Oil inlet distribution tube for wood tar fluidized bed hydrogenation reactor

A technology of oil inlet distribution pipe and hydrogenation reactor, which is applied in the fields of refining tar through chemical methods, chemical instruments and methods, chemical/physical processes, etc., which can solve the problems of wood tar coking and other problems, so as to prevent heating and coking and avoid polymerization Good effect of coking and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

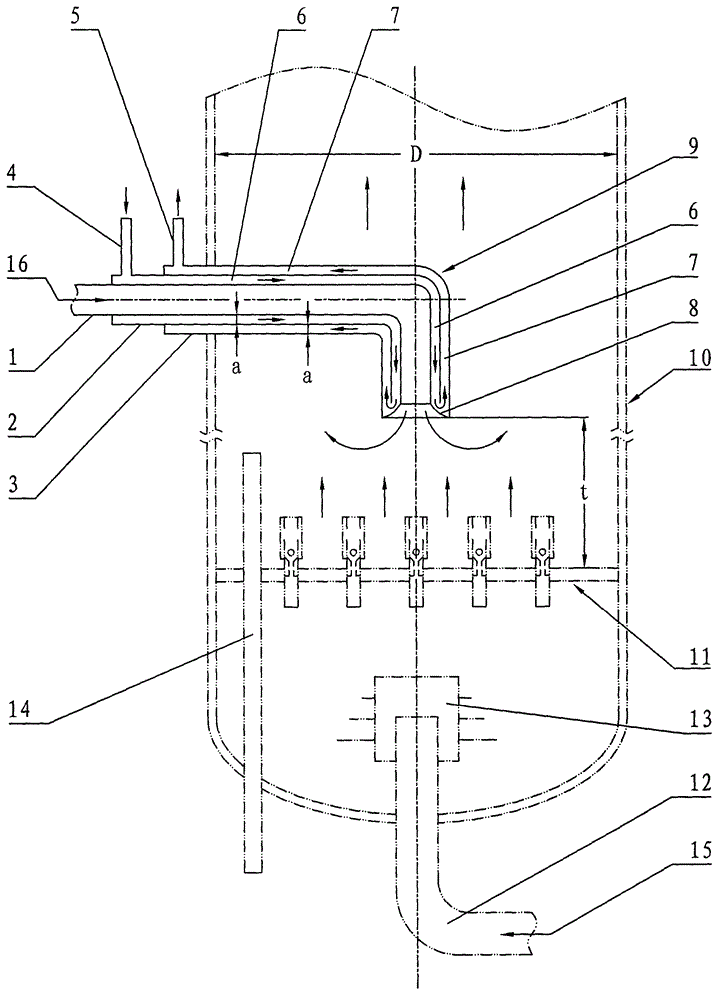

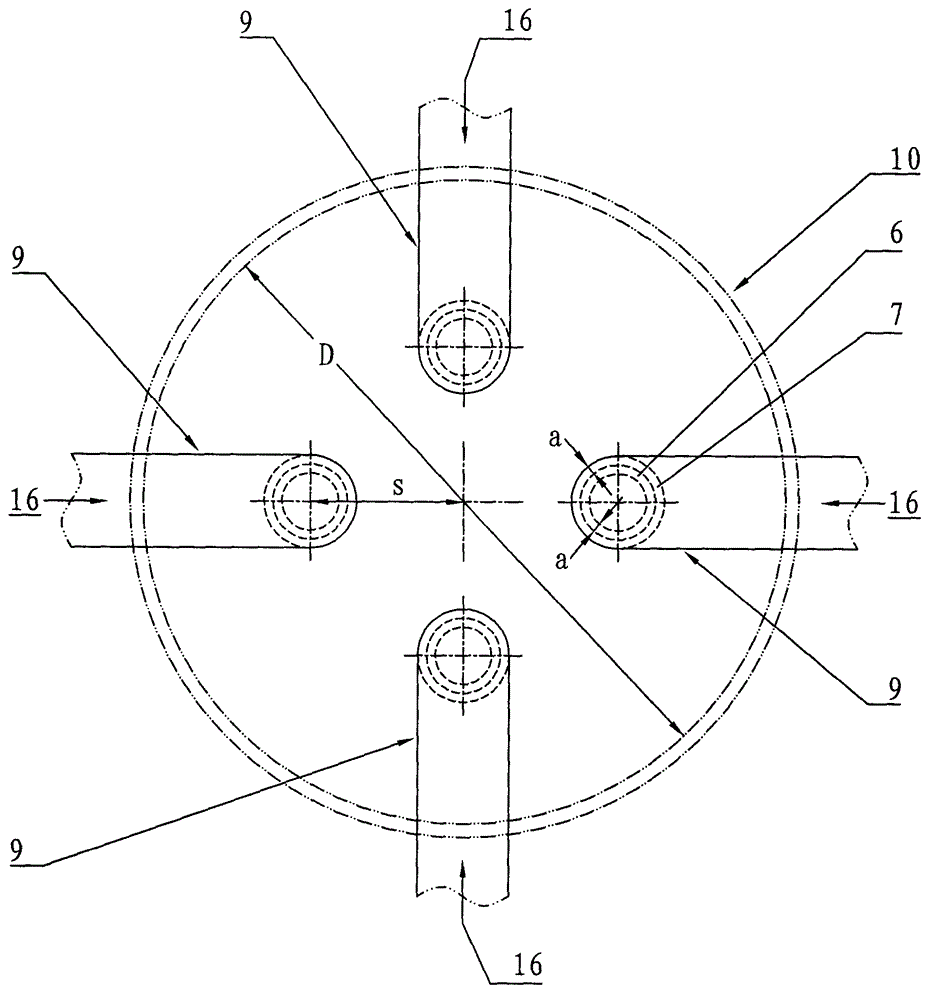

[0011] see figure 1 , the present invention is used for the oil inlet distribution pipe 9 (abbreviated as the oil inlet distribution pipe) of the wood tar fluidized bed hydrogenation reactor, and the outlet is located above the reactor distribution plate 11. The reactor distribution plate 11 is installed in the lower part of the wood tar ebullating bed hydrogenation reactor (abbreviated as the reactor) 10, and consists of a distribution plate and a plurality of bubble-cap distributors. The reactor 10 is also provided with a hydrogen and circulating oil pipe 12, a pre-distributor 13, a catalyst discharge pipe 14, a catalyst feed pipe, a gas outlet pipe, a liquid outlet pipe, etc. (not shown).

[0012] The oil inlet distribution pipe 9 includes the oil inlet pipe 1 and the cooling water jacket arranged outside it. The oil inlet distribution pipe 9 is made up of a horizontal pipe section and a vertical pipe section. The horizontal pipe section passes through the side wall of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com