Wide and narrow passage plate type flooded generator and falling film absorber, and ammonia water absorption refrigerator

A technology of falling film absorber and channel plate, which is applied in the direction of generator/analyzer, refrigerator, absorbent/adsorbent, etc., can solve the problems of slow start-up of the unit, large heat transfer area and low heat transfer efficiency, etc. Achieve the effects of reducing heat transfer area and volume, obvious temperature fluctuations, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of this solution will be described in detail below in combination with the technical solution and accompanying drawings.

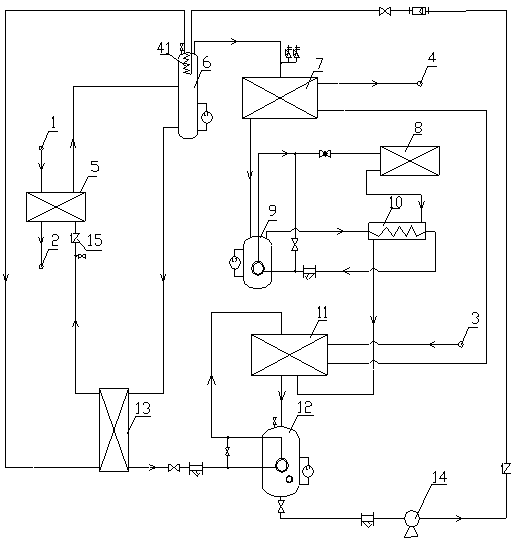

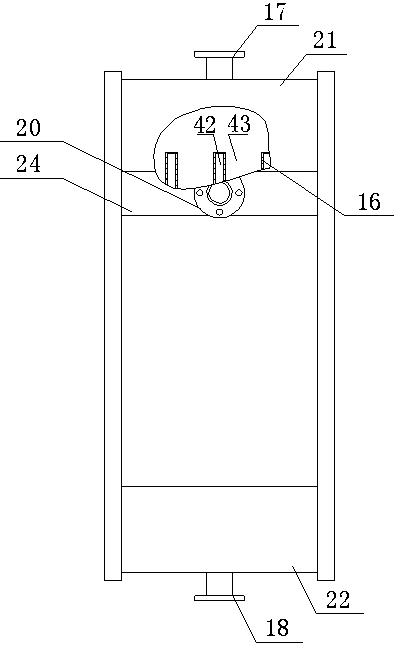

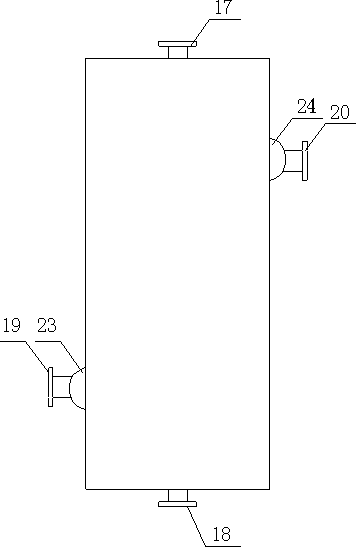

[0017] Such as figure 1 As shown, a kind of ammonia water absorption refrigerator is characterized in that it adopts wide and narrow channel plate type flooded generator 5 and wide and narrow channel plate type falling film absorber 11, and the waste heat passes through the waste heat wide channel 43 of wide and narrow channel plate type flooded generator 5 to heat concentrated The concentrated ammonia water coming countercurrently from the ammonia water narrow channel 42 produces a gas-liquid mixture and enters the gas-liquid separator 6, and the separated aqueous ammonia gas is purified by the decondenser 41 and then condensed into liquid ammonia in the plate condenser 7, and the liquid ammonia is Send in the liquid ammonia tank 9; The liquid ammonia that comes out from the liquid ammonia tank 9 enters in the heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com