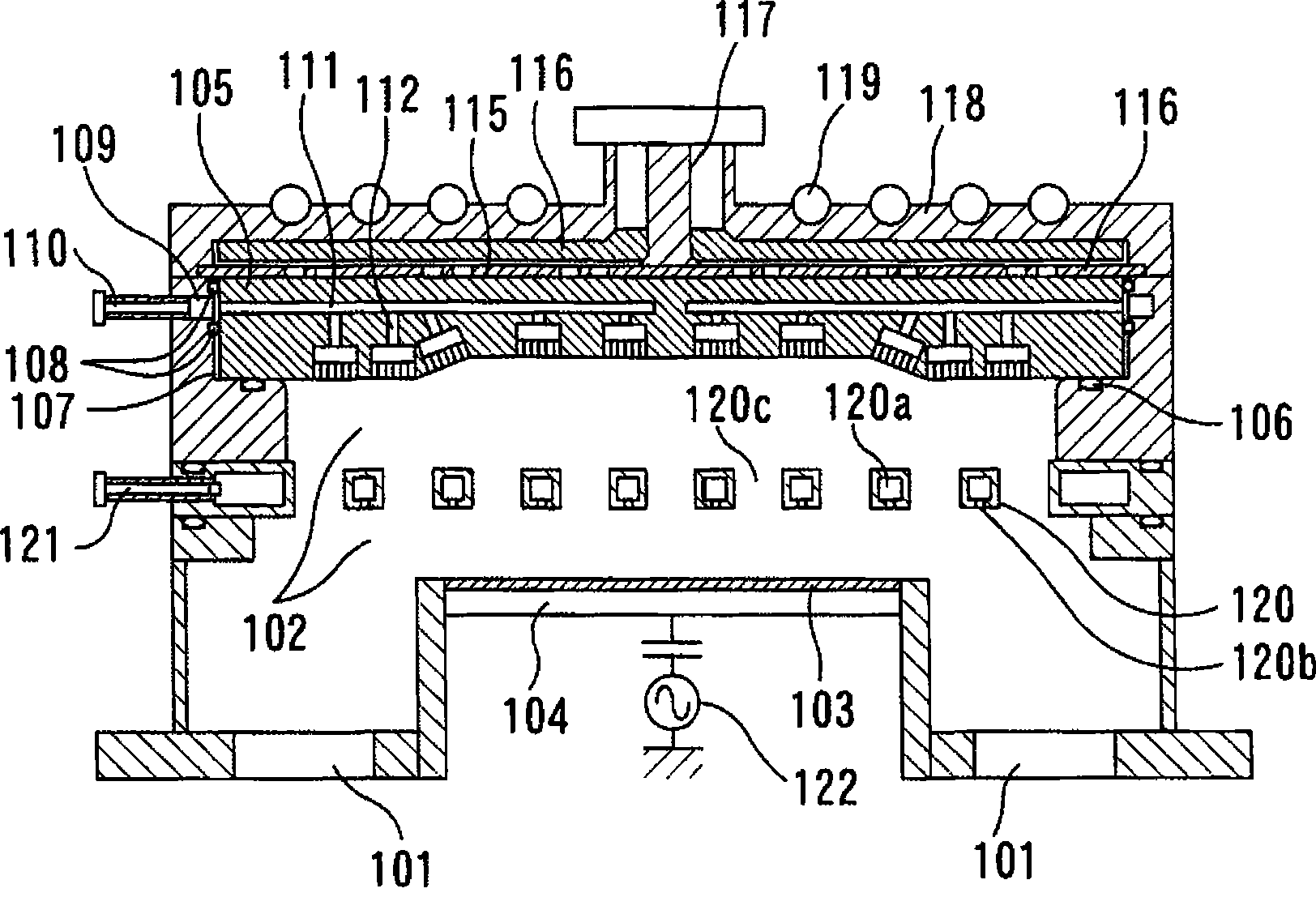

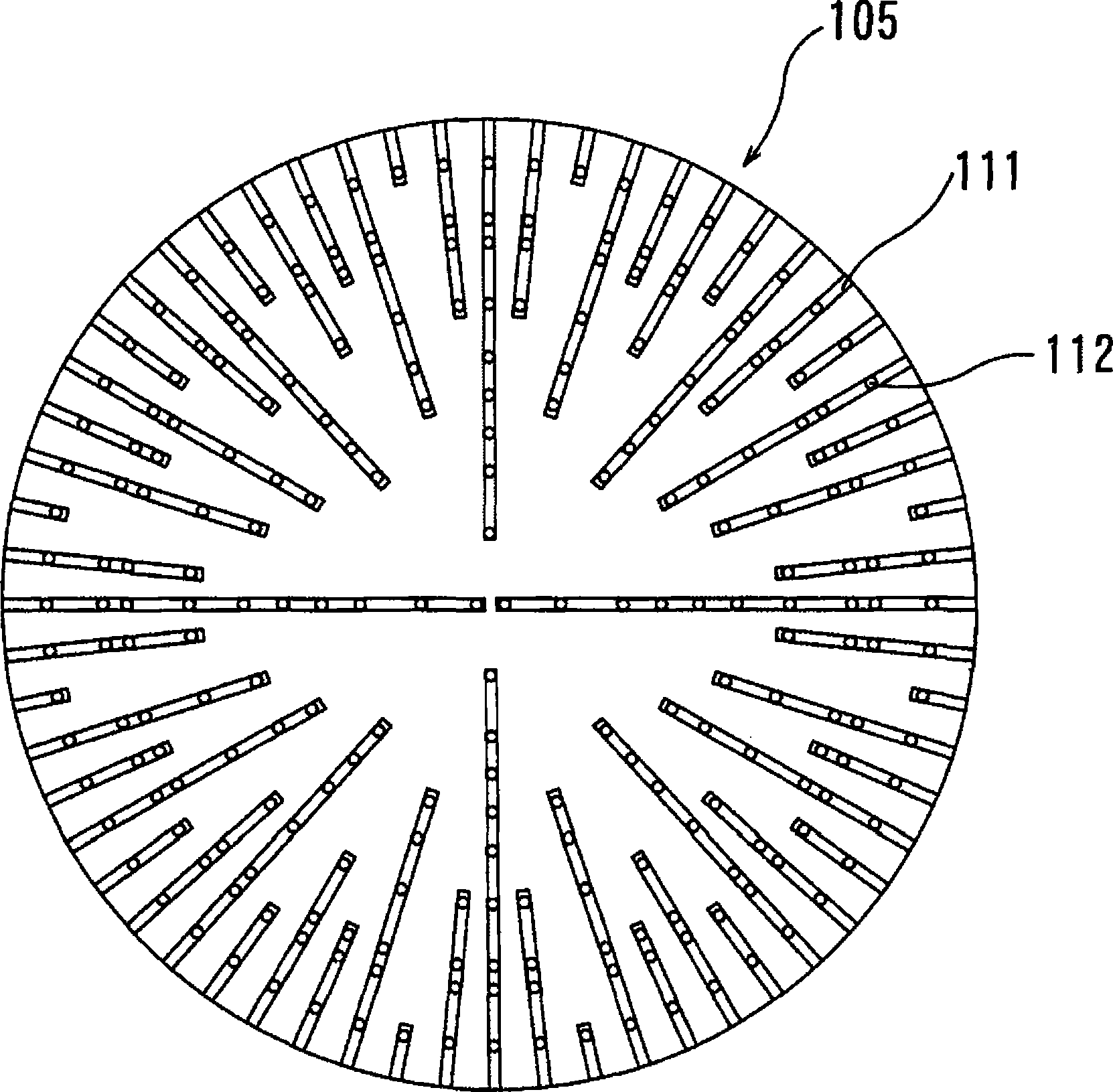

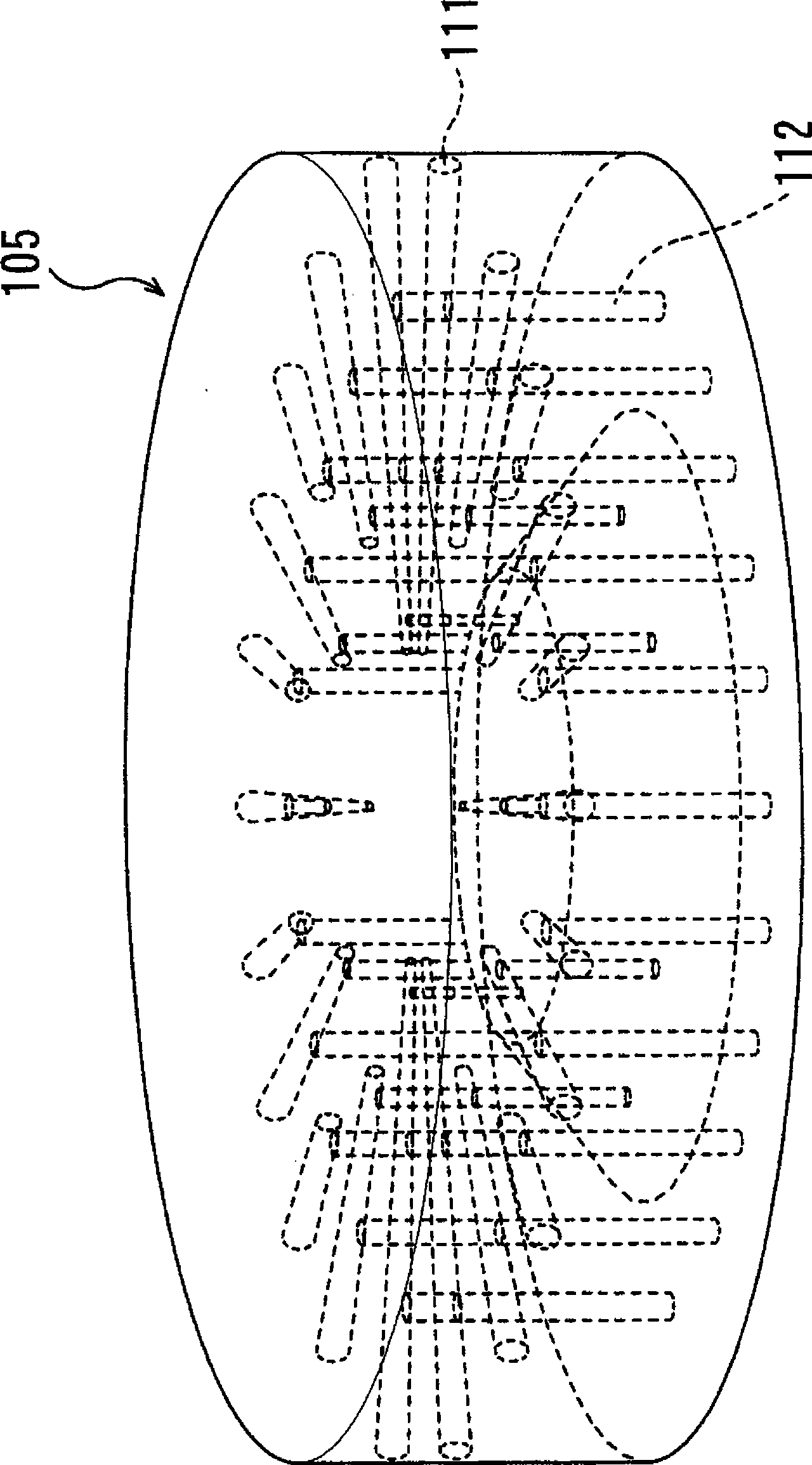

Shower plate, method for manufacturing the shower plate, plasma processing apparatus using the shower plate, plasma processing method and electronic device manufacturing method

InactiveCN101467498APrevent backflowProduce uniformSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPore diameterEngineering

Provided is a shower plate which can completely prevent generation of plasma reverse flow or ignition of plasma excitation gas at a vertical hole section for more efficient plasma excitation. A shower plate (105) is arranged in a processing chamber (102) in a plasma processing apparatus, and discharges plasma excitation gas for generating plasma in the processing chamber (102). A porous gas communicating body (114) having pores communicating in a gas communicating direction is mounted on a vertical hole (112) to be a discharge path for the plasma excitation gas. The pore diameter of an overflow path in a gas communicating path formed by the communicating pores of the porous gas communicating body (114) is 10[mu]m or less.

Owner:TOKYO ELECTRON LTD +1

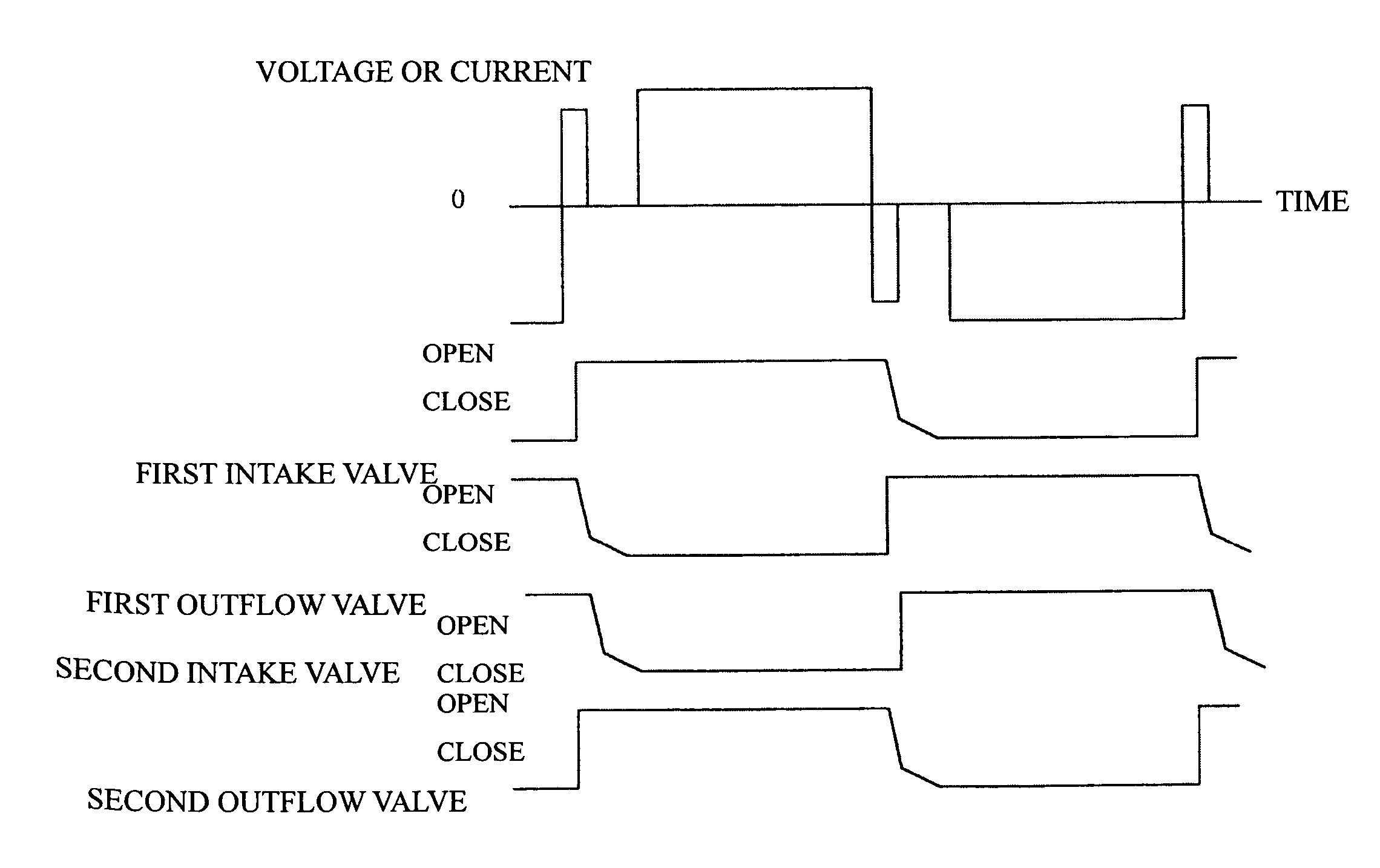

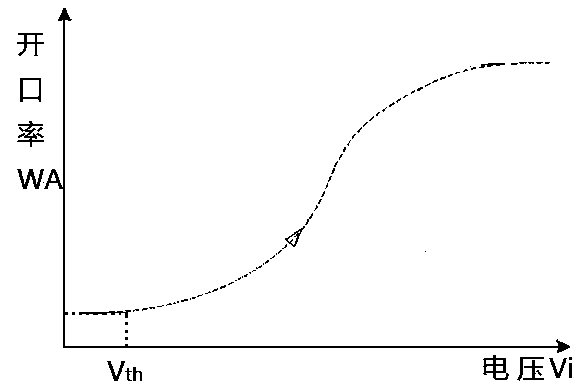

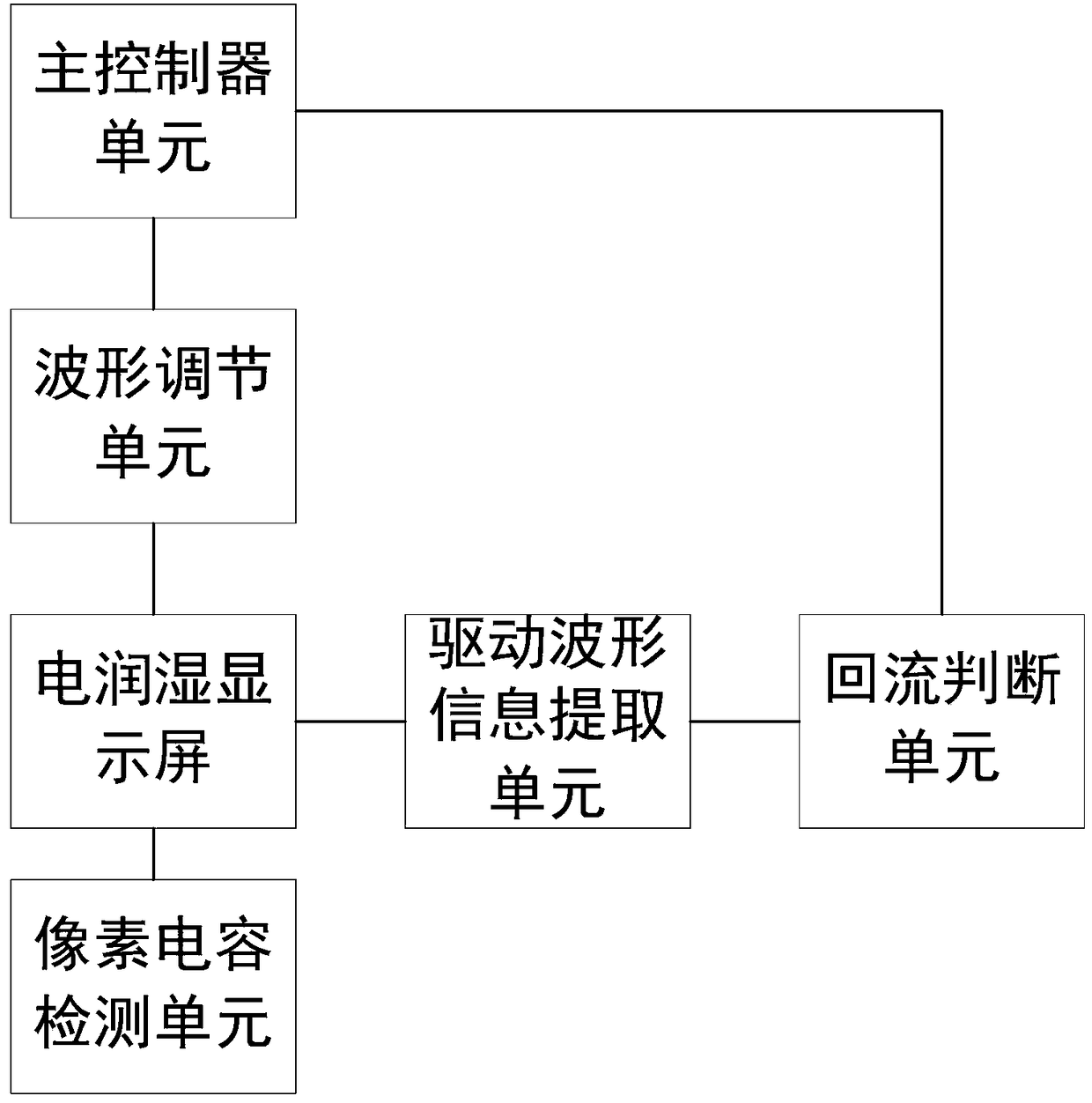

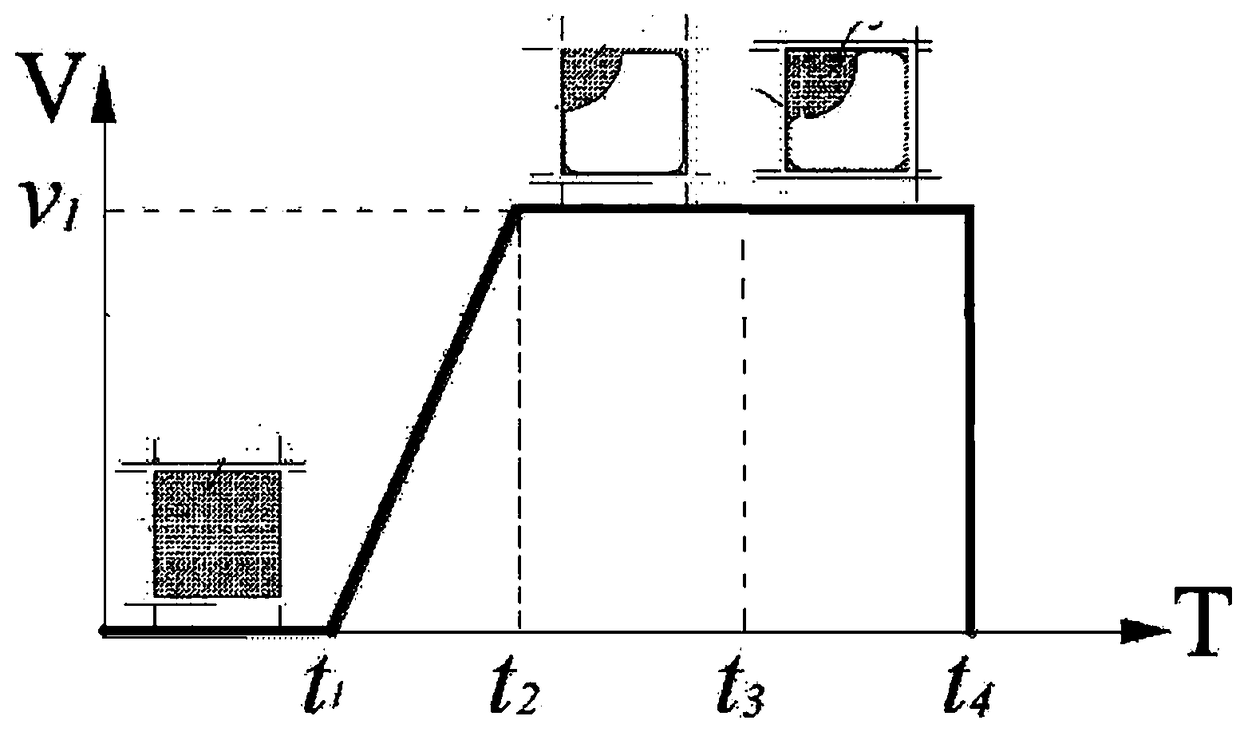

Method and device for reducing backflow of printing ink of electrically wetted electronic paper

The invention relates to a method and device for reducing backflow of a printing ink of an electrically wetted electronic paper. A driving waveform voltage displayed by a present pixel point is recorded according to detection, a present aperture ratio of a pixel of the electrically wetted electronic paper is detected, a curve is compared with an original curve to determine the backflow condition of the printing ink of the electrically wetted electronic paper, according to the backflow condition of the printing ink, an adjusting waveform is inserted into the original driving waveform, and backflow of the printing ink of the electrically wetted electronic paper is thus reduced. Thus, backflow of the printing ink of ht electrically wetted electronic paper can be reduced effectively.

Owner:FUZHOU UNIV

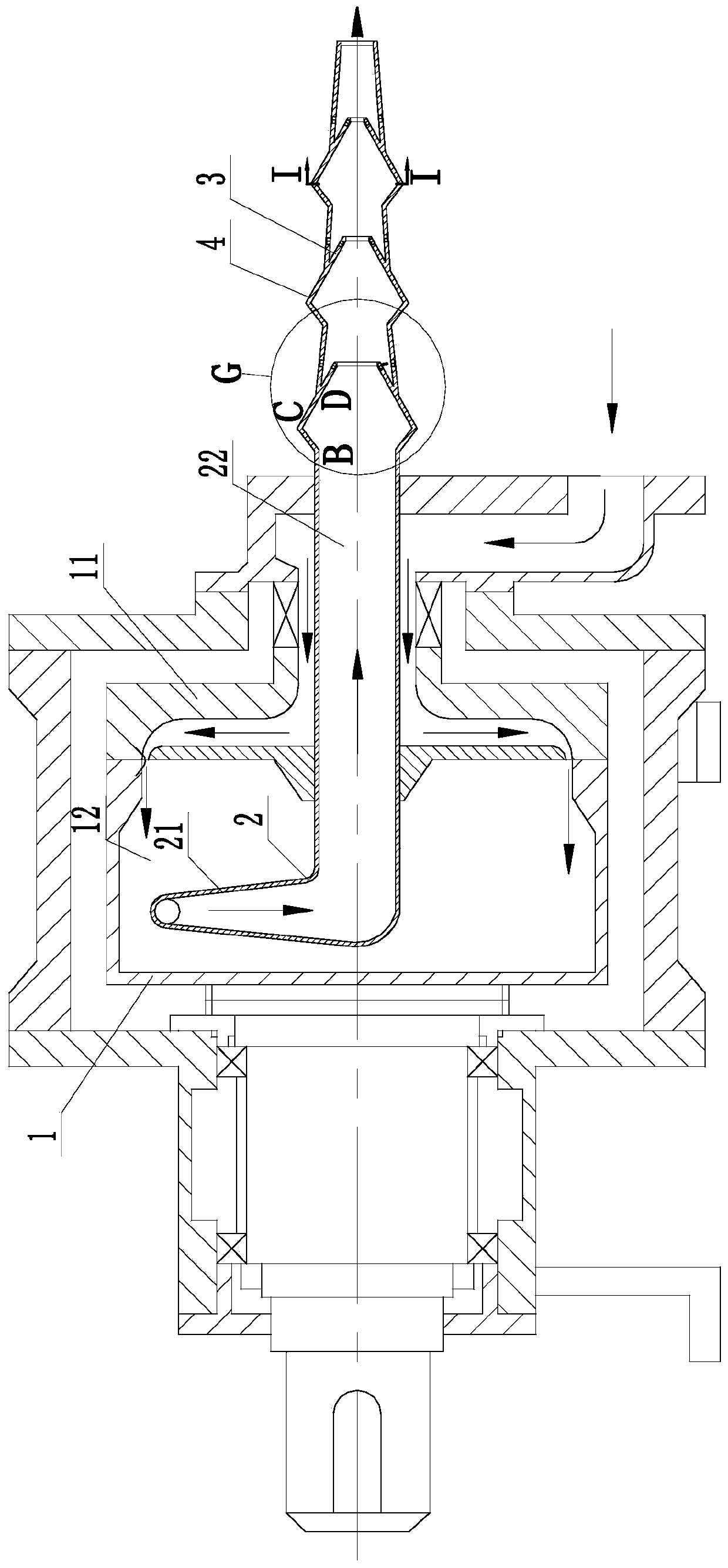

High-pressure injection pump

The invention belongs to the technical field of water pumps, and particularly relates to a high-pressure injection pump. The high-pressure injection pump includes a rotor body, a collecting main, wherein the rotor body includes impellers and a rotor cavity, and the collecting main includes diffusion sections and an outlet pipe; the outer surfaces of the diffusion sections of the collecting main are in streamline shapes; and the diffusion sections of the collecting main are evenly distributed in an array mode in the circumferential direction of the outlet pipe, the number of the diffusion sections of the collecting main is at least 3, the outlet pipe of the collecting main is made of elastic materials, and the inner diameters of the cross sections of the outlet pipe are gradually decreasedfrom the left to the right. According to the high-pressure injection pump, the number of the diffusion sections of the collecting main is at least 3, thus water amount flowing into inner cavities of the diffusion sections is increased, rate of flow of water flowing into the outlet pipe and pressure of the water flowing into the outlet pipe are increased, the pressure and the rate of flow of the water flowing out of the outlet pipe are increased, the inner diameters of the cross sections of the outlet pipe are gradually decreased from the left to the right, thus when water flow passes the outlet pipe from the left to the right, water pressure is gradually increased, and thus the pressure of the water flowing out of the outlet pipe is increased.

Owner:TONGLING ZHAOLIN IND & TRADE CO LTD

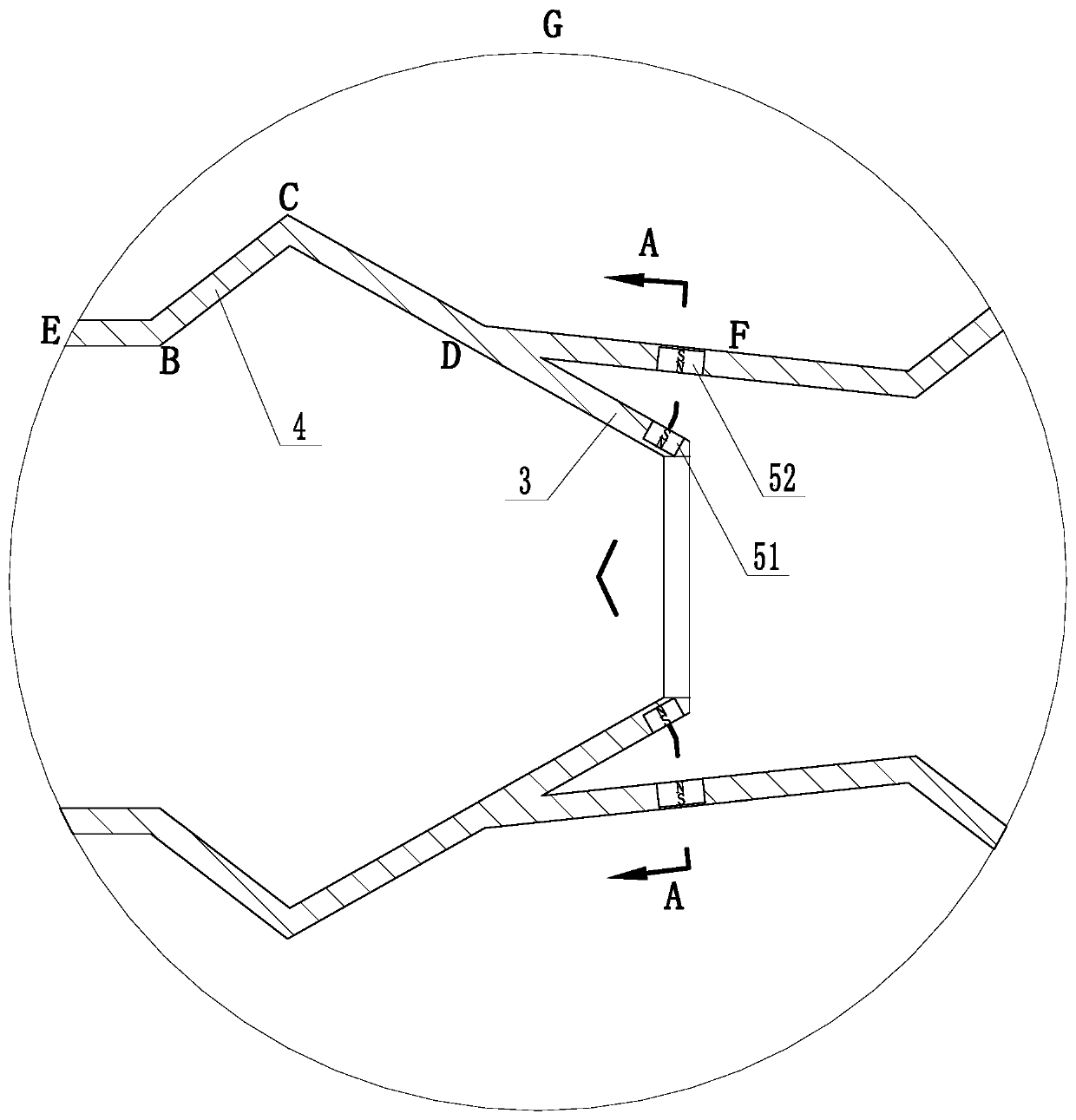

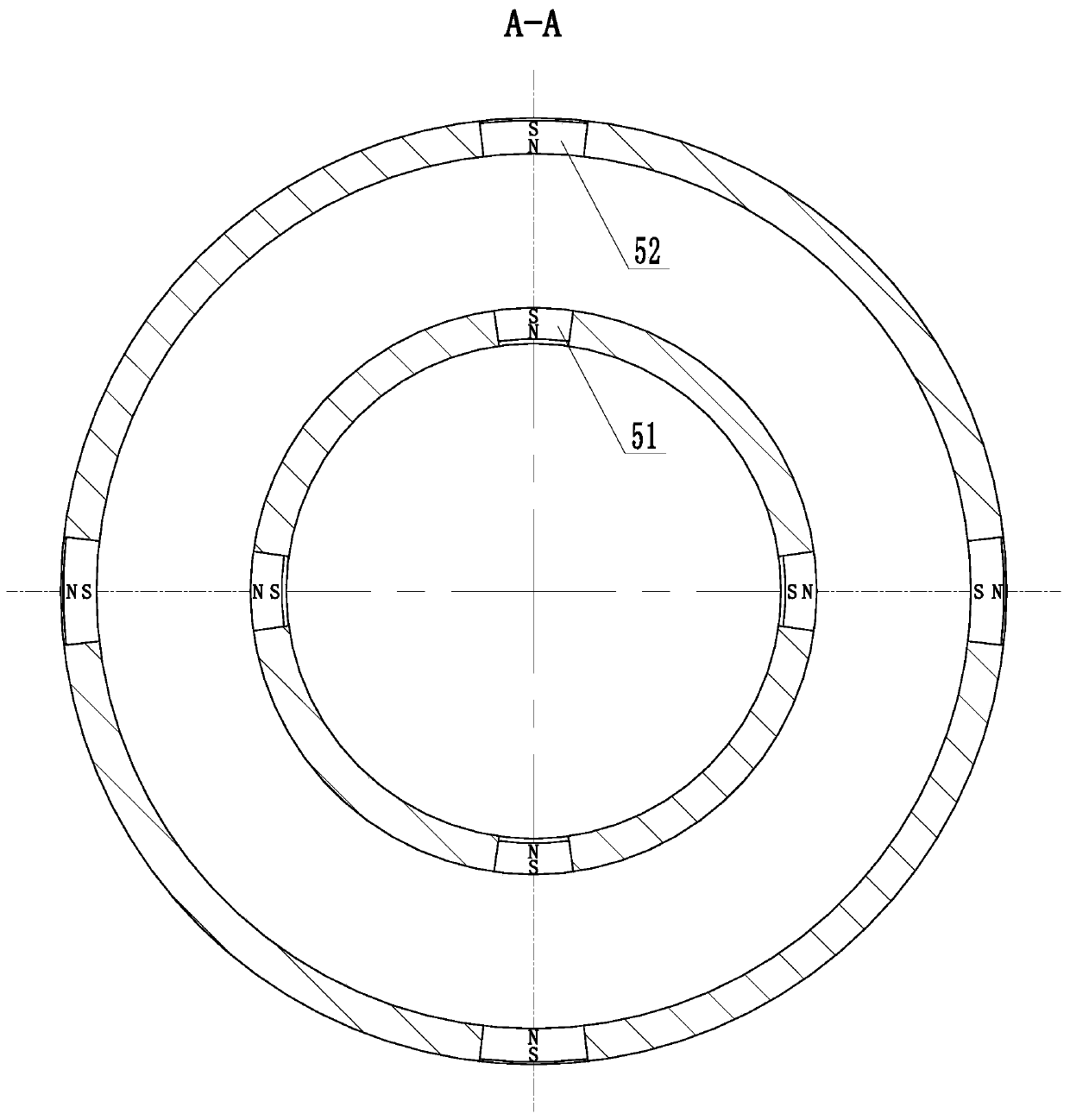

Air film hole channel structure based on Tesla valve and application of air film hole channel structure to front edge of turbine blade

ActiveCN113236373AOptimize structure sizePrevent backflowStatorsMachines/enginesSuction forceTurbine blade

The invention discloses an air film hole channel structure based on a Tesla valve and application of the air film hole channel structure to the front edge of a turbine blade, and belongs to the field of gas turbines. The air film hole channel structure comprises a Tesla valve channel and outlet air film holes, wherein the Tesla valve channel is of a Tesla valve structure, cooling airflow flows from an inlet to an outlet of the Tesla valve channel in a one-way mode, the multiple outlet air film holes are located at the outlet of the Tesla valve channel and used for introducing cooling gas into the wall face to be cooled, and the axial direction of the outlet gas film holes is parallel to the axial direction of the outlet of the Tesla valve channel. According to the air film hole channel structure, the Tesla valve channel is introduced to a film hole in the front edge of the end wall of a stationary blade, and the geometric dimension of the Tesla valve channel is matched with that of the film hole; and due to the introduction of the Tesla valve channel, not only is the backflow of high-temperature airflow obviously weakened, but also the end wall near the stagnation point of the front edge of the stationary blade and the suction surface of the stationary blade can be cooled more sufficiently and uniformly, so that the cooling efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer

ActiveCN103601886ASolve the problem of low molecular weightHigh molecular weightMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention relates to a preparation method of a poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer. The preparation method comprises two steps of prepolymerization reaction and post-polycondensation reaction. The reaction time of a prepolymer in a double-screw extruder is 10-60 minutes, and the double-screw extruder is provided with three temperature zones according to a sequence from a feeding port to a discharging port, wherein the temperatures of the tree temperature zones are respectively 160-180 DEG C, 180-190 DEG C and 190-200 DEG C. According to the preparation method, the double-screw extruder is used for carrying out the post-polycondensation reaction, and specific temperature and time are used for controlling parameters, so that the intrinsic viscosity [eta] of the PIPD polymer obtained in the end is 28-30dL / g, the molecular weight of the polymer is greatly increased, meanwhile, the stirring is facilitated, and the PIPD polymer can be easily conveyed and transferred to a spinning working section, thus the production efficiency is improved, and the production cost is reduced.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

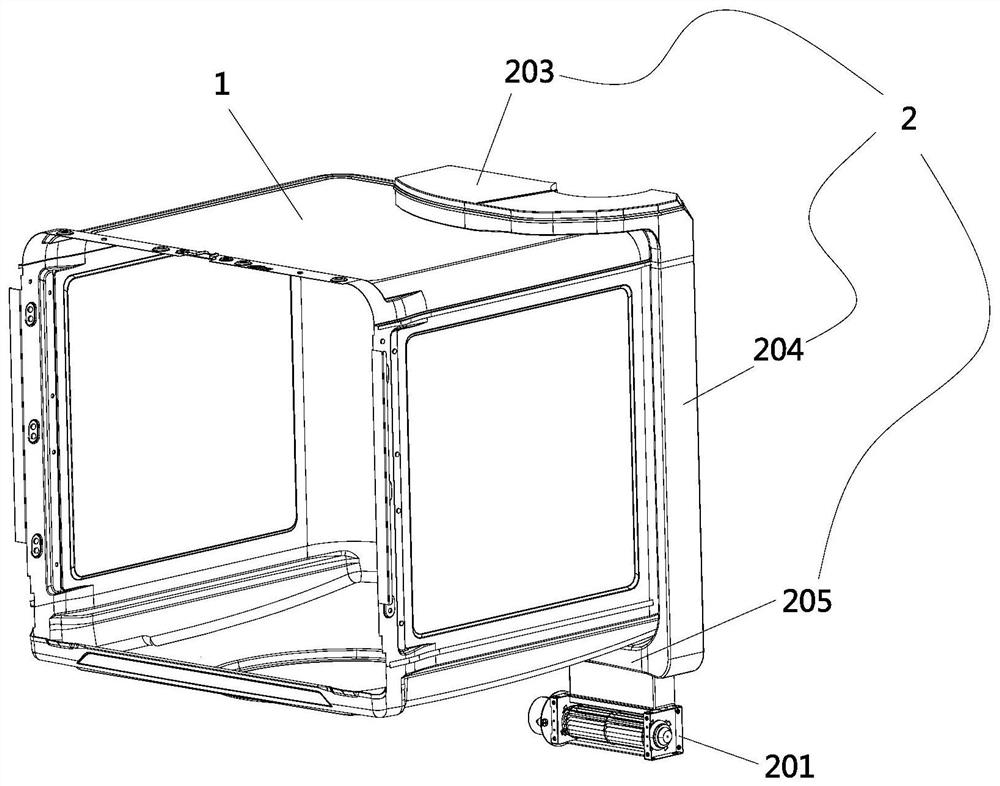

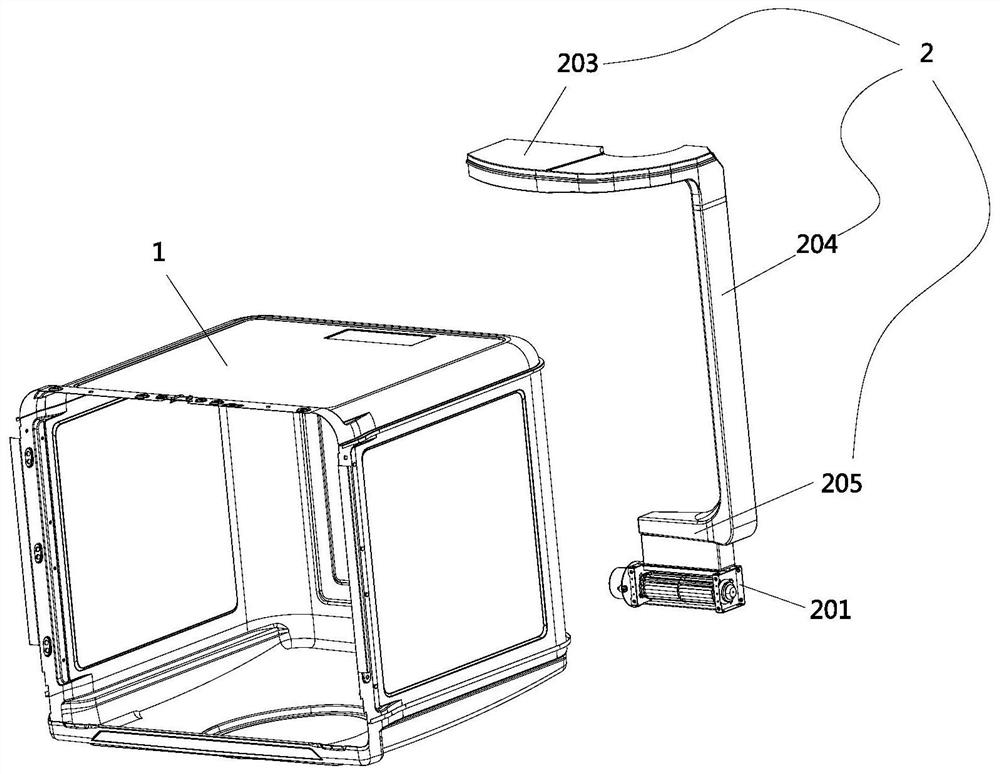

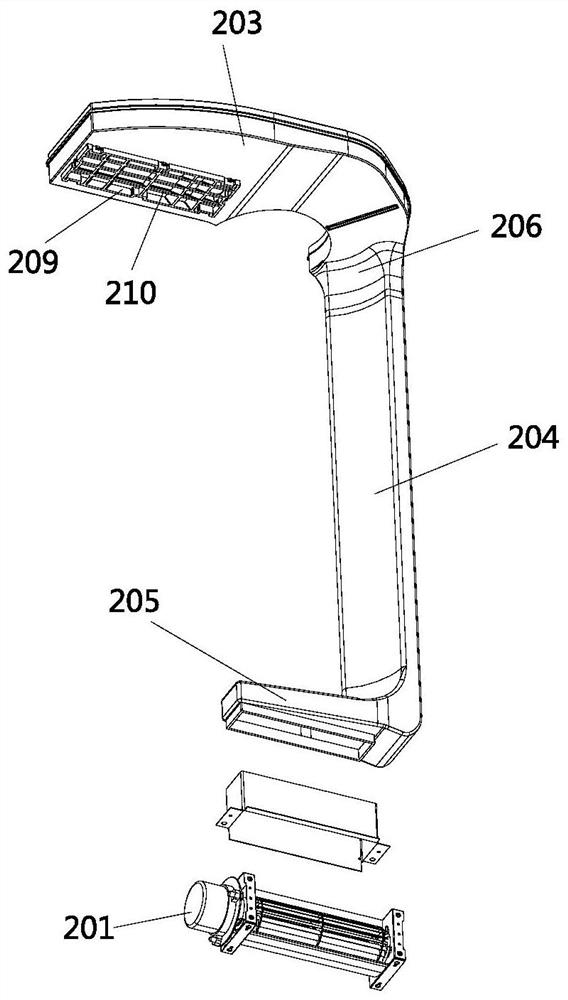

Air duct structure of dishwasher

PendingCN111728565AAchieve dryingEasy and quick passTableware washing/rinsing machine detailsAir volumeEngineering

The present invention discloses an air duct structure of a dishwasher. The air duct structure comprises a first air duct and a second air duct which communicate with a containing cavity of the dishwasher. The first air duct is provided with a fan unit; under the action of the fan unit, air in the containing cavity is exhausted out of the dishwasher through the first air duct, gas outside the dishwasher enters the containing cavity from the second air duct, and an anti-backflow structure for preventing water or steam from flowing back from the containing cavity along the air duct is also arranged in the first air duct. According to the air duct structure of the dishwasher, a cross-flow fan is arranged in the first air duct, and the characteristics that the cross-flow fan is large in air volume and low in noise are utilized, so that the influence of the dishwasher on the surrounding environment is reduced; and meanwhile, the cross-flow fan adopts a use mode of exhausting air from the containing cavity, and is matched with the PTC heater arranged on the second air duct to exhaust the containing cavity to negative pressure, and a drying mode of feeding hot air from the second air ductis adopted, so that quick drying of the containing cavity of the dishwasher is realized.

Owner:QINGDAO HAIER DISHWASHER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer](https://images-eureka.patsnap.com/patent_img/d0f58cdd-7ce6-4dd0-8c91-b0f4bbca9a4a/2013106175895100002DEST_PATH_IMAGE001.PNG)

![Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer](https://images-eureka.patsnap.com/patent_img/d0f58cdd-7ce6-4dd0-8c91-b0f4bbca9a4a/2013106175895100002DEST_PATH_IMAGE002.PNG)